IFB Diva User manual

USE ONLY GENUINE IFB SPARES & ACCESSORIES

* Company shall not be responsible for defects arising due to usage of spurious parts and accessories

OPERATING MANUAL

Advancing the science of washing

m e

achin

1

2

CONTENTS

KNOW YOUR MACHINE 6

INSTALLATION 7

=Pre Installation

=Unpacking

=Setting Up

=Water Inlet

=Water Outlet

=Electrical Connection

USING YOUR MACHINE 9

=Control Panel

=Automatic Detergent Dispenser Tray

=ON - OFF Switch / Programme Selector Knob

=Programme Selection

=Programme Selection Chart

OPERATION 13

=Sorting of Garments

=Loading the Machine

=Detergent to be used and Quantity

=Treatment of stains

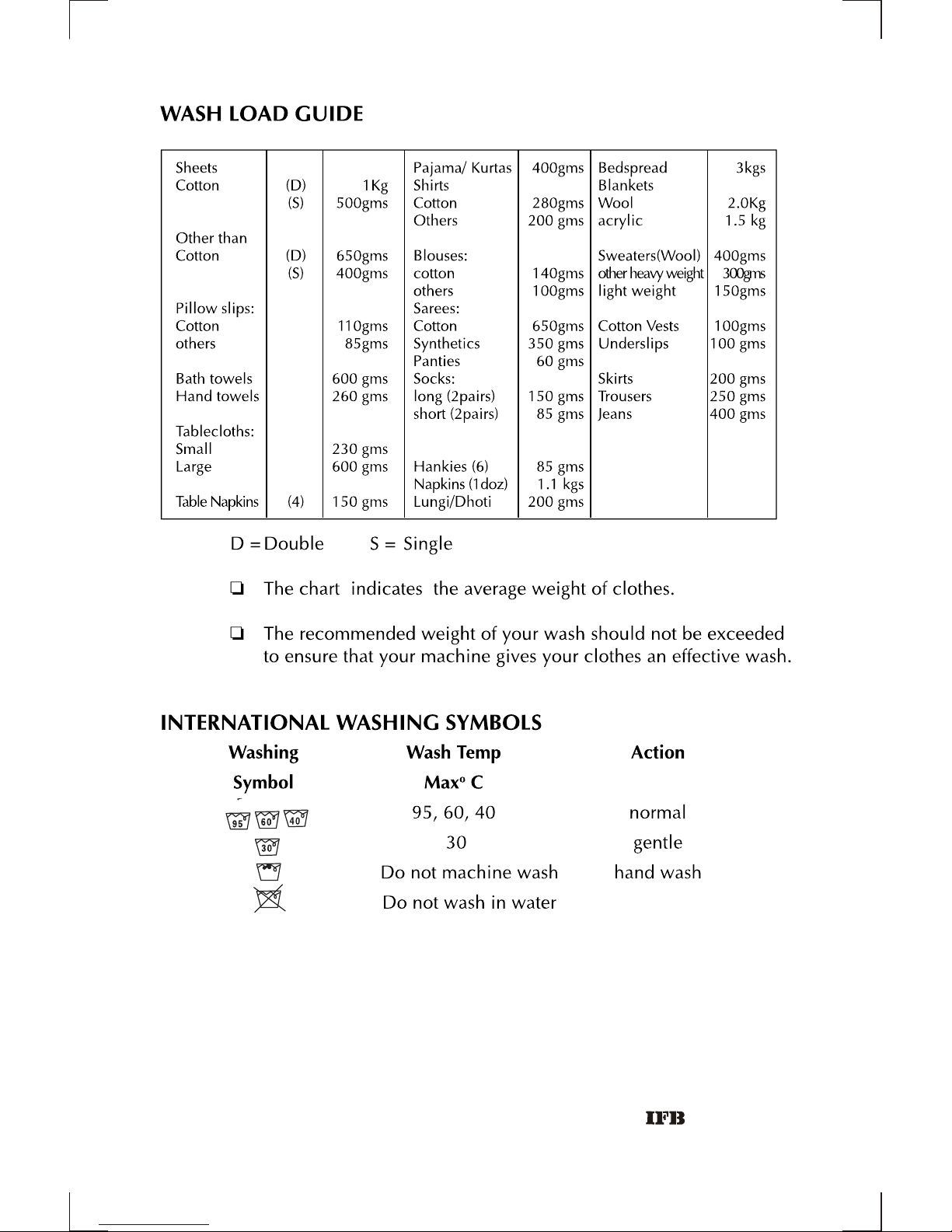

=Wash Load Guide

=International Washing Symbols

=Programme Run

=Switching Off the Machine

=Check Points

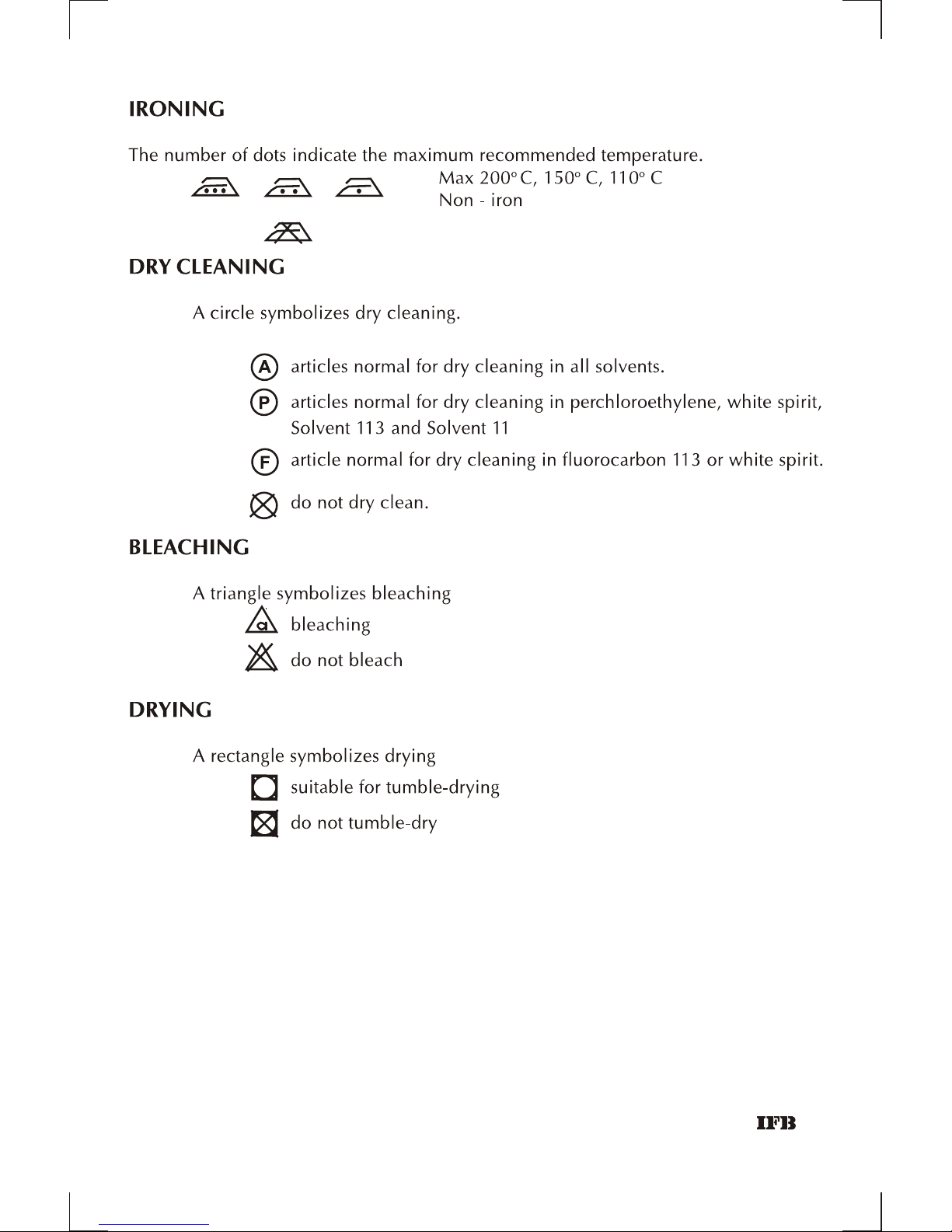

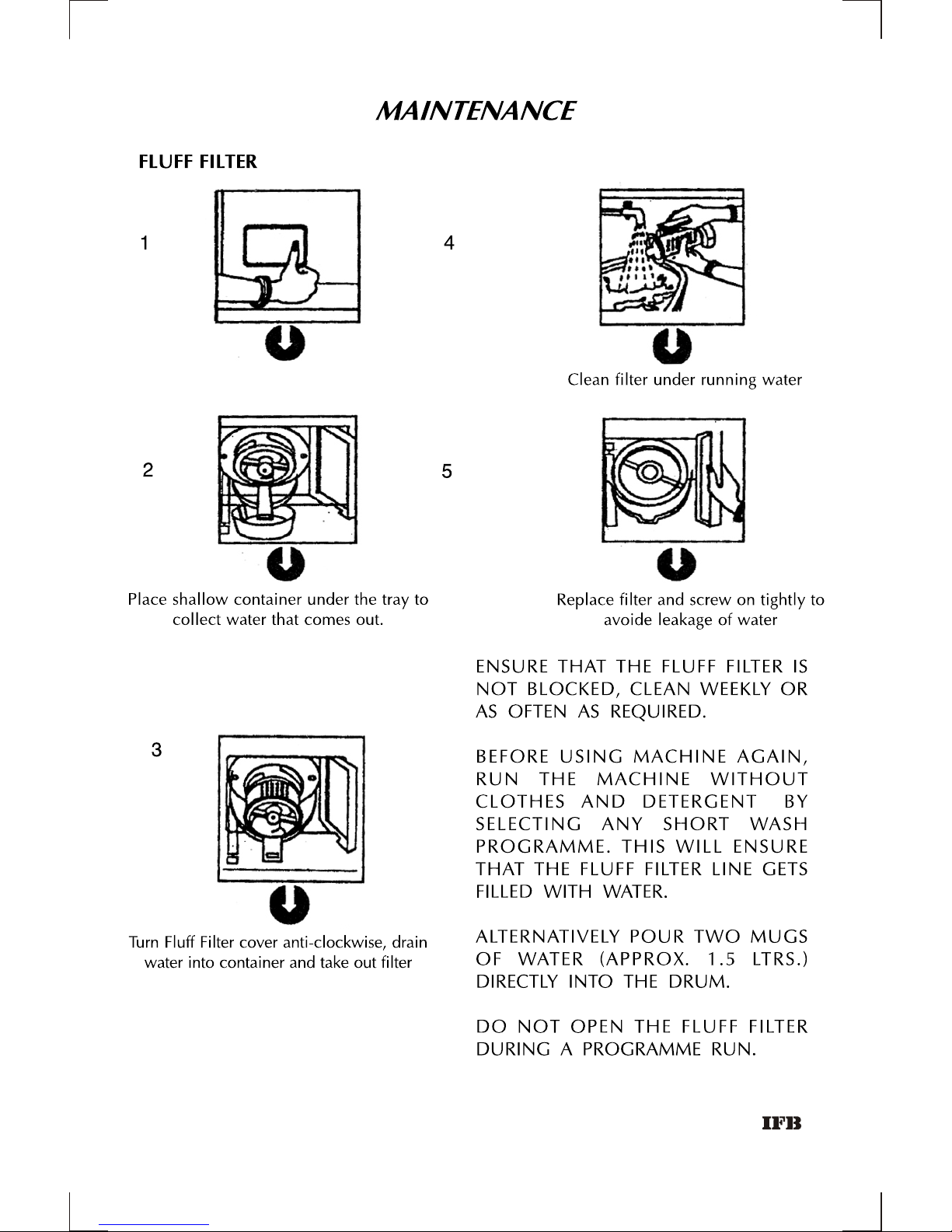

MAINTENANCE 19

=Fluff Filters

=Drum

=Sieves

