iDRY Standard User manual

Introduction 4.........................................................

Safety 5....................................................................

Specifications 5.......................................................

Technical Drawings 6.............................................

iDry Standard 6.......................................................................

iDry PLUS 7..............................................................................

Installation & Startup: 8.........................................

Placement 8..............................................................................

Track & Trolley Installation 9.................................................

Power 12...................................................................................

Plumbing 13..............................................................................

Loading 14................................................................................

Closing Door 16........................................................................

Powering Up 17........................................................................

Kiln Monitoring 19.................................................

Daily Monitoring 19.................................................................

Unloading Kiln 19...................................................

Opening Door 19..................................................................................................................

Checking Oven Weighted Samples 19.................................................................................

CORRECT USE 20..................................................

Lumber preparation 20.......................................................................................................

Baffling 20...........................................................................................................................

Proper Stacking 20..............................................................................................................

Reducing Degrade 20..........................................................................................................

Winter vs Summer 20..........................................................................................................

Initial Moisture Content 21.................................................................................................

iDRY User Manual

© 2020 iDRY, LLC

2

Mixing Species 21................................................................................................................

Mixing Thickness 21............................................................................................................

Frozen Lumber 21................................................................................................................

Drying Interruptions 21.......................................................................................................

MAINTENANCE & BASIC PROCEDURES 22......

