1

INTRODUCTION

PRS-202 Series

Chapter 1

INTRODUCTION

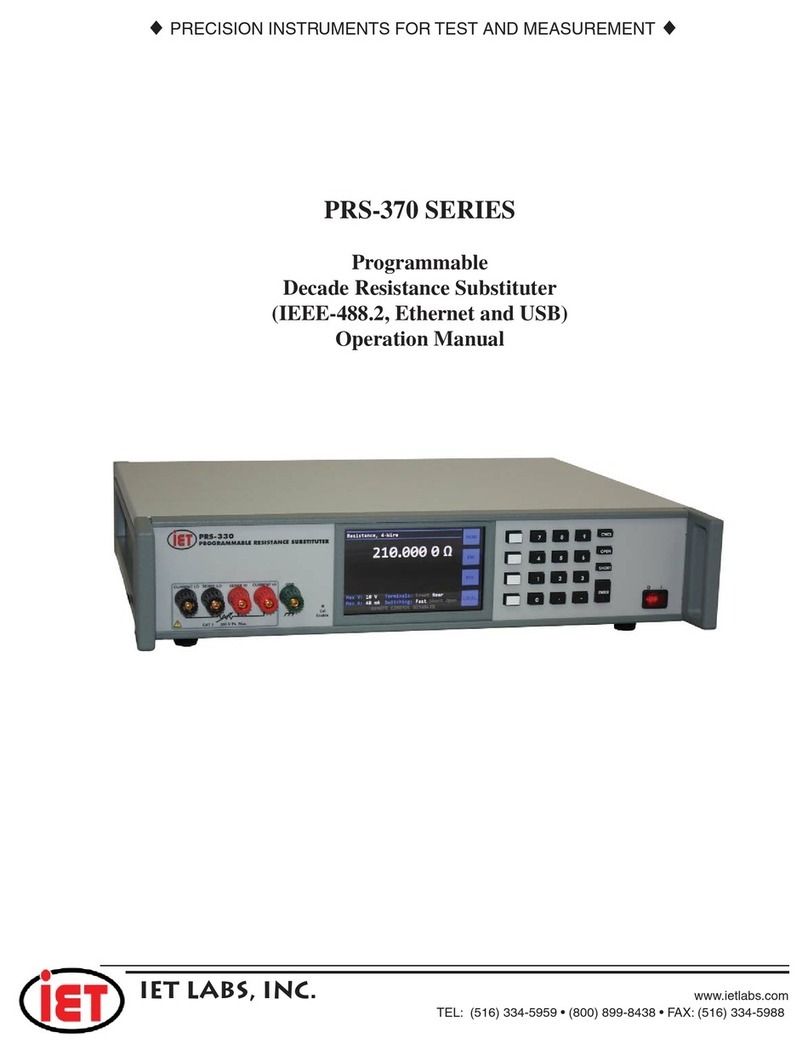

The PRS-202 (Figure 1.1) Series is a broad line of

high precision manual and programmable decade

substituters. They provide straight resistance substi-

tution as well as RTD (Resistance Temperature De-

tector) simulation, in a wide selection of ranges, tol-

erances and ratings.

The PRS-202 substituter is a precision resistance

source with excellent characteristics of stability, tem-

perature coefficient, and power coefficient. High dy-

namic ranges are available, starting as low as 1 mΩ,

and extending to as many as 10 decades. These fea-

tures combined with a low virtually constant “zero

resistance” make for very versatile instruments.

The PRS-202 Series features two optional special

settings. An “open circuit” and a “short circuit”.

These modes are useful for obtaining reproducible

transitions between settings, i.e. break-before-make

or to short between settings. The “short circuit” set-

ting also provides a reduced zero resistance.

Operation is both local using convenient direct read-

ing front panel thumbwheel switches, and remote with

optional parallel BCD or IEEE-4888 interfaces. Both

can provide an optional extra “10” position for each

decade.

The PRS-202 Series employs very low resistance, low

thermal emf relays with gold clad silver alloy con-

tacts. A special design keeps contact resistance to a

minimum. The gold plating keeps the silver contacts

from becoming tarnished when unused, or when only

low currents are passed through them. This is most

often the case when only minute test currents are

drawn by digital multimeters and other test instru-

ments. Contact resistance remains low and repeat-

able.

High quality gold plated tellurium copper five-way

binding posts serve to minimize the thermal emf ef-

fects, which would artificially reflect a change in dc

resistance measurements. All other conductors within

the instrument, as well as the solder employed con-

tain no metals or junctions that could contribute to

thermal emf problems.

With a resolution as low as 1 mΩand a maximum

available resistance of over 100 MΩ, the PRS-202

Series may be used for exacting precision measure-

ment applications requiring high accuracy, good sta-

bility, and low zero resistance. They are suited for

automatic and manual calibration and testing, simu-

lation of RTD’S, programmable loads, and many other

laboratory and industrial applications.

The PRS-202 Series may be rack mounted to serve

as components in measurement and control systems.

Figure 1.1: High Precision Manual or

Programmable Decade Resistance Substituter