IGEBA EVO 35 User manual

EVO 35 - EVO 35 E

Справочное руководство

Instruction manual

Термомеханические аэрозольные генераторы

04/2010 1.0 3 72

:Summary ./Page

Restricted fields of application………… 4

Manufacturer and Distributor…………

…

5

Warranty………………………………… 6

Declaration of conformity……………… 7-8

Mode of operation……………………… 9

Notes on the instructional manual……

…

10

: Safety instructions – product liability…

…

11-14

Warning and safety notes……………

…

15 - 17

CE/

CE Marking/short manual……………… 18

EVO 35 Functional parts EVO 35………………

…

19

Safety Instructions……………………… 20 - 26

Prepare unit ready for use……………

…

27 - 33

Starting the unit…………………………

…

34 - 35

Stopping the unit………………………

…

35 - 36

Cleaning the unit………………………

…

36 - 39

/ Cleaning the mixing chamber/mixing

pipe…………………………………….. 40 - 42

Maintenance of the pump……………… 42

Fault finding……………………………

…

43 - 52

EVO 35 E Functional parts EVO 35 E……………

…

53 - 54

Operation with Emergency-Cut-Off-

device………………………………….. 55

A

djustment of the Bowden cable……

…

56

Basic setting Emergency-Cut-Off-

device………………………………….. 57 - 58

Technical data…………………………

…

59

Manufafcturing programm……………

…

61

Spare parts list…………………………

…

62-72

04/2010 1.0 19 72

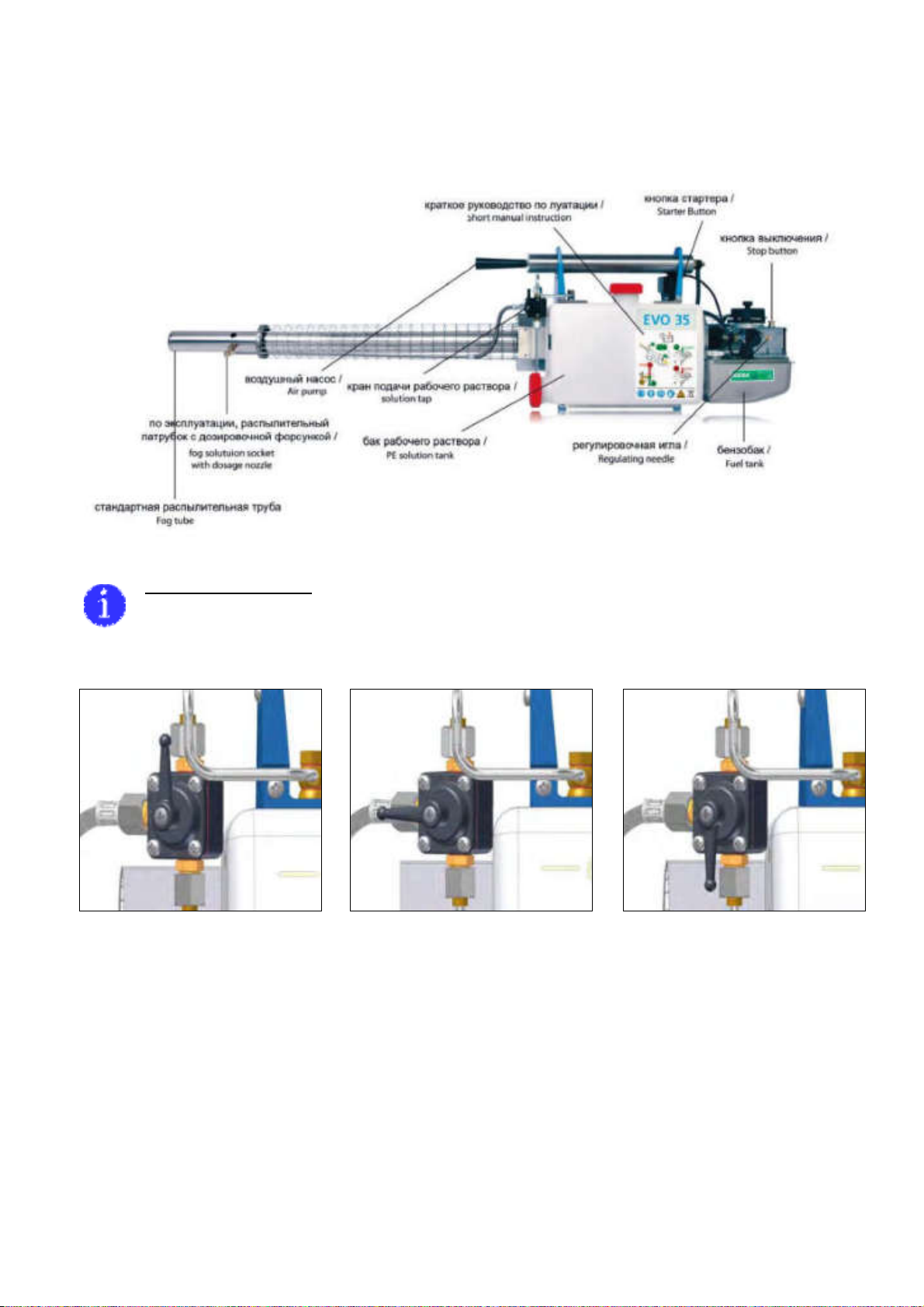

EVO 35

The important functional parts of EVO 35 at a glance

/ Notice:

Solution tap positions

– Closed - Ventilation – Open

04/2010 1.0 22 72

6.

( ..).

6. It is forbidden to fog in rooms with finest

combustible dust particles (e.g. grain silo),

because danger of dust explosion.

7.

, ,

.

7. It is forbidden to fog in enclosed rooms

where open flames, candle lights, hot

engines or electrical appliances exist,

because of fire danger.

