ifi T251-500A Manual

Prepared by:

Instruments for Industry

903 South Second Street

Ronkonkoma, NY 11779

Phone 631 467-8400

Fax 631 467-8558

OPERATING AND MAINTENANCE

INSTRUCTIONS

MODEL T251-500A

HIGH POWER TWT AMPLIFIER

DOCUMENT NUMBER

T251-500A Rev.A

SERIAL NUMBER

Prepared for: Advanced Test Equipment S/O #

10401 Roselle St. P/O #

San Diego, CA 92121

Phone: 858-588-6500

Rev. A 10/01/08

2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 INTRODUCTION ............................................................................................................................... 3

2.0 GENERAL DESCRIPTION................................................................................................................ 4

3.0 WARRANTY INFORMATION ....................................................................................................... 10

4.0 GENERAL INFORMATION

4.1 Scope Of This Manual......................................................................................................... 11

4.2 Operation Overview ............................................................................................................ 11

4.3 N/A

4.4 General Specifications......................................................................................................... 12

4.5 Functional Description ........................................................................................................ 12

4.6 Protection Circuits............................................................................................................... 13

4.7 Status Indicators, Controls and Connectors......................................................................... 13

4.8 Data Sheets ................................................................................................................. 16

5.0 PRINCIPLES OF OPERATION

5.1 Proper Usage And Warnings............................................................................................... 17

5.2 Features ................................................................................................................ 17

6.0 IEEE-488 INTERFACE OPTION

6.1 Introduction ......................................................................................................................... 18

6.2 Remote Initialization ........................................................................................................... 18

6.3 GPIB Address...................................................................................................................... 18

6.4 IEEE-488 Commands.......................................................................................................... 19

RS 232 ................................................................................................................. 21

7.0 MAINTENANCE AND SERVICING

7.1 Periodic Maintenance .......................................................................................................... 22

7.2 Servicing The Amplifier...................................................................................................... 22

7.3 Equipment Return Procedure............................................................................................... 23

LIST OF FIGURES

FIGURE DESCRIPTION PAGE

1.0 TWTA ILLUSTRATION ................................................................................................................... 3

2.0 FRONT DISPLAY PANEL START UP MENU ................................................................................ 5

3.0 FRONT DISPLAY PANEL GPIB ADDRESS MENU....................................................................... 6

4.0 FRONT DISPLAY PANEL OPERATE MENU................................................................................. 7

5.0 FRONT DISPLAY PANEL WARM UP TIME.................................................................................. 8

6.0 FRONT DISPLAY PANEL OPERATE MODE WITH RF POWER INDICATION ........................ 9

7.0 SYSTEM BLOCK DIAGRAM......................................................................................................... 11

8.0 REAR PANEL ILLUSTRATION..................................................................................................... 14

LIST OF APPENDICES

SECTION APPENDIX DESCRIPTION PAGE

8.0 A DATA SHEETS.................................................................................................... 24

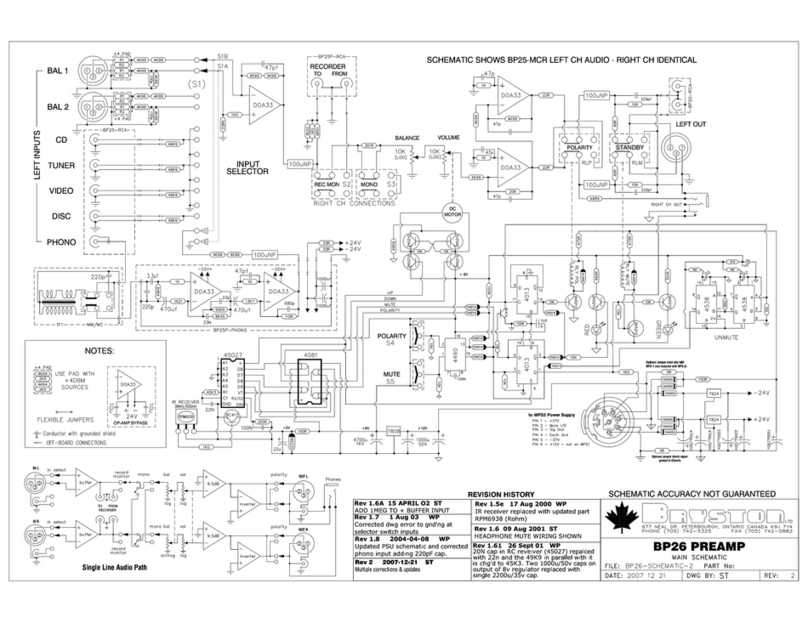

9.0 B DRAWINGS ......................................................................................................... 25

Rev. A 10/01/08

3

SECTION 1.0

INTRODUCTION

Congratulations on the purchase of your new Wide Band Amplifier from Instruments For Industry,

Inc. Your new Wide Band Amplifier incorporates the finest advancements in the state of the art

electronics technology available in a compact, portable and versatile package. Your Wide Band

Amplifier's quality, performance and trouble free operation depends on you thoroughly reading

through this manual and familiarizing yourself with its proper operation and usage.

