I.D. Systems Vehicle Asset Communicator User manual

I.D. SYSTEMS, INC.

VAC™ – Vehicle Asset Communicator™

A Wireless Fleet Management Device

VAC

User’s Guide

Version 3.1.x

VAC™ – A WIRELESS FLEET MANAGEMENT DEVICE

VAC – User’s Guide

VAC™ IDS Gateway™

IDS WAN Console™

©I.D. Systems, Inc.

1 University Plaza • 6th Floor

Hackensack, NJ 07601

Phone 201.996.9000 • Fax 201.996.9144

www.id-systems.com

Preface

This manual is a user’s guide for the VAC (Vehicle Asset Communicator), a Wireless Fleet Management

Device developed by I.D. Systems, Inc. This guide provides the instruction necessary for someone to

install, operate and maintain the VAC device in a vehicle. Note: This user’s guide may change without notice due to

enhancements or changes to VAC.

Related Documents

Vehicle Survey (Doc. #: 026-1000-01)

Publication History

Version Date Changes

2.5.x 9.18.02 Initial

2.6.x 10.25.02 New Modules: Seatbelt monitor & Battery rotation, new

installation screens and color coded connector labels

2.7.x 01-03-03 Add Ext Reader Test, Ext LED Test, Security Features

2.8.x 08-07-03 Add Critical OSHA Shutdown, Blank VAC In Motion

3.0.x 11-03-03 Now Using New Enclosure

3.1.x 03-11-04 O/T versions for new enclosure

Disclaimer and Limitation of Liability

I.D. Systems, Inc. assumes no responsibility for any damage or loss resulting from the use of its products

or services. I.D. Systems assumes no responsibility for any loss or claims by third parties, which may arise

through the use of its products or services.

The information disclosed herein is the exclusive property of I.D. Systems and no part of this information

may be reproduced or transmitted in any form or by any means including electronic storage, reproduction,

execution or transmission without the prior written consent of I.D. Systems. The information contained

in this document is subject to change without notice and should not be construed as a commitment by

I.D. Systems unless such commitment is expressly given in writing.

FCC Compliance Statement

Compliance Statement (Part 15.19)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired operation.

Warning (Part 15.21)

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Compliance Statement (Part 15.247)

This device complies with Part 15.247 of the FCC rules. Operation is subject to the following condition:

To comply with FCC’s RF exposure limits for general population/uncontrolled exposure, the antenna(s)

used for this transmitter must be installed to provide a separation distance of atleast 20cm from all

persons and must not be co-located or operating in conjunction with any other antenna or transmitter.

TableofContents

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Table of Contents

TABLE OF CONTENTS.........................................................................................................................................................................................5

INTRODUCTION......................................................................................................................................................................................................7

SYSTEM OVERVIEW................................................................................................................................................................................................ 7

INSTALLATION .......................................................................................................................................................................................................9

WARNINGS............................................................................................................................................................................................................9

STANDARD HARDWARE FOR INSTALLATION.................................................................................................................................................... 9

TOOLS REQUIRED FOR INSTALLATION (NOT SUPPLIED)............................................................................................................................. 9

SYSTEM CONNECTIONS OVERVIEW ................................................................................................................................................................. 10

INSTALLATION SUMMARY................................................................................................................................................................................... 10

BEFORE STARTING THE INSTALLATION.......................................................................................................................................................... 10

INSTALLING THE VAC (AND OPTIONAL ID READER)................................................................................................................................... 11

Selecting the VAC Mounting Location.............................................................................................................................................................. 11

Mounting the VAC............................................................................................................................................................................................. 11

INSTALLING VAC-TO-PCM HARNESS............................................................................................................................................................ 12

Vehicle Cable Harness......................................................................................................................................................................................12

Selecting the System’s Power and Ground Connections.................................................................................................................................. 12

FINISHING THE INSTALLATION.......................................................................................................................................................................... 13

System Configuration........................................................................................................................................................................................13

STANDARD VAC OPERATION.......................................................................................................................................................................14

VAC OVERVIEW .................................................................................................................................................................................................... 14

GENERAL OPERATION.......................................................................................................................................................................................... 15

BASIC OPERATION:LCD, KEYPAD,ID READER AND LEDS....................................................................................................................16

VAC Display and Keypad Basics......................................................................................................................................................................16

ID Reader..........................................................................................................................................................................................................16

Menu Selection Mode........................................................................................................................................................................................ 16

Digit Entry Mode............................................................................................................................................................................................... 17

ACCESS CONTROL (ALL USERS): LOGGING ON AND OFF THE VEHICLE ...............................................................................................18

Access Control Overview.................................................................................................................................................................................. 18

Logging onto the VAC....................................................................................................................................................................................... 19

Denial of Login .................................................................................................................................................................................................21

NOTE: Repeated failure to log into the VAC will trigger an alert on the ARDCS which can be emailed or sent by pager to specified

personnel (See ARDCS User’s Guide)............................................................................................................................................................. 22

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Logging Off of the VAC.....................................................................................................................................................................................23

ELECTRONIC OSHA SAFETY CHECKLISTS (ALL USERS)..........................................................................................................................23

OSHA Question Mode.......................................................................................................................................................................................24

Critical OSHA Shutdown (Optional)................................................................................................................................................................26

TWO-WAY TEXT PAGING (ALL USERS).......................................................................................................................................................... 26

Viewing and Responding to Text Pages............................................................................................................................................................ 27

VEHICLE UTILIZATION MONITORING (ALL USERS)..................................................................................................................................... 29

MOTION SAFETY FEATURE (OPTIONAL –STANDARD AND MASTER USERS)........................................................................................ 30

BATTERY ROTATION (OPTIONAL MODULE -ALL USERS).......................................................................................................................... 30

Battery Request:................................................................................................................................................................................................ 31

Battery Validation:............................................................................................................................................................................................ 32

Battery Request Troubleshooting:.................................................................................................................................................................... 33

SECURITY MODULE (OPTIONAL MODULE -ALL USERS)............................................................................................................................ 33

GRANTING TEMPORARY ACCESS (MASTER USERS)................................................................................................................................... 33

APPENDIX A............................................................................................................................................................................................................35

ELECTRICAL............................................................................................................................................................................................................ 35

MEMORY/OTHER....................................................................................................................................................................................................35

COMMUNICATION.................................................................................................................................................................................................. 35

USER INTERFACE.................................................................................................................................................................................................. 36

ENVIRONMENTAL ..................................................................................................................................................................................................37

MOUNTING..............................................................................................................................................................................................................37

APPENDIX B............................................................................................................................................................................................................38

VAC™ ERROR CODE GUIDE ..............................................................................................................................................................................38

Error Code: E3301 ...........................................................................................................................................................................................38

APPENDIX C............................................................................................................................................................................................................39

WARRANTY INFORMATION.................................................................................................................................................................................. 39

Limited Warranty .............................................................................................................................................................................................. 39

This Warranty Does Not Cover: .......................................................................................................................................................................39

General Provisions: ...........................................................................................................................................................................................40

To Get Warranty Service or Returned Material Authorization: ....................................................................................................................... 40

Introduction

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Introduction

This manual is a user’s guide for the VAC (Vehicle Asset Communicator), a Wireless Fleet Management

Device developed by I.D. Systems. This guide will introduce the reader to the VAC and to I.D. Systems’

Fleet Management solution. In addition, this guide also includes information about VAC installation

procedures, installation options, operator instructions, maintenance procedures, and troubleshooting. The

owner and user of a VAC can use this guide to understand how a VAC works and how to interact with it.