8.

,

.

,

.

,

.

.

.

,

.

8. When fogging in enclosed rooms, take

into account that fogging can lead to fire

and explosions if the concentration of fog

in a room exceeds a crucial value. This is

due to the combustible additives of such a

fog. Follow dosing recommendations,

particularly when fogging indoors. Do not

fog longer than necessary. Application of

formulations with combustible fractions

may lead to formation of an explosive

mixture. Make yourself familiar with the

dosage of combustible additives in

enclosed rooms. Calculate the maximum

quantity of combustible additive depending

on room size, nozzle size and fogging time,

before you start fogging into enclosed

rooms.

9.

.

9. It is not allowed to transport the unit in a

closed vehicle, as long as the unit is hot.

Wait until the unit has cooled down.

10. Э

.

10. Do not leave the working unit

unattended.

04/2010 1.0 27 72

1.

:

.

(. 1, . 9)

. W

(. 1, . 10)

.

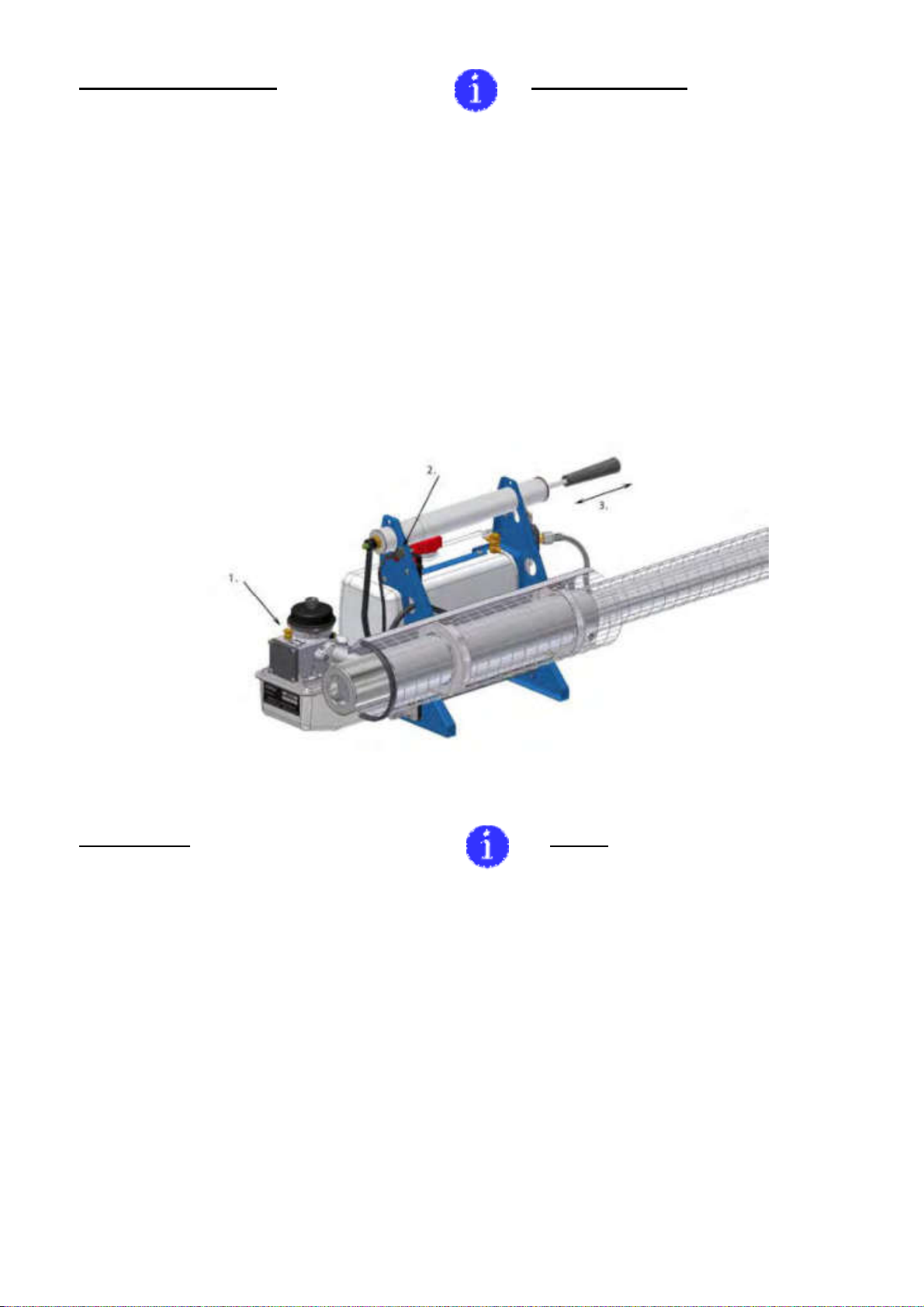

1. Prepare unit ready for use:

Due to packing reasons, the fog tube is not

mounted on the unit. The standard fog tube

(illus. 1 pos.9) must be used for oil based

formulations. The fog tube type W (iIllus.1

pos.10) must be used for water based

formulations.

. 1

() - . 68

illus. 1

SP list page 68

!

W

–

.

W

10 %

( , «»)

.

Attention!

Never use the fog tube type W for oil

based formulations, there is fire danger.

When fogging with fog tube type W,

addition of 10% special carriers (e.g.

Nebol) is allowed in order to improve the

droplet spectrum.