=Frost Protection

=Draining During Emergencies

FAULT DIAGNOSIS 21

=Why does it happen?

SAFETY PRECAUTIONS 22

TECHNICAL DATA 23

CONTENTS

KNOW YOUR MACHINE

INSTALLATION

USING YOUR MACHINE

OPERATION

MAINTENANCE

FAULT DIAGNOSIS

SAFETY PRECAUTIONS

TECHNICAL DATA

3

PORTHOLE

DOOR

DETERGENT DISPENSER TRAY

ON-OFF SWITCH/PROGRAMME

SELECTOR KNOB

INTERLOCKING

DOOR LOCK

HANDLE

ADJUSTABLE

FEET FOR

LEVELLING

SPECIAL

POWDER

COATED

GALVANISED

STEEL

CABINET

FLUFF

FILTER

DOOR

ADVANTAGES OF TUMBLE WASH

qMOST EFFECTIVE CLEANING AS THE CLOTHES PASS THROUGH

SOAPY WATER AND ALSO FALL ON SOAP SOLUTION IMPROVING

WETTING OF CLOTHES.

qRESEMBLES THE THUMPING AND RUBBING ACTION OF GENTLE

HAND WASH.

qUSES LESS WATER COMPARED TO TUB TYPE TOP LOADERS.

qLESS WATER MEANS LESS DETERGENT AND ELECTRICITY

CONSUMPTION.

qWASHING IS EFFECTIVE BY DETERGENCY, SOAKING, HEATING,

TUMBLING AND SQUEEZING.

qGIVES BETTER DRYING EFFECT BY SPINNING.

