5

Installation

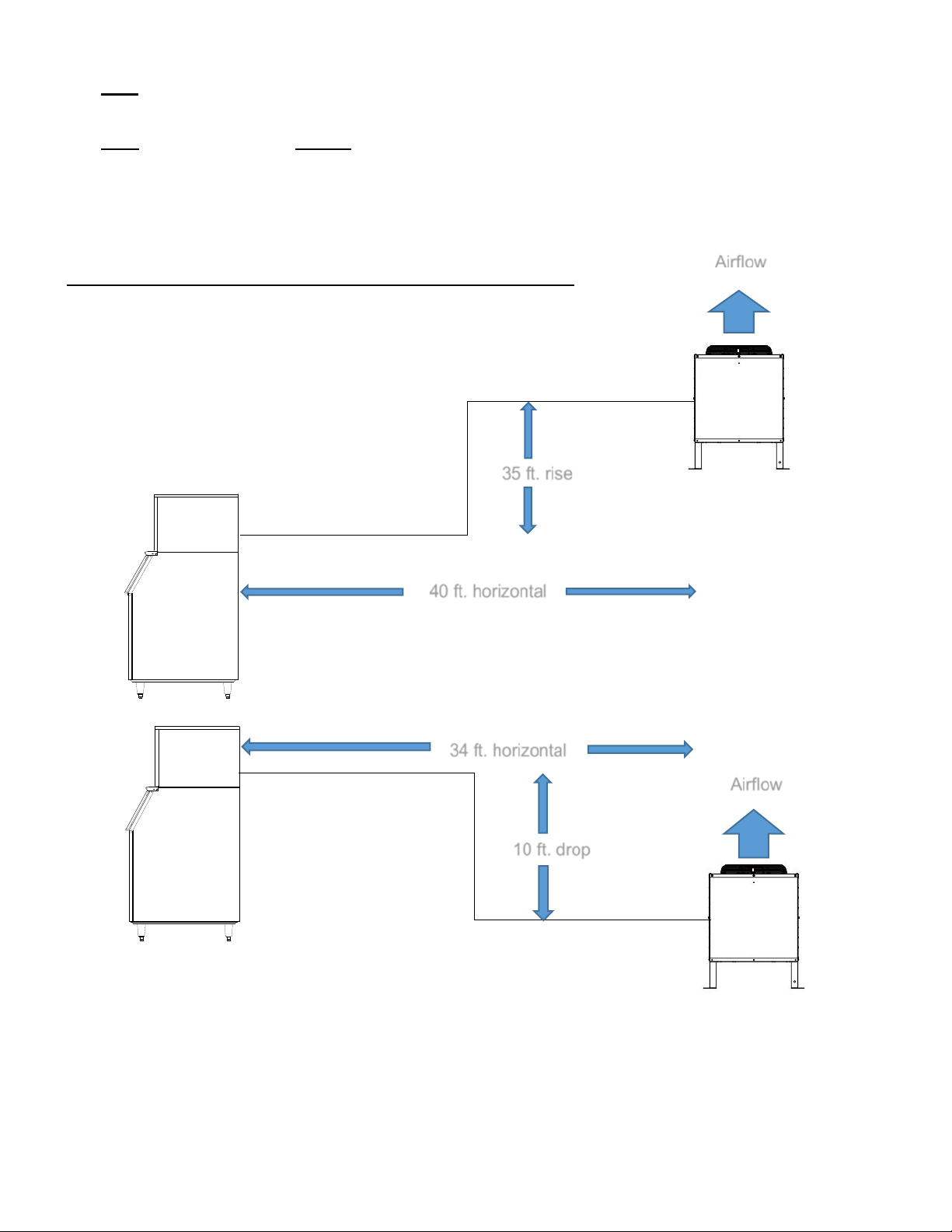

Ice-O-Matic® Remote Condenser Systems are comprised of three components. The pre-charged remote

condenser, the pre-charged ice maker and the pre-charged line set. The pre-charged line sets are available

in 25, 40, or 75 foot line set lengths.

Note: The 75 foot line set will require adding an additional 28 ounces of refrigerant.

Normal installation of the ice maker should be followed. Reference the installation instructions included with

the ice maker. In any installation, the pre-charged line sets, consisting of a liquid line (3/8” dia.) and a

discharge line (1/2” dia.) are used as a one-time initial charge type installation.

Once the sealed couplings are connected and the internal seal is broken, the lines cannot be disconnected

without losing the refrigerant charge. They are, however, reusable and when the couplers are removed and

reconnected, the complete refrigeration system must be evacuated and re-charged with the proper amount

of refrigerant. Reference the ice maker data plate or ice maker service manual for proper refrigerant

charge.

General Description

The remote condenser should not be used in areas where sufficient airflow is not available, in the area the

ice maker is being installed, or the heat being rejected by the condenser coil will be undesirable.

