IGMI IEMCA GENIUS 226 Instruction manual

REL. DATA COD.

S/N

GENIUS 226

MANUAL FOR USE AND MAINTENANCE

GB

1 26/03/01 228005400

REL. DATA COD.

S/N

302.088

GENIUS 112

GENIUS 226

GUÍA OPERATIVA DEL TECLADO

PARA EL TECNICO AUTORIZADO

E

1 29/05/00 227005505

302.087

IEMCA division of IGMI SpA

48018 - Faenza (RA) - ITALY

Via Granarolo, 167

Tel. 0546/698000 - Fax. 0546/46338 ufficio commerciale

0546/46224 centralino

TLX 550879

E-mail: iemca@igmi.it

Web site: www.iemca.com

GENIUS 226

AUTOMATIC HYDRAULIC SUSPENSION

BAR FEEDER

MANUAL FOR USE AND MAINTENANCE

GB

© 2000 - This manual is composed by 103 pages, annexes excluded. It is forbidden to even partly reproduce this document without the Manufacturer's authorisation.

REL. DATA COD.

S/N

302.088

GENIUS 112

GENIUS 226

GUÍA OPERATIVA DEL TECLADO

PARA EL TECNICO AUTORIZADO

E

1 29/05/00 227005505

1

INDEX

302.087

1GENERAL INFORMATION

1.1. WARRANTY CONDITIONS............................... 3

1.2. MANUAL PURPOSE........................................... 3

1.3. MANUFACTURER AND BAR FEEDER

IDENTIFICATION................................................ 4

1.4. TECHNICAL ASSISTANCE............................... 4

1.5. ANNEXES ENCLOSED...................................... 4

2TECHNICAL INFORMATION

2.1. GENERAL BAR FEEDER DESCRIPTION...... 5

2.2. OPERATING CYCLE - General

description............................................................. 7

2.3. SAFETY DEVICES - Position and

description........................................................... 11

2.4. SAFETY PLATES - Position and

description........................................................... 12

2.5. VERSION DESCRIPTION ............................... 13

2.6. TECHNICAL SPECIFICATIONS..................... 14

2.6.1 Noise levels ........................................................ 18

2.7. ACCESSORIES - Description ......................... 18

2.7.1 Precision facing device - Description ............. 18

2.7.2 Axial displacement device - Description........ 19

2.7.3 Bush-holder device -

Description.......................................................... 20

2.8. DEVICES FOR SLIDING HEADSTOCK

LATHE - Description......................................... 20

2.8.1 Bar/headstock synchronizing device -

Description.......................................................... 20

2.8.2 Telescopic nose - Description ......................... 21

2.9. DEVICES FOR CAM LATHES -

Description.......................................................... 22

2.9.1 Headstock return device - Description........... 22

2.9.2 Cam box - Description ...................................... 22

2.9.3 Camshaft release device - Description .......... 23

3SAFETY PROCEDURES -

GENERAL INFORMATION

3.1. SAFETY GENERAL INSTRUCTIONS .......... 25

3.2. HANDLING AND INSTALLATION - Safety

procedures ......................................................... 25

3.3. ADJUSTMENTS AND SETTING UP - Safety

procedures ......................................................... 26

3.4. USE AND OPERATION - Safety

procedures ......................................................... 26

3.5. BAR FEEDER MAINTENANCE - Safety

procedures ......................................................... 26

4HANDLING AND INSTALLATION

4.1. PACKAGING...................................................... 27

4.2. LIFTING.............................................................. 27

4.3. INSTALLATION AREA - Characteristics....... 29

4.4. INSTALLATION OF BAR FEEDER -

Introduction ........................................................ 30

4.4.1 Support plates and feet - Installation............ 30

4.4.2 Height - Adjustment.......................................... 31

4.4.3 Preliminary positioning..................................... 32

4.4.4 Nose - Installation ............................................. 33

4.4.5 Levelling and alignment ................................... 34

4.4.6 Feeder fastening ............................................... 36

4.5. ACCESSORIES - Installation.......................... 37

4.5.1 Precision facing device - Installation.............. 37

4.6. DEVICES FOR SLIDING HEADSTOCK

LATHES - Installation....................................... 38

4.6.1 Bar-headstock synchronisation device -

Installation.......................................................... 38

4.6.2 Telescopic front nose - Installation................. 39

4.7. DEVICES FOR CAM LATHES -

Installation.......................................................... 40

4.7.1 Headstock return device - Installation............ 40

4.7.2 Cam box - Installation....................................... 41

4.7.3 Camshaft release device ................................. 42

4.8. LUBRICANT OIL - Filling................................. 43

4.9. ELECTRIC CONNECTION.............................. 43

4.10. PNEUMATIC CONNECTION.......................... 44

4.11. SELF-LEARNING DIMENSIONS -

Programming ..................................................... 44

Operations described in paragraphs showing this symbol, must be performed by qualified and skilled personnel

only. Any other operation can be performed either by qualified personnel or by professional bar feeder operators.