ADVANTAGES OF TUMBLE WASH

4

1. Remove Carton.

2. Remove wooden base. Keep machine on floor

or trolley.

3. Place the machine at the site at which it is to be

installed.

4. Remove transit bolts.

5. Insert plastic caps provided into holes vacated and press till they click into

place.

6. Remove packing from the bottom of the motor

7. Keep transit bolts carefully. They will be required in case you need to shift the

machine again.

8. For shifting and re-installation at a new site,please get in touch with our service

personnel.

9. Keep packaging material carefully. It comes handy while shifting residence.

10. PLEASE DO NOT OPERATE THE MACHINE TILL TRANSIT BOLTS HAVE BEEN

REMOVED.

INSTALLATIONINSTALLATION

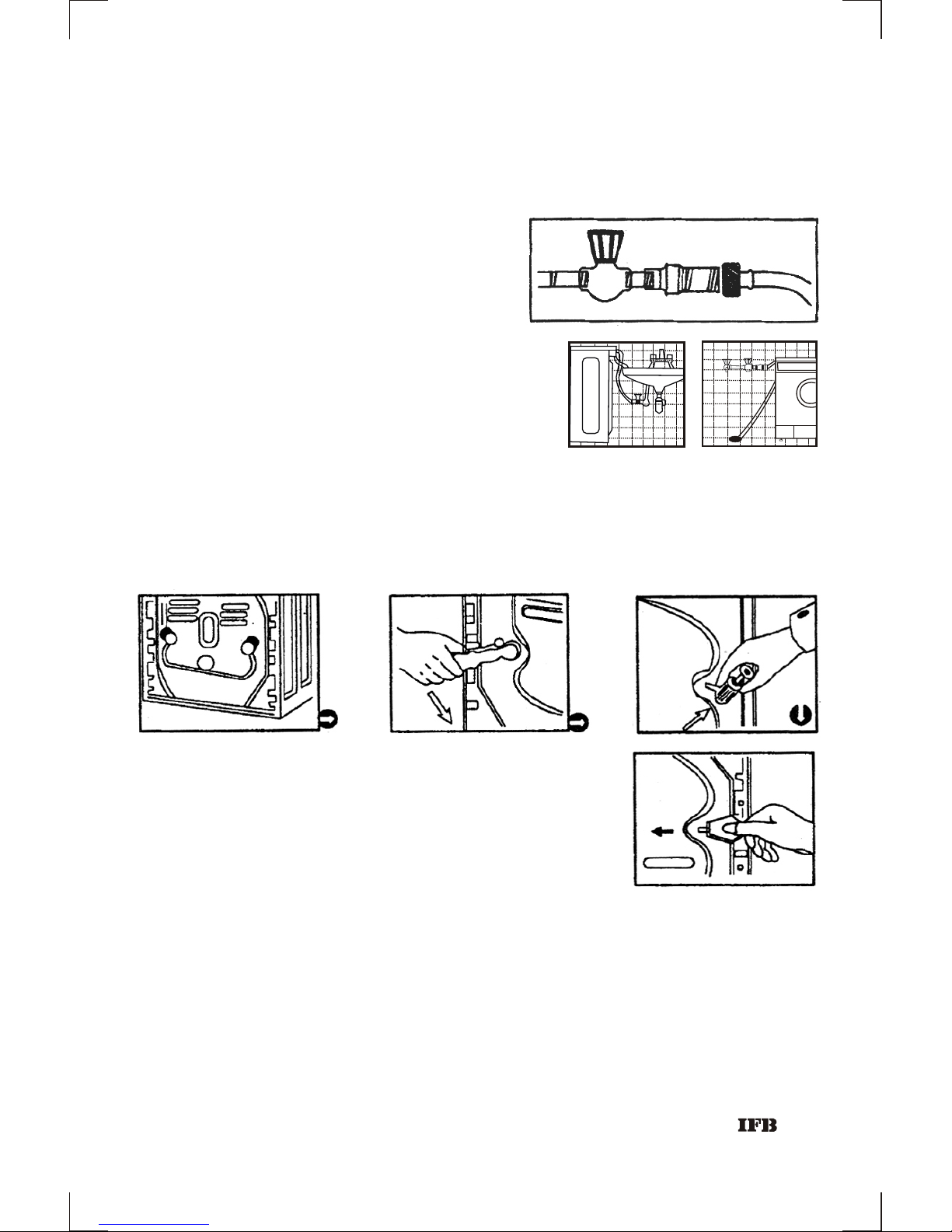

WATER INLET

DRAIN

PIPE

WATER INLET

DRAIN

PIPE

AERW T

SPL

Y

UP

PT OS

CL O K

RDCR

EUE

MACHINE

WTR

AE

INLET

21 / 3/4

1. Make sure there is a 16 amp. 3-pin electrical point preferably with a 16 amp.

fuse, within 1 meter of the machine. Make sure it has proper earthing.

2. Fixed plumbing is recommended for

the machine. The water inlet of the

machine has a collarwith3/4”parallel

internal threads. The water supply

point with an external 3/4” parallel

thread should be available within1

meter of the machine’s location.

4. Please inform our service centre for installation and demonstration of the

machine once the points mentioned above have been completed.

3. Two options on the water inlet and drain

pipe connection are shown. In case these

possibilities do not exist for the drain pipe,

please arrange an additional length of pipe.

PRE-INSTALLATIONPRE-INSTALLATION

UNPACKINGUNPACKING

5

16 AMPS

X

X

WATER INLET

DRAIN

PIPE

1. MAKE SURE THAT THE MACHINE RESTS ON ALL

FOUR FEET ON A LEVEL SURFACE.Adjustable

screws are provided at the bottom to allow

levelling.

2. Loosen securing nut. Adjust the screw to change

level. Tighten securing nut to ensure that screw is

locked into place.

3. MACHINE SHOULD BE LEVELLED AGAIN IN CASE

IT IS MOVED TO A NEW SITE.

1. A drain pump is provided in the machine to pump out

used water.

2. The end of the outlet should be placed near a drain. If

necessary, it can be placed over the edge of a sink

at a maximum height of 1 mt. from the floor level.

3. Allow free flow of water from the outlet pipe.

1. Check that the electrical line can take the required

load.