Your Wide Band Amplifier comes with the following accessories, be sure to check your packaging

for the items listed below before disposing of the packaging.

CONTENTS

( For a typical Wide Band Amplifier )

Quantity Description

1 TWT High Power Wide Band Amplifier, P/N T251-500A

1 Mating Connector, Power Line

1 Operation and Instruction Manual

1 Data Sheets (Included in Manual )

FIGURE 1.0

OUTLINE DRAWING

Rev. A 10/01/08

4

SECTION 2.0

GENERAL DESCRIPTION

The Instruments For Industry, Inc. ( IFI ) manufactured TWT Wide Band Amplifier is a Bench Top

or rack mount amplifier providing a nominal 500 Watts of RF power from 0.8 to 2.5GHz, with output

power of at least 500 Watts. The minimum saturated output power midband of the operating

frequency range is more than 500 Watts.

The Amplifier features an 8 Line Liquid Crystal Display ( LCD ) that displays continuous forward

and reflected power metering. The display also provide the operator with operating status and self

diagnostic fault indications.

The Amplifier incorporates protection circuits that monitors and controls so the amplifier cannot be

damaged by any mismatched load.

The Amplifier has an IEEE-488 BUS interface which allows the amplifier to be remotely controlled

through the use of a computer and a GPIB BUS.

To operate the Amplifier , connect a three phase power line ( 115 or 230 Vac line to line ), [or a

single phase as specified by the customer] to the Power line MS connector on the rear panel as

shown

Single Phase Connection.

PIN A - PHASE

PIN D – NEUTRAL

PIN E – GROUND

Three Phase Connection.

PIN A – PHASE A

PIN B – PHASE B

PIN C – PHASE C

PIN D – NEUTRAL

PIN E – GROUND

Rev. A 10/01/08

5

TWTA Controller Operation

A) Apply power to the unit using the front panel ON/OFF switch. Start.

Figure 2.0, Front Panel Display – Start-Up Menu

Start-Up Menu

When the circuit breaker or AC power on switch is energized, the above menu will be displayed after

the MPU booting cycle. This menu displays the company information, the amplifier model number

and serial number along with the firmware version used.

From this menu, by selecting the GPIB ADDR button a GPIB address can be set by the control knob

as seen in figure 2. After the address is set, press the RETURN key to return to the main menu.

Rev. A 10/01/08

6

Figure 3.0 Front Panel Display – GPIB address Menu

The Start-up menu will be replaced by Operate menu after about 5 seconds.

Rev. A 10/01/08

7

Figure 4.0 Operate Menu

Rev. A 10/01/08

8

Figure 5.0, Front Panel Showing Warmup time

1. Press the ON Key. The unit will display “FILAMENT WARMUP” and will start the

countdown as set per TWT used. At this mode the Filament, Collector and Grid (if applicable)

supplies will be energized.

2. After the time out, if no faults exist the STB mode will be displayed.

Rev. A 10/01/08

9

Figure 6.0 Front Display Panel Showing Operate Mode with RF Power Indication

1. Place the unit in Operate (OPR) mode. At this mode the TWT will be turned ON.

2. The display will show the Helix and Collector, Voltages and Currents as per TWT operating

data sheet (enclosed in the manual).

Rev. A 10/01/08

10

SECTION 3.0

WARRANTY INFORMATION

Instruments For Industry, Inc. (IFI) warrants each product of its manufacture to be free from any

defect in material and workmanship for a period of three years from shipment to the original

purchaser. All warranty returns, however, must first be authorized by our factory office

representative. Refer to the Service Section for information on how to return items for warranty

repair.

Warranty liability shall be limited to repair or replacement of, or part thereof, which proves to be

defective after inspection by IFI. This warranty shall not apply to any IFI product that has been

disassembled, modified, physically or electrically damaged or any product that has been subjected to

conditions exceeding the applicable specifications or ratings.

IFI shall not be liable for any direct or consequential injury, loss or damage incurred through the use,

or the inability to use, any IFI product.