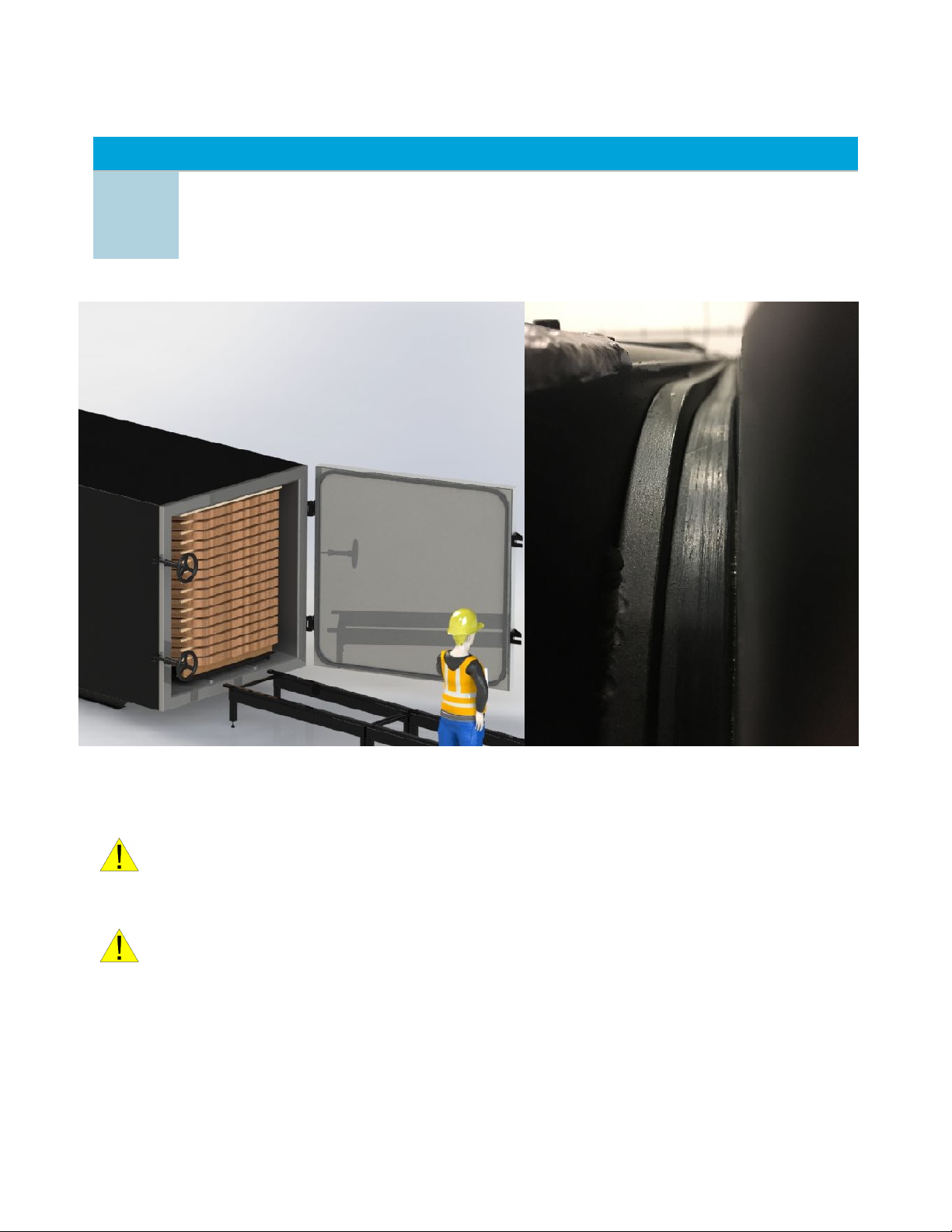

Door Seal 22.............................................................................

Handwheels 23........................................................................

Chamber Interior 23................................................................

Drain 23...................................................................................

Vacuum Pump 26.....................................................................

HMI 27......................................................................................

More Information 30...............................................................

Troubleshooting 31.................................................

Troubleshooting and Alarms 31..........................................................................................

Warning labels 34...................................................

Terms and Conditions 35.......................................

iDRY User Manual

© 2020 iDRY, LLC

3

Introduction

Congratulations on your purchase of an IDRY Systems iDRY lumber dryer. This equipment

is a product of IDRY, LLC’s quality engineering and manufacturing. With a high quality

rugged stainless steel pressure vessel and state of the art electronics this iDRY dryer will,

with proper maintenance provide long term satisfactory service. To obtain the best use of

your iDRY dryer, please read this manual carefully. It will help you become familiar with the

operation of the equipment and contains helpful information regarding installation,

operation, maintenance and troubleshooting.

We hope you find this manual to be helpful in producing the high quality lumber your

customers demand.

iDRY User Manual

© 2020 iDRY, LLC

4

Safety

This equipment should be operated by trained personnel and maintained by certified

professionals. The equipment is intended for non-treated lumber only and should not be

used for any other purpose. Any modifications of the equipment or use of unauthorized parts

is forbidden unless approved by the original manufacturer. Any electrical or plumbing work

performed on this installation should be performed by certified professionals working to

local codes.

Safety warnings are noted in each section; example below:

Specifications

The following machine specifications are for iDRY Standard and iDRY Plus Lumber Dryers:

WARNING: THE VOLTAGES INSIDE THE CONTROL BOX ARE HIGH ENOUGH TO

CAUSE DEATH IF YOU COME IN CONTACT WITH THEM.

Main Power

208-240 VAC 1 Phase, 60 Amps!

Water Supply

Soft & Clean Water @ 70 Deg F / 21 C or less with avg flow of 0.75

Gallons per Minute / 2.8 Liters per minute, MIN 50 PSI

Drains

Air Gap (included) required - 2inch / 51mm PVC Connection!

Installation Environment

Above freezing dry space. For best operating performance ambient

temperature should be kept above 60 F / 15.5 C

Remote Connection

Ethernet Cable 200 Feet / 60 Meters max!

Lumber

3/4inch / 1.9cm or greater stickers recommended!

Lumber Load Capacity

STANDARD: 13ft Long x 48in Wide x 55in Tall / 3.96M Long x 1.2M Wide

x 1.4M Tall!

PLUS: 17ft Long x 60in Wide x 65in Tall / 5.18M Long x 1.5M Wide x

1.65M Tall

Drying Time

Approximately 1 week per 1 inch (2.54cm) of thickness (Maple)