2. Connect to a 220V, 50 Hz single phase AC supply.

3. Machine must be earthed properly before

operation. This can be done by using a 3 pin plug

and properly earthed socket of 16 ampere rating.

4. Ensure that there is a firm connection between the 3

pin plug and socket, else it may result in sparking and

subsequent failure of 3 pin plug.

5. Use of extension cord not recommended.

SETTING UPSETTING UP

WATER INLET

DRAIN

PIPE

1. Connect inlet hose to water tap/line.

2. Do not connect machine to a hot water supply.

WATER INLETWATER INLET

WATER OUTLETWATER OUTLET

ELECTRICAL CONNECTIONELECTRICAL CONNECTION

6

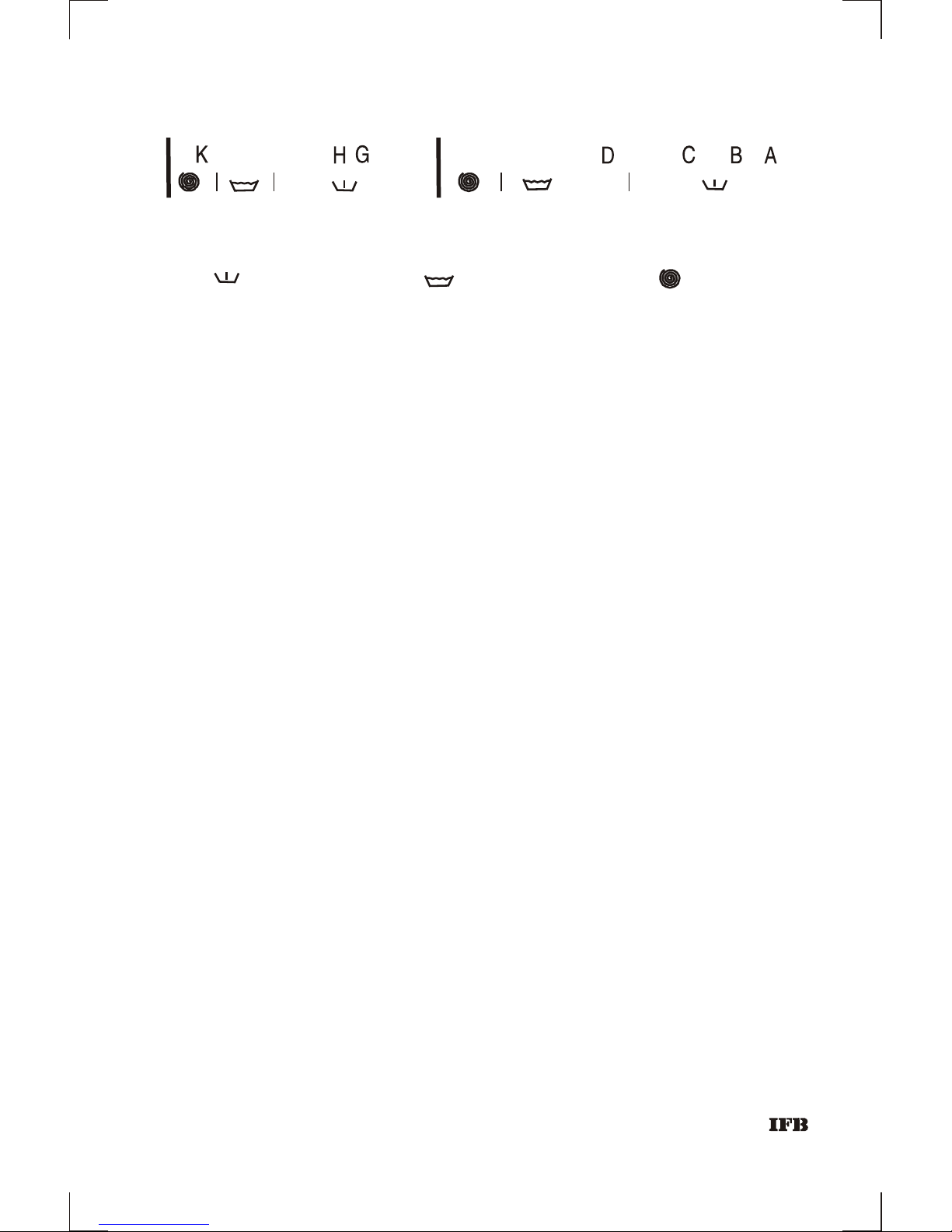

ON-OFF SWITCH / PROGRAMME SELECTOR KNOB

DETERGENT DISPENSER TRAY

7

AUTOMATIC DETERGENT DISPENSER TRAY

Designed for automatic dispensing of detergent. The Detergent

Dispenser Tray should be filled with recommended detergent quantity

before the start of a programme.

The detergent tray must be pulled out, filled as required and shut before

the machine is switched on.

ON - OFF SWITCH / PROGRAMME SELECTOR KNOB

To switch ON the machine and to select the right programme as per

the fabric being washed and extent of soilage.

qA choice of 10 programmes is available to wash different kinds / loads

of clothes.

qProgramme selection should be done before the machine is switched

ON.

qTHE STARTING POINT OF PROGRAMME NEEDS TO BE SELECTED

BY SHIFTING THE PROGRAMME SELECTOR KNOB ADJACENT

TO PRINTED LETTERS. OPERATING THE MACHINE BEYOND

PRINTING ZONE MAY RESULT IN HIGHER CONSUMPTION OF

WATER & ELECTRICITY AND WILL NOT IMPROVE WASH

QUALITY.

qMachine should be switched on by gently pulling out the programme

selector knob.

qAfter initiating the programme, machine runs through automatically.

If for any reason you wish to change the programme switch OFF the

machine by pushing in the programme selector knob, then set the

desired programme and re-start.

qKNOB SHOULD BE TURNED ONLY IN CLOCKWISE DIRECTION.

AUTOMATIC DETERGENT DISPENSER TRAY

ON - OFF SWITCH / PROGRAMME SELECTOR KNOB

THE STARTING POINT OF PROGRAMME NEEDS TO BE SELECTED

BY SHIFTING THE PROGRAMME SELECTOR KNOB ADJACENT

TO PRINTED LETTERS. OPERATING THE MACHINE BEYOND

PRINTING ZONE MAY RESULT IN HIGHER CONSUMPTION OF

WATER & ELECTRICITY AND WILL NOT IMPROVE WASH

QUALITY.

8

PROGRAMME SELECTION

Symbols of the Programme Selector

Wash Rinse Spin

1. Normal wash programme A to E

To be used for whites and coloureds of cotton or predominantly

of cotton in case of mixed load.