The Introduction section covers general information about the IDS Fleet Management System, and what

part the VAC device plays in the system. Users of the IDS Fleet Management System should familiarize

themselves with this information to better understand the detailed instructions in this guide.

The Installation section provides detailed procedures and guidelines for hardware installation.

Electricians, mechanics or maintenance persons responsible for VAC installation or troubleshooting

should familiarize themselves with this hardware installation process. This will allow them a better

understanding of the interface between the VAC and the vehicle being managed. In addition, those who

perform vehicle maintenance will better understand the implications of parts replacement or rewiring.

Finally, VAC troubleshooting is more easily understood with an understanding of hardware installation

procedures and guidelines. In order to complete VAC installation, maintenance user software, covered in

the VAC Operation section is required.

The Standard VAC Operation section explains how the user interacts with the VAC user interface

(keypad, display and ID reader). As a mini-computer, the VAC is an interactive device requiring an

operator to interact with it. Standard operators (vehicle drivers) must familiarize themselves with the

section on Basic Operation, Access Control, Electronics, OSHA Checklists, and Two-Way Text Paging,

either through reading the Guide, or through hands-on training. Floor supervisors with special system

privileges (Master Users) should also become familiar with the Master User features.

The appendices include additional information for those who have purchased or who maintain the VAC.

Appendix A details the physical specifications of the system, which is useful for those who wish to

understand how the VAC will work in specific environments. Appendix B is a troubleshooting guide for

maintenance personnel to handle issues with the VAC that may arise through installation or operation.

Finally, Appendix C covers warranty information for those who have purchased the VAC product.

System Overview

The VAC is part of a comprehensive fleet management solution, integrating access control, vehicle

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

monitoring, safety, maintenance and communication technology in an industrial vehicle. Within the VAC,

a processor is integrated with an RF transceiver and vehicle interface and runs an embedded computer

application. Information about the attached vehicle is communicated from the VAC over the wireless

infrastructure of Gateways™, to I.D. Systems software (refer to the system diagram in Figure 1).

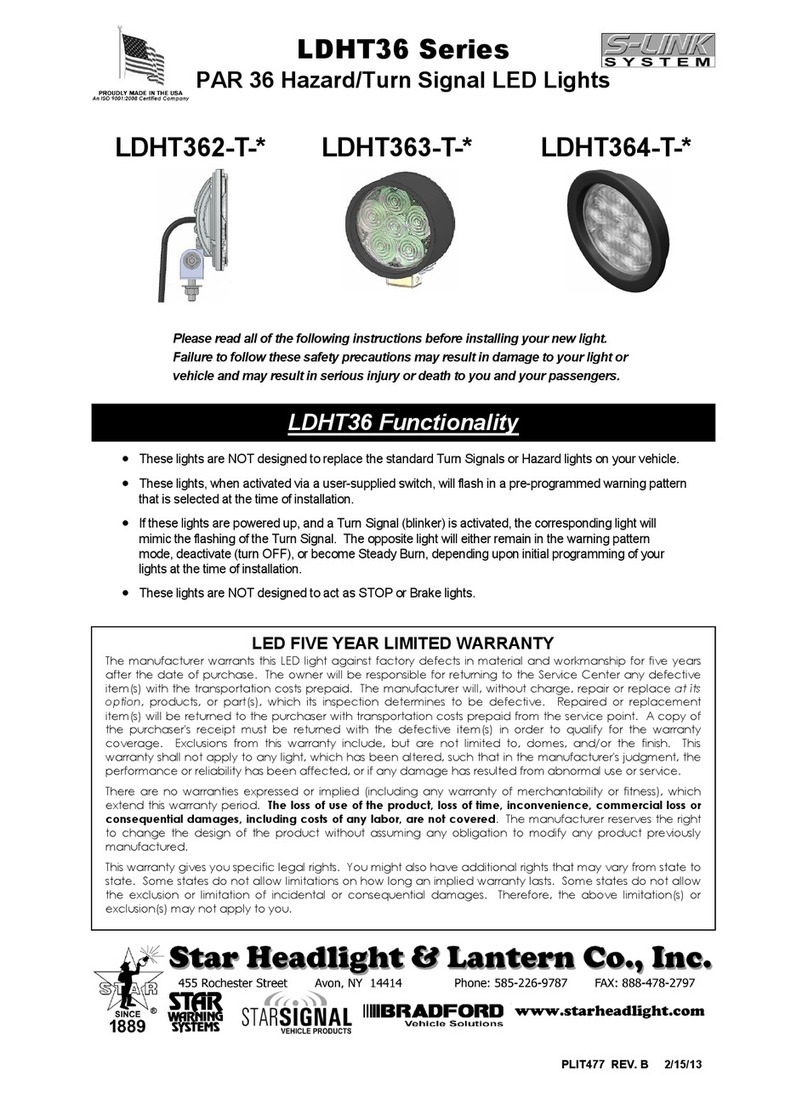

Figure 1: IDS Fleet Management System Diagram

The VAC device both sends and receives information, such as access control updates, pages, updated

configuration settings, and scheduled maintenance event information, and interacts with the vehicle’s

driver using a keypad, display, and optional ID readers.

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Installation

WARNINGS

* Please read this document in its entirety

BEFORE performing any installation. *

* Please disconnect main vehicle battery

BEFORE performing any installation. *

Standard Hardware for Installation

The standard components of the VAC system are installed on every vehicle type (Industrial Electric and

Internal Combustion). The following is a list of standard equipment that is required to install each VAC

system:

900-0144-02: Universal Vehicle Asset Communicator (VAC)

810-0113-0x: VAC-to-PCM Cable

835-0121-01 and -03: Mounting Hardware Assortments

825-0111-01: Vehicle Asset Communicator Mounting Bracket

During hardware installation and system configuration, a test sheet must be filled out and sent (via mail or

fax) to I.D. Systems, Inc. to certify that the installation was performed correctly. The test sheet is

provided with the hardware.