iDRY User Manual

© 2020 iDRY, LLC

5

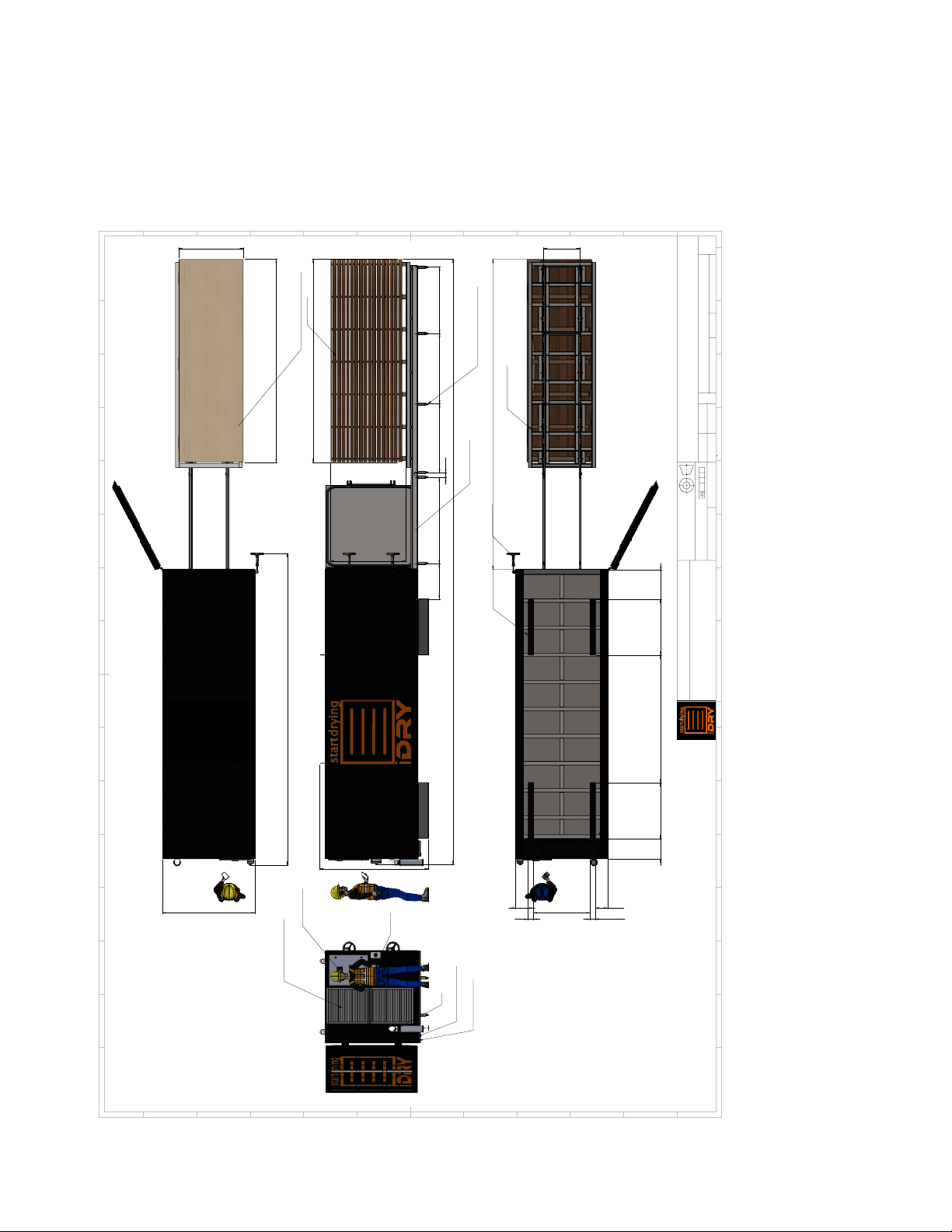

Technical Drawings

iDry Standard

iDRY User Manual

© 2020 iDRY, LLC

6

446.83

55.75

150.00

48.98 52.00 51.02

80.27

3.50

63.50 26.16

WOOD PILE

SHIM FEET SO WATER ON FLOOR

FLOWS TO BACK DRAIN ON

CONTROL PANEL END

ADJUST LEVELING FEET ON TRACK

FOR SMOOTH TROLLEY ROLLING

SIDE VIEW

OPTIONAL BRIDGE

150.00

48.00

230.02

68.62

RECOMMENDED PLYWOOD TOP

TOP VIEW

21.40

41.25 94.28 41.25

3.94

15.00

229.02

9.09

41.89

9.39

3.94

27.00

KILN CHAMBER FEET

INTERNAL TROLLEY

HAND WHEEL

BOTTOM VIEW

208-230v

1PH

60A

POWER

VENT

DRAIN CONNECTION

AIR GAP CONNECTION

0.75GPM

WATER CONNECTION

TOUCH SCREEN

REMOVABLE VENT PANELS

END VIEW

F

8

E

D

C

B

A

G

H

J

K

L

M

7

6

5

4

3

2

1

9

10

11

12

13

14

15

16

9

1

2

3

4

5

6

7

8

10

11

12

K

G

A

B

C

D

E

F

H

J

SEE NOTES SEE NOTES

DWG BY:

