Safety rules:

1. Read carefully and understand entirely the following instructions before using the product.

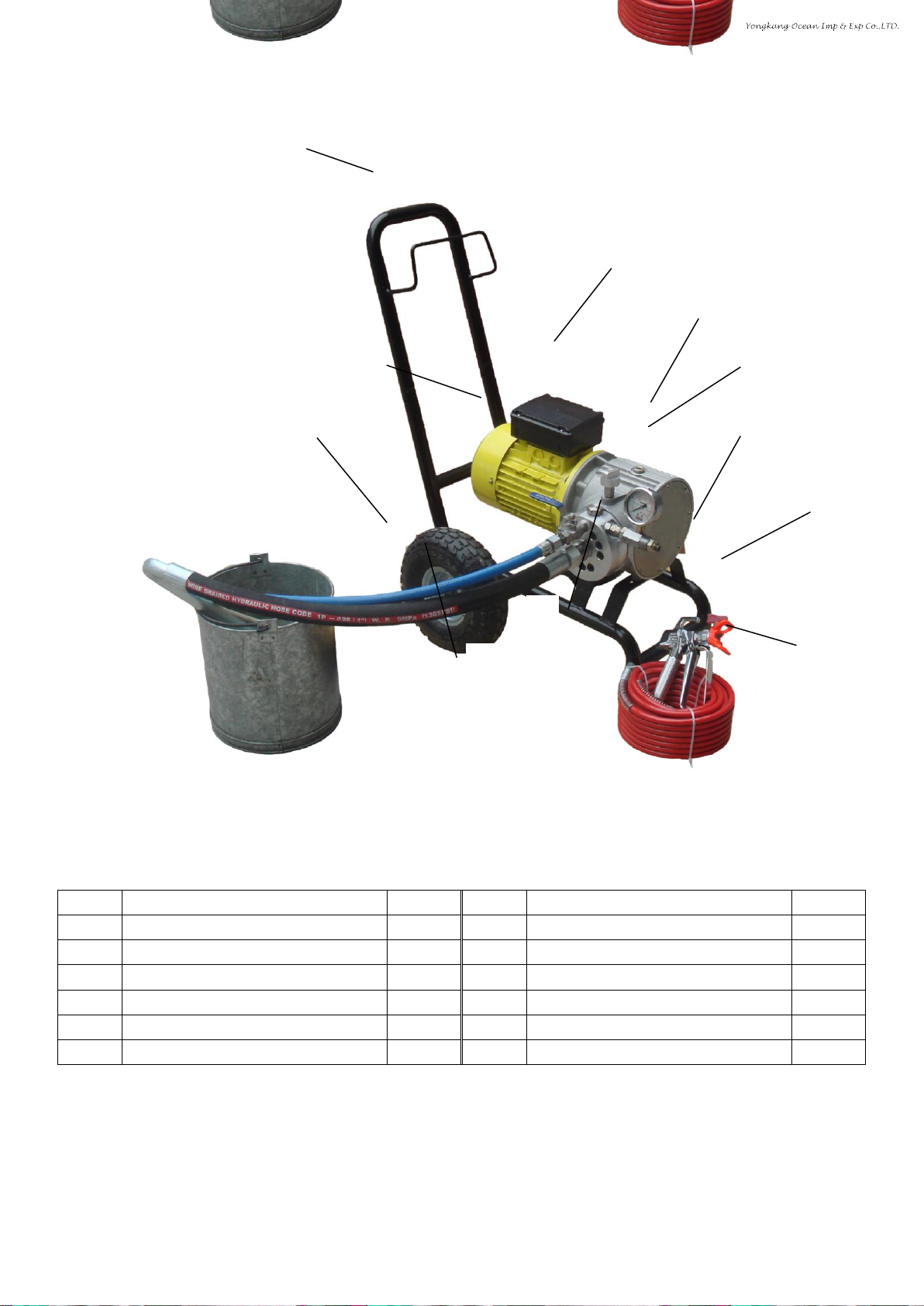

2. The product should be placed on a smooth surface. The user should ware necessary safety clothing.

3. The working Area is well-ventilated. The cable and hoses can’t be pressed by anything. To avoid any

damage, hold the hose when the product is moved.

