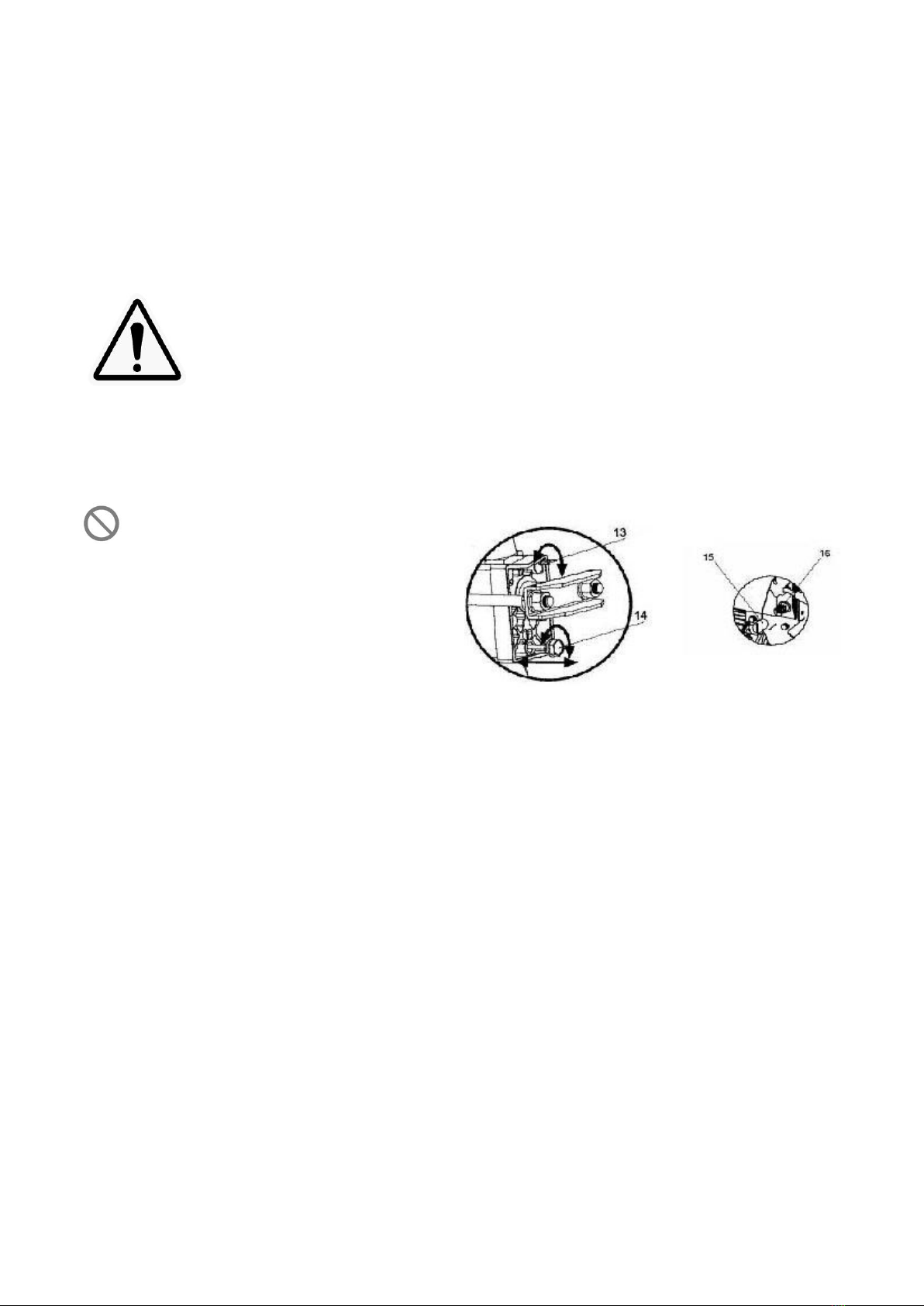

PROTECT YOUR HANDS

Keep you hands away from splits and cracks which open in the

log; They may close suddenly and crush or amputate your hands.

Do not remove jammed logs with you hands.

DON’T FORCE TOOL

It will do a better and safer job at its design rate. Never try to split

logs larger than those indicated in the specifications table. This

could be dangerous and may damage the machine.

Don’t use log splitter for a purpose for which it was not intended.

NEVER LEAVE TOOL RUNNING UNATTENDED

Don’t leave tool until it has come to a complete stop.

DISCONNECT POWER

Unplug when not in use, before making adjustments, changing

parts, cleaning, or working on the log splitter; Consult technical

manual before servicing.

PROTECT THE ENVIRONMENT

Take used oil to an authorized collection point or follow the

stipulations in the country where the log splitter is used.

Do not discharge into drains, soil or water.

MAINTAIN YOUR LOG SPLITTER WITH CARE

Keep the log splitter clean for best and safest performance.

MAKE THE WORKSHOP CHILDPROOF

Lock the shop. Disconnect master switches. Store the log splitter

away from children and others not qualified to use it.

- Operator must receive necessary training and instruction from a qualified person

before handling the tool.

- Use the tool only for the intended use. Misuse (such using material other than log)

can damage the tool and cause accidents and injuries.

- The splitting operation of the machine is designed to be activated by one person.

While there is the possibility that additional operators could be working with the machine

(e.g. for loading and unloading), only one operator should activate splitting operations.

- The machine shall not be used by children.

- Wear suitable personal protective equipment (PPE), including safety footwear, close

fitting clothing and suitable work gloves, eye protection and hearing protection.

- Before starting work, hydraulic pipes and hoses shall be inspected and the stopping

devices shall be tested.

- Tests of the machine's safety devices before use the tool. If safety devices do not

work properly, do no use the tool and bring it to a qualified technician for inspection and

reparation.

- The working area shall be free from obstructions; before installation and operation,

clear the working area. Keep the working area free from obstructions, e.g. logs, split

wood, etc.