2

INDEX

302.087

5ADJUSTMENTS AND SETTING-UP

5.1. ADJUSTMENT AND SETTING-UP -

Foreword............................................................. 45

5.2. GENERAL ADJUSTMENTS - Foreword........ 45

5.2.1 Feed chain - Adjustment................................... 46

5.2.2 Drive belt - Adjustment ..................................... 46

5.3. SETTING-UP THE BAR FEEDER

ACCORDING TO THE BAR TO

BE MACHINED................................................... 47

5.3.1 Guide channels, bar pusher and collet -

Replacement ...................................................... 49

5.3.2 Half-bushings - Replacement .......................... 55

5.3.3 Nose - Replacement ......................................... 56

5.3.4 Bar magazine - Adjustment.............................. 57

5.3.5 Bar selection device - Adjustment................... 58

5.3.6 Clamps - Adjustment......................................... 59

5.3.7 Clutch thrust - Adjustment................................ 61

5.4. PRECISION FACING DEVICE -

Adjustment.......................................................... 63

5.5. CAM BOX - TIMING.......................................... 64

6BASIC INFORMATION

6.1. DESCRIPTION OF THE CONTROLS ........... 67

6.2. DESCRIPTION OF KEYBOARD

CONTROLS........................................................ 68

6.3. INDICATOR LIGHTS - Description of

indications........................................................... 70

6.4. BARS TO BE MACHINED -

Characteristics and preparation ...................... 70

6.5. FEEDER SET-UP AND AUTOMATIC

CYCLE START .................................................. 72

6.5.1 Bar magazine - Filling....................................... 73

6.5.2 Lubrication oil - Flow adjustment..................... 74

6.5.3 Starting the automatic cycle............................. 74

6.5.4 Guide channel opening/closing mode............ 75

6.5.5 Cycle actuation mode in

the “STEP-BY-STEP” function......................... 77

6.6. FEEDER STOP.................................................. 77

7BAR FEEDER MAINTENANCE

7.1. MAINTENANCE - GENERAL RULES........... 79

7.2. SCHEDULED MAINTENANCE ...................... 80

7.2.1 Revolving tip and collet - Check ..................... 80

7.2.2 Lubricating oil - Level check............................ 81

7.2.3 Lubricating oil - Change................................... 81

7.2.4 Clutch oil - Checking......................................... 82

7.2.5 Clutch oil - Change ........................................... 82

7.2.6 Clutch disks - Checking for wear.................... 83

7.2.7 Feed motor brushes - Checking for wear...... 84

7.2.8 Air filter unit - Check ......................................... 85

7.3. AXIAL DISPLACEMENT DEVICE - Use....... 86

8TROUBLES - CAUSES - CURES

8.1. GENERAL FAULTS.......................................... 87

8.2. BAR MAGAZINE - Faults................................. 87

8.3. INSERTION IN THE COLLET - Faults.......... 88

8.4. BAR FEEDING - Faults.................................... 88

9PART REPLACEMENT

9.1. FEED CHAIN - Replacement.......................... 89

9.2. CLUTCH DISKS - Replacement..................... 89

9.3. FEED MOTOR BRUSHES -

Replacement...................................................... 89

9.4. PLC BATTERY - Replacement....................... 90

9.5. KEYBOARD BATTERY - Replacement ........ 91

9.6. FEED MOTOR DRIVE - Replacement.......... 92

9.7. RECOMMENDED SPARE PARTS - List...... 93

LIST OF AFTER-SALES

CENTERS..................................................... 95

Operations described in paragraphs showing this symbol, must be performed by qualified and skilled personnel

only. Any other operation can be performed either by qualified personnel or by professional bar feeder operators.

3

302.087

1

GENERAL INFORMATION

Before carrying out any servicing whatsoever

on the bar feeder, it is of the utmost impor-

tance to read this manual carefully.

1.1. WARRANTY CONDITIONS

The warranty validity is conditional on good alignment

between the bar feeder and the lathe and the subse-

quent bar feeder fixing to the ground with expansion

plugs, as explained in the sections “Levelling and

alignment” and “Feeder fastening”.

1.2. MANUAL PURPOSE

This manual has been written and supplied by the

manufacturer and is integral part of the bar feeder and

of its equipment.

The compliance with the instructions contained herein

ensures the operator and bar feeder safety as well as

a running economy and a longer life of the bar feeder

itself.

In order to allow a quick search of contents, consult the

descriptive index.

Particularly important parts of this manual have been

highlighted in bold type and preceded by the following

symbols:

DANGER - WARNING: shows impending dan-

ger which might cause serious harm, hence it is

necessary to pay the greatest attention.

CAUTION: n order to avoid accidents or damag-

es to property, suitable measures shall be adopt-

ed.

INFORMATION: Information: technical instruc-

tions having particular importance.

For a quick search according to subjects, consult the

table of contents and/or the index.

Two more manuals are supplied along with this manu-

al, which contains all the operating instructions and

maintenance instructions for the bar feeder: the “Key-

board instruction manual” and the “Quick procedure”

manual.

The “Keyboard instruction manual” contains all the in-

structions on how to use the installed software.