IFI reserves the right to make design changes to any IFI product without incurring any obligation to

make the same changes to previously purchased units.

This warranty is the full extent of obligation and liability assumed by IFI with respect to any and all

IFI products. IFI neither makes, nor authorizes any person to make, any other guarantee or warranty

concerning IFI Products.

Rev. A 10/01/08

11

SECTION 4.0

GENERAL INFORMATION

4.1 SCOPE OF THIS MANUAL

This manual is intended to inform a qualified transmitter operator or technician of the normal

operating and maintenance procedures for the TWT Amplifier. It is not intended to be a course of

instruction for unqualified personnel.

4.2 OPERATION OVERVIEW

The Amplifier is designed to amplify a low level microwave signal and supply a high power CW

output. The Amplifier system function is accomplished primarily through the use of a Traveling

Wave Tube (TWT), control circuitry and power supplies, which can be controlled either locally or

remotely. The major subassemblies are mounted on two separated decks. The upper deck houses the

Collector supply, Filament supply, TWT, control circuitry and all the RF components. The lower

deck houses the Helix supply.

FIGURE 7.0

SYSTEM BLOCK DIAGRAM

Rev. A 10/01/08

12

4.4 GENERAL SPECIFICATIONS

The specifications listed below represent the minimum performance characteristics at the time of

delivery.

SPECIFICATIONS

Frequency Response 0.8 to 2.5 GHz (Functional)

Rated Power Output: 500 Watts minimum 1.0-2.5GHz

250-500 Watts nominal increasing from 0.8-1.0GHz

Power Gain: 57 dB, 1.0-2.5GHz

Input Impedance: Nominal 50 Ohms

Output Impedance: Nominal 50 Ohms

Input Signal Levels: < 0 dBm ( 1.0 mW ) See data sheet for specific input drive levels

Harmonics: -3dBc

Duty Factor: CW

Prime Power : 220 VAC, 50/60 Hz, Single Phase

Power Requirements: 10Amps ( less than 2.5 KVA )

4.5 Functional Description

The required voltages and currents to operate the TWT are provided by the Helix, Collector and

Filament supplies. The Helix supply provides the negative high voltage potential between TWT

Cathode and ground. The Collector supply provides the high voltage potential between the TWT

Cathode and Collector. The Filament supply provides the Heater voltage and floats at high voltage

Cathode potential. In some tubes a Grid element is used to switch the TWT beam ON and OFF.

The primary control circuitry and the service power supplies (+5V, +/-12V, + 24V) are energized

when the main circuit breaker is turned ON. Upon pressing the AMP ON switch, the Filament and the

Collector supplies are energized and a three minute warm up time is initiated. At the completion of

the three minute time out, the Amplifier then goes to STBY mode if no faults were detected. Upon

pressing the OPERATE switch the TWT is then turned ON.

Rev. A 10/01/08

13

4.6 PROTECTION CIRCUITS

The TWT Amplifier is designed with a variety of protection circuits to provide safeguards for the

amplifier should any adverse electrical conditions occur or if the amplifier accidentally experiences

operator deviation of the design application. Listed below are the safeguards.

4.6.1 Overheat Protection

The TWT, a critical component of this Amplifier, is mounted to a heat sink, which is in turn, air

cooled by high efficiency blower. Should an overheating condition occur, either through component

failure or by a restricted airflow, the Amplifier contains heat sensors that will shut down the system.

As a result, the air inlet and outlet openings should be free of obstructions for proper cooling of the

amplifier. Operation is restored by the Reset button when the amplifier cools to normal temperature

levels.

4.6.2 Power Supply Faults

The Power Supply Fault circuit monitors the Helix and Collector power supplies and produces a fault

indication should any voltage level deviate from normal operating parameters. Each power supply

voltage output is monitored and displayed. Should any power supply voltage deviate from the design

parameters, the Power Supply Fault Indication LED (RED), located on the front panel of the

Amplifier will illuminate and the related fault will be displayed on the LCD display located on the

front panel.

4.6.3 Mismatch Protection

The Amplifier is designed to operate with a tuned 50 Ohm load. Should any mismatching of the 50

Ohm load occur, the Reverse Power, also called Reflective Power, will increase, producing a high

VSWR. The Amplifier microprocessor monitors the Reverse Power levels by utilizing a Dual

Directional Coupler. When the Reflected Power exceeds 25% the Amplifier Output Power The

amplifier will go to STBY and the High VSWR message will be indicated on the LCD display. The

Reverse Power is also displayed on the LCD Display for operator monitoring for any mismatched

load.