For technical support, contact I.D. Systems, Inc.:

By Phone: (201) 996-9000

By Fax: (201) 996-9144

By email: [email protected]

Tools Required for Installation (Not Supplied)

In order to install the standard components of the VAC system, certain tools are required. The VAC is

mounted rigidly to each vehicle, thus requiring mounting hardware (supplied in Mounting Hardware

Assortment kits) and requiring holes to be drilled. In addition to mechanical mounting, some wiring and

electrical testing must be performed. Therefore, wire strippers and simple electrical test equipment are

required.

MOLEX RHT-1991 Ratchet tool or equivalent

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Minimum ¼” chuck drill

¼” drill bit

1 ¼” or 1 ½” hole saw

#10 socket and ratchet (or open-end wrench)

Medium sized slotted and Phillips screwdrivers

Wire stripper

Multimeter and test lead assortment

Note: The system is shipped with a set of hardware used to install the system on a vehicle (Mounting

Hardware Assortment kits). The hardware should accommodate most vehicle types. The hardware kit is

specified for high vibration industrial applications. I.D. Systems highly recommends using the MOLEX

RHT-1991 Ratchet tool (or equivalent) for crimping terminals. If using a different tool, I.D. Systems will

bear no responsibility for resulting installation failures.

System Connections Overview

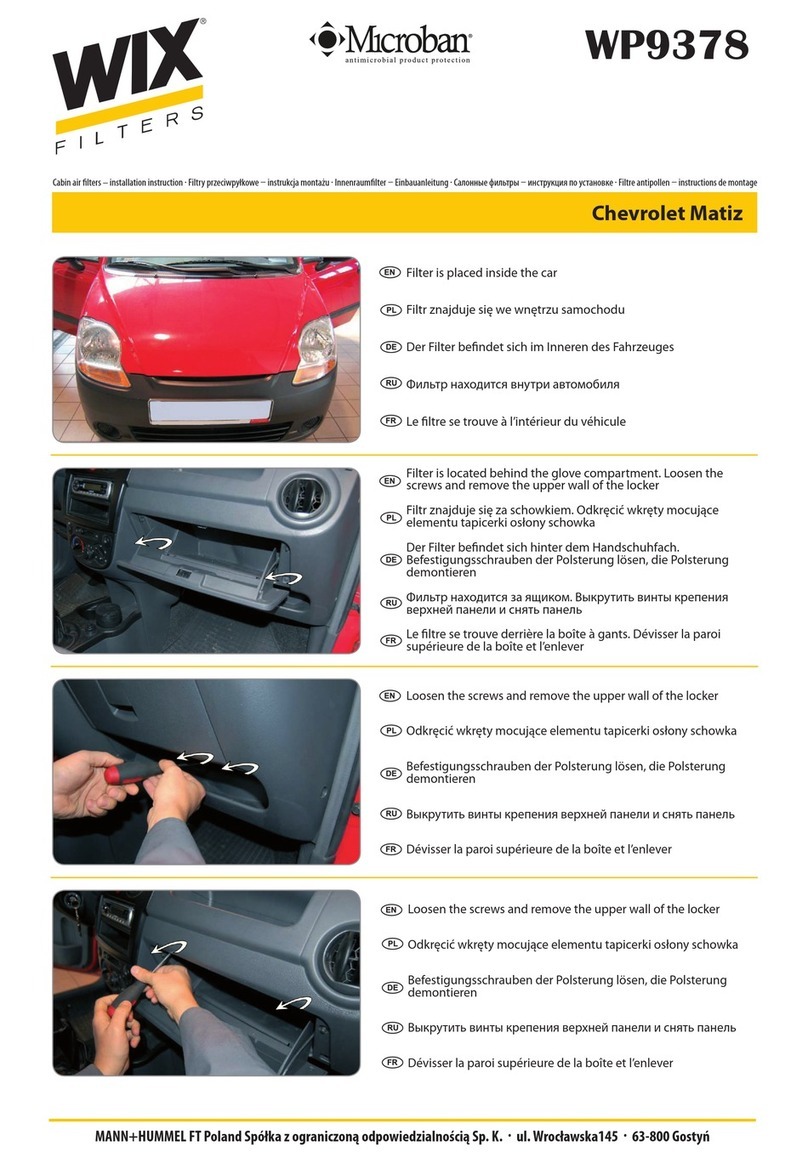

Figure 2: System Diagram

1. VAC: Vehicle Asset Communicator. User interface and intelligent industrial control device.

Operators read the display and use the keypad to interact with the vehicle control system. A two-

way radio transceiver is embedded within the VAC.

2. VAC-to-PCM Cable: Cable that connects the VAC to the vehicle’s Power and Control system.

This cable must route from the VAC mounting location (driver area) to the vehicle (typically the

engine/motor compartment).

Installation Summary

The installation must be performed in the order that follows:

Installing the VAC (with optional ID reader) [Items 1, 2]

Configuring the VAC using On-Screen Display

Before Starting the Installation

Before starting a VAC installation, make sure that all required tools and equipment and the Installation

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Verification test sheet are available. If not, do not proceed with installation. If all equipment is

available, record the following on the installation sheet:

The VAC serial number

Installing the VAC (and optional ID Reader)

The VAC contains the driver’s user interface to the system and also contains the embedded fleet

management software and RF capability. The VAC, therefore, must be mounted in a location that is

convenient for operator access (to the keypad, LCD and optional ID reader) and that is optimized for RF

performance. The VAC is wired into the vehicle. Therefore, selecting the proper location and verifying

correct installation is important to ensure correct functionality.

Selecting the VAC Mounting Location

Notes:

The VAC is mounted to the vehicle using the supplied VAC Mounting Bracket (modifications or

custom brackets must be approved by I. D. Systems in order to ensure proper functionality).

Procedure:

Select a location on the dash area of the vehicle to mount the VAC.

oThe operator of the vehicle should be able to view the VAC’s display and access the

keypad and optional ID reader while sitting in the vehicle.

oThe VAC should not obscure the operator’s line of sight or accessibility to the vehicle.

oThe VAC display should not be obscured.

oThe VAC’s antenna should be as far away from the vehicle’s chassis as possible (having

the antenna close to the metal of the vehicle [less than 3”] attenuates the unit’s RF

communications).

oThe VAC should be securely affixed to the vehicle and is not adjustable for different

operator heights.

Select the location on the vehicle to which the bracket should be bolted or welded.

