I-G3N Z-RANGE 48V User manual

Z-RANGE 48V

INSTALLATION MANUAL

Version 1.2

Revision Date 20/09/2022

3

Z -RANGE INSTALLATION MANUAL

DO NOT INSTALL THE

BATTERY BEFORE

THOROUGHLY READING THE

USER MANUAL

4Z -RANGE INSTALLATION MANUAL

Contents of the Box

Inside each box is the 5.14 kWh battery (51.2 Vnom , 100 A capacity), negative and a positive DC

cable with amphenol connectors (battery side) and M8 lugs (inverter / DC busbar side). Each

box also contains a pin-to-pin CAT cable for communication to either the inverter or between

the battery units.

Handling the Battery

Work on the battery should be carried out by qualified personnel only.

Please use the provided handles to lift and move the battery. Please handle the battery with

care as the battery is sensitive to mechanical shock.

Ports used During Operation of the

Battery

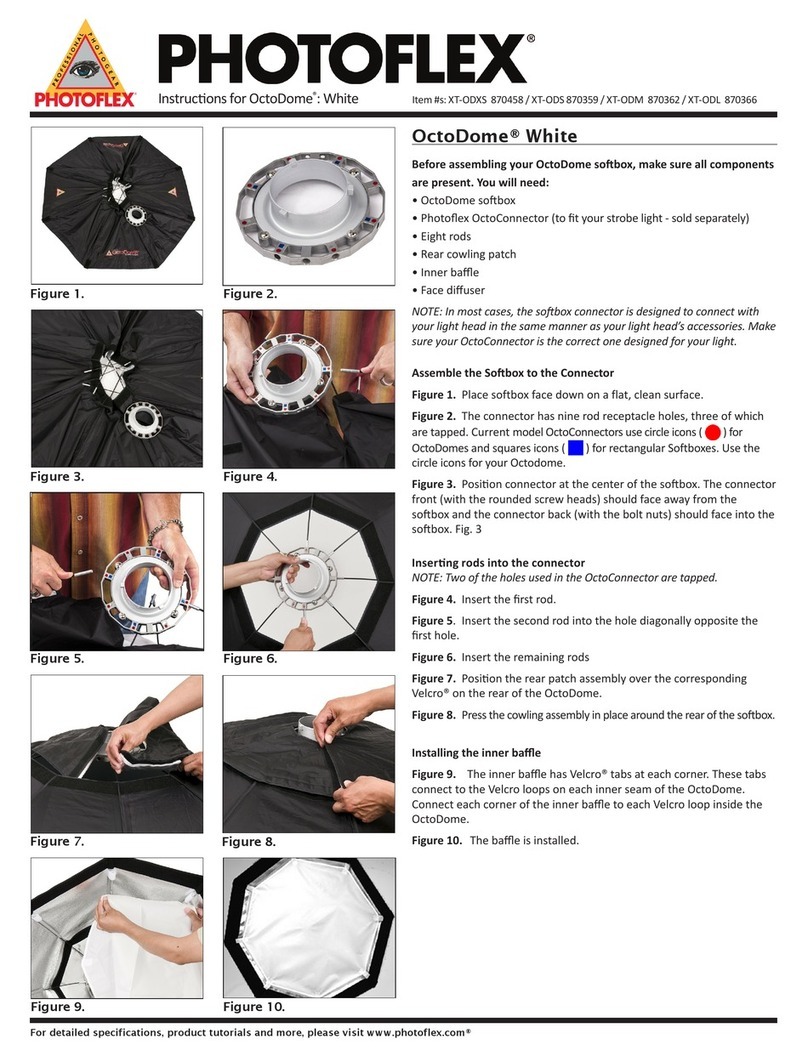

Figure 1 shows the ports that are used during the operation of the battery. Please pay close

attention to which ports are used and connected during operation. The Figure should be read

in conjunction with Table 1.