STAGE I : Main Wash - A/B/C

qClothes are soaked, tumbled in hot water with detergent to remove

dirt. Before draining dirty water,it is cooled down by adding cold

water. Clothes are tumbled to expose more surface, squeezed by

spinning to remove dirt inside the fabric.

qIF CLOTHES ARE NOT VERY DIRTY, THE WASH CYCLE CAN BE

STARTED BY DIRECTLY SETTING THE PROGRAMME SELECTOR

KNOB AT POINT B, OR C TO REDUCE WASHING TIME.

STAGE II : Rinse - D

qAfter washing, the rinsing is done automatically four times to

remove traces of detergent and dirt from clothes.

qFor most efficient rinsing, two intermittent shorts spin are provided.

STAGE III : Spin Drying : E

qSpin drying takes place at 600 rpm.

PROGRAMME SELECTION

Symbols of the Programme Selector

1. Normal wash programme A to E

J E

9

2. Easy Care Programme : G to K

To be used for easycare fabrics like polyester blends or predominantly

having such fabric in mixed load.

STAGE I : Main Wash : G/H

qClothes are soaked, tumbled in hot water with detergent for lesser

duration than main wash of Normal wash programme before

draining of dirty water, it is cooled down by adding cold water.

Clothes are tumbled to expose more surface, squeezed by spinning to

remove dirt from the fabric.

STAGE II : Rinse : J

qAfter washing the rinsing is done automatically three times to

remove traces of detergent and dirt from clothes.

STAGE III : Spin Drying : K

qSpin drying takes place at 600 r.p.m.

Exclusive spin drying programmes : E & K

qCan be used for spin drying hand washed/wet clothes.

qTurn programme selector knob directly to the spin drying points after

loading the clothes.

qSwitch ON the machine.

Note:

IN CASE ELECTRICITY/WATER SUPPLY GOES OFF,THE MACHINE

STOPS AND STARTS AGAIN FROM THE SAME POINT,

AUTOMATICALLY, ON RESUMPTION OF ELECTRICITY/WATER

SUPPLY.

2. Easy Care Programme : G to K

10

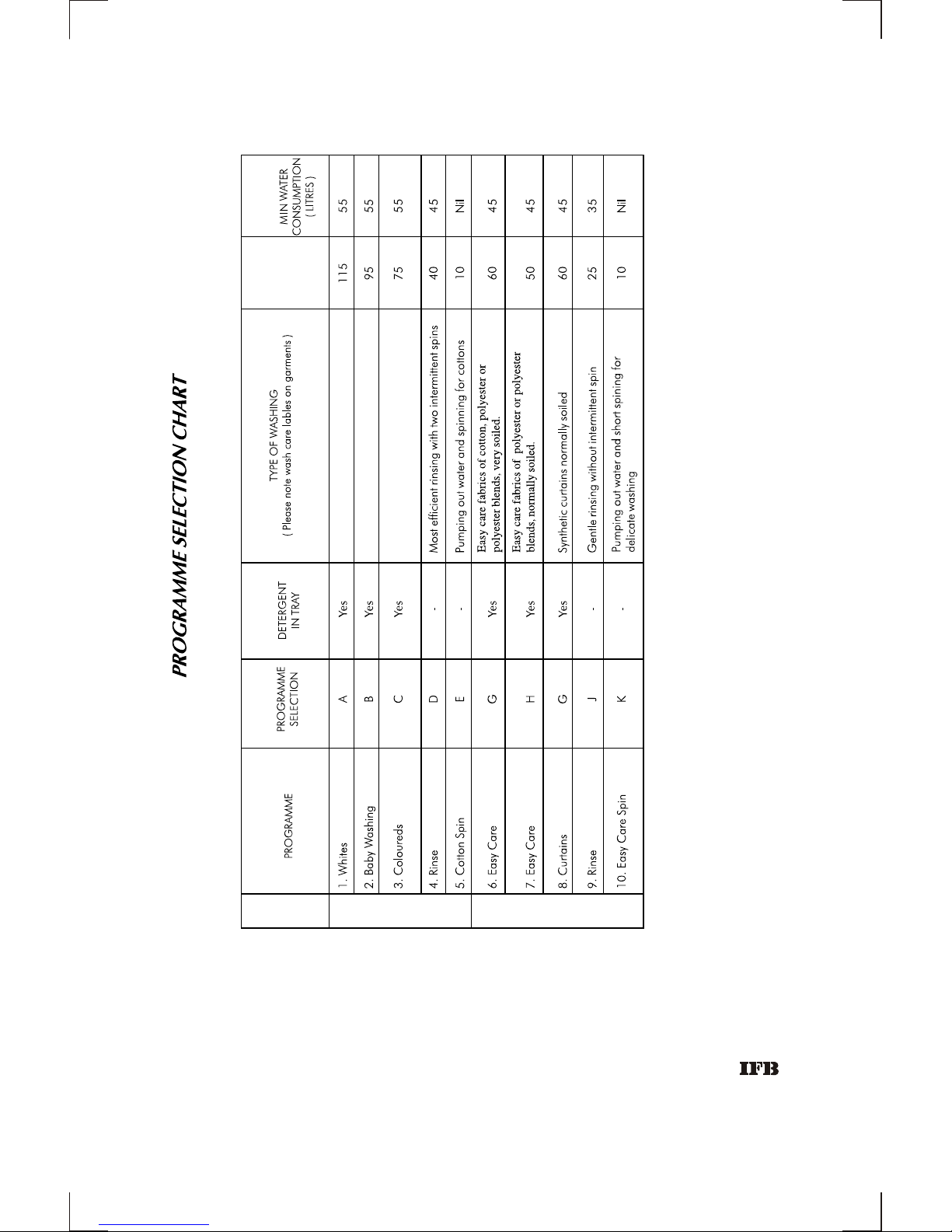

COMPLETE

CYCLE TIME

(MINUTES)