Mounting the VAC

If mounting with bolts, use the bracket as a template to drill holes in the vehicle for mounting the

VAC bracket. The bracket has to be secured to the vehicle by at least two bolts. Make sure that

nothing can be damaged on the vehicle while drilling or welding.

If the VAC-to-PCM cable has to run through the dash of the vehicle, drill using a 1¼” hole saw.

Assemble the VAC onto the Bracket.

If the VAC-to-PCM cable runs through the vehicle’s dash, insert a Grommet (supplied) in the

hole to prevent the cable from being damaged.

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Using the attached hex key tighten the hex nuts to secure the swivel points. The bracket is not

supposed to be adjustable. Failure of tightening the hex nuts will result in assembly failure.

Attach the 9-pin circular connector of the VAC-to-PCM cable (Item 4) to the circular connector

on the back of the VAC.

Route the VAC-to-PCM cable through the hole in the VAC mounting bracket and route all the

way to the vehicle interface location.

oUse the vehicle’s pre-existing cable-routing channels (where other cables are also run

throughout the vehicle) to prevent the cable from being damaged during vehicle use or

maintenance.

Installing VAC-TO-PCM Harness

The VAC-TO-PCM Harness connects the VAC to the vehicle. Through the harness, the VAC system

will get power from the vehicle, and have the ability to receive commands from the vehicle via the I.D.

Systems Serial Data Interface (IDSY SDI) protocol. Installation of this cable must be performed

according to the instructions below for the VAC system to operate properly.

Vehicle Cable Harness

Cable Pin-Out:

Pin Color Signal Name Comments

1 RED POWER Power (+)- TO REGULATED 6.5 VDC

2 BLACK POWERRTN Power return (-) - TO 6.5 VDC RETURN

3 WHITE ISEN(-) IDSY SDI SIMO (OPTIONAL)

4 GREEN RELAYIN IDSY SDI SOMI (OPTIONAL)

5 ORANGE RELAYOUT IDSY SDI SCLK (OPTIONAL)

6 BLUE VSEN1(-) IDSY SDI INT_NCS (OPTIONAL)

7 WHITE/

BLACK

VSEN1(+) IDSY SDI INTRPT (OPTIONAL)

8 RED/

BLACK

VSEN2(+) IDSY SDI WAKEUP (OPTIONAL)

9 RED/

BLACK

N/C NO CONNECT

Selecting the System’s Power and Ground Connections

Notes:

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

The system requires an uninterrupted, regulated 6.5 VDC supply from the vehicle. The

supply should be continuous regardless of the condition of the vehicle. The only time the supply

is discontinued is when the vehicle’s battery is unplugged.

The interface should be the cleanest possible power source, free from noise and damaging voltage

spikes.

The current draw of the system in normal mode at 6.5 VDC is approximately 0.25 Amperes

Finishing the Installation

System Configuration

In order to complete the installation of the VAC system on a vehicle and to ensure proper operation of

the system.

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Standard VAC Operation

VAC Overview

The VAC device is the vehicle component of a comprehensive fleet management system provided by I.D.

Systems. The VAC incorporates a highly customized computer application, a two-way wireless

communications port, and a vehicle power and data interface. The complete fleet management solution

also requires other system elements: wireless infrastructure devices, termed Gateways, a server computer

running the ARDCS software, and at least one computer running WAN Console software. Combined,

the IDS Fleet Management solution provides the following major benefits:

Automated compliance with OSHA rules

Electronic, paperless OSHA checklists

Automated vehicle utilization analysis

Operator accountability

Real-time vehicle location tracking

Enhanced maintenance efficiencies

Significant cost savings

To achieve the above benefits, the VAC is designed to implement several critical Fleet Management

functions, including:

Driver OSHA checklist interface – allowing drivers to identify and communicate vehicle status by

answering vehicle-specific safety questions

Two-way paging – option that allows drivers to receive and respond to messages sent from plant

computers

Vehicle Utilization Monitoring – If the vehicle interface permits, provides accurate fleet

information through motion sensing, lift sensing, log-on time, and battery monitoring

Maintenance Management - predictive forecasting and driver notification of scheduled

maintenance

Access Control – tracks the current operator using the equipment. If the vehicle interface

permits, also prevents unauthorized operators from driving vehicles, using individual driver IDs

instead of vehicle keys

As a radio frequency (RF) and computing device, the VAC utilizes the most robust communication

protocol in the industry to ensure that all relevant data is communicated with the rest of the system.

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

When in range of IDS Gateways, the VAC will:

Display an ‘in-range’ indicator, letting the driver know that information can currently be

communicated

Send any stored data, verifying receipt through a robust confirmation process

Synchronize with the most up-to-date access control information (add, delete or modify

authorized driver information)

Receive any updates to vehicle settings, such as battery and impact thresholds, or OSHA

questions

Update the vehicle’s location, and, if necessary, send a location update to the system

General Operation

Three different groups of operators will interact with the VAC – the standard driver, the Master User

driver, and the maintenance/installation user.

The standard driver will perform certain basic functions with the VAC (for Standard Driver Instructions,

see Basic Operation: LCD, Keypad, ID Reader on page 16). These features are:

Logging onto the vehicle to gain access

oIdentifying himself/herself using an ID (either by typing the ID or through an ID device)

oVerifying his/her identity using a PIN (if required)

Logging off of the vehicle prior to leaving the vehicle unattended

Answering OSHA-required safety questions

Reading, responding to, and deleting pages (optional)

Identifying low vehicle battery condition

The Master User driver can perform the same basic functions with the VAC (For Master User

Instructions, see Granting Temporary Access (Master Users) on page on page 33), as well as:

Logging onto all vehicles

Granting temporary access to a currently unauthorized standard driver

The Maintenance/Installation User can perform the same functions as a Master User driver as well as

VAC configuration (For Maintenance Instructions, see Error! Reference source not found. on page

Error! Bookmark not defined.). The additional features include:

Assigning the Vehicle ID to the VAC

Enabling and disabling access control

Configuring the VAC sensors for motion sensing, lift sensing, and battery sensing