The “Quick procedure” manual contains all the mini-

mum required instructions to use the bar feeder and its

software.

4

1

GENERAL INFORMATION

302.087

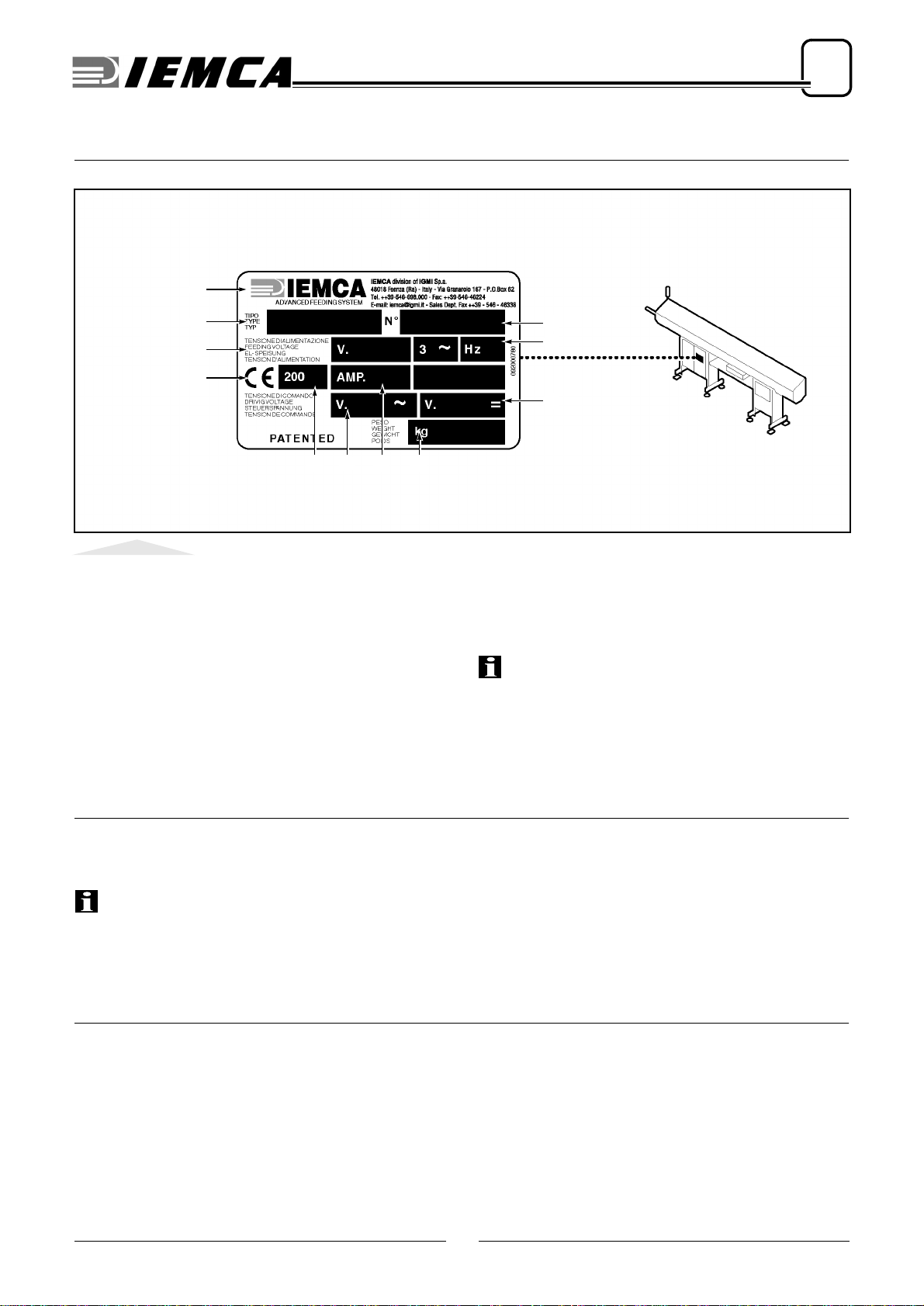

1.3. MANUFACTURER AND BAR FEEDER IDENTIFICATION

A- Manufacturer’s identification

B- CE conformity marking

C- Year of manufacture

D- Bar feeder model

E-Serial number

F-Feeding voltage

G- Mains frequency

H- Amperage

L-Alternate driving voltage

M- Direct driving voltage

N- Bar feeder weight.

INFORMATION: Always provide the Manufac-

turer with the above mentioned specifications in

order to obtain information or whenever ordering

spare parts, etc.

1.4. TECHNICAL ASSISTANCE

For any requirement, contact one of the centres listed

in our ”CUSTOMER SERVICE CENTRE LIST”.

INFORMATION: As far as technical servicing rel-

evant to the bar feeder is concerned, always specify

the technical data printed nameplate.

1.5. ANNEXES ENCLOSED

Keyboard instruction manual.

Quick-reference guide.

GUIDE CHANNELS –BAR PUSHER –REVOLVING

TIPS –COLLETS. Choice manual.

Wiring diagram.

Lathe coupling instructions.