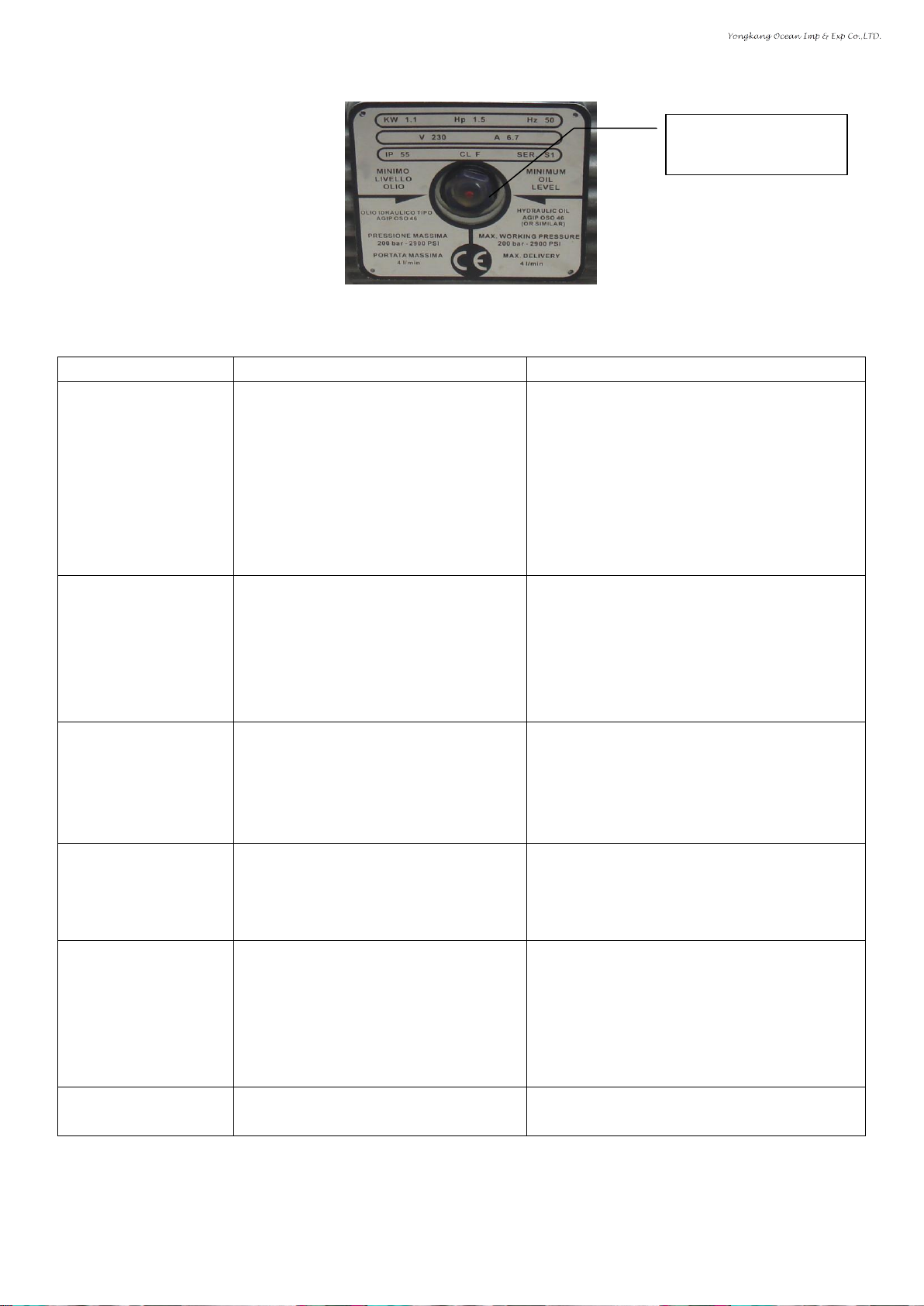

4.The power and frequency used should be compatible with that on the label, the power should be

grounded properly. Don’t operate it with low voltage.