4.7 STATUS INDICATORS, CONTROLS AND CONNECTORS

The Amplifier has various controls and status indicators which are identified below and can be

visually located on Figure 1.0, Outline Drawing and Figure 8.0, Rear Panel Illustration. A narrative

description for the function and purpose of each control and status indicator is provided within

paragraphs 4.7.1 and 4.7.2.

Rev. A 10/01/08

14

RF AMPLIFIER

Front Panel: Rear Panel:

POWER ON/OFF Ckt Bkr AC Source IEC Power Connector

Local/Remote Switch IEEE-488, Connector

Amp ON / OFF Switch RF Output, SC Female

RF Input, N Female

RF Sample, N Female

Operate / Standby Switch

Fault/Reset Switch

Control Knob

LCD Status Display

FIGURE 8.0

REAR PANEL ILLUSTRATION

Rev. A 10/01/08

15

4.7.1 FRONT PANEL STATUS INDICATORS

INDICATOR FUNCTION

Fault LED The Fault LED illuminates when either the Helix or the Collector

Power Supplies deviate from the design parameters. The Amplifier will

revert to AMP OFF mode. It also illuminates when either a Thermal or

Airflow condition occurs outside design parameters. Should an

excessive temperature condition occur while monitoring the TWT

temperature of the Heatsink, the Amplifier will revert to AMP OFF

mode. The LCD Display will indicate which fault had occurred.

Filament/Beam HOUR Elapsed time Indication on the LCD display, presents total hours that

the TWT Filament or Beam has been energized.

GPIB Remote The Remote Green LED indicates, when illuminated, that the amplifier

is in the remote control mode of operation via the IEEE-488 GBIP Bus.

The address selection can be done through the front panel using the

Control Knob. Follow instructions on the LCD display.

4.7.2 CONTROLS

CONTROL FUNCTION

Power ON / OFF Circuit Breaker to turn On/Off main prime power to the Amplifier.

Local The Local switch is a momentary switch. When depressed, the

amplifier is restored to the local control from the Remote mode of

control.

Amp ON/OFF The Power On/Off switch is a momentary switch which, when pressed

to ON position, Filament and Collector supplies are energized.

STBY / OPERATE Switch, when set to OPERATE mode it turns TWT Beam ON, when

set to STBY it turns TWT Beam OFF.

RESET Switch, when pressed resets Faults.

Rev. A 10/01/08

16

4.8 DATA SHEETS

Provided with each Amplifier are specific Test Data Sheets measured from the amplifier using a

calibrated 50 Ohm Pad to assist the operator in maximizing the performance of the Wide Band

Amplifier.

The accuracy of the Metering is ± .5 dB ( nominal ) so to provide the operator with the ability to

maximize the performance of the wide band amplifier.

The Test Data Sheets are located within Appendix A

Rev. A 10/01/08

17

SECTION 5.0

PRINCIPLES OF OPERATION

5.1 PROPER USAGE AND WARNINGS

5.1.1 Controlling Power Output

With a nominal 50 ohm resistive load and an input signal appropriate to produce a power output

within the limitations specified above, the amplifier may be placed in operation. To interrupt the

output, simply interrupt the input signal. The amplifier may be run indefinitely at rated output.

Output power is usually measured with a power meter and suitable power Termination.

5.1.2 Input Signal Levels

The Amplifier is designed to operate with less than a 0 dBm (1.0 mW) input signal. It is not

advisable to over drive any amplifier and depend on protection circuits to maintain proper gain

control. IFI makes available with each shipped amplifier specific data and curves so the operator will

know the proper input signal levels to more efficiently operate the amplifier, refer to Paragraph 4.7

herein.

7.2 Features

5.2.1 Preamplifier (Optional)

The Preamplifier provides the proper drive levels to the TWT to obtain the proper Output Power.

The preamplifier is powered from a low voltage power supply that is independent of the main power

supply.

5.2.1.2 Power Amplifier

The Power amplifier consists of TWT as the main amplification stage. It is powered by several

power supplies; Filament supply, Helix supply and Collector supply.

Rev. A 10/01/08

18

SECTION 6.0

IEEE-488.2 INTERFACE

6.1 INTRODUCTION

The Instruments For Industry, Inc. (IFI) Amplifiers can be operated remotely from a personal

computer having an IEEE-488 interface. This interface allows the amplifier to be remotely

controlled over the General Purpose Interface Bus (GPIB) by sending commands to the amplifier.

Additionally, amplifier status and forward and reverse power readings may be read over the GPIB.

