3

RS-925D

3Specifications

RS925D OPERATING GUIDE

MODEL: RS925D SN: D5-2307704

WARNING

IET LABS, INC. www.ietlabs.com

Accuracy

±(20 ppm+0.5 mΩ)

At 23°C "true ohm" measurement, 30-70% RH,

absolute reading, case grounded, SI traceable

No zero subtraction required

Minimum resistance:

10 mΩ ± 0.5 mΩ; determined by the lowest settable

position, “1”, of the 10 mΩ/step decade

Resistance repeatability:

Better than 100 µΩ, short-term, average value

Environmental Conditions:

Operating Temperature: 0°C to 55°C

Storage Temperature: -40°C to 70°C

Switch Type:

Multiple solid silver contacts; dust-tight diallyl-

phthalate body.

To allow continuous rotation, a blank position is

added on most decades.

Resistance

per step

Total

decade

resistance

Max

current

Max

power Temperature

coefficient

(±ppm/ºC)

Power

coefficient

(±ppm/mW)

Stability

(±ppm/yr) Decade positions Resistor type

whichever applies first

100 µΩdivision

20 µΩresolution 10 mΩ 2 A NA 20 1

20 ppm+0.5 mΩ

Continuous Rheostat

1 mΩ 10 mΩ 2 A NA 20 1 11 positions "0"-"10"

Resistance wire

10 mΩ 100 mΩ 2 A NA 20 1 10 positions "1"-"10"

(10 mΩ minimum reading

100 mΩ 1 Ω 2 A NA 20 1

11 positions "0"-"10"

1 Ω 10 Ω 1 A 5 W 20 0.4

Wirewound

hermetically sealed

low-inductance

10 Ω 100 Ω 0.33 A 5 W 10 0.3

100 Ω 1 kΩ 0.1 A 5 W 3 0.1

1 kΩ 10 kΩ 33 mA 5 W 3 0.1 10 ppm

(<5 ppm typical)

10 kΩ 100 kΩ 10 mA 5 W 3 0.1

100 kΩ 1 MΩ 3 mA 2,000 V peak 3 0.1 12 positions "0"-"11"

Wiring and switch resistance NA 50 µΩ/ºC 0.2 µΩ/W NA

For Best Performance:

Whenever the unit has been idle, turn each switch 7-10

times both ways before using. This switch "break-in"

procedure is standard metrology practice required for

best accuracy to remove any silver oxide fi lm on the

contact surfaces, typically <1 mΩ.

Terminals:

Four, 5-way, gold-plated, tellurium-copper

binding posts with low thermal emf and

low resistance, for four-terminal Kelvin

measurements, plus one binding post

connected to case for shielding. Rear outputs

are available as an option.

RS925D OPERATING GUIDE

MODEL: RS925D SN: D5-1645634

WARNING

IET LABS, INC. www.ietlabs.com

Accuracy

±(20 ppm+0.5 mΩ)

At 23°C "true ohm" measurement, 30-70% RH,

absolute reading, case grounded, SI traceable

No zero subtraction required

Minimum resistance:

10 mΩ ± 0.5 mΩ; determined by the lowest settable

position, “1”, of the 10 mΩ/step decade

Resistance repeatability:

Better than 100 µΩ, short-term, average value

Environmental Conditions:

Operating Temperature: 0°C to 55°C

Storage Temperature: -40°C to 70°C

Switch Type:

Multiple solid silver contacts; dust-tight diallyl-

phthalate body.

To allow continuous rotation, a blank position is

added on most decades.

Resistance

per step

Total

decade

resistance

Max

current

Max

power Temperature

coefficient

(±ppm/ºC)

Power

coefficient

(±ppm/mW)

Stability

(±ppm/yr) Decade positions Resistor type

whichever applies first

100 µΩdivision

20 µΩresolution 10 mΩ 2 A NA 20 1

20 ppm+0.5 mΩ

Continuous Rheostat

1 mΩ 10 mΩ 2 A NA 20 1 11 positions "0"-"10"

Resistance wire

10 mΩ 100 mΩ 2 A NA 20 1 10 positions "1"-"10"

(10 mΩ minimum reading

100 mΩ 1 Ω 2 A NA 20 1

11 positions "0"-"10"

1 Ω 10 Ω 1 A 5 W 20 0.4

Wirewound

hermetically sealed

low-inductance

10 Ω 100 Ω 0.33 A 5 W 10 0.3

100 Ω 1 kΩ 0.1 A 5 W 3 0.1

1 kΩ 10 kΩ 33 mA 5 W 3 0.1 10 ppm

(<5 ppm typical)

10 kΩ 100 kΩ 10 mA 5 W 3 0.1

100 kΩ 1 MΩ 3 mA 2,000 V peak 3 0.1 12 positions "0"-"11"

Wiring and switch resistance NA 50 µΩ/ºC 0.2 µΩ/W NA

For Best Performance:

Whenever the unit has been idle, turn each switch 7-10

times both ways before using. This switch "break-in"

procedure is standard metrology practice required for

best accuracy to remove any silver oxide fi lm on the

contact surfaces, typically <1 mΩ.

Terminals:

Four, 5-way, gold-plated, tellurium-copper

binding posts with low thermal emf and

low resistance, for four-terminal Kelvin

measurements, plus one binding post

connected to case for shielding. Rear outputs

are available as an option.