04/2010 1.0 28 72

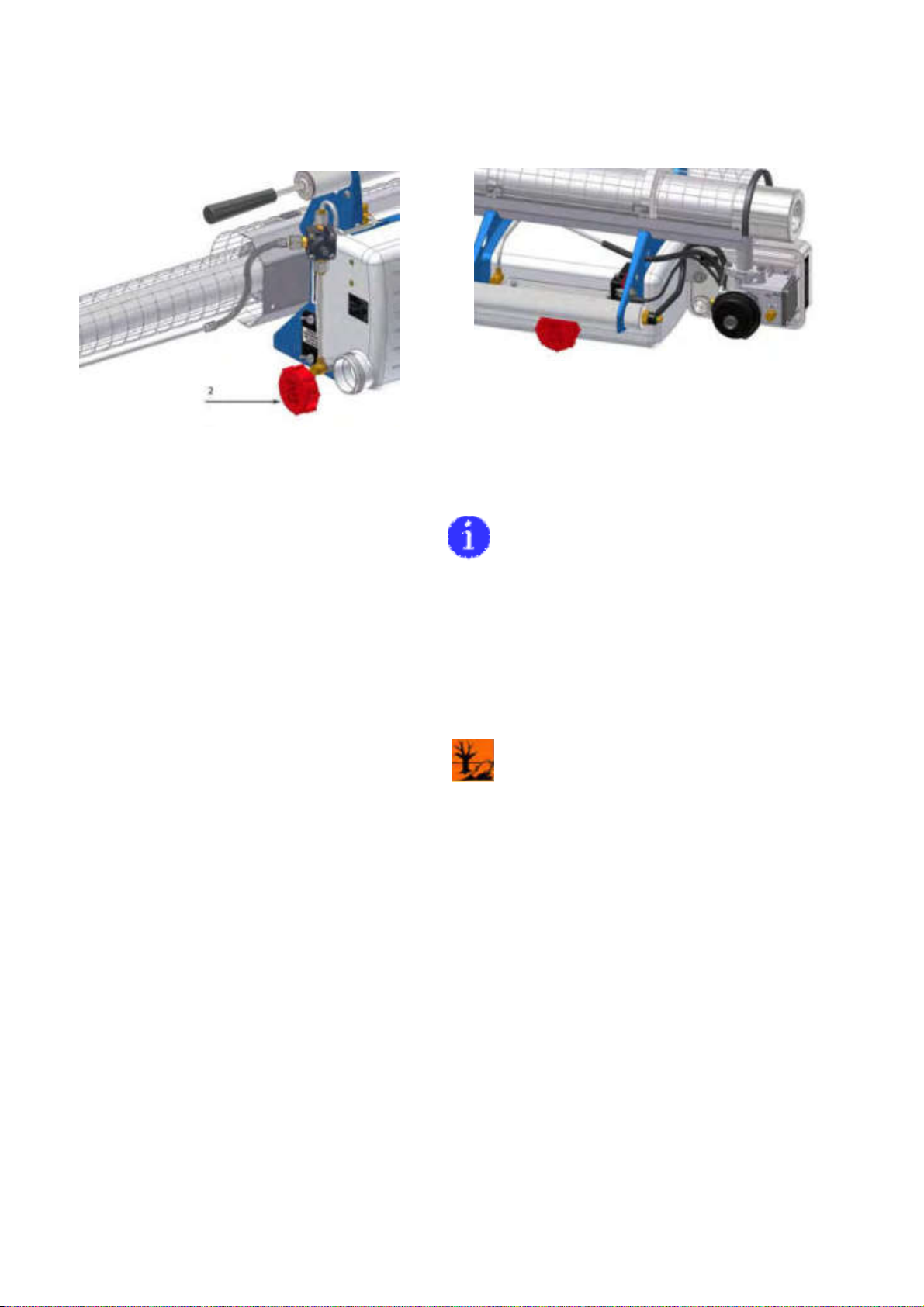

(. 2,

.11)

.

Fit the protective guard (illus. 2 pos.11) to

the end of the cooling jacket and tighten

clamp.

. 2

- . 68

illus. 2

SP list page 68

(.

3, . 9)

,

(. 3A, . 9)

.

Push fog tube (illus.3 pos.9) over the

resonator into the cooling jacket until the

hole is aligned (illus.3a pos.9) with the

screw neck to screw in the fog solution

socket.

. 3 / illus. 3

- . 68 / SP list page 68

рис. 3a / illus. 3a

СЗЧ - стр. 68 / SP list page 68

04/2010 1.0 29 72

(. 4).

(.

5). ,

(. 5).

Screw in the fog solution socket by hand

(illus. 4). Connect fog solution socket and

solution line via the dosage nozzle and

related copper gaskets (illus.5). When

tightening the dosage nozzle secure the

position of the fog solution socket with a

second flat spanner (illus.5).

. 4

- . 68

illus. 4

SP list page 68

. 5

- . 68

illus. 5

SP list page 68

04/2010 1.0 30 72

йки:

.

. (.

).

1,5 LR20

.

(. 6).

Inserting the batteries:

Remove the upper wing thumb screw

completely. It is sufficient to loosen the

lower thumb screw a few revolutions. You

can take off the battery cover now (see

note). Insert four batteries Type 1,5V LR20

with the positive pole forward inside the

unit. Mount the battery cover and tighten

thumb screws evenly by hand (illus. 6).

. 6

- . 64

illus. 6

SP list page 64

(. 7, .13)

.

.

Check ignition coil by pressing starter

button (illus. 7 pos. 13) a buzzing sound

must be easily audible.

. 7

- . 64

illus. 7

SP list page 64

04/2010 1.0 31 72

,

> 75.

е .

(. 8, . 2).

,

.