0.1

MATERIAL:

INTERPRET GEOMETRIC

TOLERANCES PER ANSI Y14.5-2009

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

PART NUMBER:

MOD BY:

DESCRIPTION:

CHK BY:

A1

SIZE:

SCALE:

SHT

20

OF

23

REV

1:50

iDRY Drying Systems

20

JAP

C

BA

FINISH:

MASS:

UNLESS OTHERWISE SPECIFIED

ALL UNTOLERANCED

DIMENSIONS ARE BASIC:

INSTALLATION

APR BY:

Green Mountain Mechanical Design, Inc

29 PITMAN RD BARRE, VT 05641

©2018 All Rights Reserved

CONFIDENTIAL

13

14

15

16

L

M

LAST SAVED

Monday, February 11, 2019 3:24:54 PM

iDry PLUS

iDRY User Manual

© 2020 iDRY, LLC

7

45 52 52 51

3.00

41 39.25 25 41 121 41 41

96.27

554.96

SIDE VIEW

OPTIONAL BRIDGE

ADJUST LEVELING FEET

ON TRACK FOR SMOOTH

OPERATION

252.00

82

264

9

4 58

9

4

41 37 121 41 22

BOTTOM VIEW

CHAMBER FEET

HANDWHEEL

INTERNAL TROLLEY

60.00

200.00

94.43

TOP VIEW

RECOMMENDED PLYWOOD TOP

REMOVABLE

VENTED PANELS

0.75GPM

WATER CONNECTION

208-230V

1PH

60A POWER

TOUCHSCREEN

LIFT POINTS

WATER DRAINS

END VIEW

SHIM FEET SO WATER ON FLOOR

FLOWS TO BACK DRAIN ON

CONTROL PANEL END

FOR OPTIMAL PERFORMANCE INSTALL

IN ABIENT TEMPERATURES ABOVE 60F

F

8

E

D

C

B

A

G

H

J

K

L

M

7

6

5

4

3

2

1

9

10

11

12

13

14

15

16

9

1

2

3

4

5

6

7

8

10

11

12

K

G

A

B

C

D

E

F

H

J

SEE NOTES SEE NOTES

DWG BY:

0.1

MATERIAL:

INTERPRET GEOMETRIC

TOLERANCES PER ANSI Y14.5-2009

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

PART NUMBER:

MOD BY:

DESCRIPTION:

CHK BY:

A1

SIZE:

SCALE:

SHT

21

OF

23

REV

1:50

iDRY Drying Systems

1

JAP

C

BA

FINISH:

MASS:

UNLESS OTHERWISE SPECIFIED

ALL UNTOLERANCED

DIMENSIONS ARE BASIC:

INSTALLATION

APR BY:

Green Mountain Mechanical Design, Inc

29 PITMAN RD BARRE, VT 05641

©2018 All Rights Reserved

CONFIDENTIAL

13

14

15

16

L

M

LAST SAVED

Wednesday, April 17, 2019 4:45:27 PM

Installation & Startup:

Complete the following prior to iDRY Systems assisted startup procedure:

*You can also find tutorial videos here: www.youtube.com/watch?v=Mg9MixxbL-M

Placement

1

Locate Kiln Chamber in Dry, Climate controlled space at recommended temperature of 70 DegF!

/ 21.1 C

2

Loosen Handwheels just enough to rotate them out of the way (if you continue to loosen the

threads the hand wheels will come off.

3

Shim chamber to ensure water flows to drain (chamber is pre-shimmed 1/2inch / 1.27cm)

4

Remove the ratchet Straps, then remove Track, Trolley and Bridge sections from chamber. Set

aside the cardboard box.

iDRY User Manual

© 2020 iDRY, LLC

8

Track & Trolley Installation

4

The two pieces on top are called the track bridge extensions.

5

Match up the track bridges to the chamber and the track frame using the two alignment tabs.

6

Adjust the track feet so that both the track and bridge are level leading up to the kiln chamber.