Table 1: Ports and switches used during operation of the Z-Range

No Instructions No Instructions

1 Negative DC post #1 9 Address dial switch

2 Negative DC post #2 10 RS232 port

On/ Off switch 11 Link B

4 SOC indicator 12 Link A

5 Alarm indicator 13 Reset button

6 Run indicator 14 CAN/RS485 port

7 Dry contact 15 Positive DC post #1

8 GND 16 Positive DC post #2

Figure 1: Z-Range Battery Module

5

Z -RANGE INSTALLATION MANUAL

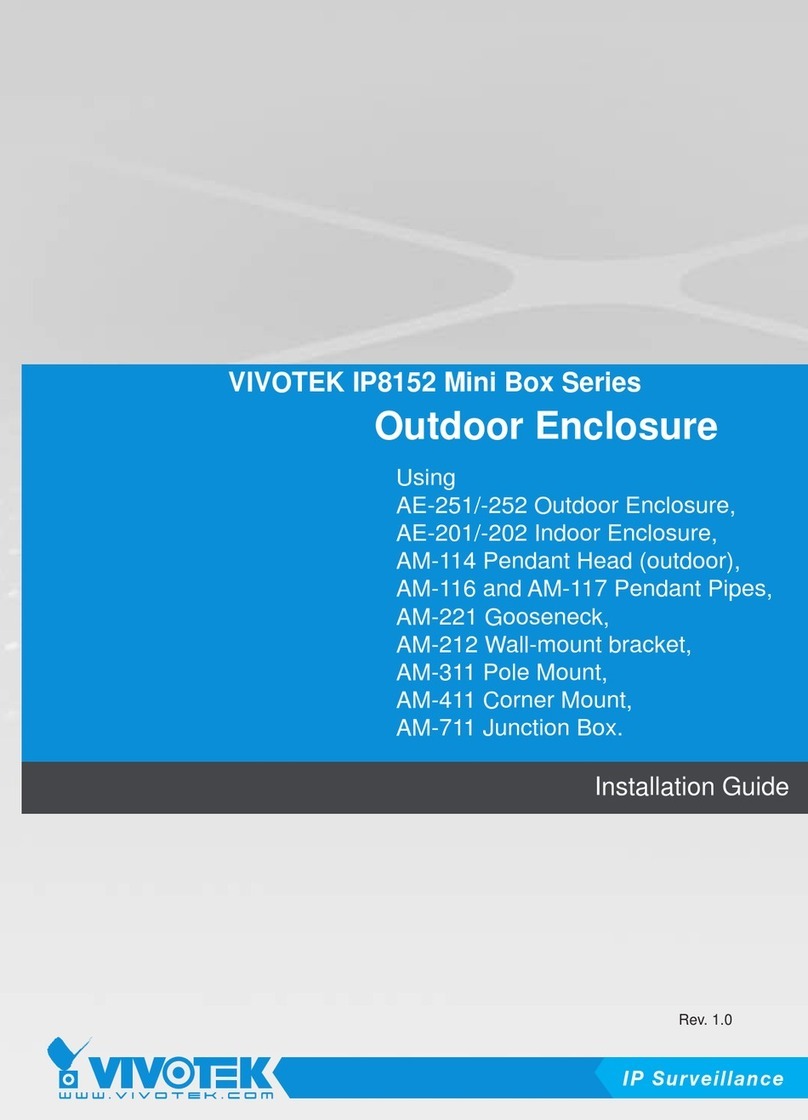

Stacking

The Z-Range battery can be stacked in 3 different configurations:

• Standing on its back

• Stacked with brackets

• Stacked in a cabinet (each battery is 3U in height)

Figure 3: Z-Range Battery Module dimentions

Figure 2: 4 Stacked Z-Range Battery Modules

A maximum of 4 units can be stacked when using the brackets. It is recommended to use

two or more stacks when more than 4 units are installed. Figure 2 illustrates the stacking

methodology of the Z-Range using the brackets.

The battery voltages need to be within +- 0.5 V to be integrated. The batteries are shipped at

100%, and tend to settle around 53.5 V during transport. If an additional battery is added to the

system, it is recommended that the existing units be charged to 100% and allowed to settle (be

without loads or charging) to integrate the new battery.

Figure 3 shows the Z-Range dimentions

6Z -RANGE INSTALLATION MANUAL

Wiring

Before connecting the DC cables, please ensure the polarity of the connections are correct.

Note that it is required to have a DC disconnect between the battery and the inverter.

DC Connections

The Amphenol connections on the battery can only sustain 100 A output. There are two

different ways to connect the battery in parallel.

It is recommended that the disconnect be 1.25 x Rated current.

Wiring methodology #1:

Connect all the batteries to a common busbar. Each battery can produce its maximum

recommended output current, with this methodology. This methodology allows each battery

unit to produce its maximum recommended output current. Connect the provided DC cables

to the top DC post of each unit, and the M8 lug to the common busbar. Figure 4 depicts the

connection methodology.

Figure 4a: Illustration of 1 x

Z-Range battery connected to an

inverter

Figure 4b: Illustration of 3 x

Z-Range batteries connected to

common busbar

7

Z -RANGE INSTALLATION MANUAL

Communication

The communication cables start from the master unit’s Link A port to Link B on the second

unit. This A -> B loop continues, in sequence, up to the last unit. No termination plug is

necessary on the final Z-Range unit. Figure 6 shows the connection of the communcation

cables between the batteries.

Figure 6: Communication connections between the battery

modules

Figure 5: Illustrating daisy chain DC connections from top

to bottom

Wiring methodology #2:

Daisy chain the DC connections, from bottom to top. This wiring methodology limits the

current output to the maximum recommended output of a single battery, but increases the

available capacity. Figure 5 illustrates how to connect the batteries with this method. For this

configuration we recommend that the provided cable from the master box be connected

to the top unit and the DC disconnect. The interconnecting cables can be made from the

other batteries’ DC cables by cutting the lug side cable, and crimping the provide amphenol

connecter. The recommended length of this interconnecting cable is 150 mm.