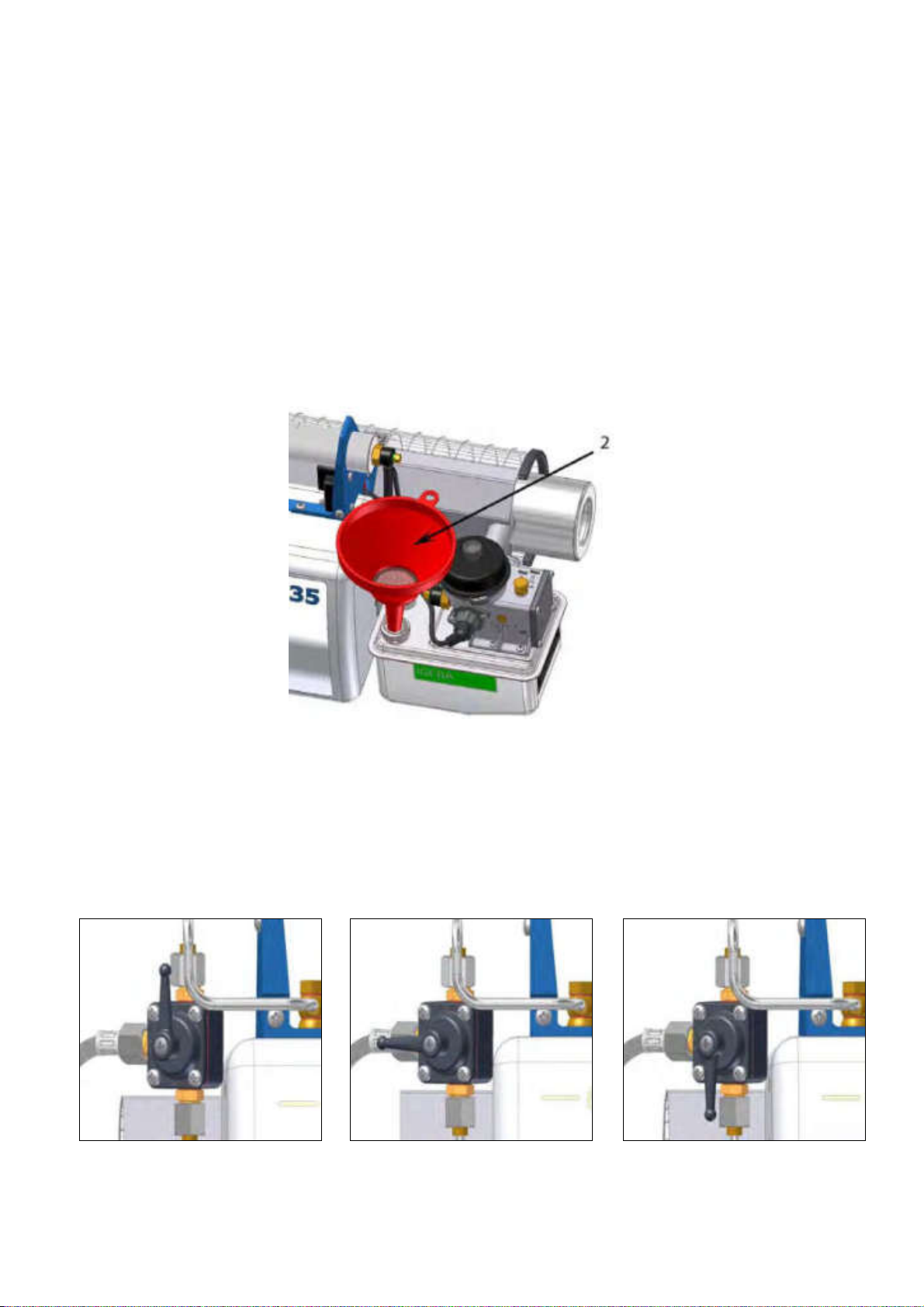

Fill petrol tank with petrol > 75 ROZ,

without any additives. There is no

advantage achieved in using higher grade

petrol. Please use the provided funnel with

strainer (illus. 8 pos. 2). After filling, tighten

petrol cap firmly by hand.

. 8

- . 71

illus. 8

SP list page 71

,

.

(. 9).

Make sure that solution tap is closed. Lever

points upwards (illus. 9).

. 9

- . 70

illus. 9

SP list page 70

– Closed - Ventilation – Open

04/2010 1.0 32 72

.

(. 10, . 1).

.

Fill solution tank. Always use the provided

solution funnel with filter (illus. 10 pos. 1).

Tighten tank cap firmly by hand.

. 10

- . 71

illus 10.

SP list page 71

Solution output through Dosage

Nozzles

EVO 35

1.2.

0.8.

EVO 35 is already equipped with a dosage

nozzle size of 1.2. A Nozzle with size 0.8 is

in the scope of supply.

EVO 35 W

1.0.

Another nozzle with size 1.0 is in the scope

of supply, when you order

EVO-W 35.

()

:

›0.8*1.0* 1.2 1.4 1.6 2.0

/ ›10 15 20 30 35 42

*

EVO W 35.

Water has been used to determine the

following outputs (rough values):

Nozzle size ›0.8*1.0* 1.2 1.4 1.6 2.0

Liter/hour ›10 15 20 30 35 42

* solely use these dosage nozzles for

EVO W 35.

04/2010 1.0 33 72

20%.

. Э

.

W

1.0.

The output (liter/hour) differs up to 20%

due to the different chemical and physical

properties of the formulations. We advise

you to do your own metering of the output

under prevailing conditions. This refers

mainly to tropical countries.

When applying water based formulations

use a small dosage nozzle size max. 1.0

and assemble fog tube type W (109) for

water based formulations.

:

.

1000 3:

Caution:

Overdosage of agent in closed rooms my

lead to formation of an explosive mixture.