*You will need either an adjustable wrench or an 1-1/8inch / 29mm wrench. All feet should be

on the ground *The track can be used with, or without the track bridge extensions.

iDRY User Manual

© 2020 iDRY, LLC

9

7

Using a string or straight edge, aligned the track angle peak from the chamber to the opposite

far end of the track. It is imperative that the tracks on the track frame and extensions are in

alignment with the track in the chamber. Failure to do so will result in the trolley coming offthe

tracks.

iDRY User Manual

© 2020 iDRY, LLC

10

8

Place the trolley onto the track and perform an unloaded test to confirm the trolley rolls easily all

the way in and out of the kiln chamber!

*For door operation you will need to move the track bridge extensions. For best results mark the

floor where the track and bridge sections are lined up, or permanently affix the track frame to the

floor

iDRY User Manual

© 2020 iDRY, LLC

11

Power

9

Connect 208-240V 1PH 60A 60Hz electrical at Rotary disconnect located at control panel end

of chamber

iDRY User Manual

© 2020 iDRY, LLC

12

Plumbing

10

Connect 0.75GPM / 2.8 LPM of clean, 70F / 21C or less fresh water to connection port located

on control panel end of kiln, left side underneath. The fitting is a 1/2” / 13mm female brass

fitting.

11

Connect vessel drain with air gap (2” PVC / 51mm) to your facilities drain!

12

Connect vacuum pump drain with air gap (2” PVC / 51mm) to your facilities drain!

Electrical and plumbing installations should be performed by certified

professionals based on local building codes only.

iDRY User Manual

© 2020 iDRY, LLC

13

Loading

13

Place stickered pile of lumber or slabs onto Internal Trolley with not more than 3 inches of

overhang on either side of trolley, with no overhang on either end of trolley

14

Confirm that pile height is 55inches from top of track to top of lumber pile!

15

Place stickers on top of pack of lumber and place a sheet of plywood or similar on top of

stickers to prevent condensation from dripping on top layer of wood

16

Sticker placement in pile should be straight and provide for good air circulation through pile

17

Push trolley with stickered pile of lumber into chamber.

iDRY User Manual

© 2020 iDRY, LLC

14

17

Remove bridge track sections.

iDRY User Manual

© 2020 iDRY, LLC

15

Closing Door

18

After confirming all persons have exited the chamber, close door and tighten hand wheels until

rubber gasket contacts chamber sealing surface.!

*DO NOT OVERTIGHTEN HANDWHEELS, AND NEVER TIGHTEN HANDWHEELS WHEN

CHAMBER IS IN OPERATION UNDER VACUUM

WARNING!! CHAMBER IS A CONFINED SPACE. NO PERSONS SHALL ENTER THE CHAMBER

WITHOUT A TRUSTED “BUDDY” TO SUPERVISE AND ENSURE NO PERSONS ARE IN THE CHAMBER

WHEN THE DOOR IS CLOSED OR WHEN THE MACHINERY IS IN OPERATION

WARNING!! DO NOT TIGHTEN HAND-WHEELS AFTER CHAMBER IS UNDER VACUUM - THIS

WILL RESULT IN DAMAGE TO THE HAND-WHEEL!!

iDRY User Manual

© 2020 iDRY, LLC

16

Powering Up

19

At Control Panel turn rotary disconnect switch to power up machine

20

Allow Touch Screen to power up and Press START

iDRY User Manual

© 2020 iDRY, LLC

17

21

Monitor the vacuum set point for a few minutes to ensure that the actual vacuum begins to drop

towards 7-8inHg (270 hPa) Vacuum

22

The temperature will automatically warm up the wood slowly and continue to rise over time. The

temperature will raise slower using low power mode.

23

The kiln will reach a max temperature of 160 Deg F / 71C but the time to get there will vary

depending on low or full power mode, species, initial MC%, thickness and other factors.

24

Moisture content should be checked weekly. Time will vary by species but 4/4 Maple will take

about one week to dry. Each inch more would take and additional week. Some species take

longer. Moisture content can be checked with either a moisture meter or by oven weight

method. *it is recommended you wait at least 25 minutes to open the door after machine

is stopped to allow vacuum to release and chamber to cool

20

If wood is not dried to desired moisture content, close door and press start to continue drying

Problem: Actual Vacuum value not decreasing

Possible Cause: Door may be leaking vacuum due to seal not fully contacting the sealing

surface of the chamber. Solution A: For a short term solution Using tape the operator

may plug small cracks to make the door seal, once the door has pulled in and the seal is

compressed the problem should stop.