8Z -RANGE INSTALLATION MANUAL

The communication cables between the units must follow the address of the units. Address 1

needs to be connected to Address 2, and Address 2 is connected to Address 3, as mentioned in

Table 3.

The CAN connection between the GX device and the battery connects on the CAN port of the

master unit. The battery has a baud rate of 500 kbps.

Table 2 below shows the pin outs of the inverters that the Z-Range battery is compatible with.

These are the only cables that are necessary to connect.

Table 2: Inverter and Battery communication pin outs (CAN/RS485)

Connect to Victron Inverter Connect to SUNSYNK Inverter

Connect to Growatt SPF Inverter Connect to Sofar Inverter

Connect to Solis Inverter Connect to Goodwe Inverter

9

Z -RANGE INSTALLATION MANUAL

Master Configuration

The configuration of all the Z-Range units can be set to either be the master or a secondary

in a stack. The dip switches are used to change the address of the unit in the stack. Table 3

illustrates the arrangement of dip switches to configure each individual unit in a stack.

Table 3: Assignment of Addresses to Z-Range Battery

Address Dip Switch Position Unit Stack

1 2 3 4 5 6

1 1 0 0 0 0 0 Master unit / individual unit

2 0 1 0 0 0 0 First secondary

3 1 1 0 0 0 0 Second secondary

4 0 0 1 0 0 0 Third secondary

5 1 0 1 0 0 0 Fourth secondary

6 1 1 1 0 0 0 Fifth secondary

… … … … … … … …

63 1 1 1 1 1 1 Sixty third secondary

Note that the 1 indicates that the dip switch needs to be in the “up” position, while the 0

indicates a “down” dip switch.

Battery Parameters

The following are the recommended voltage parameters for the Z-Range battery. Note that

each battery has a capacity of 100 A.

Low voltage alarm - 50 V

Low voltage cut off - 46 V

Restart - 48 V

Low voltage alarm - 30%

Low voltage cut off - 20%

Restart - 30%

Absorption - 56 V

Float - 54 V

Equalization - 56.2 V

Recommended charge limit - 70A

Recommended discharge limit - 90A

10 Z -RANGE INSTALLATION MANUAL

Startup Procedure

Refer to Table 1 and Figure 1 for the port and switches layout. Double-check polarity of the DC

connections between the battery and inverter.

1. Ensure the fuses to the battery are completely open or removed. The communication cable

to the GX device/inverter must also be removed.

2. Before switching on the battery ensure the wiring of the battery is done correctly, according

to this manual

a. Communication cable

b. Electric cables

3. Start by switching on the Master unit (using switch 3).

a. The battery will go through a boot up procedure where the SoC, Alarm and Run

lights flicker on

b. The Run light will flicker on for 1 second and off for 3 seconds if the start up procedure is

done correctly and the SoC lights are on

4. The next unit can be switched on if the previous unit’s Run light flashes as mentioned in

step 3b

a. The next unit’s Run light must flash at the same tempo as the master unit before any

additional unit can be switched on

b. The lights will not flicker simultaneously, but at the same tempo

5. Repeat step 4 for all the additional units

6. Connect the communication from the GX device to the CAN port on the master unit once

all the units in the stack have been switched on and the Run lights flash correctly

7. Close the fuses

The battery bank might indicate an Alarm event when the fuses are closed. If the bank does

not recover on its own, it is recommended to first energize the DC busbar with the inverter

before start by switching on the Master unit.

The battery bank might indicate an Alarm event, when the fuses are closed. Especially when

the inverter:Battery ratio is lower than 1:1. If the battery does not recover on its own, it is

recommend to energize the DC busbar with the inverter or PV (if present) before closing the

fuses.

11

Z -RANGE INSTALLATION MANUAL

Restart Procedure

1. Switch system over to grid

2. Switch off entire system

a. Switch off PV inverter

b. Switch off Inverter/charger (Victron)

3. Switch off battery

a. Start at the top unit and switch the unit off

b. Switch off the secondary unit

c. Repeat

4. Isolate Battery (remove Fuses)

5. Restart battery (Start at the top unit and move down sequentially)

a. Switch the unit on

b. Wait until the “Run” light (green light) flashes

i. 1 sec on, 3 sec off

c. Switch the second unit on

6. Wait until both the units’ “run” light flashes at the same tempo

a. They don’t have to flash simultaneously, but just at the same tempo

7. Repeat step 5 and 6 until the final unit

8. Close the DC disconnect if the battery run light flashes at the same tempo

Table of contents

Other I-G3N Camera Accessories manuals