2022

©

Ideal

V

acuum

Products,

LLC

|

(505)

872-0037

| [email protected] | www.idealvac.comHESP-02072023 - V 1.01 4

This manual provides general information and set up information about each of Ideal Vacuum’s spray

gun probe models. It also outlines spraying techniques for achieving optimal leak detection results.

Last, step-by-step detailed instructions are presented for safely relling the small helium gas cylinder in

our premium helium spray gun probe kit (P1012177).

OVERVIEW

P104871 - Basic Helium Spray Probe Gun Kit:

The included 10 ft. supply hose has a push-to-connect tting on the gun end and a male 1/4” NPT tting

on the other end for connection to a regulated helium supply tank hose. This kit also includes a 4” rigid

stainless steel probe tip and an 8” long exible probe tip. The helium inlet pressure to the gun must not

exceed 10 psig. Helium ow is adjusted on the tank or cylinder’s regulator.

P105182 - Regulated Helium Spray Probe Gun Kit:

This model has a regulator attached to the gun which can be adjusted to supply a light ow of helium

(1-5 psig). The included 10 ft. supply hose has a push-to-connect tting on the gun end and a male 1/4”

NPT tting on the other end for connection to a regulated helium supply tank hose. This kit also includes

a 4” rigid stainless steel probe tip and an 8” long exible probe tip. Helium ow is adjusted on the supply

tank’s regulator and must be less than 250 psig into the gun’s low ow adjustable regulator.

P1011211 - Precise Flow Valve Regulated Helium Spray Probe Gun Kit:

This model includes a Swagelok® S series low ow precise ow metering valve with Swagelok 1/4”

tube compression ttings. The valve’s vernier handle help’s ensure repeatable ow adjustments and

provides accurate readings to 1/25 turn. Factory ow settings are set at 4 to 10 std cm3/min with 15

psig (1.0 bar) inlet pressure. Maximum ow coefcient (Cv) is 0.004 at 10 full turns open. The included

10 ft. supply hose has a Swagelok 1/4” tube compression tting for the gun’s regulator end and a male

1/4” NPT tting on the other end for connection to a regulated helium supply tank hose. This kit also

includes a 4” rigid stainless steel probe tip, and an 8” long exible probe tip. Helium ow is adjusted on

the supply tank’s regulator and must be less than 250 psig into the gun’s precise ow regulator.