C L H N

A

D

F

B

M

G

E

IDM-3020870010.tif

5

302.087

2

TECHNICAL INFORMATION

2.1. GENERAL BAR FEEDER DESCRIPTION

The GENIUS automatic bar feeder is used in the ma-

chine-tool industry and in particular, for automatic lathe

feeding. It is particularly suitable for feeding fixed or

sliding headstock lathes, numerical control or cam

lathes.

The working cycle is controlled by a control panel with

built-in PLC, which is able to dialogue with the lathe

control.

The hand-held keyboard facilitates programming and

enables to control bar feeder functions without having

to leave the lathe

The bar feeder can be used to feed bars, pipes and

various sections.

The guide channel is fully closed during machining; a

pump is provided to maintain a continuous oil flow in-

side the channel, creating a hydrodynamic support ef-

fect; these characteristics allow the bar to rotate at a

high r.p.m. number, with no vibrations and no surface

damaging.

The use of a d.c. motor and adjustable clutch make it

possible to adjust feed speed and thrust to optimum

values at every moment of the working cycle.

6

2

TECHNICAL INFORMATION

302.087

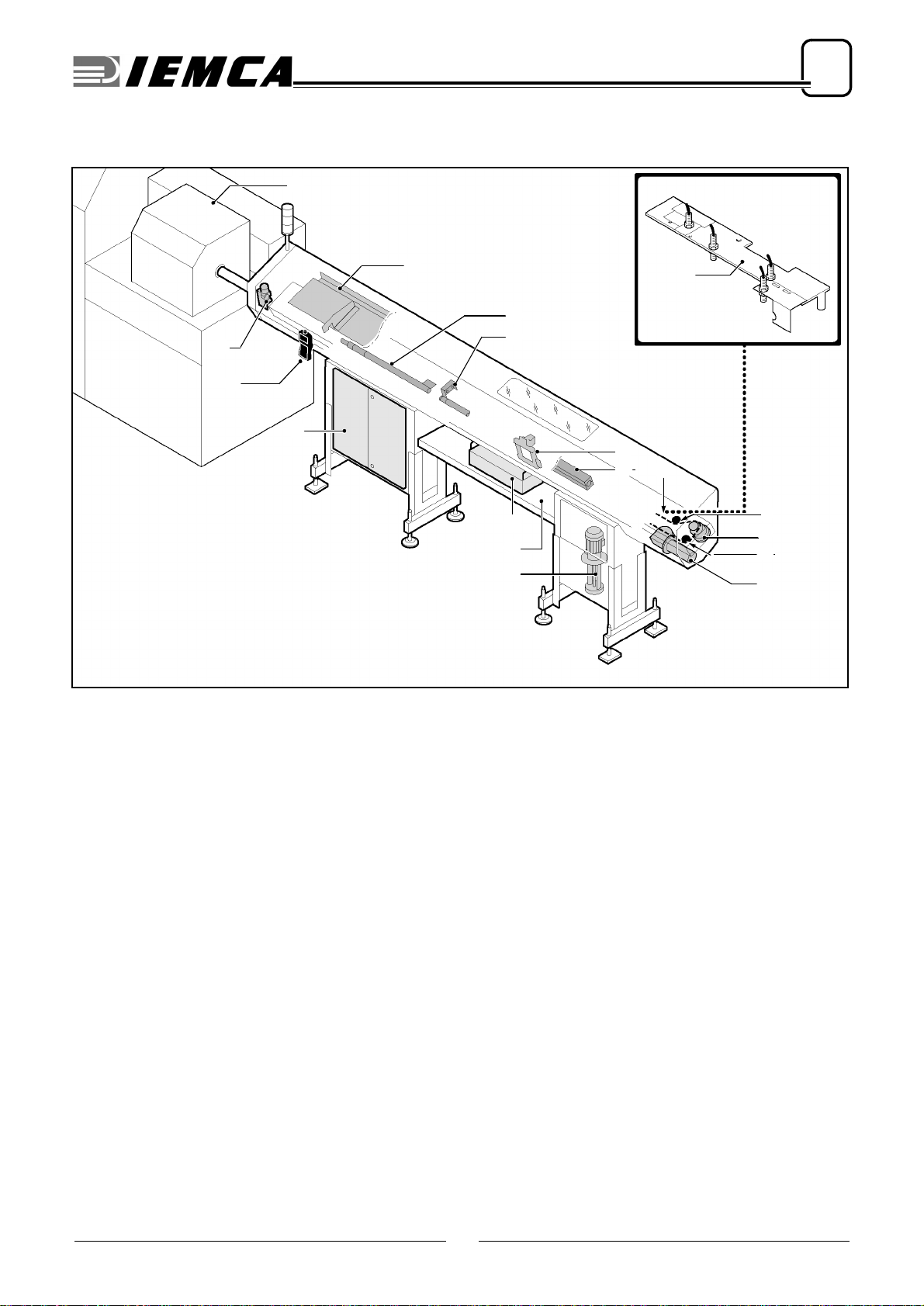

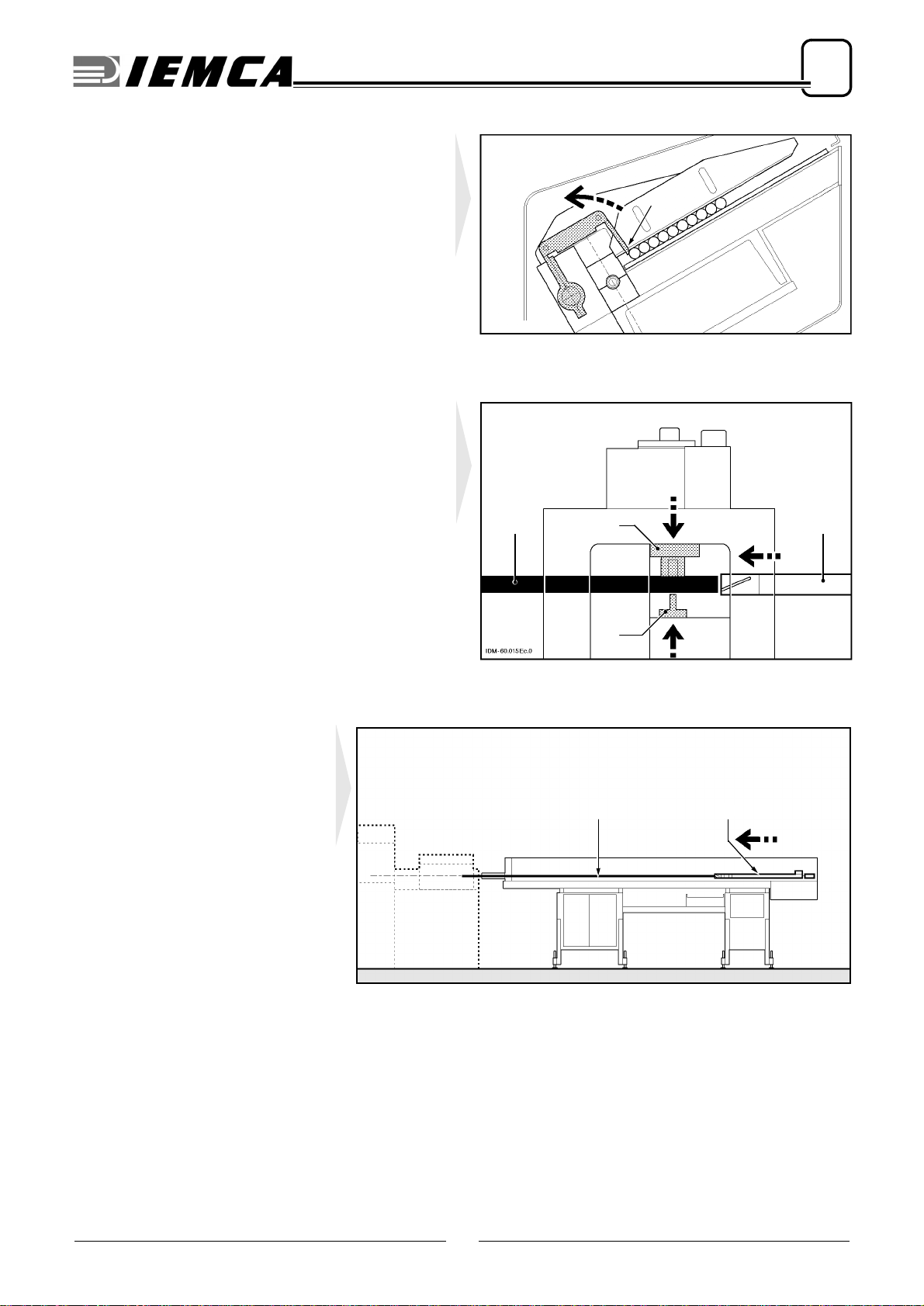

❑Main parts

A - Magazine; where bars are stored.

B - Bar selection device; it allows the first bar to be

lowered into the guides and holds back the re-

maining bars in the magazine.

C-Guides

; they guide the bars during machining.

D - Bar-pusher; it pushes the bar during machining.

E - Feed chain; it transmits motion from the drive

system to the bar-pusher.

F - Drive system; it drives the bar-pusher and the bar

feeder parts controlling bar insertion into the collet

and subsequent bar remnant extraction. It also

drives the bar feeder parts controlling guide open-

ing/closing and bar selection.

G- Clutch

; it transmits motion from the drive system

to the feed chain. It can be set to obtain thrust ad-

justment.

H - Sensors unit; enable control and command of

bar feeder movements.

L-Clamps

; they hold the bar during bar introduction

in and extraction from the bar-pusher collet.

M - Facing device; it sends a signal at bar passage.

N - Remnant collection box; bar remnants are

dropped into this box after extraction from the bar-

pusher collet.

P - Lubricating pump; it delivers oil to the guides.

Q - Oil recovery device; it collects oil flowing out of

the guides.

R - Hand-held keyboard; it allows bar feeder pro-

gramming and function actuation.

