WATERCOMPASS FM300-US-OD FLOW MONITOR: INSTALLATION INSTRUCTIONS 2 ½ - 3”

Wall Mounting Instructions

Use the template enclosed with the Water

Compass Data Collector for assistance when

mounting the enclosure to a wall.

Locate the 2 mounting holes on the back of

the enclosure. The two upper mounting holes

are keyholes. This design allows the two upper

fasteners to be installed first. The enclosure is

then slipped over and pushed down to complete

the installation.

A third mounting hole can be found in the center

of the enclosure. A typical mounting height for

a wall-mount enclosure is between 41” and 48”

above a finished surface.

Before drilling, verify that the controller is level and

vertically straight before installing.

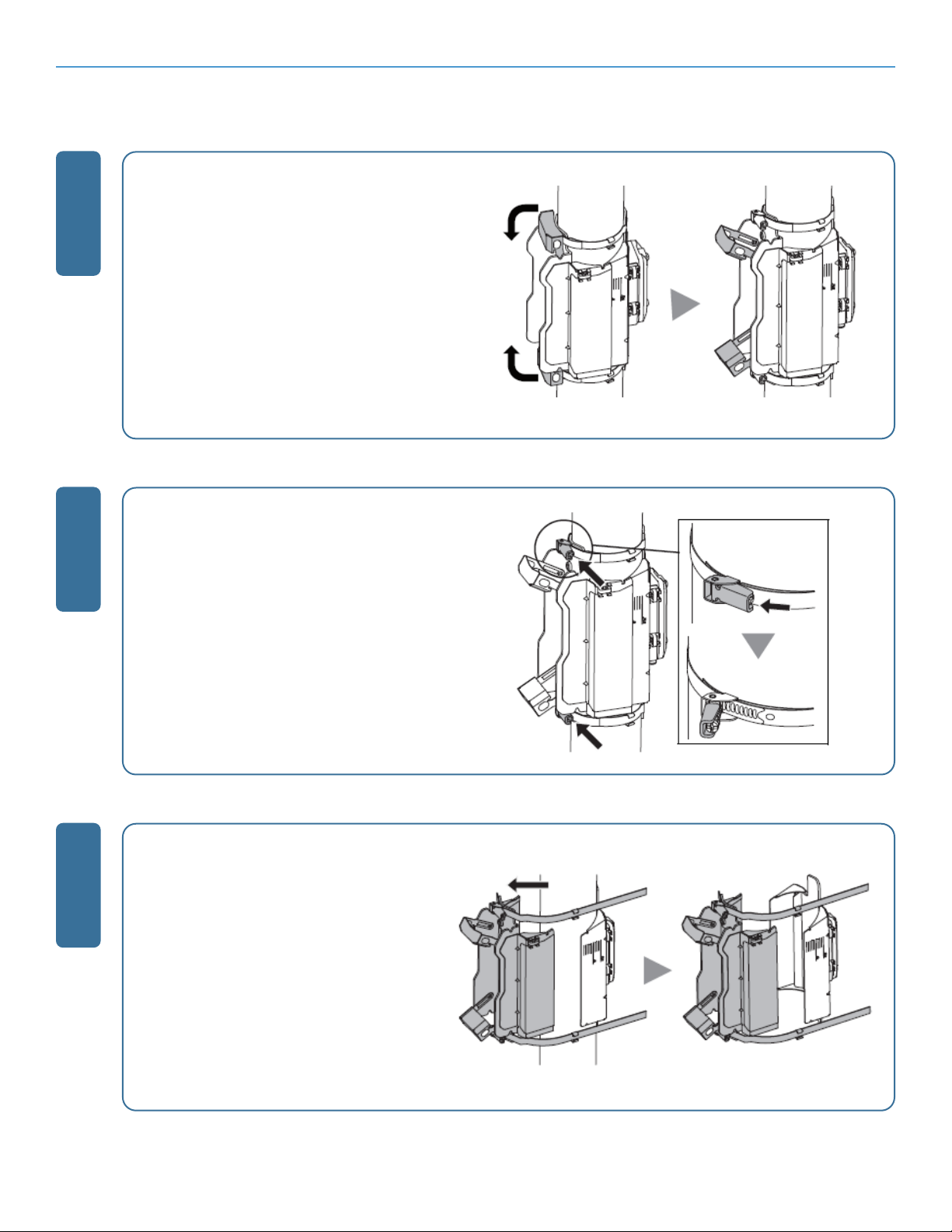

1. Remove the outer door for access to the

interior of the enclosure. Slide it upwards, then

place it in a location to prevent damage.

2. Mark and drill new mounting holes using the

paper template, then drill appropriately sized

holes with a hammer-drill as needed. Use

plastic inserts and mounting screws (taped

to the controller with the enclosure keys) to

secure the controller.

3. Hang the enclosure on these fasteners and

verify the enclosure is mounted level both

vertically and horizontally.

4. Locate the third center mounting hole and

insert the last fastener. Tighten all fasteners to

the enclosure to secure to the vertical surface.

Step 1: Mount the WaterCompass Data Collector Enclosure

1