Precautions and preparations listed are for general knowledge and to define basic guidelines. Local codes and existing practices should be observed and preformed by a professional.

Due to ICE AIRs ongoing product development programs, the information in this document is subject to change without notice.

Installation

Installing the Unit

1. Ensure all preparations are met within

the “Pre-Requisite Section.”

2. Within the concealed ceiling, mark the

position of where threaded rods will

attach to. Refer to the submittal for

specific dimensions.

3 Embed four (4) threaded rods into the

indicated positions. Ensure the ceiling is

structurally intact to support weight of

the unit.

Refer to

table at right

for specific

weights.

4. Connect the

ICE AIR unit to

the threaded

rods through

the four (4) brackets on each corner.

Attach a Vibrational Isolator beneath the

bracket and a washer below that. Latch

these pieces in place with a hex nut.

Dual hex nuts are recommended as a

precautionary measure (see below).

5. Ensure the discharge vent is level,

elsewise adjust the threaded rods to

correct the unit. WARNING: Do not

loosen the nuts, this will increase the

chance of vibrational failure.

6. Attach all necessary pipes and wiring

connections. Additional ductwork should

only be installed if instructed.

7. (RECESSED) Fasten the Access Panel

to the bottom of the unit and tighten to

the unit. Ensure the open panel is not

fastened.

8. Run the unit.

Piping Installation

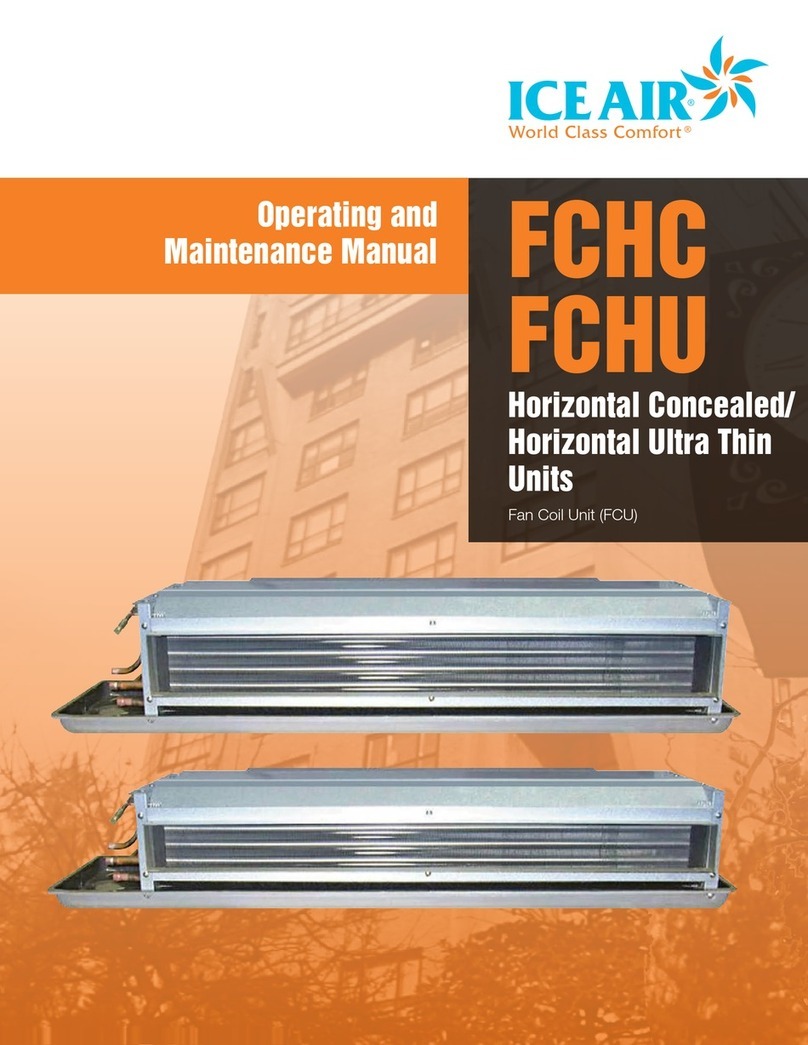

ICE AIRs Horizontal Concealed Fan Coil

is available in either 2 pipe or 4 pipe

configurations (see below) that are

connected to the system through the use

of a flexible hose or rigid pipe. The piping

system should be flushed to remove dirt,

pipe shavings, chips and other foreign

material prior to operation (refer to System

Cleaning and Flushing section). The flow rate

is generally set between 2 and 3 GPM per

ton of cooling for most applications of water

loop fan coils. To ensure proper maintenance

and servicing, P/T ports are imperative for

temperature and flow verification, as well as

performance checks.

Ducting Installation

If the system calls for ducting, attach the

duct to the duct collar on the supply vent. To

secure the duct, fasten to collar until there is

no exposed airflow (See below).

Filter Installation

Only configurations with a plenum on the

return vent for the Horizontal Concealed

Fan Coil are delivered with a filter. Filters

are placed on the bottom slot and pressed

forward into place.

Filter Replacement

The ICE AIR unit is delivered with a

Dispensable Filter. Dispensable Filters should

be replaced twice every year, before the start

of every heating or cooling season. Please

contact your local sales representative for

replacements.

2 Pipe

Configuration

4 Pipe Configuration

Bracket

Vibration

Isolator

Washer

Hex Nut

Threaded

Rod

Threaded

Rod Detail

DUCT

COLLAR

FCHC/FCHU Weight Table

Gross Net

Unit lbs. kg. lbs. kg.

02 30 13.5 25 11

03 31 14 26.5 12

04 40 18 37.5 17

06 45 20.5 41 18.5

08 53 24 46 21

10 60 27 50.5 23

12 64 29 54 24.5

FILTER SHOWN INSTALLED

9