S - Electric cabinet; it contains the electric switch-

board.

T-Lathe

M

R

T

S

P

N

A

D

B

C

L

G

E

F

E

H

E

Q

IEMCA228510011

7

2

TECHNICAL INFORMATION

302.087

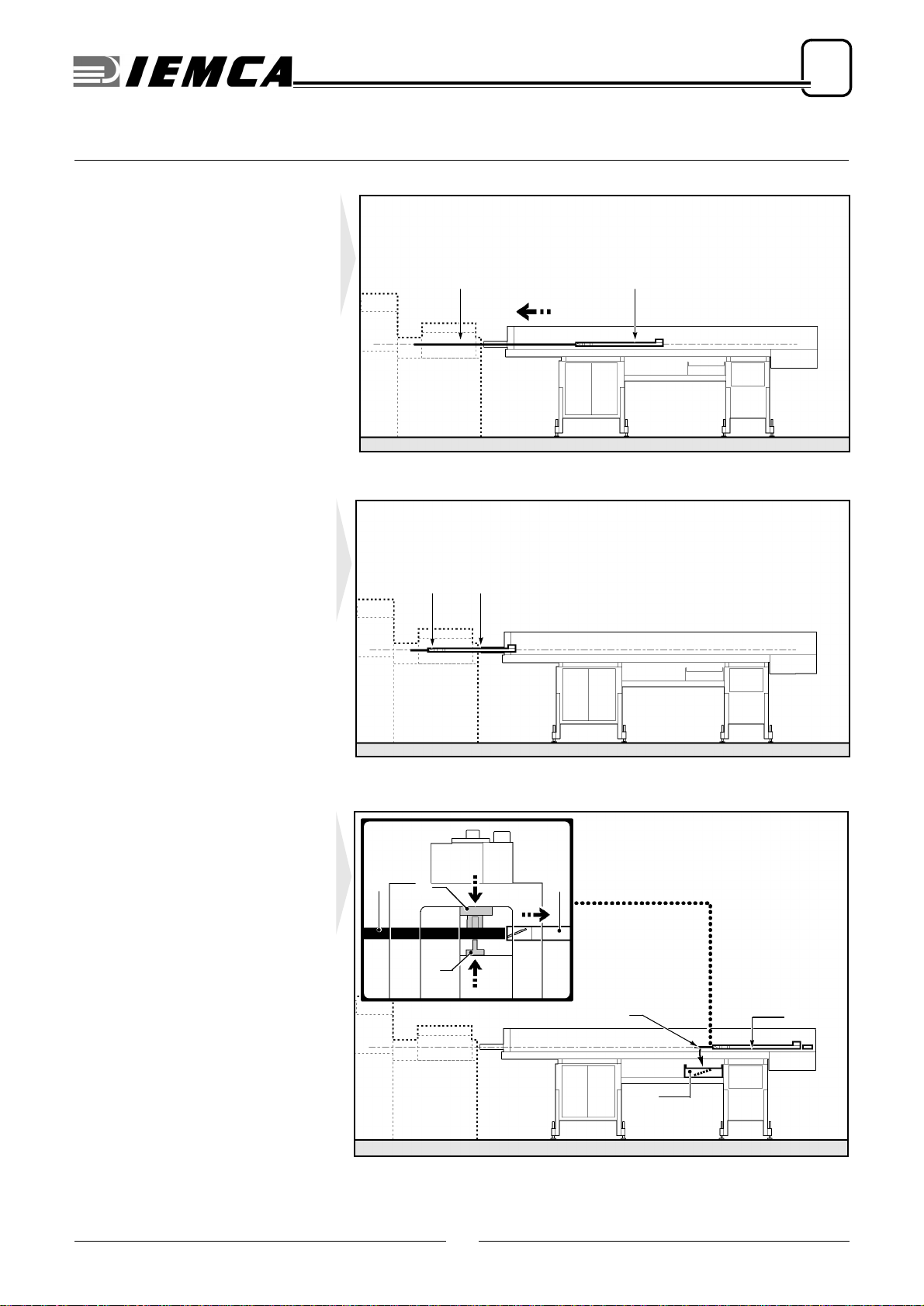

2.2. OPERATING CYCLE - General description

In the automatic operation mode, bar

feeder movements are controlled in

the sequence described below:

Phase 1

The bar-pusher A feeds bar B in the

lathe by following lathe impulses un-

til bar end.

Phase 2

The bar-pusher A and remnant C

are in their forwards limit stop posi-

tion.

Phase 3

The bar-pusher Aand remnant C

reach their backwards limit stop po-

sition.

The clamps Dclose and the bar-

pusher moves back; the remnant is

extracted from the collet. The

clamps open and the remnant is

dropped into the box E.

B A

IDM - 3020870030.tif

C A

IDM - 3020870040.tif

A

CD

D

CA

E

IDM - 3020870050.tif

8

2

TECHNICAL INFORMATION

302.087

Phase 4

Clamps Dclose again to perform

remnant Cextraction check.

If the remnant is still inserted in the

bar-pusher collet, the feeder stops;

otherwise, it continues its cycle.

