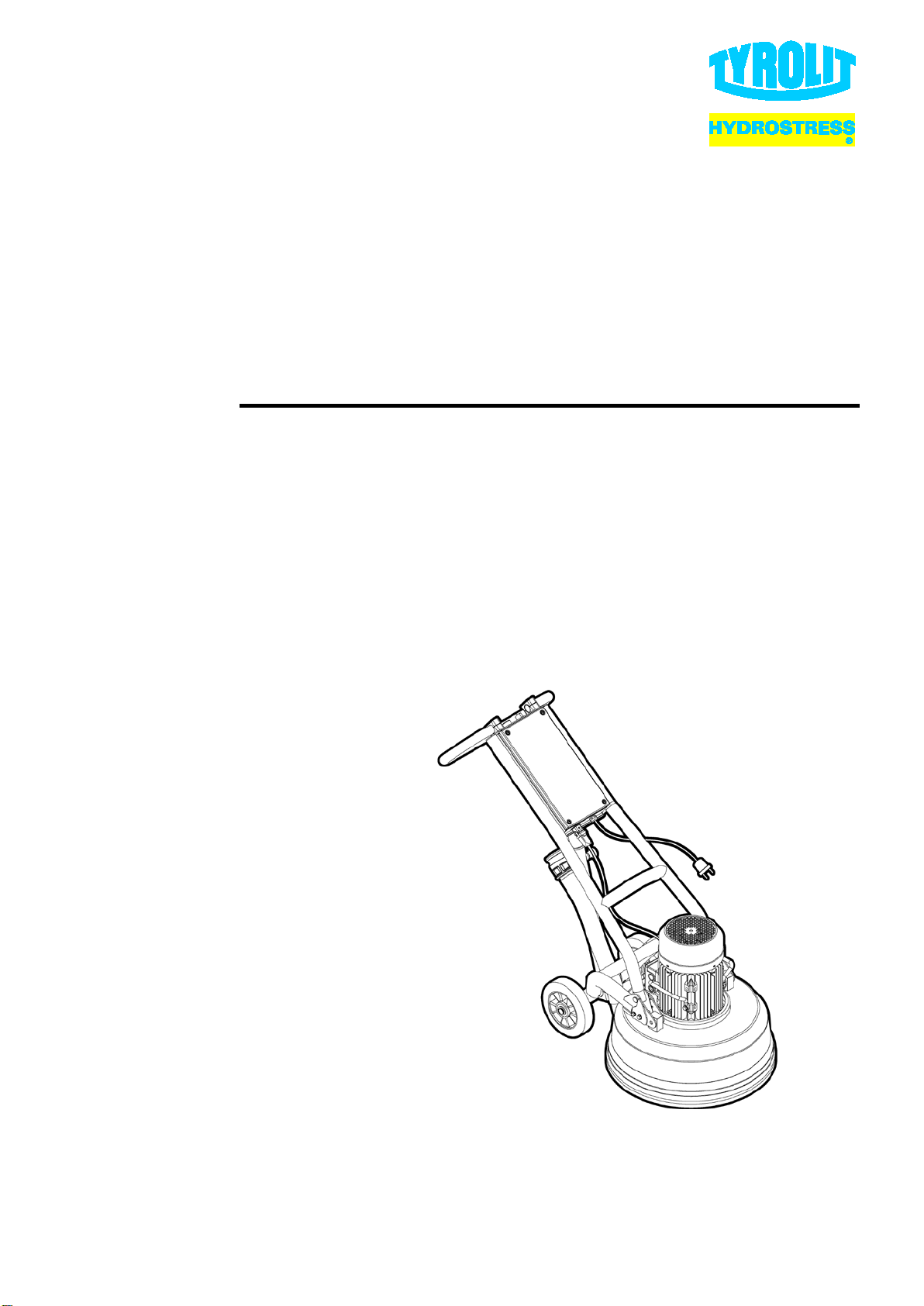

Schleifmaschine FGE270

Wir erklären in alleiniger Verantwortung, dass dieses Produkt mit den folgenden Richtlinien und Normen übereinstimmt:

Angewandte Richtilinie

Maschinen-Richtlinien 2006/42/EG

EMV 2004/108/EG

NSR 2006/95/EG

Angewandte Normen

EN 12100-1

EN 12100-2

Sicherheit von Maschinen-Grundbegrien, allgemeine Gestaltungsgrundsätze.

EN 14121-1 Sicherheit von Maschinen-Risikobeurteilung, Teil 1: Leitsätze

Vibrationsverordnung ISO 5349-1 / ISO 5349-2 / ISO 20643:2005

Lärmschutzverordnung ISO 3741

Konformitätserklärung

Typenschild hier auf kleben

Declaration of conformity

Déclaration de conformité

Ponceuse FGE270

Nous déclarons, sous notre seule responsabilité, que ce produit répond aux directives et normes suivantes:

Directive appliquée

Directive relative aux machines 2006/42/CE

EMV 2004/108/EG

NSR 2006/95/EG

Normes appliquées

EN 12100-1

EN 12100-2

Sécurité des machines, notions fondamentales, principes généraux de conception

EN 14121-1 Sécurité des machines - Appréciation du risque - Partie 1 : principes

Décret relatif aux vibrations ISO 5349-1 / ISO 5349-2 / ISO 20643:2005

Décret relatif à la protection contre les

nuisances sonores

ISO 3741

Grinding machine FGE270

We declare under our sole responsibility that this product complies with the following directives and standards:

Directive applied

Machinery Directives 2006/42/EC

EMV 2004/108/EG

NSR 2006/95/EG

Applied standards

EN 12100-1

EN 12100-2

Safety of machinery – Basic concepts, general design principles.

EN 14121-1 Safety of machines - Risk assessment, Part 1: Principles

Vibration Regulation ISO 5349-1 / ISO 5349-2 / ISO 20643:2005

Noise Protection Regulation ISO 3741

TYROLIT 10991209