2

DIN 18381 Gas, water and drainage installations inside buildings

DIN EN 12828 Heating installations in the building. Design of DHW systems

EN 12897 Heat transfer to water - Specified for indirectly heated water heaters and pressure storage tanks

(closed).

EN 12975 Solar thermal installation and its components.

6. Installation

They shall be installed in a weatherproof enclosure having the necessary access dimensions to facilitate

inspection of the accumulator.

The installation in which the puffer tank is placed must provide for the installation of a safety system to limit

the pressure and ensure that the pressure does not exceed the upper design limit of the buffer tank. The

maximum working pressure value and pressure differentials must be taken into account when selecting a

suitable safety relief valve.

The safety relief valve (DIN4753 Part 1 section 6.3.2) shall be installed by a T-connection at the upper

connection V of the buffer storage tanks. It shall be connected directly to the storage tank, without any

interposed valve, which would allow it to be shut off. An air vent shall be fitted at the other end of the T

connection. The valve shall be accessible and mounted vertically.

If the heating capacity of the storage tank is higher than indicated forthe nominal volumes given in the table,

a suitably dimensioned safety relief valve must be used.

¡¡¡ The opening pressure of the safety relief valve must be at

most equal to the working pressure of the tank!!!

The warning according to DIN 4753 part 1 section 6.3.4.2 must be read on the safety relief valve:

¡¡¡ During the heating phase, for safety reasons, water may

escape from the exhaust duct!!!

¡¡¡ Keep the exhaust pipe open!!!

Safety valve evacuation pipeline: The evacuation of boiling water and steam must not endanger people.

The discharge lines of 2 or more safety valves must lead freely and separately to a drainage point.

The exhaust duct must be made with the same outletsection as the safety valve. It must not have more than

2 bends or be longer than 2 metres. If more than 2 bends or more than 2 metres in length are unavoidable,

the cross-section of the exhaust duct must be increased accordingly. More than 3 bends and a duct length

of more than 4 metres shall never be permissible.

The end of the drainpipe must be clearly visible, protruding 20 to 40 mm above the drain pan or drain trap.

The duct outlet must be within the ice protected area.

It is recommended to install a pressure reducer when the pressure in the network exceeds 4 bar.

Provide for the installation of a correctly dimensioned expansion vessel (EN12828). Ensure the correct

functioning of the selected safety devices (safety valve, reducer, expansion vessel, ....) avoiding their

interception by other elements.

Use a non-return valve or siphon at the cold water inlet with a length of 10 times the pipe diameter to avoid

heat loss due to reverse circulation.

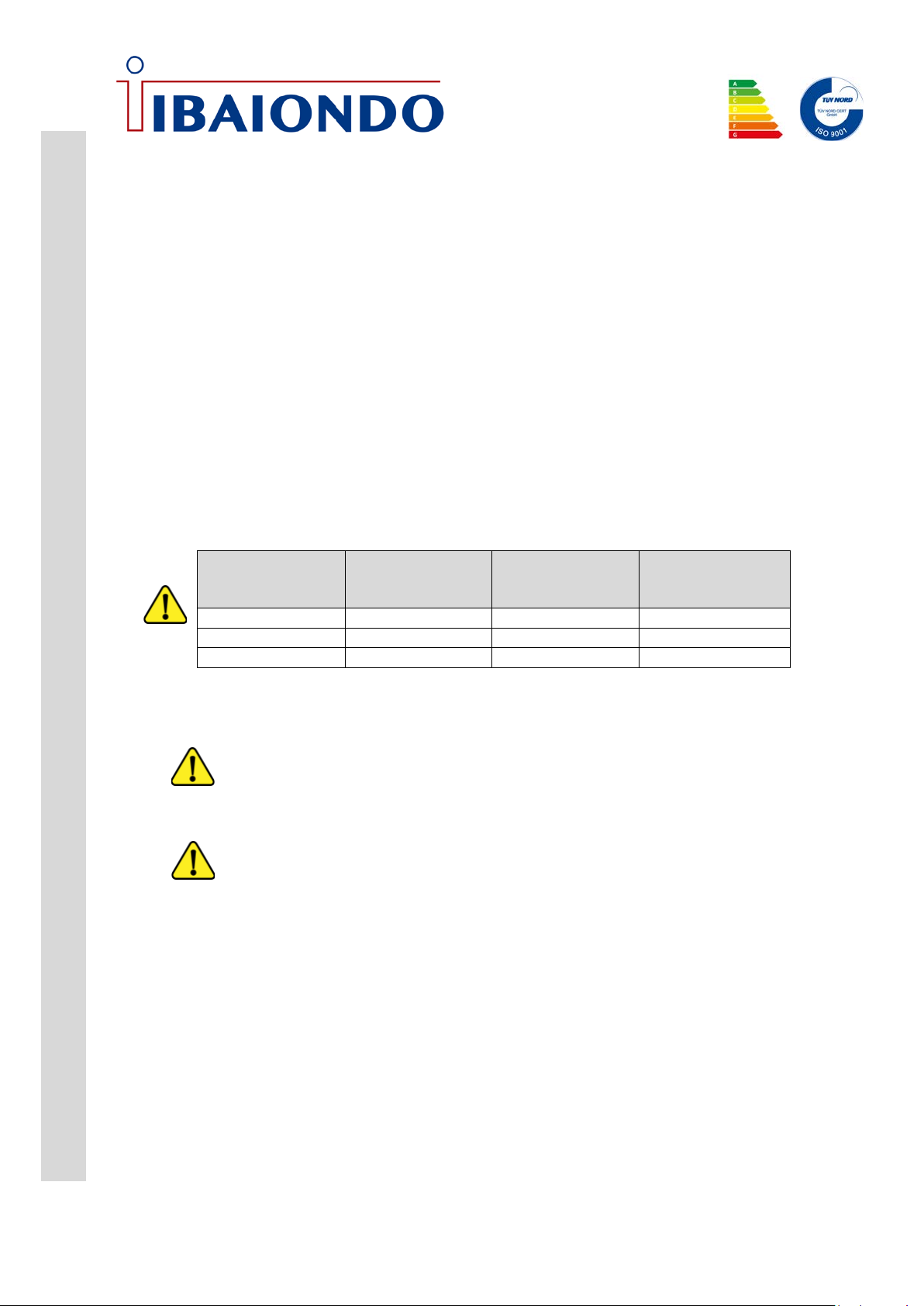

Sizing of the safety relief valve and the exhaust duct

Nominal capacity of

Maximum heating

Minimum safety

of the input-output