ibaBM-DPM-S Manual

Issue 2.11 3

Inhaltsverzeichnis

1About this manual.............................................................................................5

1.1 Target group......................................................................................................5

1.2 Notations...........................................................................................................5

1.3 Used symbols ...................................................................................................6

2Introduction.......................................................................................................7

3Scope of delivery ..............................................................................................9

4Safety instructions..........................................................................................10

5System requirements......................................................................................11

5.1 Hardware ........................................................................................................11

5.2 Software..........................................................................................................12

6DIN rail mounting/dismounting......................................................................13

6.1 Mounting .........................................................................................................13

6.2 Dismounting....................................................................................................13

7Device description..........................................................................................14

7.1 Communication interfaces ..............................................................................14

7.2 Views of device, control elements and connections........................................15

7.2.2 On / Off switch S11 ......................................................................................16

7.2.3 Operating status display (status LEDs) .....................................................16

7.2.4 24 V Power supply .....................................................................................17

7.2.5 Status LEDs on the communications interface ..........................................17

7.2.6 Rotary switches S1 and S2....................................................................17

7.2.7 Pushbutton S10 .........................................................................................18

7.2.8 CompactFlash® card slot X24 .....................................................................18

7.2.9 TCP/IP interface (bottom) ..........................................................................18

7.2.10 USB interface (bottom) ..............................................................................18

7.2.11 LEDs for PROFIBUS Bus0, Bus1 .........................................................19

7.2.12 PROFIBUS DP connectors X40 (Bus0) and X41 (Bus1) , .....................19

7.2.13 PROFIBUS switches S4, S5, S6 ,,.....................................................20

7.2.14 Shield connector ........................................................................................20

8System integration..........................................................................................21

8.1 ibaBM-DPM-S in the ibaPDA environment......................................................21

8.1.1 Connection to the DP-Master (unidirectional).................................................21

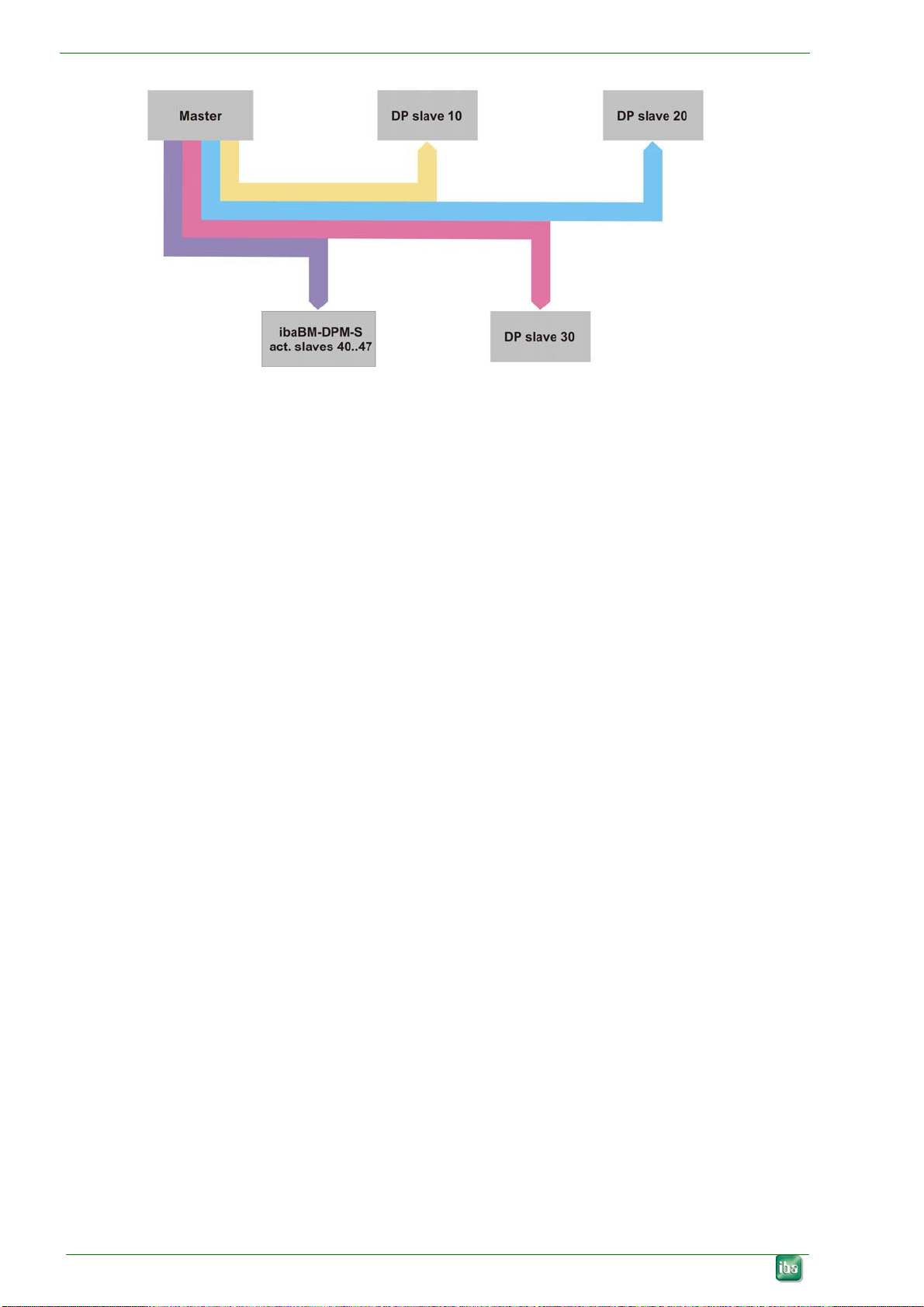

8.1.2 Connection to the DP master and other DP slaves (unidirectional)...............22

8.1.3 Connection to the DP master and other DP slaves on the redundant

PROFIBUS....................................................................................................................23

9Configuring and setting up the device..........................................................25

9.1 Basic principles...............................................................................................25