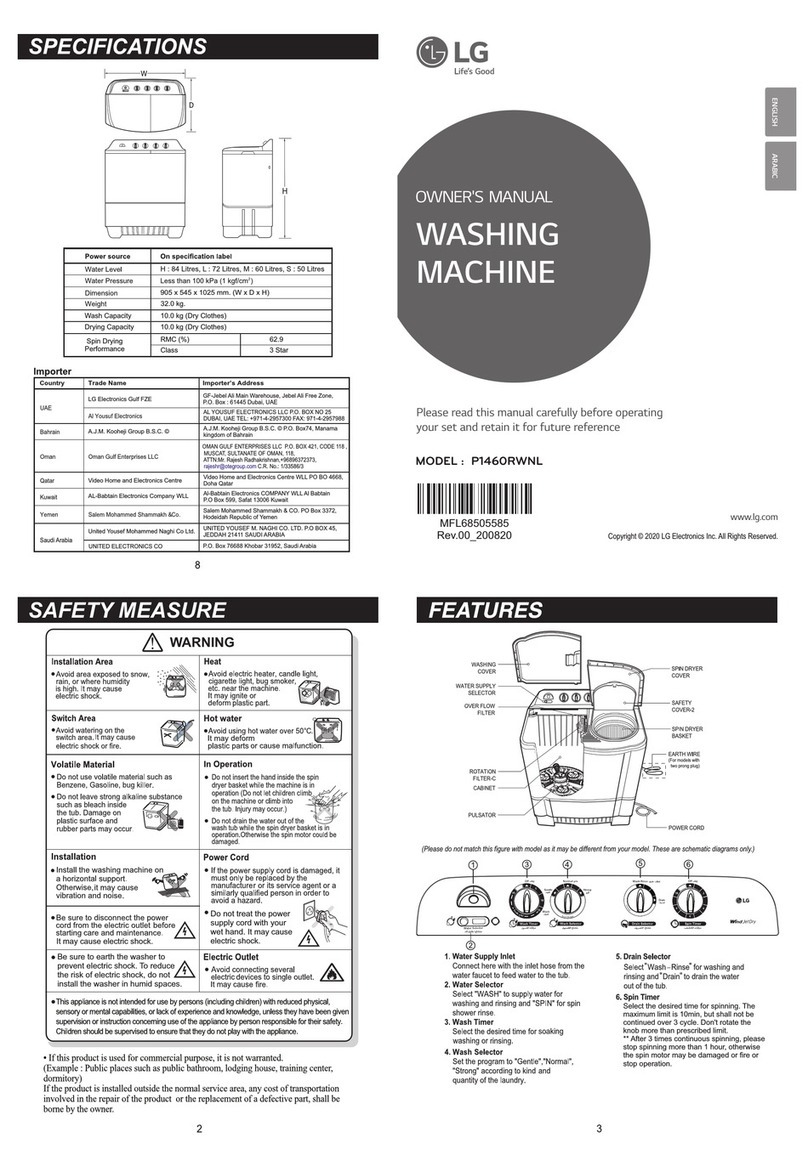

Refer detailed Programme Chart given below showing 10 fully automatic wash programes.

EASY CARE 2.5 KG MAX. COTTON 5 KG MAX CAPACITY

Note:

Cycle time does not includes water filling time.

Water consumption does not include the quantity of water taken during cool down time

and additional water filling time.

The above values are under standard test conditions.

Very soiled cotton, or boil - proof linen

Normally soiled, non boil - proof baby washing

Cotton fabrics or linen which are colour fast.

non boil - proof ( 2.5 Kg Max. )

( 2.5 Kg Max. )

OPERATION

SORTING OF GARMENTS

qMachine to be used for machine washable fabrics only (Look for wash

symbols given on your garments.)

qNon-fast coloured should be washed with like colours only. Wash

whites separately from colours.

qCheck the pockets for any loose articles like coins, keys, keychain etc.

Remove these articles as these can damage the drum/tub.

qDo not mix clothes that give lint with clothes that attract lint (e.g. lint

givers-woollens, socks, coarse cotton fabrics etc. Lint takers - synthetic

fibres and corduroys).

OPERATION

SORTING OF GARMENTS

LOADING THE MACHINE

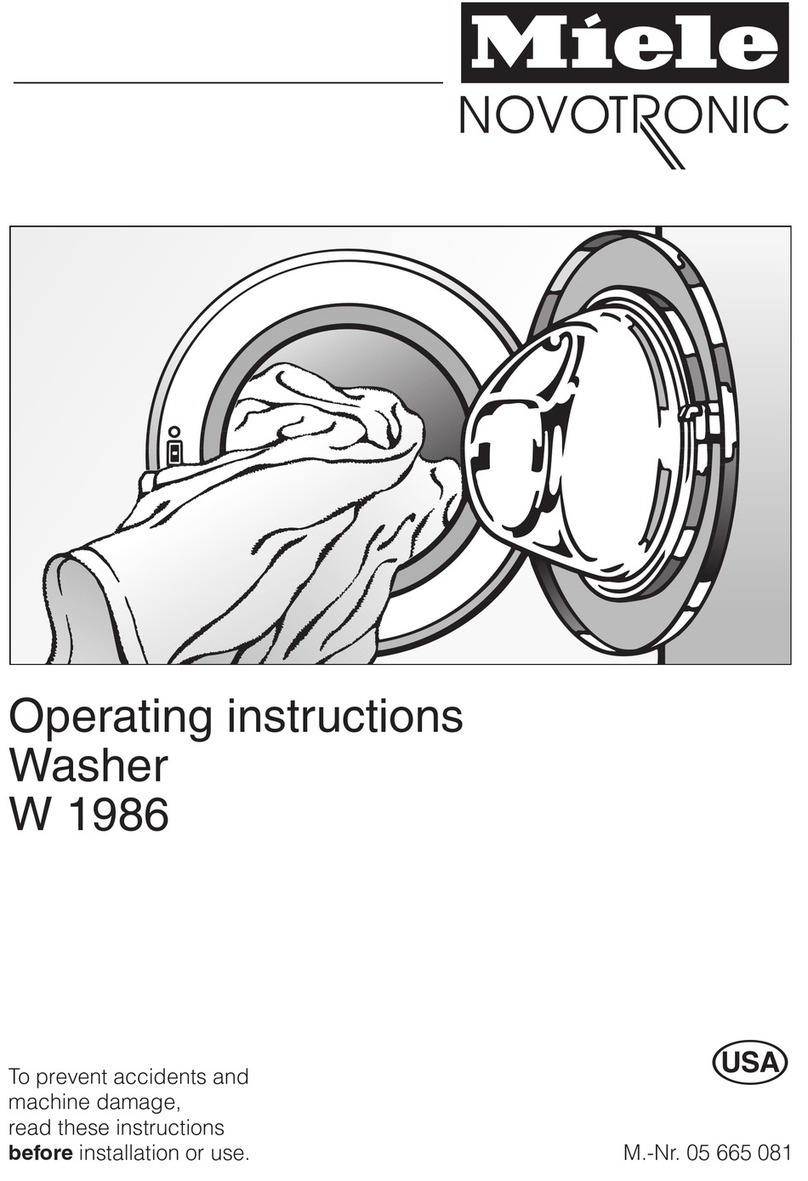

qOpen the front porthole door, place garments

loosely inside drum. For best results load garments

one by one, preferably mix of large and small

clothes.

qTurn knitted garments inside out,remove loose

hooks, rings and pins found on curtains etc.