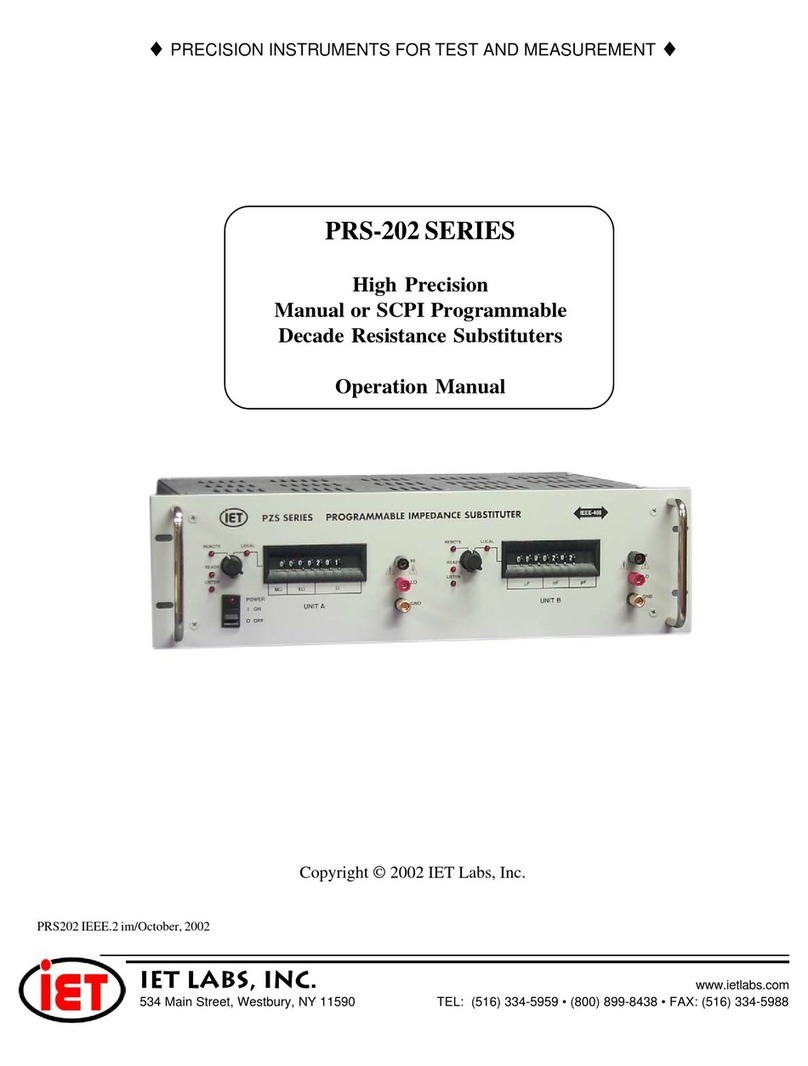

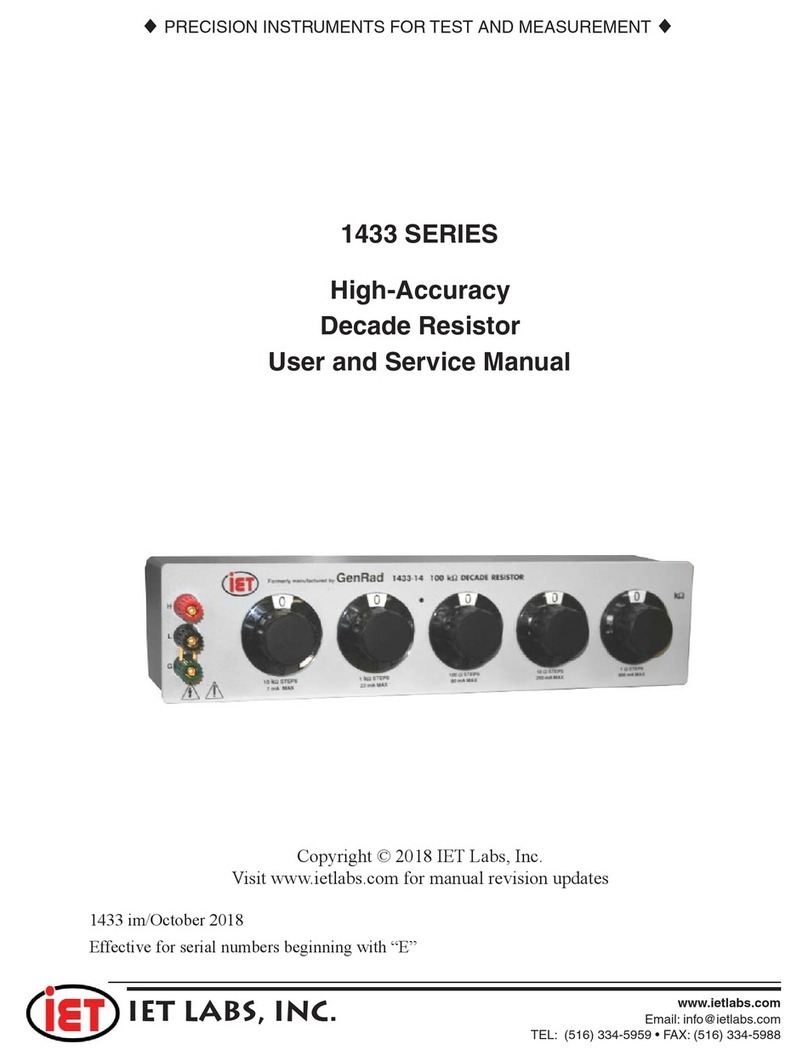

Figure 2-1: Typical Operating Guide Affixed to Unit