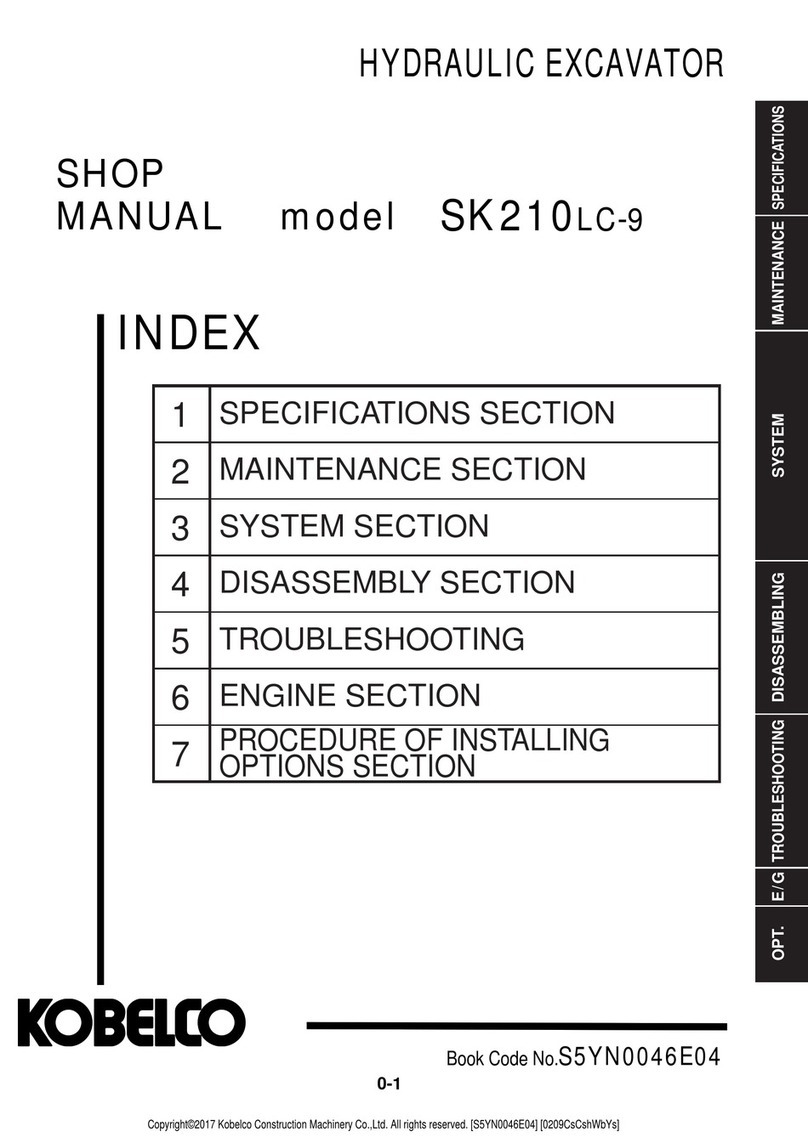

CONTENTS

SECTION 1 GENERAL

Group 1 Safety Hints

----------------------------------------------------------------------------------------------------

1-1

Group 2 Specifications

-------------------------------------------------------------------------------------------------

1-9

SECTION 2 STRUCTURE AND FUNCTION

Group 1 Pump Device

-------------------------------------------------------------------------------------------------

2-1

Group 2 Main Control Valve

-----------------------------------------------------------------------------------------

2-9

Group 3 Swing Device

-------------------------------------------------------------------------------------------------

2-28

Group 4 Travel Device

--------------------------------------------------------------------------------------------------

2-38

Group 5 RCV Lever

-----------------------------------------------------------------------------------------------------

2-45

Group 6 RCV Pedal

-----------------------------------------------------------------------------------------------------

2-52

SECTION 3 HYDRAULIC SYSTEM

Group 1 Hydraulic Circuit

---------------------------------------------------------------------------------------------

3-1

Group 2 Main Circuit

----------------------------------------------------------------------------------------------------

3-2

Group 3 Pilot Circuit

-----------------------------------------------------------------------------------------------------

3-5

Group 4 Single Operation

--------------------------------------------------------------------------------------------

3-10

Group 5 Combined Operation

-------------------------------------------------------------------------------------

3-22

SECTION 4 ELECTRICAL SYSTEM

Group 1 Component Location

-------------------------------------------------------------------------------------

4-1

Group 2 Electrical Circuit

---------------------------------------------------------------------------------------------

4-3

Group 3 Electrical Component Specification

---------------------------------------------------------------

4-23

Group 4 Connectors

----------------------------------------------------------------------------------------------------

4-31

SECTION 5 MECHATRONICS SYSTEM

Group 1 Outline

------------------------------------------------------------------------------------------------------------

5-1

Group 2 Mode Selection System

--------------------------------------------------------------------------------

5-3

Group 3 Travel Speed Control System

------------------------------------------------------------------------

5-4

Group 4 Automatic Warming Up Function

------------------------------------------------------------------

5-5

Group 5 Engine Overheat Prevention Function

----------------------------------------------------------

5-6

Group 6 Anti-Restart System

--------------------------------------------------------------------------------------

5-7

Group 7 Self-Diagnostic System

---------------------------------------------------------------------------------

5-8

Group 8 Engine Control System

---------------------------------------------------------------------------------

5-10