7

Mexico Super RS 3/40 - 3/80 - Installation

GENERAL

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

The boiler is to be installed only on a gas supply with a governed

meter.

A gas meter can only be connected by the local gas supplier or by

a local regional contractor.

Check that the appliance is suitable for the proposed gas supply.

An existing meter should be checked, preferably by the gas supplier,

to ensure that the meter is adequate to deal with the rate of gas

supply required. A minimum gas pressure of

20 mbar MUST be available at the boiler inlet, with the boiler

operating.

Installation pipes MUST be fitted in accordance with BS. 6891.

Pipework from the meter to the boiler MUST be of an adequate

size.

The complete installation MUST be tested for gas soundness and

purged as described in the above code.

FLUE INSTALLATION

Some pluming may occur at the termination so terminal

positions where this could cause a nuisance should be avoided.

The flue must be installed in accordance with the

recommendations of BS. 5440:1.

The following notes are intended for general guidance:-

1. The boiler MUST be installed so that the terminal is exposed

to external air.

2. It is important that the position of the terminal allows the free

passage of air across it at all times.

3. Minimum acceptable spacing from the terminal to

obstructions and ventilation openings are specified in

Table 3.

4. Where the lowest part of the terminal is fitted less than 2m

Table 3 - Balanced flue terminal position

Terminal Position Minimum Spacing

1. Directly below an opening window,

air vent or other ventilation opening 300 mm (12")

2. Below guttering, drain pipes or soil

pipes 300 mm (12")

3. Below eaves 300 mm (12")

4. Below balconies or a car port roof 600 mm (24")

5. From vertical drain pipes or soil pipes 75 mm ( 3")

6. From internal or external corners 600 mm (24")

7. Above adjacent ground, roof or

balcony level 300 mm (12")

8. From a surface facing the terminal 600 mm (24")

9. From a terminal facing a terminal 600 mm (24")

10. From an opening in a car port

(e.g. door or window) into dwelling 1200 mm (48")

11. Vertically from a terminal on the

same wall 1500 mm (60")

12. Horizontally from a terminal on the wall 300 mm (12")

(6' 6") above a balcony, above ground or above a flat roof

to which people have access then the terminal MUST be

protected by a purpose designed guard.

Terminals guards are available from boiler suppliers. In case

of difficulty seek advice from:

Tower Flue Components Ltd.,

Vale Rise, Tonbridge, Kent TN9 1TB

Telephone No. 01732 351 555

Ensure that the guard is fitted centrally

5. Where the terminal is fitted within 1000mm (39 1/2") of a plastic

or painted gutter or 500mm (19 1/2") of painted eaves then

an aluminium shield at least 1000mm (39 1/2") long should

be fitted to the underside of the gutter or painted surface.

6. The air inlet/products outlet duct and the terminal of the boiler

MUST NOT be closer than 25mm (1") to combustible material.

Detailed recommendations on the protection of combustible

material are given in BS.5440: 1990.

IMPORTANT.

It is absolutely ESSENTIAL to ensure, in practice, that products

of combustion discharging from the terminal cannot re-enter the

building or any other adjacent building through ventilators,

windows, doors, other sources of natural air infiltration or forced

ventilation/air conditioning. If this should occur, the appliance

MUST be turned OFF, labelled 'unsafe' and corrective action

taken.

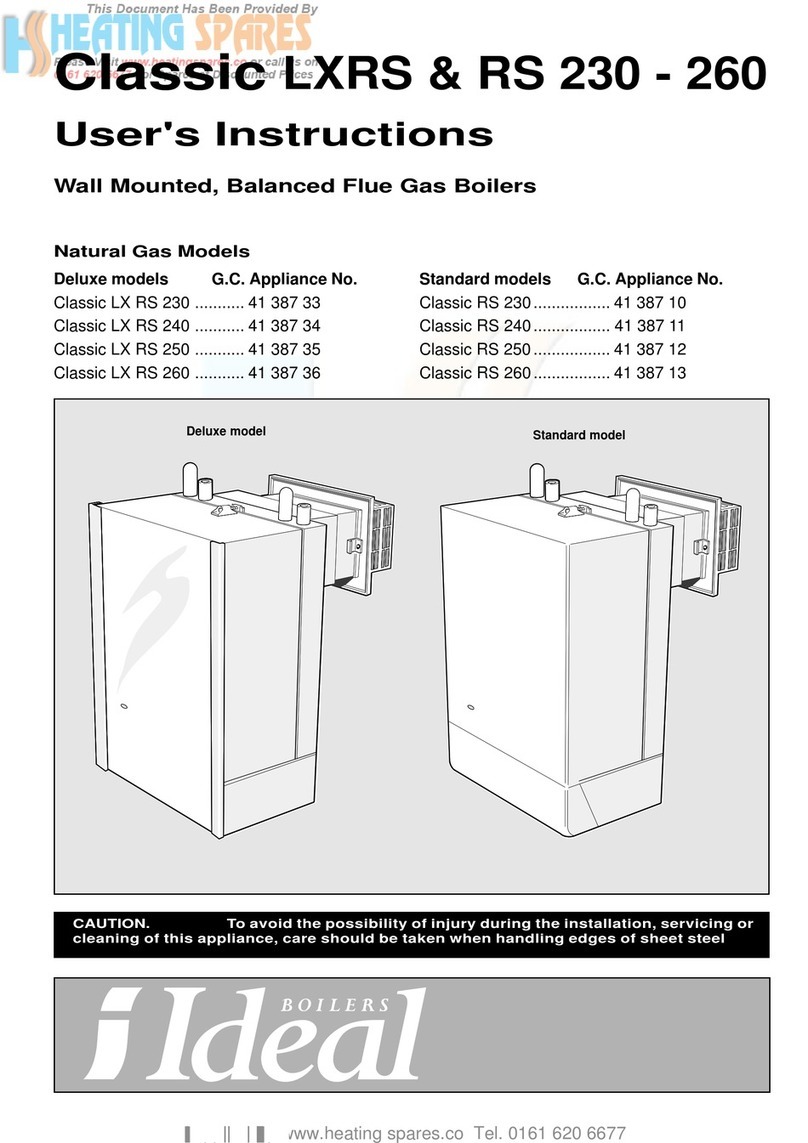

TERMINAL

The terminal assembly can be adapted to accommodate various

wall thicknesses. Refer to Frames 9 and 10.

AIR SUPPLY

Detailed recommendations for air supply are given in BS.5440:2.

The following notes are for general guidance:

1. It is NOT necessary to have a purpose provided air vent in

the room or internal space in which the boiler is installed.

2. If the boiler is to be installed in a cupboard or compartment,

permanent air vents are required (for cooling purposes) in

the cupboard/compartment, at both high and low levels. The

air vents must either communicate with room/internal space,

or be direct to outside air. The minimum effective areas of the

permanent air vents, required in the cupboard/compartment,

are specified as follows and are related to maximum rated

heat input.

3. Both air vents MUST communicate with the same room or

internal space or MUST be on the same wall to outside air.

4. In siting the air vents care must be taken to avoid the freezing

of pipework.

Table 4 - High and low vent areas

Boiler Air from room/internal Air direct from

space cm2(in.2) outside cm2(in.2)

High level Low level High level Low level

RS 3/40 143 (23) 143 (23) 72 (12) 72 (12)

RS 3/50 173 (27) 173 (27) 87 (14) 87 (14)

RS 3/60 208 (33) 208 (33) 104 (17) 104 (17)

RS 3/70 245 (38) 245 (38) 123 (19) 123 (19)

RS 3/80 282 (44) 282 (44) 141 (22) 141 (22)