The dose of these combustible materials in

ready mixed fogging formulations must not

exceed the following maximum

concentrations per 1.000 cu. metres.

a) д: ) , :

3,0 2,5

2,5 /. 2,0

Э 2,0 2,0

Э 2,0 Petropal 2,0

2,0 Shell Risella 15 1,5

VK 2-spezial 2,0

a.) Special Carriers: b.) Fuels/White Oils:

Nebol 3,0 l Vegetable oils 2,5 l

Glyzerine 2,5 l Diesel-/Heating oil 2,0 l

Ekomist 2,0 l Kerosene 2,0 l

Ethylenglykole 2,0 l Petropal 2,0 l

Diethylenglykole 2,0 l Shell Risella 15 1,5 l

VK 2-spezial 2,0 l

,

,

.

, по

предварительным подсчетам

обрабатываемого .

Though these values may not correspond

with those given by the manufacturers and

may be higher than limits quoted in dosage

tables. We recommend to fill in only the

calculated (necessary) volume of agent for

the treated room.

04/2010 1.0 34 72

2. :

(. 11, . 1) .

( ) (. 11,

. 2).

, -

(. 11, . 3).

,

1–2

.

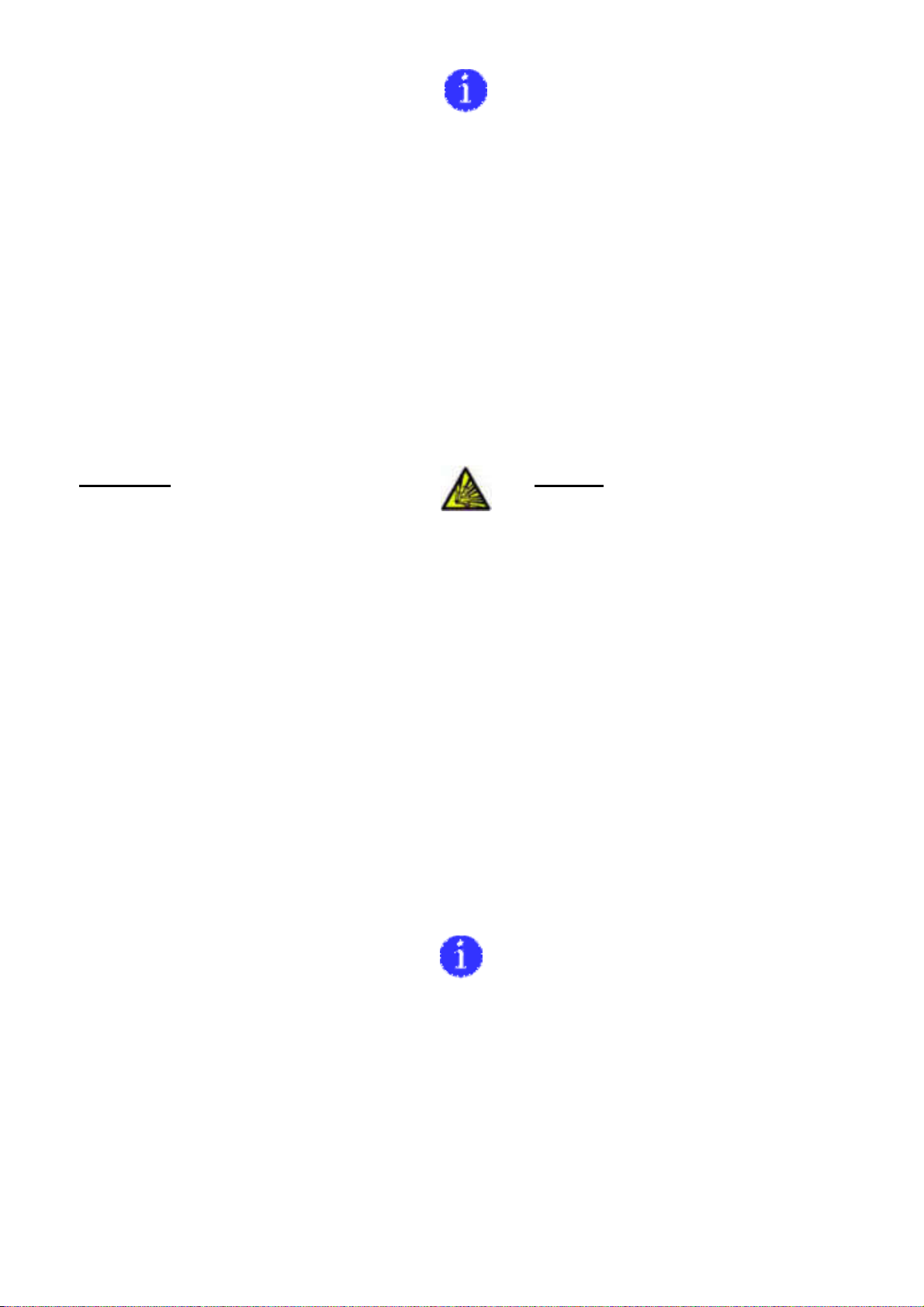

2. Starting the unit:

Pull stop button at the carburettor upwards

(illus. 11 pos.1).

Press starter button (for ignition) and keep

pressed (illus 11 pos.2).

Actuate air pump . Pump evenly, (illus. 11

pos.3) not fitfully.

When the first explosions are audible,

pump another 1–2 strokes. The unit should

run properly now. Release starter button.

. 11 illus. 11

:

, ..

,

.

. ,

1 .

(. . 12, .

35). После разогрева прибора,

„ON“ ().

Notice!

The air pump creates pressure for the

petrol supply. The lower the petrol in the

tank, the more pumping strokes are

necessary. Always start with a full tank if

possible. Bring the solution tap in position

“ON” (Fogging) after the warm-up period

(illus.12 page 35).

04/2010 1.0 35 72

. 12

- . 70

illus. 12

SP list page 70

– Closed - Ventilation – Open

!

,

, .

6,5- -

,

,

8-36 .

2 /, .. 1,2

36 .

Important!