Solution B: iDRY, LLC can provide rubber shims for problem areas where the rubber seal

does not fully contact the chamber

Problem: Temperature is above 70F

Possible Cause: Higher than normal water temperature will cause the vacuum pump to

run more and possibly not reach the vacuum set point.

Solution: Check that water supply hasn’t warmed up.Lower water temperature by chiller

or new water source.

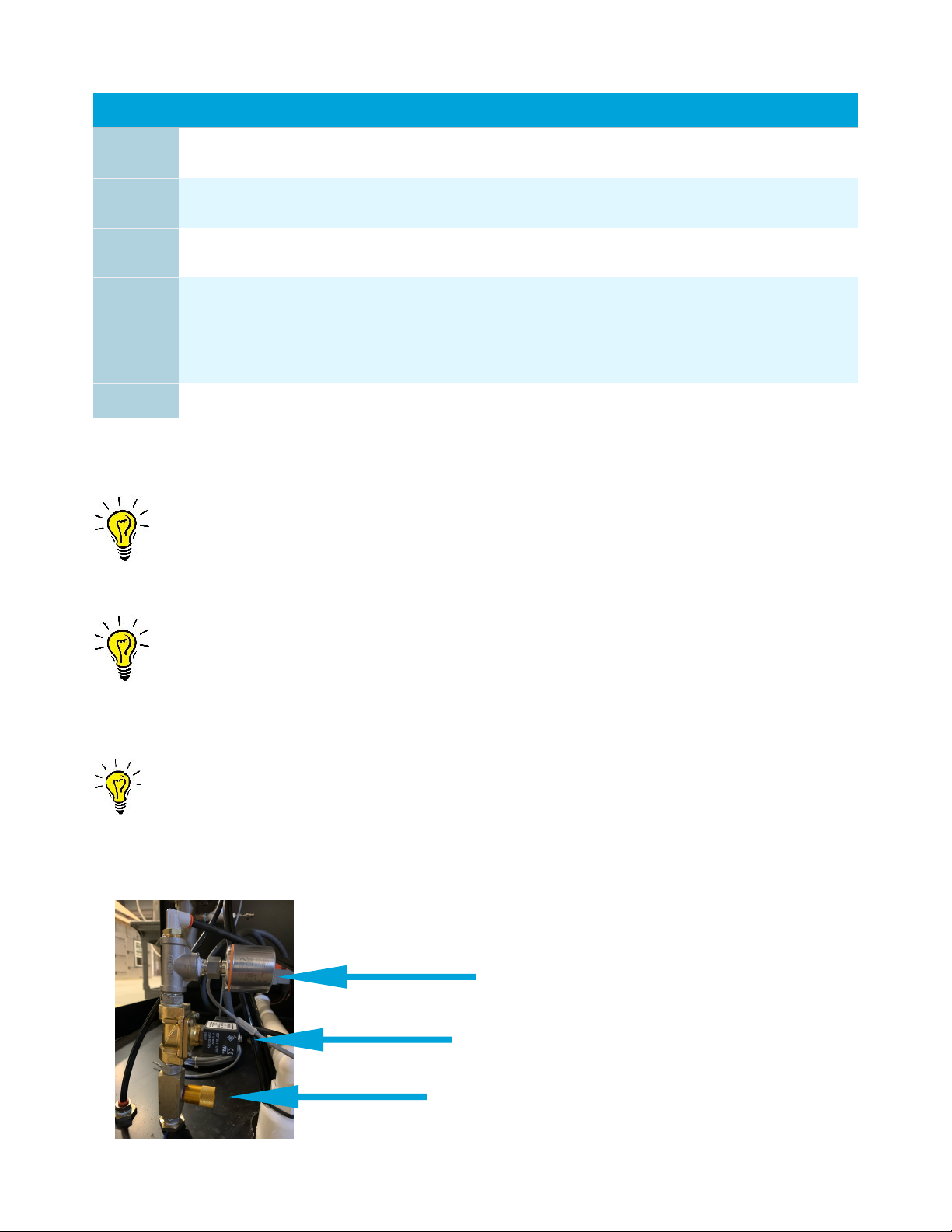

Problem: Vacuum Pump Water Flow is below 0.25 gpm

Possible Cause: Lack of water pressure caused by restriction, solenoid

valve closed, water pump failure, Flow meter failure, or insufficient supply

Solution: Check Flow/Temp sensor ahead of vacuum pump water feed.