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

Verifying impact sensing

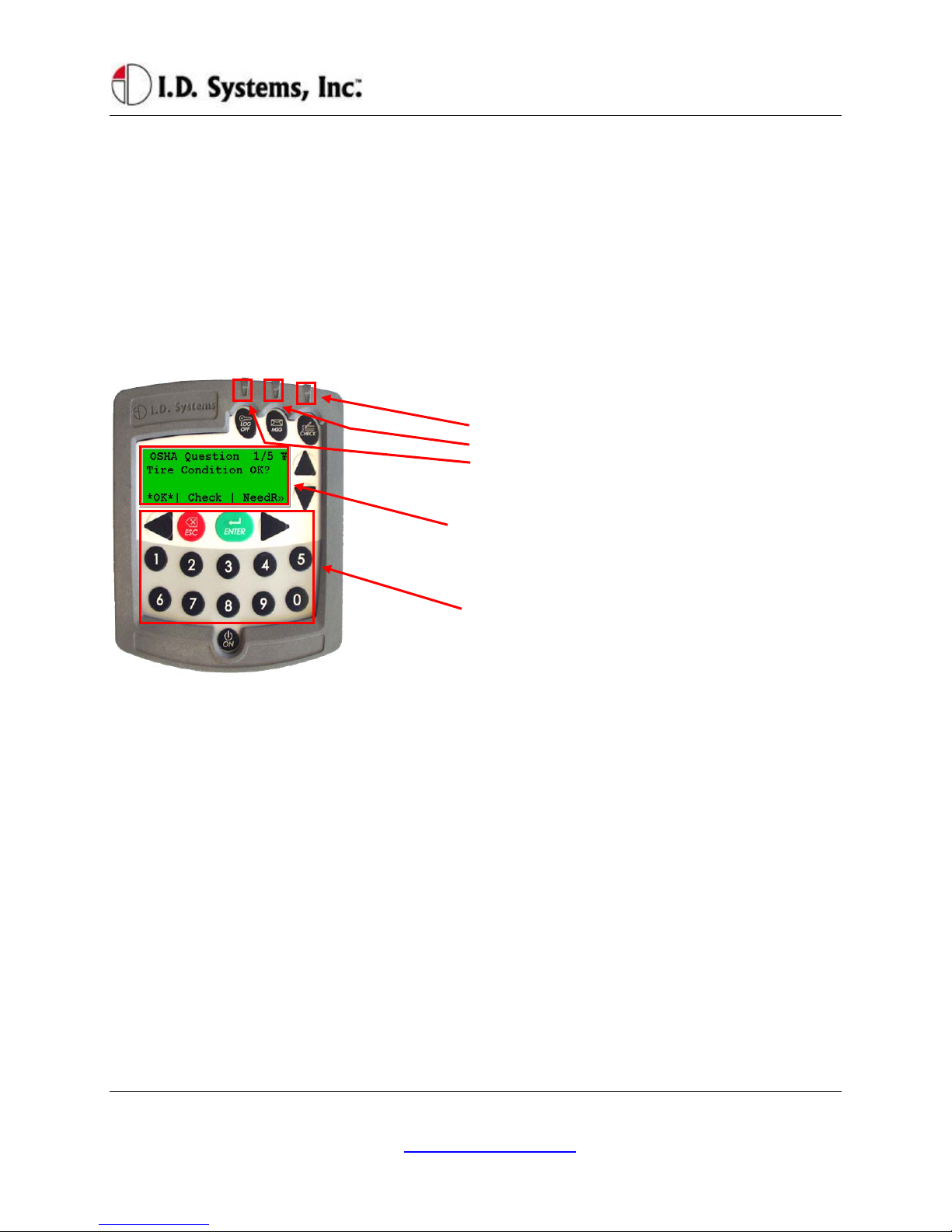

Basic Operation: LCD, Keypad, ID Reader and LEDs

The VAC incorporates a robust 20-key keypad and a 20-by-4 character display that is backlit for 15

seconds when a key is pressed. In addition, certain units are equipped with identification device readers

(proximity card, magnetic card, 1-wire memory chip such as an iButton, or smart card). The operator

interacts with the VAC using these devices in the following way:

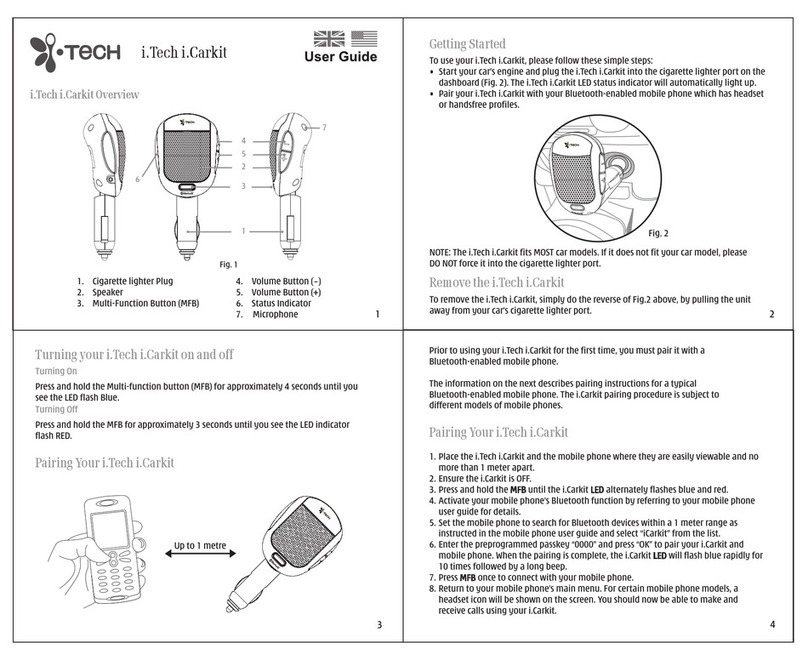

VAC Display and Keypad Basics

LEDs:

•OSHA not filled

•Incoming, unread page

•Access Enabled

LCD Display: (Backlit, 20-by-4 characters)

Screen Contents: To interact with the driver, the VAC uses

a backlit display. The same display is used in Menu

Selection Mode, Digit Entry Mode and Pager Mode.

Keypad: (20-Key, Rugged with Tactile Keys)

20-Key Keypad: The keypad allows the driver to make

menu selections (in Menu Selection Mode), type digits (in

Digit Entry Mode) and review and respond to pages (in

Pager Mode).

ID Reader

VACs may be equipped with ID Readers for the quick and secure entry of driver ID numbers. ID

readers are mounted in the VAC. The ID reader is used:

During the Access Control log-in process (to quickly enter the driver ID)

During the Access Control log-off process (to quickly log off the current driver)

During the Grant Temporary Access process (to enter the ID of the temporarily-authorized

driver)

Menu Selection Mode

Most screens on the VAC involve reading displayed text and selecting from menu options. These screens

contain four major components:

Screen Title: The top line of the display. Indicates the title or subject of the current screen.

¥ (Yen): This symbol is the in-range indicator for the VAC. The faster it blinks, the closer the

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

VAC is to a Gateway. When in range of a Gateway, a VAC will download any required data and

will attempt to upload data. The VAC will continue to function and record data, however, when

not in range of a Gateway.