Make sure that the amount of petrol is

sufficient for the intended period of fogging.

The content of the standard solution tank is

6,5 liter, which is fogged according to the

size of the dosage nozzle between 8 and

36 minutes. The unit runs about 36

minutes w ith a full fuel tank (1,2l).

3. :

рабочего

,

.

„“

(. 13).

,

. З

(

,

- . 13).

,

«STOP». ,

.

3. Stopping the unit:

Turn lever of solution tap at first into

position VENTILATION. Lever is in

horizontal position. In position

VENTILATION air is ventilated through the

solution line and through the fog solution

socket (illus. 13).

Wait until fog is no longer visible.

Now turn lever of solution tap into position

closed (illus. 13).

Push stop button at the carburettor down

into position STOP. The unit stops and no

explosions are audible (illus. 11 page 34).

Actuate air pump about 3–4 times and

press simultaneously starter button.

04/2010 1.0 36 72

3–4 ,

.

ки а

(. 11, . 34).

,

.

!

.

Explosions of remaining gases might be

audible (illus. 11 page 34).

Release pressure from solution tank by

turning tank cap to the left.

Attention!

Do not tighten tank cap hard during

storage of the unit.

. 13

- . 70

illus. 13

SP list page 70

– Closed - Ventilation – Open

4. Ч :

,

коррозионноустойчивых ,

.

0,5

, ,

.

,

(. 14, . 2)

,

.

.

4. Cleaning the unit:

Although all solution carrying pipes are

made of rust proof material, the solution

line should be cleaned after the application

/ change of active substance. Pour a half

liter of water into the solution tank, shake

the unit and fog. If fogging is not possible,

unscrew fog solution socket and atomizer

nozzle, so that the water can flow through

solution line into a container. Water can

also flow out of the opening at the bottom

of the solution tank (illus.14 pos.2).

04/2010 1.0 37 72

. 14 illus 14.

- . 65 SP list page 65

. 14a illus. 14a.

При и

.

0,25

,

, (.

14a) .

.

.

By using dirty petrol cans or polluted

petrol, debris may be piled up inside the

petrol tank. This debris can be removed of

the tank by filling up a quarter liter of

gasoline. Shake the unit carefully and

decline the entire unit so that fuel together

with debris can flow out of the opening

(illus.14a.) of the fuel tank. Prepare an

appropriate container to collect the

solution. If necessary repeat the

procedure. The unit must be cooled-down

before cleaning.

04/2010 1.0 38 72

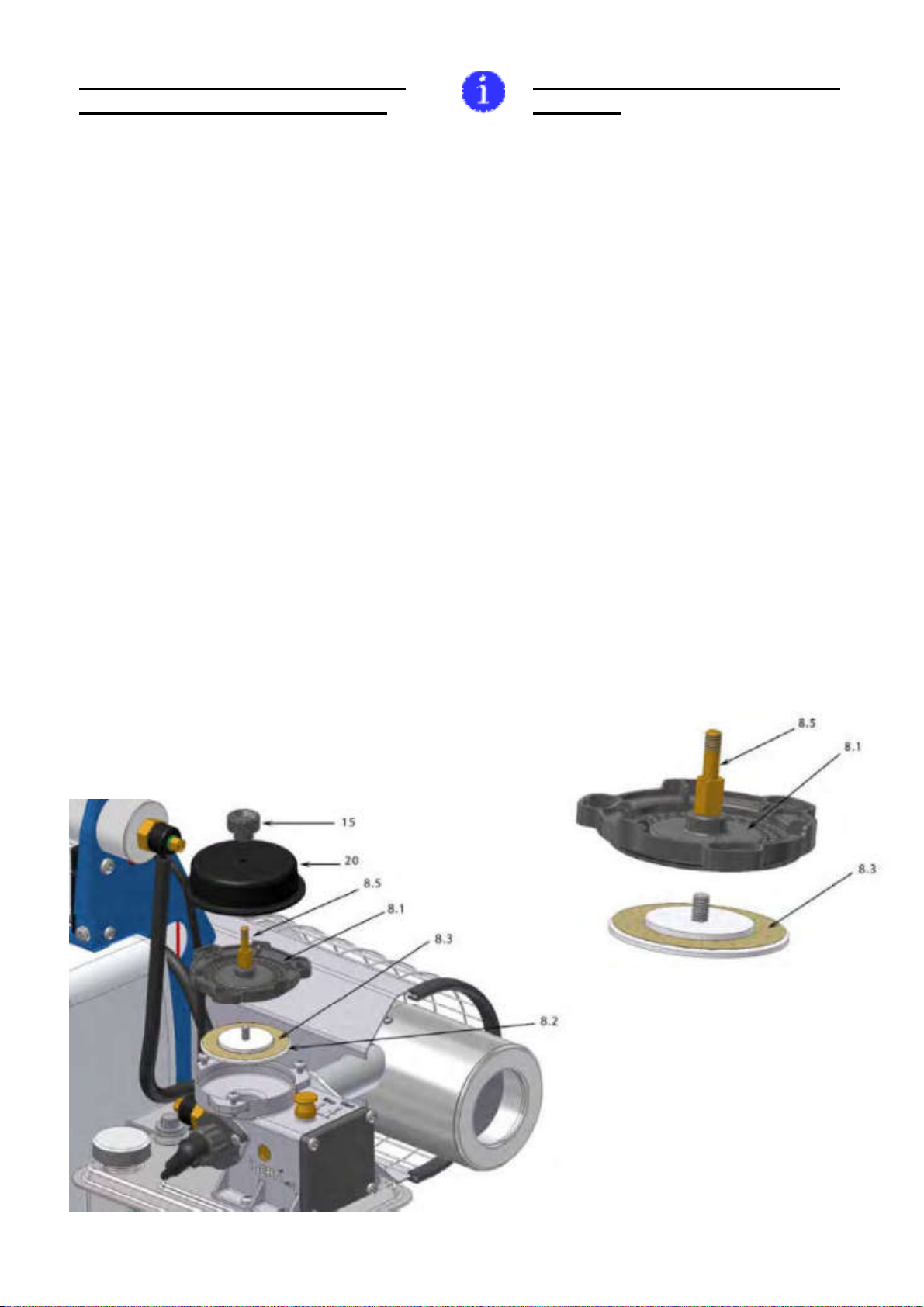

:

a)

)

(. 14, . 37);

)

)

(. 15, . 8.3),

( , ) .