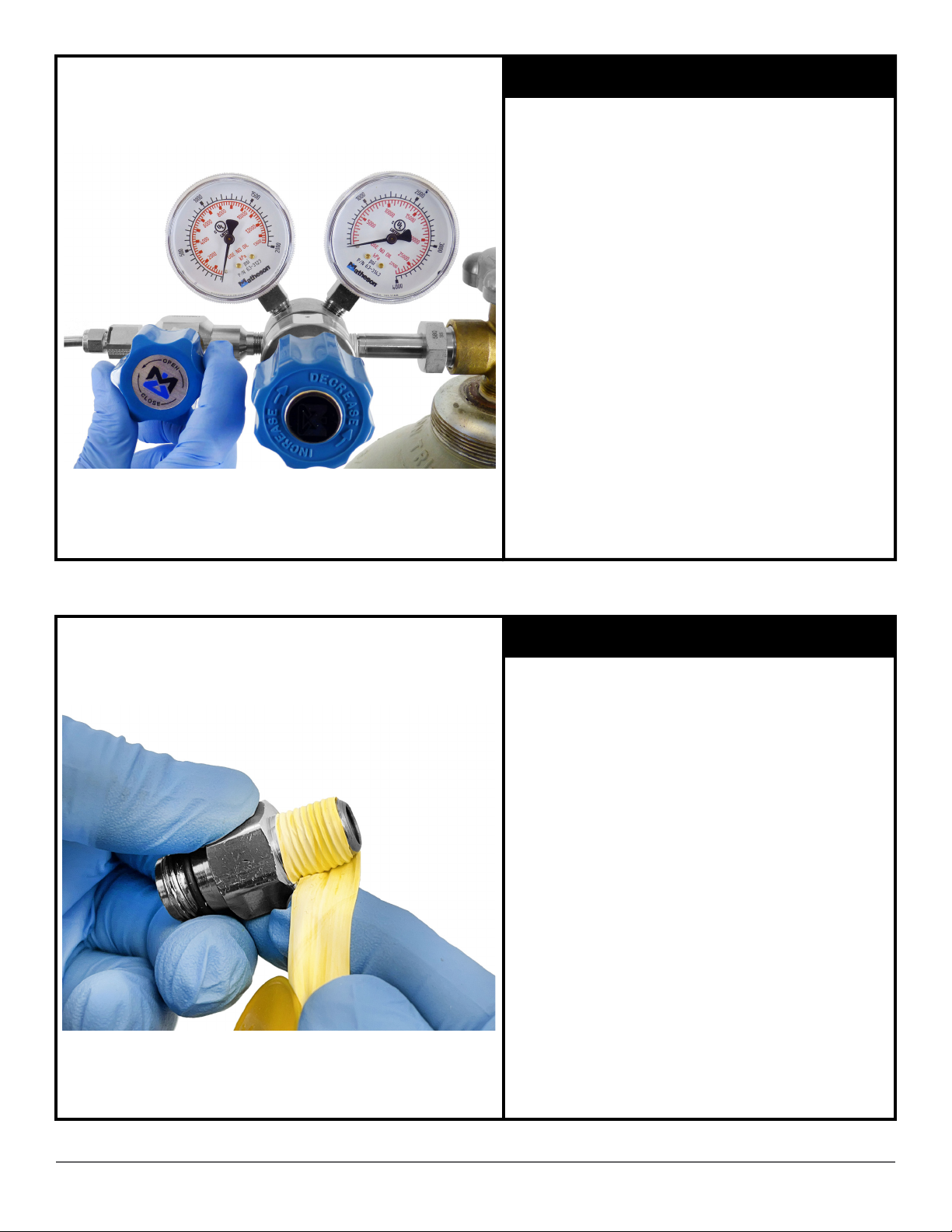

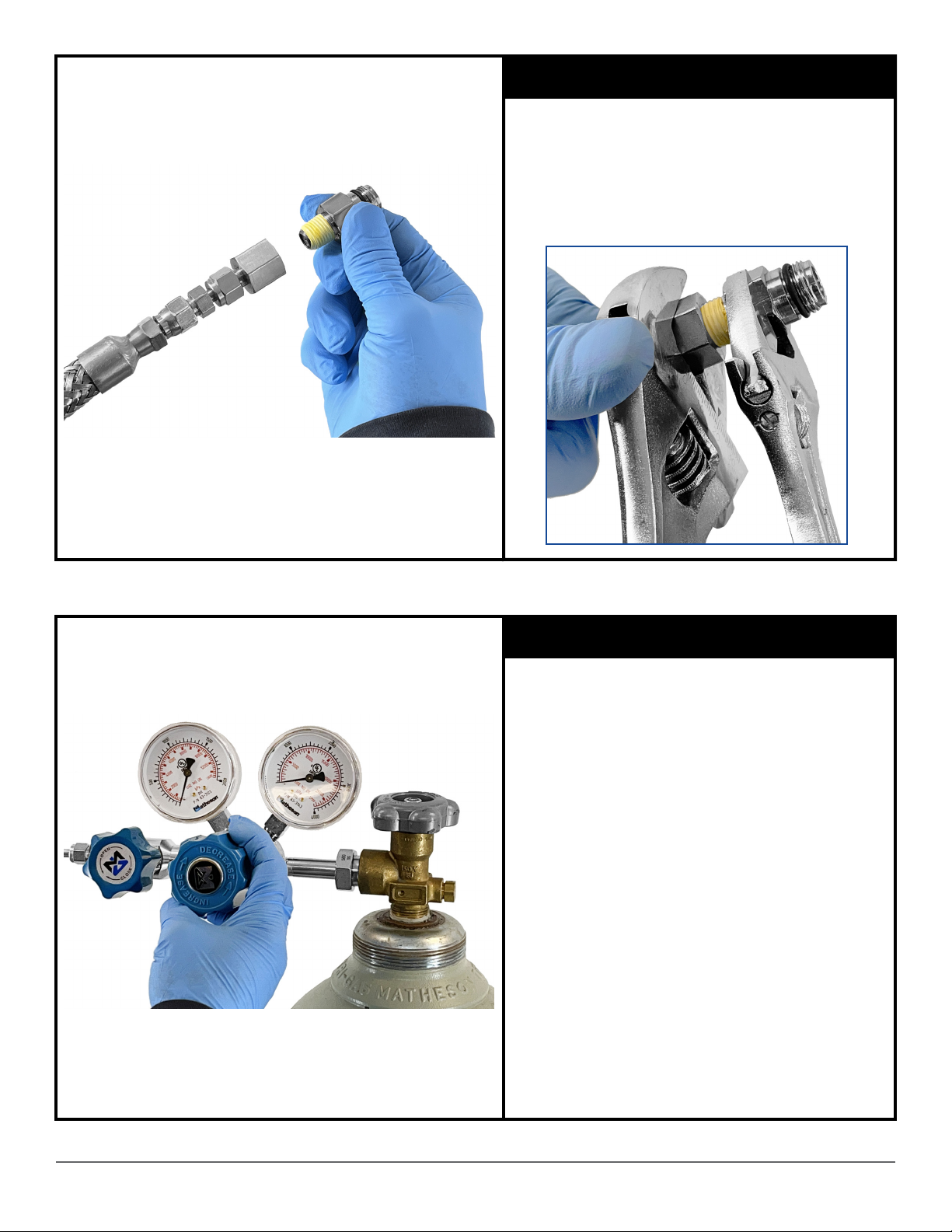

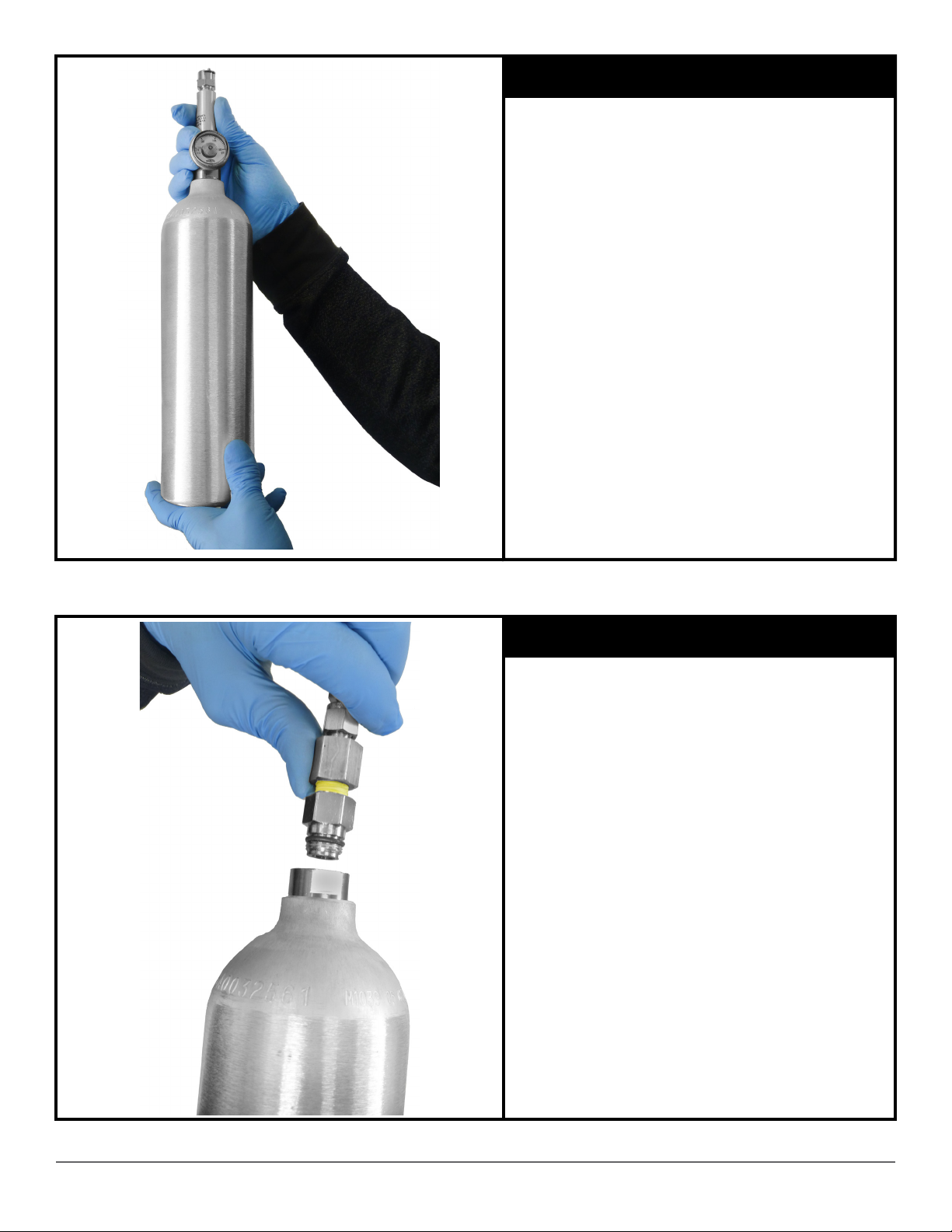

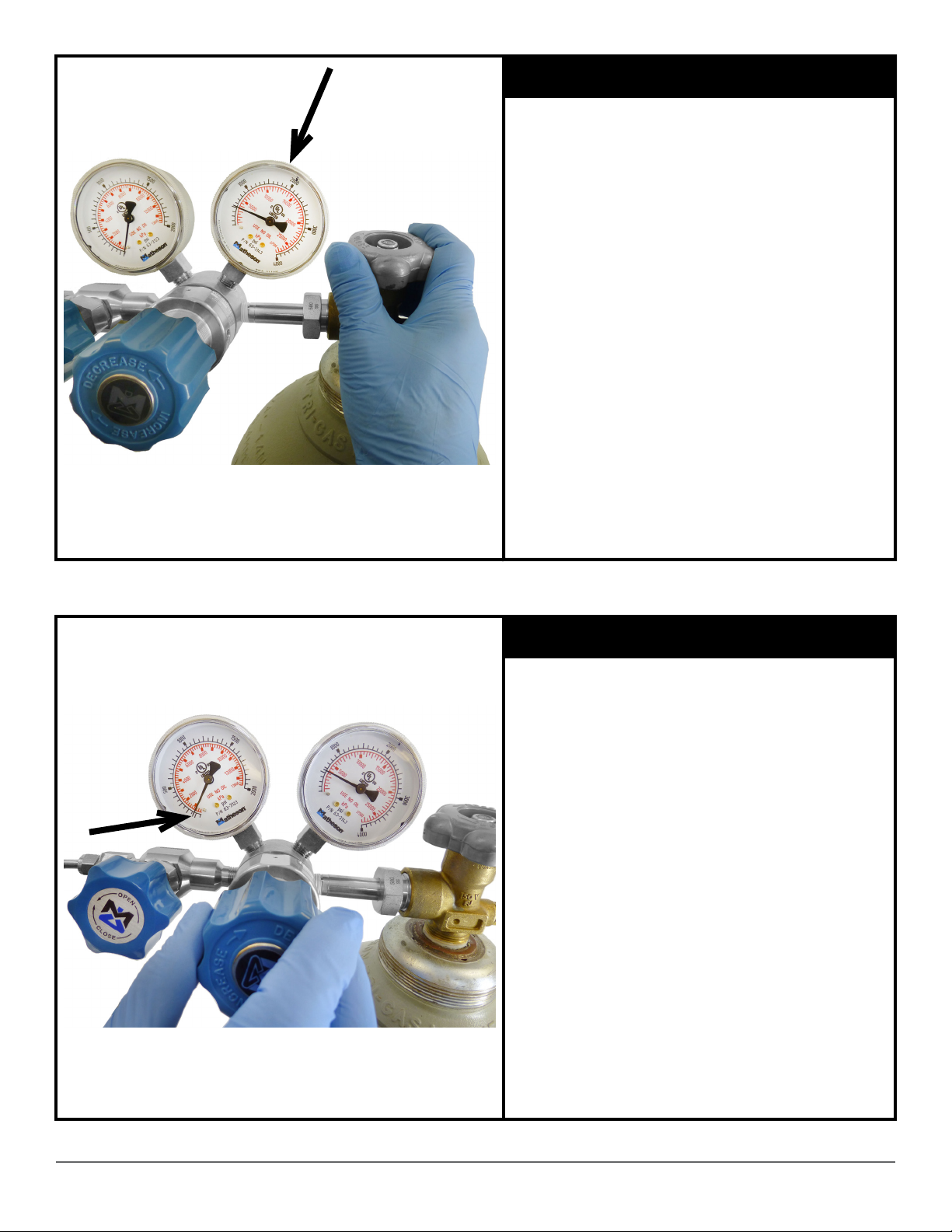

P1012177 - Premium Helium Spray Gun Probe Kit with 1 Liter Cylinder:

This model includes a rellable high pressure aluminum cylinder with a precise, detacheable regulator.

Helium ow rate can be adjusted between 0 and 0.1 Standard Liters Per Minute (SLPM). The cylinder

is 3” diameter x 11” tall, has a 1000cc volume, and a burst pressure rating of 1800 psi. We recommend

it be lled normally to about 500 psig. This kit includes a rell adapter for relling the cylinder from a

larger supply tank (see relling instructions , p. 6). The 10 ft exible supply hose has C10 quick connect

ttings on either end to connect the cylinder’s regulator to the spray gun. Also included is a 1/4 turn

shutoff valve mounted on the gun, a 4” rigid stainless steel probe tip, and an 8” long exible probe tip.

Please contact us for additional cylinders.

SPRAY PROBE MODEL INFORMATION

Do not exceed the rated pressure of tank, cylinder,

regulator or supply hose.