The condenser coil should not be exposed to temperatures below -20F (-29C) or above 120F (49C).The

remote condenser functions as a normal refrigeration system until the temperature at the condenser coil

drops below 70F. At this time the mixing valve will begin to bypass enough hot gas from the discharge line

directly into the receiver to keep the liquid line feeding the expansion valve at a steady pressure. The

amount of gas bypassed will depend on the temperature at the condenser coil (the colder the temperature

at the condenser coil, the more gas will bypass and the tubing between the mixing valve and receiver will

become warmer).

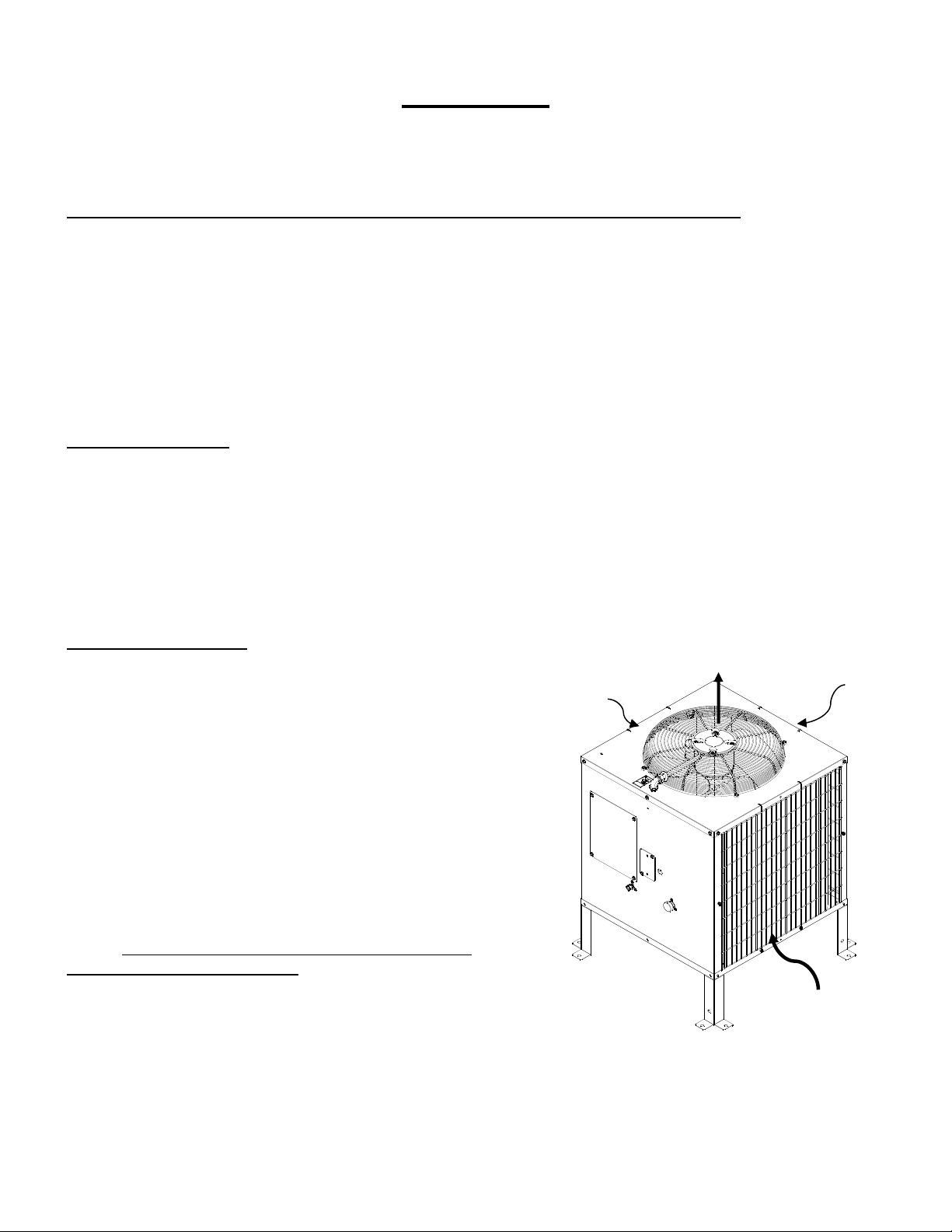

Condenser LocationWhen choosing a location for the remote condenser, reference the following

guidelines:

1. Choose a location that is protected from extremes of dirt,

dust, rain, sun and prevailing winds.

2. Vertical air discharge mounting of the condenser is

required with at least 48 inch clearance above the

condenser.

3. Condenser should be mounted higher than the ice

machine.

4. Condenser must be level.

5. Condenser should not be exposed to temperatures below

-20F or above 120F.

6. Installation must meet all local and national building,

plumbing and electrical codes.

7. The condenser must have a minimum clearance of

18 inches around all 4 sides.

8. Install condenser with the included legs or other elevated

mounting solution. There should be clearance between

the bottom of the condenser and the surface on which it is

mounted.

Airflow In

Airflow In

Airflow In

Airfl

w