All functions can be controlled by coded messages sent over the interface bus via the 24-pin socket

connector on the rear panel of the unit. IEEE-488.2 Standard is implemented, which defines the

protocols and syntax of commands. The GPIB command codes for the IFI Amplifier series are

discussed on subsequent pages and, for ease of identification; the command codes are identified

within the text by bold capital characters. For full information on the IEEE protocols and syntax the

IEEE-488.2 Standard should be consulted.

6.2 REMOTE INITIALIZATION

When the amplifier receives a command over the GPIB, it automatically switches to REMOTE

operation, pressing the LOCAL key on the front panel returns the unit to normal manual local

operation.

6.3 GPIB ADDRESS

The GPIB address of the amplifier is set by via the Front panel using the Control knob at the start up

menu.

NOTES ON USING NATIONAL INSTRUMENTS' GPIB CONTROLLERS:

In order for the amplifier to operate correctly with a National Instruments GPIB controller card, the

following must be done: (Items 1-5 are done in the IBCONF program.)

1. Set "Terminate reads on EOS" to yes.

2. Set "Set EOI with EOS on Writes" to yes.

3. Set the EOS byte to 0Ah (an ASCII line feed character).

4. Set "Send EOI at end of writes" to yes.

5. Set "Enable repeat addressing" to yes at the board level.

6. When sending command strings to the amplifier, a carriage return character (0Dh) followed by a

line feed character (0Ah), must always be appended to the command, otherwise the amplifier will

wait indefinitely for the CR-LF combination. If this happens the unit will have to be powered off

and back on to reset this condition. (The interface device will automatically assert the EOI line

during the LF if items 2 - 4, above, are set to yes in the IBCONF program.) As an example,

when issuing the zero attenuation command using the IBIC or WIBIC program, the command

string would look like this: "ZA\r\n". (The \r is National Instruments' notation for the carriage

return, and the \n is the line feed or 'new line' character.) Notice that the commands are upper

case only.

Rev. A 10/01/08

19

6.4 IEEE COMMANDS FOR TWTA

CODE TWTA FUNCTION

OFF AMP OFF

ON AMP ON

STBY Standby

OPRT Operate

RESET Fault Reset

ATTUxx Increase Attenuation (xx- # of steps) [Response with Attenuator

value](optional)

ATTDxx Decrease Attenuation (xx- # of steps) [Response with Attenuator

value](optional)

REQUEST STATUS

Code AMPLIFIER STATUS

STATUS OFF

ON

STANDBY

OPERATE

FAULT

REMOTE OPERATION DISABLED

INTERLOCK OPEN

EXCESS PULS W

EXCESS DTY CYC

FAULT RETURNS DETAILED MESSAGE

THERMAL FAULT

HIGH VSWR

HIGH HELIX CURRENT FAULT

HELIX VOLTAGE FAULT

COLLECTOR CURRENT FAULT

COLLECTOR VOLTAGE FAULT

LOW AIRFLOW FAULT

Rev. A 10/01/08

20

REQUEST AMPLIFIER STATUS

(POWER AND METERING)

CODE TWTA FUNCTION

POWERFWD Returns Forward Power Value

POWERRFL Returns Reflected Power Value

HELIXV Returns Helix Volts Value

HELIXI Returns Helix Current Value

COLLV Returns Collector Volts Value

COLLI Returns Collector Current Value

FILAMENTV Returns Filament Volts Value [ Optional ]

GRIDV Returns Grid Volts Value [ Optional ]

FILAMENTH Returns Filament Hours Value

BEAMH Returns Beam Hours Value

PULSEW Returns Pulse Width Value [ In Pulse unit only ]

FRQNCY Returns Pulse Frequency Value [ In Pulse unit only ]

DUTYCYC Returns Duty Cycle Value [ In Pulse unit only ]

*IDN? Returns ASCII response comprising of four data fields in the format

<Manufacturer>, <Model>, <Serial Number>, <Firmware Version>

*RST Reset Command, Sets the Amplifier to the factory default power up state

NOTES:

1. ALL GPIB COMMANDS AND REQUESTS MUST CONSIST ENTIRELY OF UPPER CASE

ALPHANUMERIC CHARACTERS.

2. WHEN SENDING COMMAND STRINGS TO THE AMPLIFIER, A CARRIAGE RETURN

CHARACTER (0Dh) FOLLOWED BY A LINE FEED CHARACTER (0Ah), MUST ALWAYS BE

APPENDED TO THE COMMAND, and OTHERWISE THE AMPLIFIER WILL WAIT

INDEFINITELY FOR THE CR-LF COMBINATION.

Table of contents

Other ifi Amplifier manuals