.

(. 16, . 8.1)

(. 16, .

8.2).

.

We recommend before longer periods

of storage:

a.) Remove batteries from the unit and

store them at a safe and dry place.

b.) Remove solution from the solution tank

and clean as stated above. (illus. 14 page

37 ) Do not tighten tank cap hard.

c.) Clean the unit from the outside.

d.) Remove diaphragm of air intake valve

(illus.15 pos.8.3). Check for any damage.

A damaged diaphragm must be replaced.

Clean diaphragm (illus. 16 pos. 8.1), valve

plate (illus. 16 pos. 8.2) and spacer plate.

Clean with a tidy cloth and/or suitable

cleaning agent.

. 15

- . 69

illus. 15

SP list page 69

. 16 illus.16

- . 69 SP list page 69

04/2010 1.0 39 72

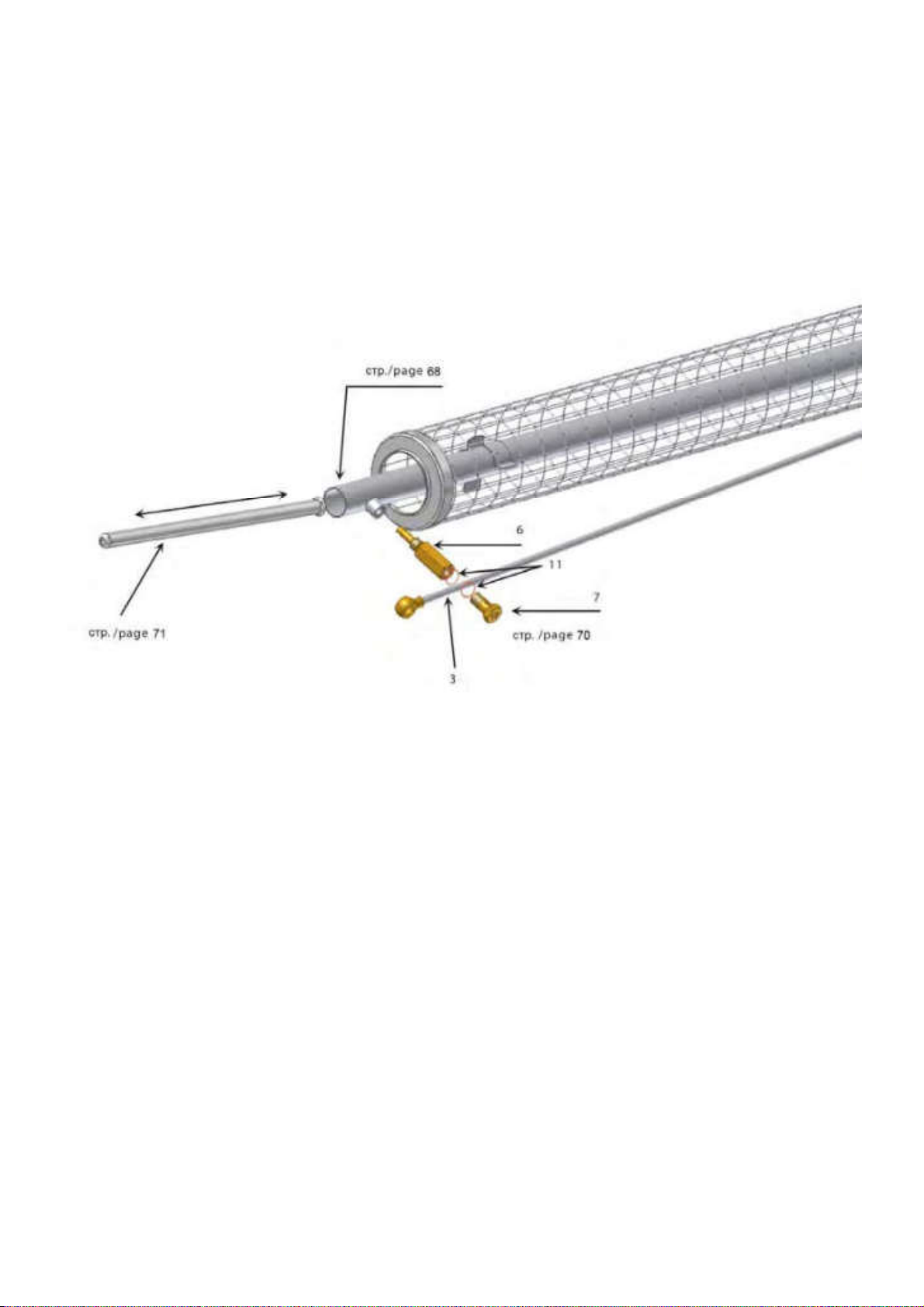

) ,

(. 17, . 3).

e.) Remove residues in resonator, fog -

solution socket and possibly fog tube with

pipe cleaning tool (illus.17, pos.3).

. 17

- . 68-70

illus. 17

SP list page 68-70

04/2010 1.0 40 72

5. Ч

a) отсоедините контактный наконечник от плунжера

(. 18,поз. 2).