Or

Tie a knot around them with the garments itself.

qClose door and press till you hear a click. Ensure

that no cloth is jammed between door and rubber

gasket of frame.

qFor large garments like bed covers and curtains

etc. open out the garments and hold from the centre

to load.

qEnsure that volume of load allows the clothes to

tumble freely in the drum for best wash results.

qOver-loading the drum will affect wash quality. It

can also damage the machine and clothes in the

long run.

qRunning the machine underloaded may cause

excessive vibration, noise and damage.

LOADING THE MACHINE

Close door and press till you hear a click. Ensure

that no cloth is jammed between door and rubber

gasket of frame.

11

DETERGENT TO BE USED AND QUANTITY

qThe best results will be achieved using correct amount of washing machine

detergent .

qApproximate quantities to be used:

Fullload i.e. 5kgs Detergents to be used as per direction

indicated by the manufacturer on their package.

Half Load

i.e. 2.5 kg and below Use 20 to 25% less detergent

qLiquid detergents can be used.

qHard water and heavily soiled clothes require more than the recommended

quantity of detergents.

qFrequent use of insufficient detergent will be noticeable as follows:

- Washing appears grey or not properly clean

- Grey - brown stains form on the washing

qExcess use of detergent will result in

- Higher environment pollution

- Generation of too much foam

- Scale builds up

TREATMENT OF STAINS

qStains need to be treated immediately when they are fresh. Usually stains are

catagorised as absorbed stains, built-up stains, and compound stains.

qAbsorbed stains can be removed by rubbing gently a pad containing a

suitable solvent over the stain from outer edge towards centre by keeping

stained cloth on absorbent fabric.

qBuilt up and compound stains may be removed by first carefully brushing

off stained area. Then rub gently with a pad containing solvent from the back

of fabric.

qIt is advisable to try out the solvent on hidden part of the garment to verify its

effect on cloth.

DETERGENT TO BE USED AND QUANTITY

TREATMENT OF STAINS

12

13

14

15

PROGRAMME RUN

Note :

qDuring the programme run the knob turns automatically in the

clockwise direction only.

qWashing, rinsing and spining can be seen through the porthole window.

qAt any moment the position of the knob with respect to its start

position shows how far the programme has advanced.

qThe starting point is just beyond the thick line on the knob.

SWITCHING OFF THE MACHINE

qThe wash ends automatically at the end of each programme at the

thick line on the knob

qTo switch the machine OFF push in the programme selector knob

qPorthole door can be opened only after 90 seconds

qRemove clothes from Inside the machine

qLeave door slightly ajar to dry out the inside of the machine.

CHECK POINTS

Before switching your machine ’ON’ check...

qThe machine is connected to a 220V, 50Hz supply with proper earthing.

qThe water inlet stopcock is fully open.

qThe hoses are not bent or twisted

qDry clothes are loaded into the machine drum, and door is closed firmly

with a click

qThe required amount of detergent is filled in the detergent dispenser tray.

qAfter completing the above check points the machine should be

switched ON by gently pulling out the programme selector knob.

qThe programme Selector knob is turned to the appropriate position in a

clockwise direction only.

qThe Fluff Filter/Drain Hose is not open.

PROGRAMME RUN

SWITCHING OFF THE MACHINE

CHECK POINTS

16

Open door flap by pressing on the right hand

edge and pull out the plastic tray.

17

DRUM

Rust Stains

Never leave metal items e.g. paper clips, pins etc. in the

drum as there is a danger of rusting. If there are any rust

stains remove with a non-chlorine agent. Special non-

metal sponges (never use steel wool) may also be used

SIEVES

Cleaning of Water connection Sieves, filter

1. Turn off Taps. Disconnect Power supply to the

machine. Unscrew inlet hose from machine as well

from the tap and drain out water from the hose.

2. Pull the sieve out of the magnetic valve with a pair of

flat nosed plier and clean under running water with a

brush. Fit Sieve back to the Valve.

3. Remove the filter mesh from the tap end of the inlet

hose and clean under running water with a brush.

4. Fit the filter mesh back to inlet hose.

5. Screw inlet hose back to the machine and the tap.

Ensure that both the sieves and the filter are in place.