Screen Data: The second and third lines contain screen data. If there are more than two lines of

screen data, the up and down arrows (keys 2 and 7) must be pressed to scroll through the data.

Menu Options: The bottom line of screen. Available menu options are listed, separated by ⎢

characters.

oAsterisked *selection* shows response that will be selected by pressing ENTER key

oChange *selection* by pressing right arrow or left arrow keys

o>> indicates more responses available by scrolling with right arrow key

o<< (not shown) indicates more responses available by scrolling with left arrow key

oAfter highlighting *selection*, press ENTER key to confirm selection and proceed

automatically to the next screen.

Keypad: (20-Key, Rugged

with Tactile Keys)

Up-arrow and down arrow

scroll through screen data.

Left-arrow and right arrow

scroll through menu options

ESC: Return to previous

screen

ENTER: Confirm the

currently highlighted

selection.

LCD Display: (Backlit, 20-by-4

characters)

Screen Title: First line indicates title or

subject of current screen

¥ –‘Yen:’ In-range indicator. The faster

this blinks, the better the receipt of data

from Gateways.

Screen Data: Second and third lines

contain screen data.

Menu Options: Appear along the bottom

line of screen, separated by ⎢characters

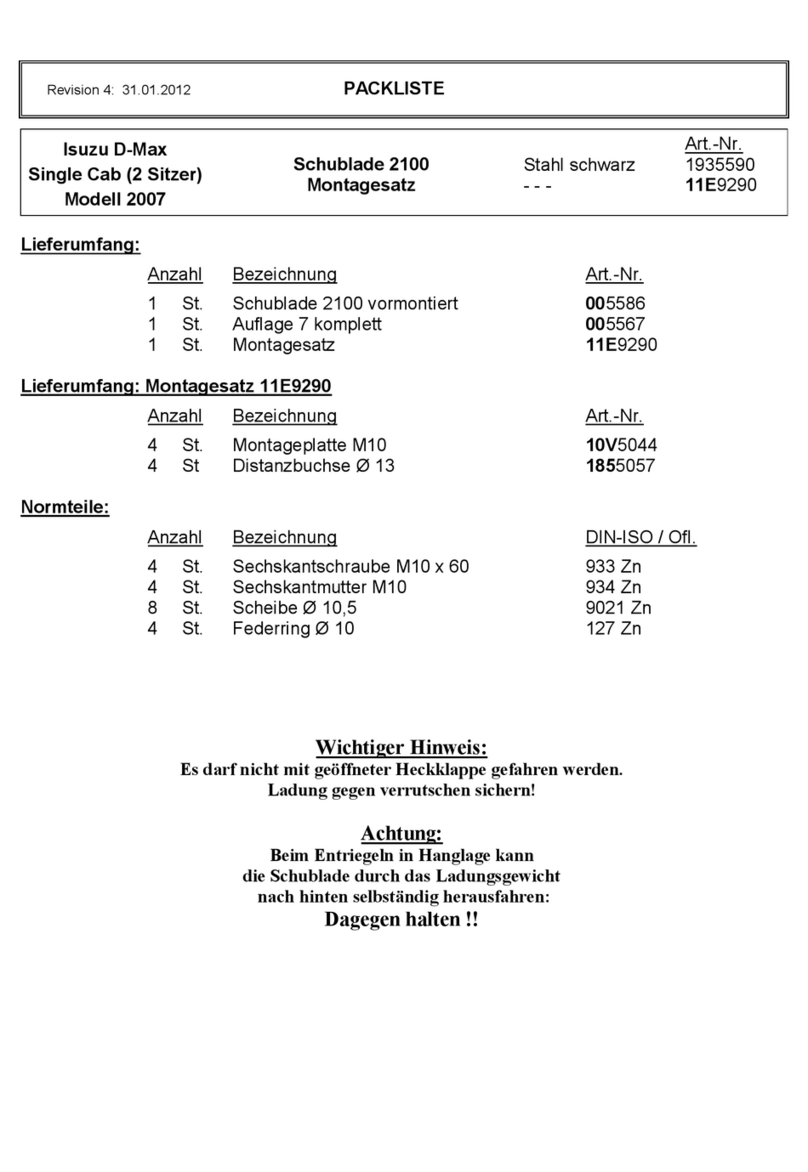

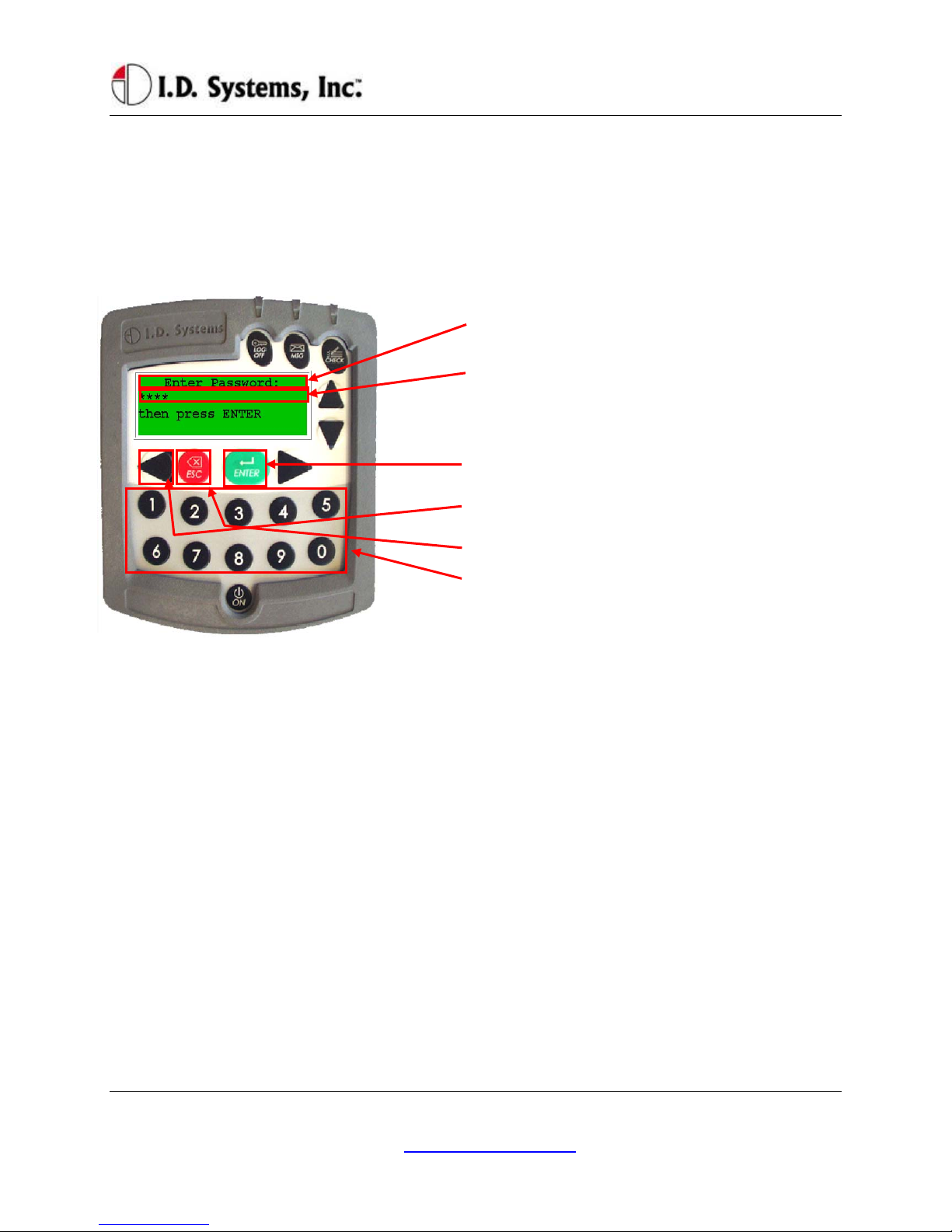

Digit Entry Mode

For VAC screens, which ask for a numerical entry, the digit entry mode screen will appear. These screens

contain two major components:

Screen Title: The top line of the display. Indicates the title or subject of the current screen.

Numerical Data: The second line contains the numerical data. A default value will appear of the

correct data length when entering this screen.

oA blinking cursor shows the current cursor location for data entry.

oEnter digits by typing desired number, 0-9 using the keypad

oBackspace using the Left Arrow key.

oPressing ESC key will return to the previous screen.

oPress ENTER key to confirm numerical entry. The entry will consist of each digit

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

displayed on the screen (typed as well as default digits, EXACTLY AS THEY APPEAR

ON THE SCREEN. For example, if ‘0000’ appears on the screen, and the user presses 2

then 1, the screen will read ‘2100’. In this case, 2100 will be submitted if the ENTER key

is pressed.).

oTherefore, to keep the default entry without making a change, simply press ENTER

without pressing any digits.

o

–LCD Display: (Backlit, 20-by-4 characters)

Screen Title: First line indicates title or subject of current

screen

Numerical Data: Second line contains numerical data

(Note: Password screen uses asterisks (*) to hide entered

data). Third line may contain helpful information.

Keypad: (20-Key, Rugged with Tactile Keys)

ENTER: Press this key to confirm the current entry

Left Arrow: Press this key to back up one space

ESC:Press this key to return to previous screen

0-9: Press these keys to enter a digit at the current cursor