5.Cleaning from the mixing chamber and

mixing pipe.

a.) Remove the plug from the swirl vane

(illus. 18 pos.2).

. 18

- . 69 illus. 18

SP list page 69

) (. 18

. 11) , плунжер

(.

19, . 21, . 41):

.

,

,

, .

.

b.) Release the fixing screws (illus.18

pos.11) a few revolutions until you can

remove the swirl vane with a short counter-

clockwise rotation (illus 19 pos.21 page 41).

Remove the O-Ring from the carburettor

housing. Please check the O-Ring, a

damaged O-Ring must be replaced.

Please lay the O-Ring aside during the

cleaning.

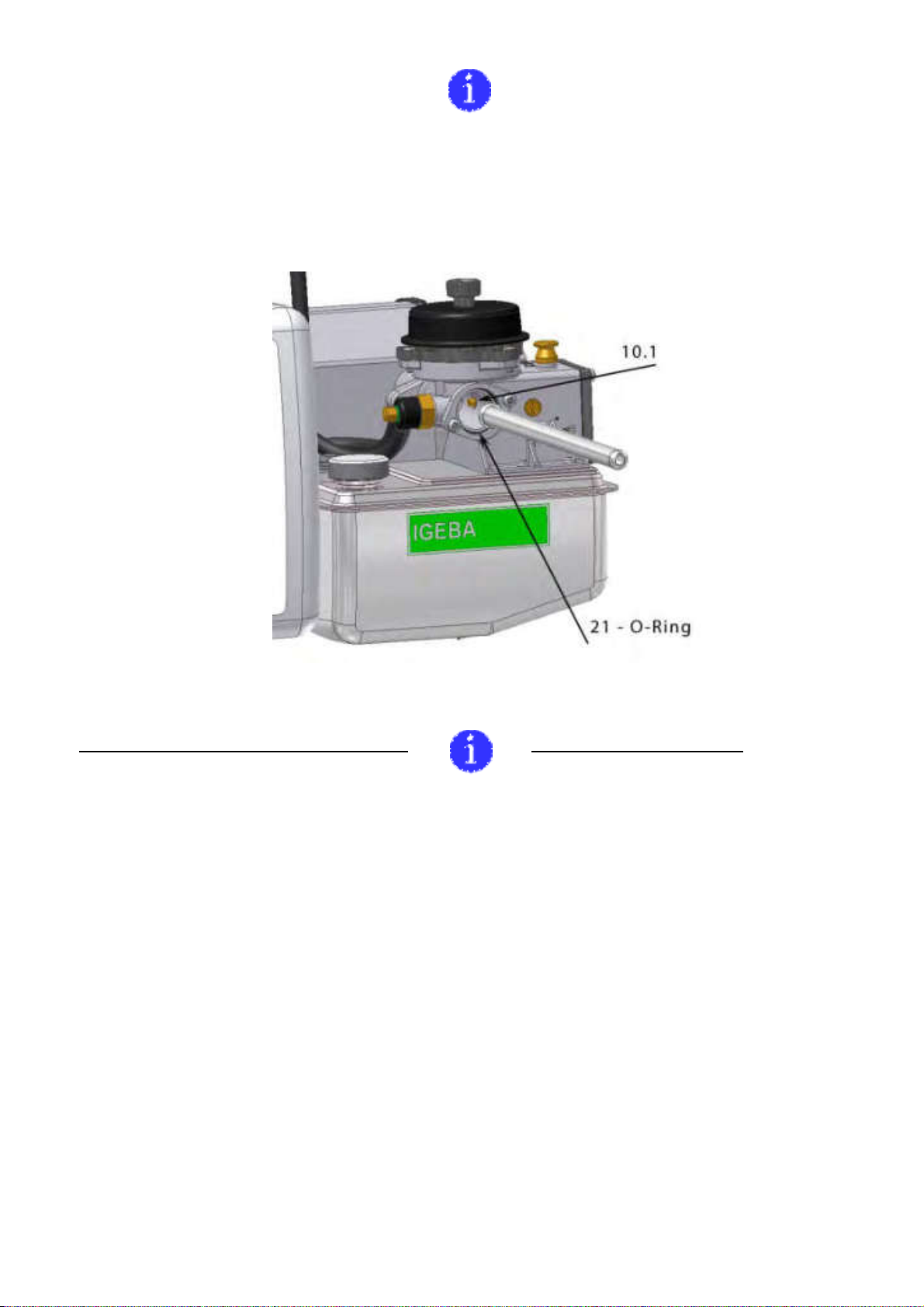

04/2010 1.0 41 72

. 19

- . 69

illus. 19

SP list page 69

)

. ,

(. 20, . 10.1, . 42).

,

.

c.) Clean the inside of the mixing chamber

and mixing pipe. Remove combustion

residues with pipe cleaning tool. When

inserting the pipe cleaning tool into the

mixing chamber pay special attention to

the atomizer nozzle which enters the

mixing chamber from the right side (illus 20

pos.10.1 page 42). Take care and do not

damage the fuel atomizer nozzle with the

cleaning tool.

04/2010 1.0 42 72

,

. 20, . 21.

The O-Ring has to be placed like shown in

iIlus.20 pos.21 in the carburettor housing.

. 20

- . 69

illus 20.

SP list page 69

:Maintenance of the pump:

1-2 ( .

29, . 49).

(1)

(2).

•

(. 29, . 2.4)

.

. ,

.

•The maintenance of the pump has to

be performed one or two times per year.

(illus. 29 page 49)

Unscrew the cap by turning it counter-

clockwise (1.) and pull the complete pump

spindle out of the pump tube afterwards.

• Check collar (illus. 29 pos. 2.4) of pump

spindle for proper position and replace if

damaged. Lubricate the collar with grease.

Mount the pump in reversed order.

This manual suits for next models

1

Table of contents