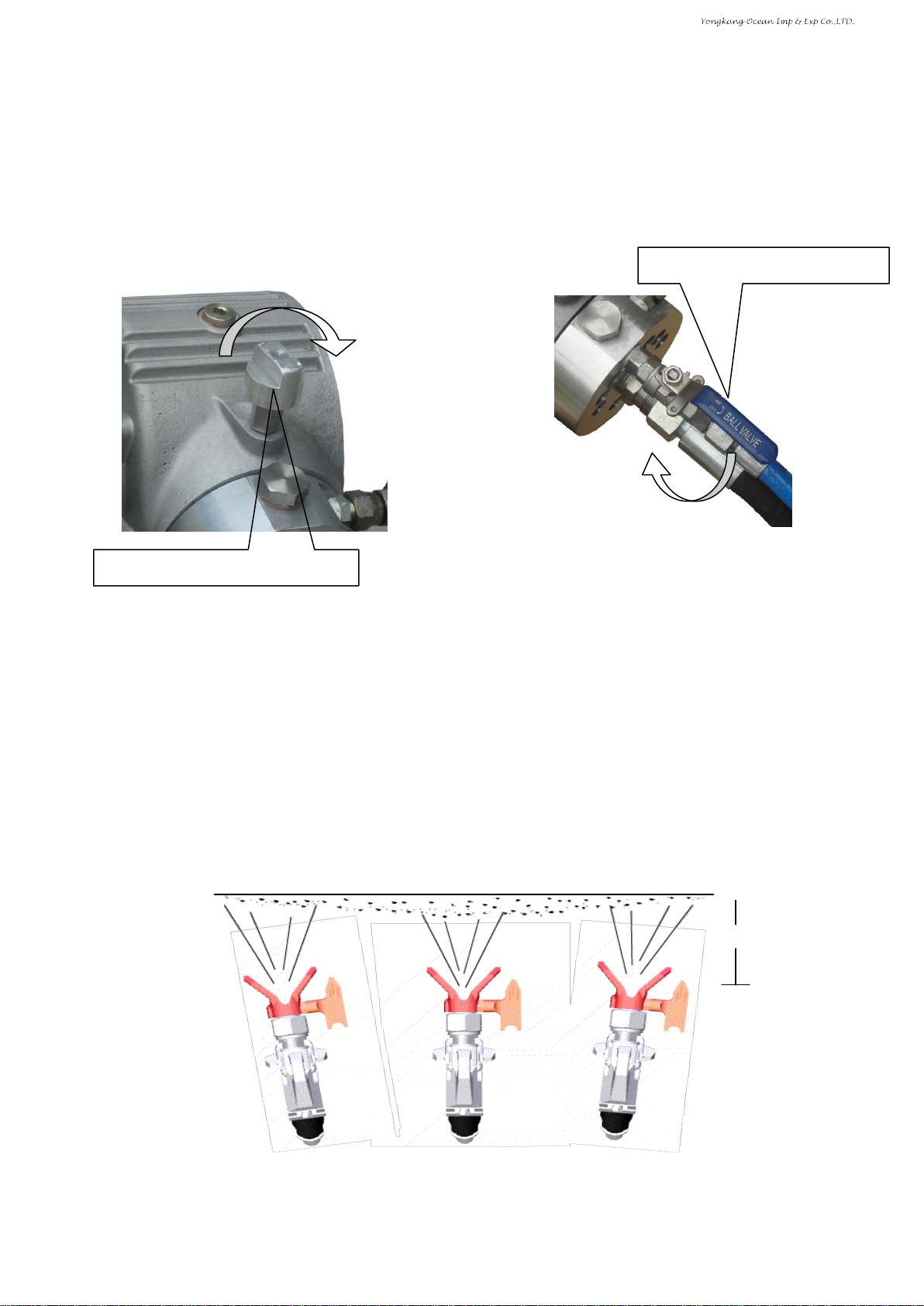

5. Make sure the all the fittings are tight, and hoses are connected properly before you use the machine.

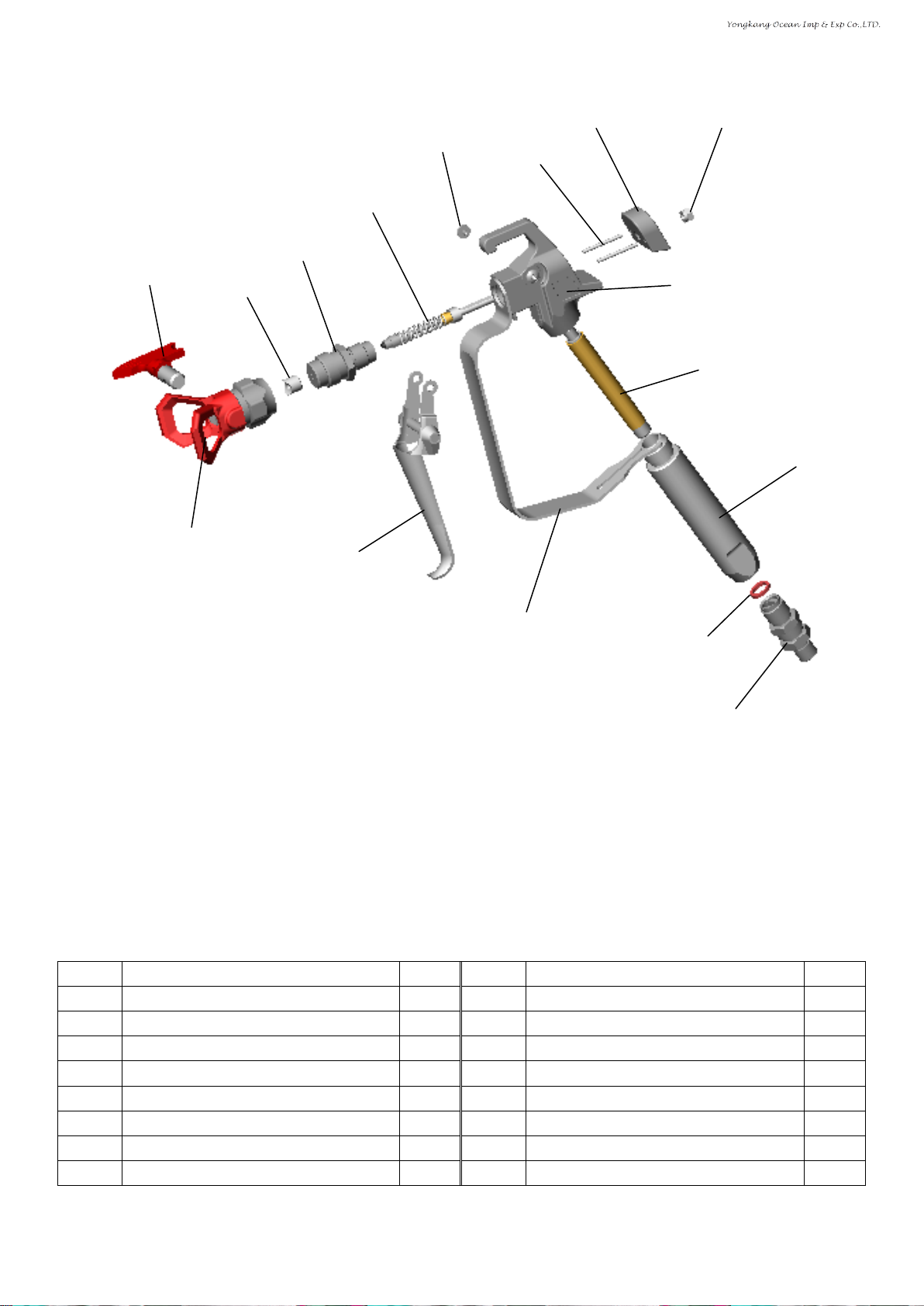

6. To get a good performances, make sure the painting used is clean,, pure, use a filter bigger than 80.

7. The pressure adjustment can’t be more than 22.5MPa, if you need to replace the hose, it should be

from the manufacturer.

8. Never point the spray gun at yourself or anyone else.

9. Don’t use it to spray acid products, corrosion solvents or toxic chemicals. Never use with methylene

chloride.

10. Never eat anything or smoke during operation.

11. After use it, discharge the paint, release the pressure, then turn off the machine. Clear the

parts with cleanser.

12. Shut off the power during transportation, keep the motor and plug from water or paint. Keep the

machine clean and dry.

13. Use proper tools when to tight, adjust or maintain the machine with proper procedures, avoid damage

machine and injury of the user.

14. Never change the structure of the machine, always use the parts from the manufacturer.

Technical data