location

Access Control (All Users): Logging on and off the Vehicle

Access Control Overview

One feature of the VAC is to prevent unauthorized access to the VAC, and, optionally, the vehicle. Each

VAC is assigned a vehicle number (often similar to the number marked on the side of the vehicle), and

that number has an associated authorization list that contains valid drivers and, for each driver, the times

of day and days of week for which they are allowed drive that particular vehicle. The VAC stores the

authorization list and is updated, if changes have been made, when in radio range of any Gateway.

In order for vehicle access control to prevent vehicle access, it is required that the vehicle comply with the

I.D. Systems Serial Data Interface protocol. For a compliant vehicle, unless the VAC is in ‘bypass mode,’

all Standard, Master User and Maintenance drivers must log into the VAC to gain access to the vehicle.

Once authorized, the driver may also be required to use a key to start or drive vehicle.

Whether or not access is controlled by the VAC, once logged onto (or ‘assigned to’) a VAC, the driver is

Installation

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

responsible for the vehicle. Therefore, it is imperative that drivers do not leave assigned vehicles

unattended. If, however, a driver forgets to log off, the VAC is configured to ‘time out’ after a

configurable period of non-use. (system-wide default: twenty minutes, changed via the ARDCS –

Beacon). While this idle-timeout feature is a fail-safe, it will not prevent another driver from taking an

assigned vehicle during the time prior to the time-out. In addition, the idle-timeout feature may be

disabled for the entire system (via ARDCS Beacon) or set on a vehicle a vehicle-by-vehicle basis (via

System Admin Tool – Modify Vehicle – Advanced Settings).

Drivers identify themselves to the VAC for access to a vehicle using their Access ID number. To enter

that number, the driver either uses the keypad or an ID device (such as a proximity card, smart card,

magnetic card, or iButton). The ID method is usually chosen to match that which the driver already uses

for other access control purposes (such as doorway entry). The Access ID number may not be the same

as the employee ID number, depending on the methodology used at the facility. The Access ID numbers

are linked to the drivers using the Console’s System Admin Tool.

Driver IDs are associated with VAC IDs using groups. Authorization groups are created using the

Console’s System Admin Tool. Both vehicles and drivers are added to groups. When a driver belongs to

the same group as a vehicle, and if that group is granted an authorization for the current time of day/day

of week, then the driver may gain access to the vehicle. All driver, group and authorization time

information is configured with the System Admin Tool and stored on each VAC. Initial configuration

and ongoing updates occur wirelessly and automatically, when VACs are in range of Gateways.