6. Turn on the tap.

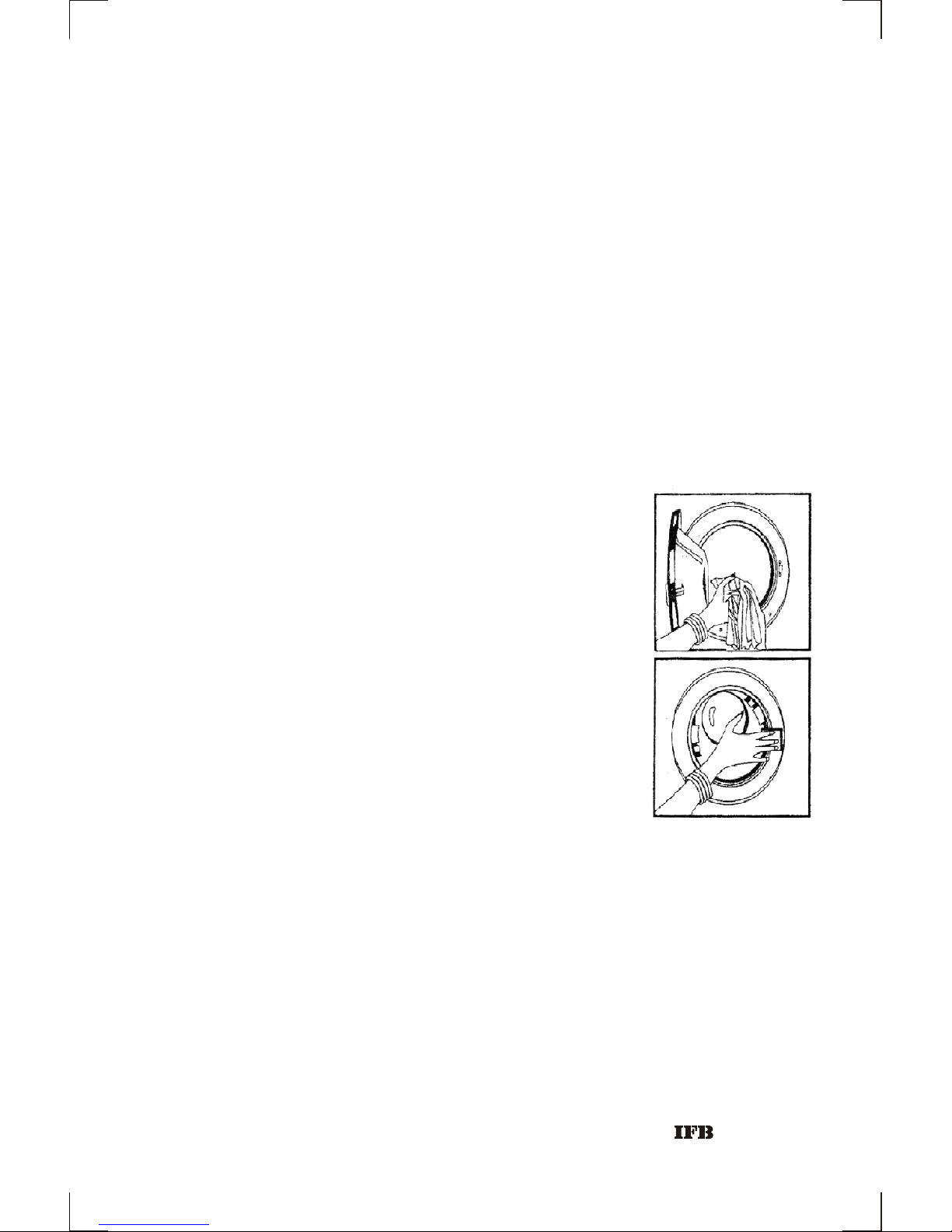

Cleaning of Porthole Door Area:

qAfter every wash clean vapour off porthole door.

qLift the fold in the rubber gasket under porthole

periodically to remove lint and dirt preferably after

every wash.

DRUM

Rust Stains

SIEVES

Cleaning of Water connection Sieves, filter

FROST PROTECTION

If the machine is being operated in very cold temperature, all the water

should be drained out after use.

qRemove Fluff Filter.

qLocate the drain hose and drain the water.

qDisconnect inlet hose from the tap and drain.

DRAINING DURING EMERGENCIES

Incase of a long power faliure during a programme run, the water can be

drained from the drum through the drain hose

qAllow the water in the machine to cool down sufficiently.

qLocate the drain hose and pull out the drain hose to drain water in a

large shallow container.

qBefore restarting machine, ensure that drain plug is fixed on drainhose

properly and fluff filter water line is filled with water by running the

machine without any clothes or detergents.

qSpillage of water can rust the base plate. Draining through drain hose

prevents rusting.

FROST PROTECTION

DRAINING DURING EMERGENCIES

18

FAULT DIAGNOSIS

WHY DOES IT HAPPEN ?

WATER DOES NOT ENTER MACHINE/DETERGENT NOT BEING

FLUSHED INTO DRUM.

qCheck water supply

qPorthole door not firmly closed

qWater tap not turned on

qBent inlet hose

qSieve on inlet valve clogged

SUDS ESCAPING FROM DETERGENT DISPENSER TRAY.

qDetergent used is not a washing machine detergent

qExcessive detergent used

WATER LEAKAGE FROM THE MACHINE.

qInlet / Outlet hose connection loose

qFluff Filter not screwed on properly

qInlet hose leaking

qDrain plug not fixed properly onto Drain hose.

MACHINE DOES NOT DRAIN.

qFluff Filter clogged

qOutlet hose end above 1 meter from floor level

MACHINE VIBRATES STRONGLY DURING SPINNING.

qMachine not levelled properly

qClothes not loaded as instructed

qwater not drained completely

MACHINE DOES NOT START.

qCheck position of programme selector knob

qCheck water supply

qPorthole door not closed properly

MOTOR NOISE.

qIt is normal for noises to be heard while motor is running. However

wash load, belt tension and motor mounting bolt should be

checked for specified limits.

PUMP NOISE.

qIt is normal for noises to be heard from the pump during the start-

up and final stage of draining. However check for fluff filter

clogging.

FAULT DIAGNOSIS

WHY DOES IT HAPPEN ?

WATER DOES NOT ENTER MACHINE/DETERGENT NOT BEING

FLUSHED INTO DRUM.

SUDS ESCAPING FROM DETERGENT DISPENSER TRAY.

WATER LEAKAGE FROM THE MACHINE.

MACHINE DOES NOT DRAIN.

MACHINE VIBRATES STRONGLY DURING SPINNING.

MACHINE DOES NOT START.

MOTOR NOISE.

PUMP NOISE.

19

SAFETY PRECAUTIONS

1. Ensure that the machine is properly balanced on four adjustable feet.

2. Ensure that the machine is connected to 3 pin socket with earth and

16 amps fuse.

3. The machine is tested with water during assembly for performance

checking. Condensed droplets of water may remain inside the

0

drum. It is advisable to run the machine without wash load at 50 C

with detergent for the first time after installation.

4. The programme knob should be turned clockwise only.

5. Programme selection must be done prior to switching on the

machine. For resetting of programme, switch off the machine, select

the programme and re-start. Do not operate the machine beyond the

printed zone.

6. Servicing should be handled by the Company’s authorized

personnel only.

7. Check for the end of the programme before opening porthole door.

The door can be opened about 90 seconds after the wash cycle is

over or machine is switched off. This is a safety feature. The door

should not be forced open.

8. Check label on garments for determining conditions under which

fabrics are to be washed.

9. Use detergent recommended for washing machine.

10. Ensure that the electrical line on which the machine is used can take

the required load.

11. Check the inside of drum before loading the clothes.

12. Protect the machine from direct sunlight and do not splash water on

it. Clean with a damp cloth.

13. Keep your machine dry to avoid corrosion / rusting. Take special

care to wipe the machine after cleaning fluff filter.

14. The machine should ideally be installed on the floor, it can be

installed on any suitable platform or trolley, if desired by the

customer.

15. Clean the shell lower and detergent tray periodically by taking out

the detergent tray.

16. Incase of plastic tabletop do not use the tabletop as an ironing

board or for placing heavy items.

SAFETY PRECAUTIONS

Other manuals for Diva

1

Table of contents

Other IFB Washer manuals

IFB

IFB Eva VX 700RPM User manual

IFB

IFB EVA-VX 5.5; Elena Aqua SX 6.0 User manual

IFB

IFB EXECUTIVE PLUS WTEX+B User manual

IFB

IFB SENORITA PLUS User manual

IFB

IFB Diva User manual

IFB

IFB Executive Plus User manual

IFB

IFB AW60-90210 User manual

IFB

IFB ELENA User manual

IFB

IFB AW60-806 User manual

IFB

IFB ELENA User manual

IFB

IFB Senator User manual

IFB

IFB AW6501SB User manual

IFB

IFB WASHER 9KG DRYER 7KG User manual

IFB

IFB Elite 5 Kg User manual

IFB

IFB TL-REG 6.5 KG AQUA User manual

IFB

IFB Senorita Dx User manual

IFB

IFB Executive Elite User manual

IFB

IFB Digital User manual

IFB

IFB Elite SX Series User manual

IFB

IFB Digital User manual