Phase 5

The bar selector Fis lowered, and all the bars in the

magazine are held back except for the first bar G.

Phase 6

The front top guide channels Hand rear top guide

channels Lrise up together with the bar pusher M, and

bar G falls into the lower guide.

D

D

C

IDM - 3020870060.tif

F

G

IEMCA228510211

H

MG

L

IEMCA228510221

9

2

TECHNICAL INFORMATION

302.087

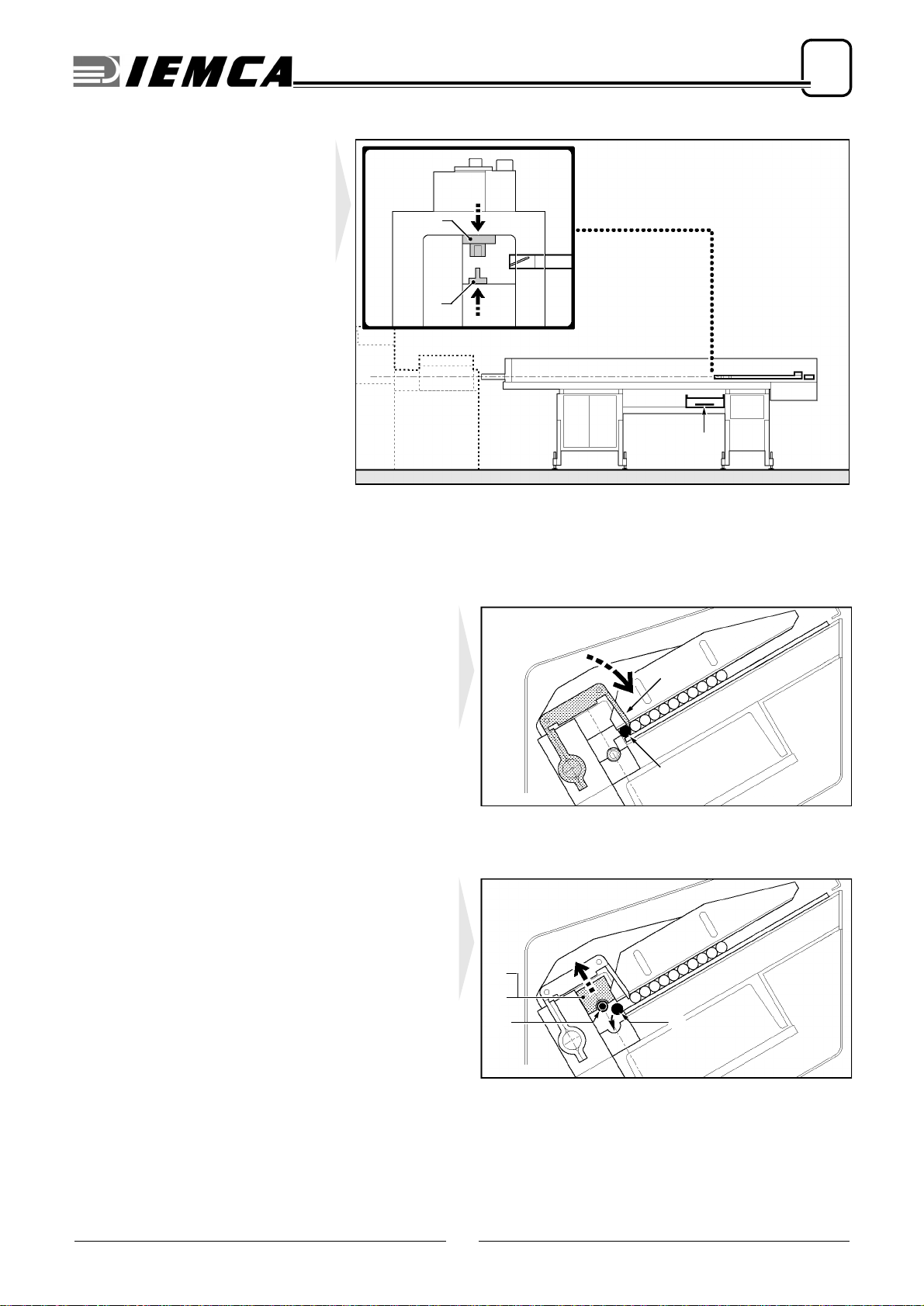

Phase 7

The small pusher truck N starts its

stroke.

Phase 8

When the small pusher truck N com-

pletes its stroke, the required space

has been created for bar-pusher in-

sertion.

The small pusher truck executes its

return stroke.

Phase 9

The front top guide channels Hand

rear top guide channels L close; the

bar pusher places itself along the bar

axis.

N

IDM - 3020870070.tif

N

IDM - 3020870080.tif

LH

IDM - 3020870090.tif

10

2

TECHNICAL INFORMATION

302.087

Phase 10

The bar selector Frises.

Phase 11

The clamps Dclose, the bar-pusher Amoves for-

wards; the bar Gis inserted into the bar-pusher collet.

Phase 12

The bar-pusher A and bar G execute

their facing stroke. A new automatic

work cycle is started.