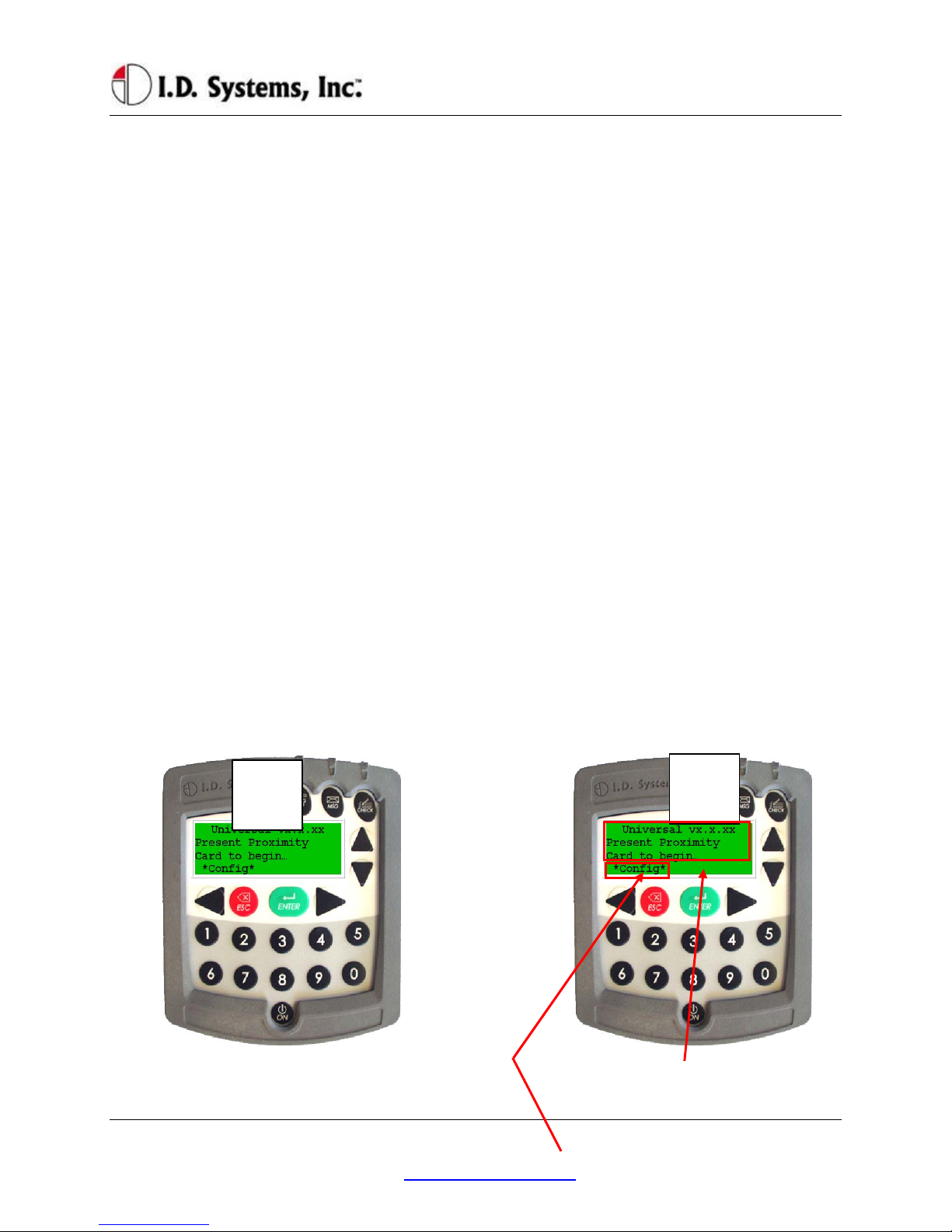

Logging onto the VAC

If VAC screen is blank (only on certain internal

combustion vehicles), turn vehicle ignition key on. Follow instructions on how to enter driver’s ID

(either by typing driver ID or presenting an ID

card – proximity, magnetic stripe, smart-card or

1 2

VACUser’sGuide

I.D. Systems, Inc. One University Plaza, Hackensack, NJ 07601 000-0144-01

iButton)

*Config*: (if applicable) Allows a Maintenance

User to log in without an ID card; for keypad-

only systems, this menu option does not appear.

A PIN code will then be requested (if the system is

configured to have PIN). Use the numeric keys to

enter PIN. After entering PIN (hidden by ****

characters for security), press ENTER key. If no PIN

is required, press ENTER when prompted with default

PIN of 0000.

If driver ID and PIN are authorized, vehicle

start-up will be enabled and driver can use

vehicle. VAC screen will prompt driver to

complete OSHA vehicle inspection checklist. If

driver is not authorized, see Denial of Login on

page 21.

3 4

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

FVC

FVC Sprinter Side Ladder installation guide

Easee

Easee Base 1-Way USER GUIDE / INSTALLATION GUIDE

Kargo Master

Kargo Master 4081M installation guide

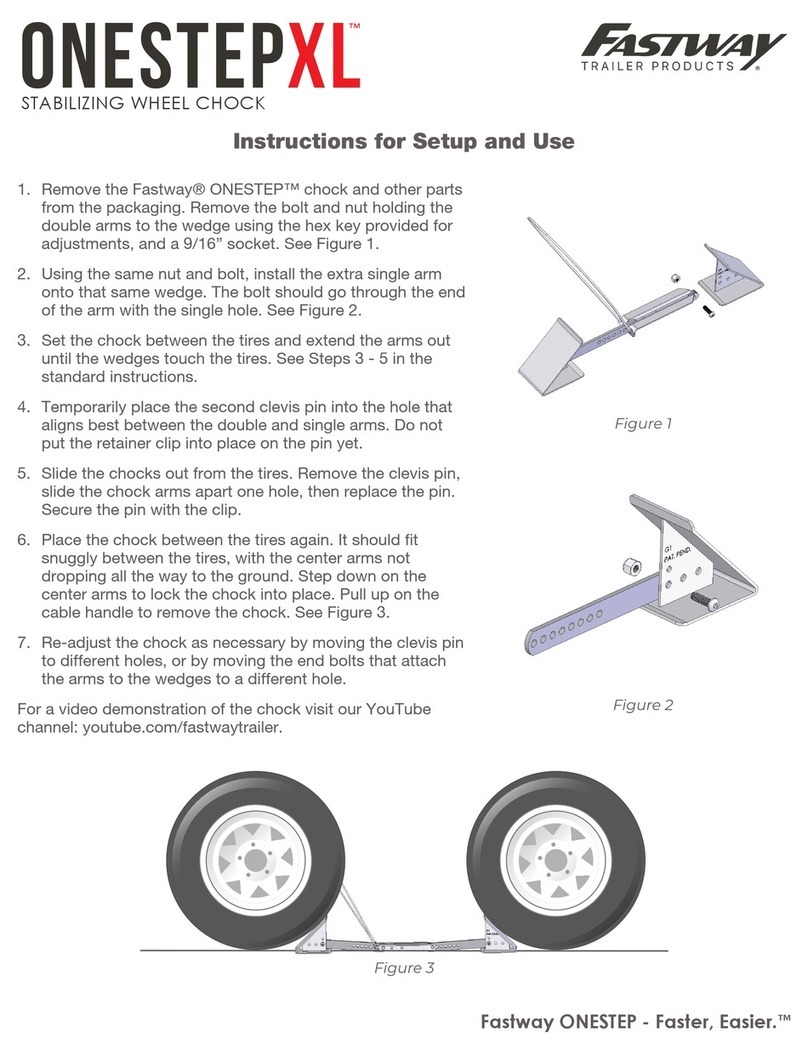

Fastway

Fastway ONESTEP XL Instructions for setup

Voxx Electronics

Voxx Electronics ACA800 Installation & owners guide

AKE

AKE PB-HC2 Additional instructions