I Installation Instructions Combination Units I

1. Safety Labeling and Signal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION are used

to identify levels of hazard seriousness. The signal word DAN-

GER is only used on product labels to signify an immediate haz-

ard. The signal words WARNING and CAUTION will be used on

product labels and throughout this manual and other manuals that

may apply to the product.

Signal Words

DANGER -immediate hazards which WILL result in severe per-

sonal injury or death.

WARNING - Hazards or unsafe practices which COULD result in

severe personal injury or death.

2. Safe Installation Requirements

CAUTION - Hazards or unsafe practices which COULD result in

minor personal injury or product or property damage.

Signal Words in Manuals

The signal word WARNING is used throughout this manual in the

following manner:

The signal word CAUTION is used throughout this manual in the

following manner: CAUTION

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the ANSI Z223.1-1990 National Fuel

Gas Code and the National Electrical Code

NFPA70-1990 or in Canada the National Standard CAN/

CGA B149.1 and CSA C.22.1 -Canadian Electrical

Code Part 1.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in furnace malfunction, property

damage, personal injury and/or death.

• Installation MUST conform to the most current version of

the following standards or a superseding standard.

In the USA:

•. ANSI Z223.1-1990 National Fue! Gas Code

• National Electrical Code NFPA70-1990

In Canada:

• National Standard CAN/CGA B149.1

• CSA C.22.1 - Canadian Electrical Code Part 1.

• Do NOT use this furnace as a construction heater.

• Use only the type of gas approved for this furnace (see rat-

ing plate).

• Do NOT use open flame to test for gas leak.

• Seal supply and return air ducts.

NOTE: It is the personal responsibility and obligation of the cus-

tomer to contact aqualified installer to ensure that the installation

is adequate and conforms to governing codes and ordinances.

CAUTION

It is recommended that a qualified service technician check

the heat exchanger integrity every two (2) years, after the first

four (4) years of operation.

Check Pre-existing Common Vent From Old

Furnace

If the installation of the combination unit involves removing an ex-

isting furnace from a common vent with other appliances, the

venting system will probably be too large for the remaining ap-

pliances and they will not vent properly. The venting system

MUST be checked according to the following procedure.

NOTE: The following steps shall be followed with each appliance

remaining connected tothe common venting system placed in op-

eration, while the other appliances remaining connected to the

common venting system are not in operation.

1. Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and hor-

izontal pitch to ensure there is no blockage or restriction,

leakage, corrosion or other deficiencies which could cause

an unsafe condition.

insofar as is practical, close all doors and windows and all

doors between the space in which the appliances remain-

ing connected to the common venting system are located

and other spaces of the building

Turn on clothes dryers and any appliance not connected to

the common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do NOT operate a summer

exhaust fan. Close fireplace dampers.

Follow the lighting instructions, Place the appliance being

inspected in operation. Adjust thermostat so appliance wil!

operate continuously.

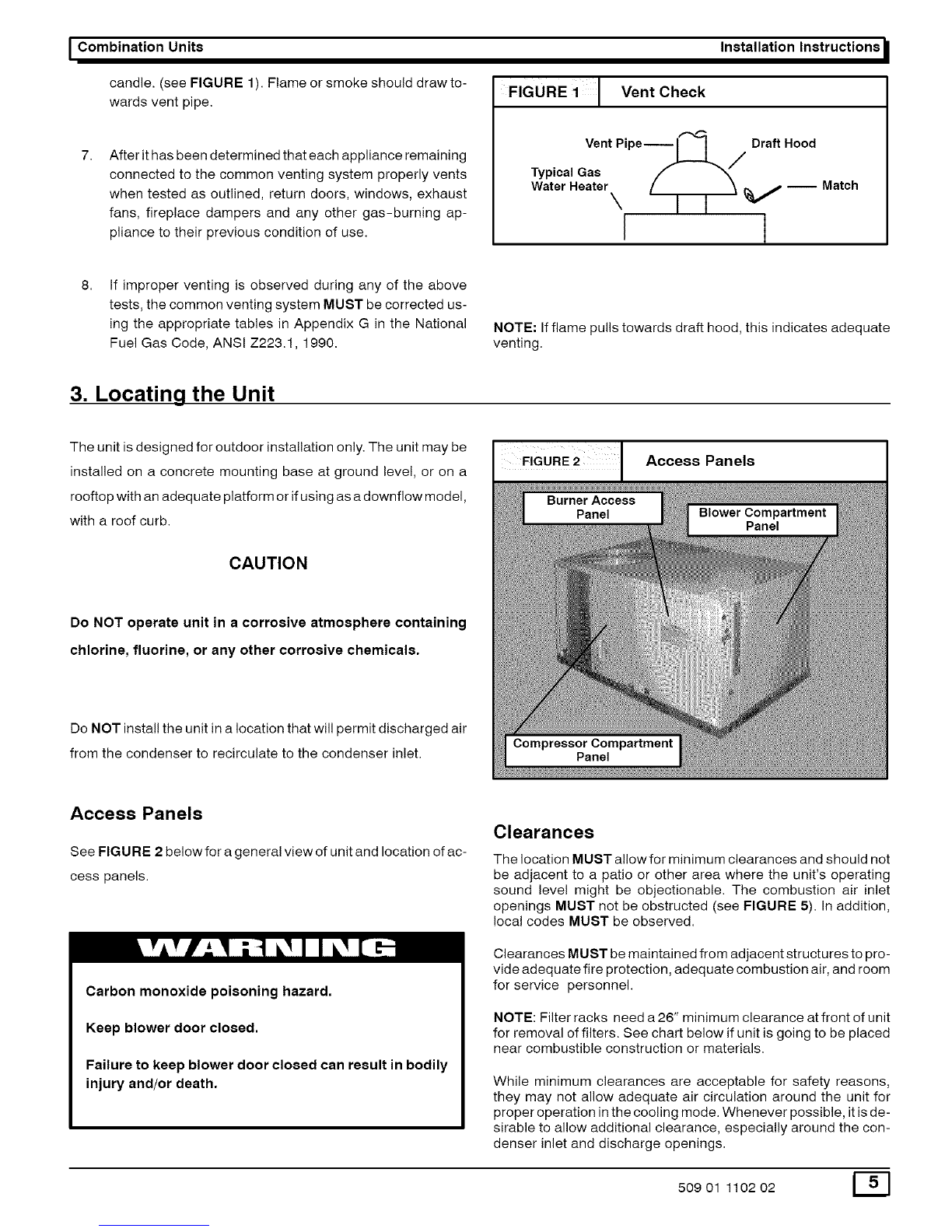

Test for spillage at the draft hood relief opening after 5 min-

utes of main burner operation. Use the flame of a match or

E_I 50901 110202