Check water booster pump (if installed) is running. Check overall water

supply from well or city.

Confirm no blockages in supply line

Adjust brass Needle Valve to allow for increased flow

iDRY User Manual

© 2020 iDRY, LLC

18

Brass Needle Valve

Water Solenoid Valve

Temperature and flow meter

Kiln Monitoring

Daily Monitoring

Once or twice per week the operator should spend a few minutes at the kiln to monitor the

drying process and functionality of the kiln equipment.

The vacuum pump may only run periodically to maintain vacuum pressure.

At any time in the drying process the operator may press STOP and Release Vacuum.

Once the vacuum is completely released the operator can open the door and check the

condition of the wood.

The operator may also choose to open and check during a drain cycle. The kiln will enter a

drain cycle once a day and drains for approx 20 Mins.

Unloading Kiln

Opening Door

1. Press STOP at control panel HMI (touchscreen)

2. Press Vacuum Release on the Touchscreen

3. Loose and swing free Door Hand wheels

4. Swing open door

Checking Oven Weighted Samples

1. Pull at least 4 of the sample boards that were oven tested and weight prior to starting the

load. (Reference the ASTM D4442-15 standard for proper oven weight sampling of

lumber samples for proper procedure.)

iDRY User Manual

© 2020 iDRY, LLC

19

CORRECT USE

Lumber preparation

Care must be taken when preparing stacks of green lumber before the stacking and loading

process begins. Pack widths and length combinations need to fill the complete length and

width of the Internal Trolley with no less than 6 inches / 2.54cm of a gap between boards

and chamber walls. Reference Stacking guide for more detail.

Baffling

Evening the air flow equals more even drying. If you have enough lumber to fill the kiln use

additional material to baffle.

Proper Stacking

Lumber pile and stickers must be stacked vertically enough to fit into the kiln chamber using

3/4 inch / 1.9cm stickers. It is recommended that a sheet of plywood be placed on top of the

lumber pile with stickers between the lumber and plywood to provide airflow over the top of

the pile while reducing condensation dripping onto top of lumber.

Reducing Degrade

Drying slower can reduce degrade. Use LOW POWER mode or lower temperature set point

until the lumber is below 25%.

Winter vs Summer

The kiln is designed to operate most efficiently in an operating environment of 70 Degs F /

21.1C. If your space is colder in the winter time then the kiln could dry slower. If your space

is warmer in the summer then it may dry faster. Using LOW POWER mode in the summer

and improving the ventilation in the space would be recommended. Adding more insulation

or space heating in the winter would be recommended.

Large gap between pile and one end of chamber may result in short circuiting of

airflow and improper heating. Move packs so the total lumber length is equal to the

Trolley Length or baffle as necessary.

Freezing temperatures could damage equipment. Excessive hot temperatures could

damage electronics! Do not operate equipment in freezing environments.

iDRY User Manual

© 2020 iDRY, LLC

20

This manual suits for next models

1

Table of contents

Popular Dryer manuals by other brands

GE

GE Profile DPVH880GJ Dimensions and installation information

Alliance Laundry Systems

Alliance Laundry Systems 70260301?8 Installation

Air Wolf

Air Wolf V Series manual

Beko

Beko DHS 7413 PA0 user manual

Airflow

Airflow ecoDRY mini Installation and operating guide

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL HG 2520 E Information

Electrolux

Electrolux TD6-14 installation manual

GE

GE GFDS150EDWW installation instructions

Whirlpool

Whirlpool WED9050X Dimensions and installation

Fisher & Paykel

Fisher & Paykel Smartload DGGX1 Technical bulletin

Hotpoint

Hotpoint AQUALTIS AQC9 BF5 Instruction booklet

therm-ic

therm-ic ThermicDryer Instructions for use