F

IEMCA228510231

D

D

AG

AG

IDM - 3020870100.tif

11

2

TECHNICAL INFORMATION

302.087

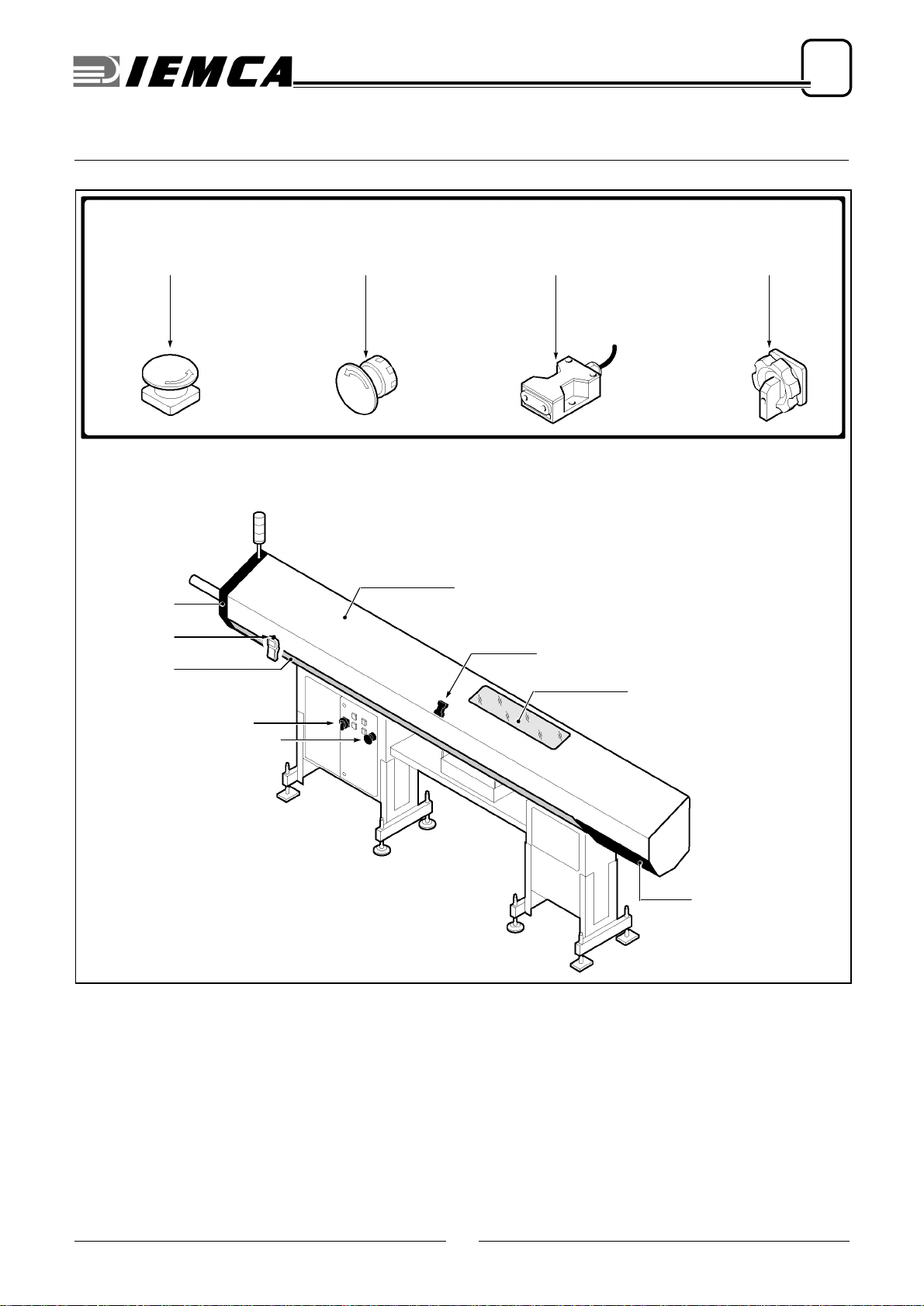

2.3. SAFETY DEVICES - Position and description

A B-Emergency button; by working it, all feeder and

lathe functions are stopped in an emergency situ-

ation.

C - Interlocked sliding guard: connected with the mi-

croswitch C1.

When this guard is opened, the bar feeder and lathe

will stop.

Onlyifthisguardisopenedduringthe feedingphase

will the bar feeder and lathe continue towork without

this implying any risks for the operator.

D - Fixed guard: made of transparent material to allow

visual inspection of the bar magazine area and the

terminals.

E - Fixed guard: prevents unintentional access to

moving parts.

F - Fixed guard: it prevents accidental access to the

drive area.

G - Fixed guard: iprevents unintentional access to

moving parts.

H-Mainswitch

: disconnects the electric supply source

when operations are being performed on the electric

panel, and when the feeder is not in use.

C

C1

F

HA C1B

H

B

D

IDM - 3020870130.tif

A

G

E

12

2

TECHNICAL INFORMATION

302.087

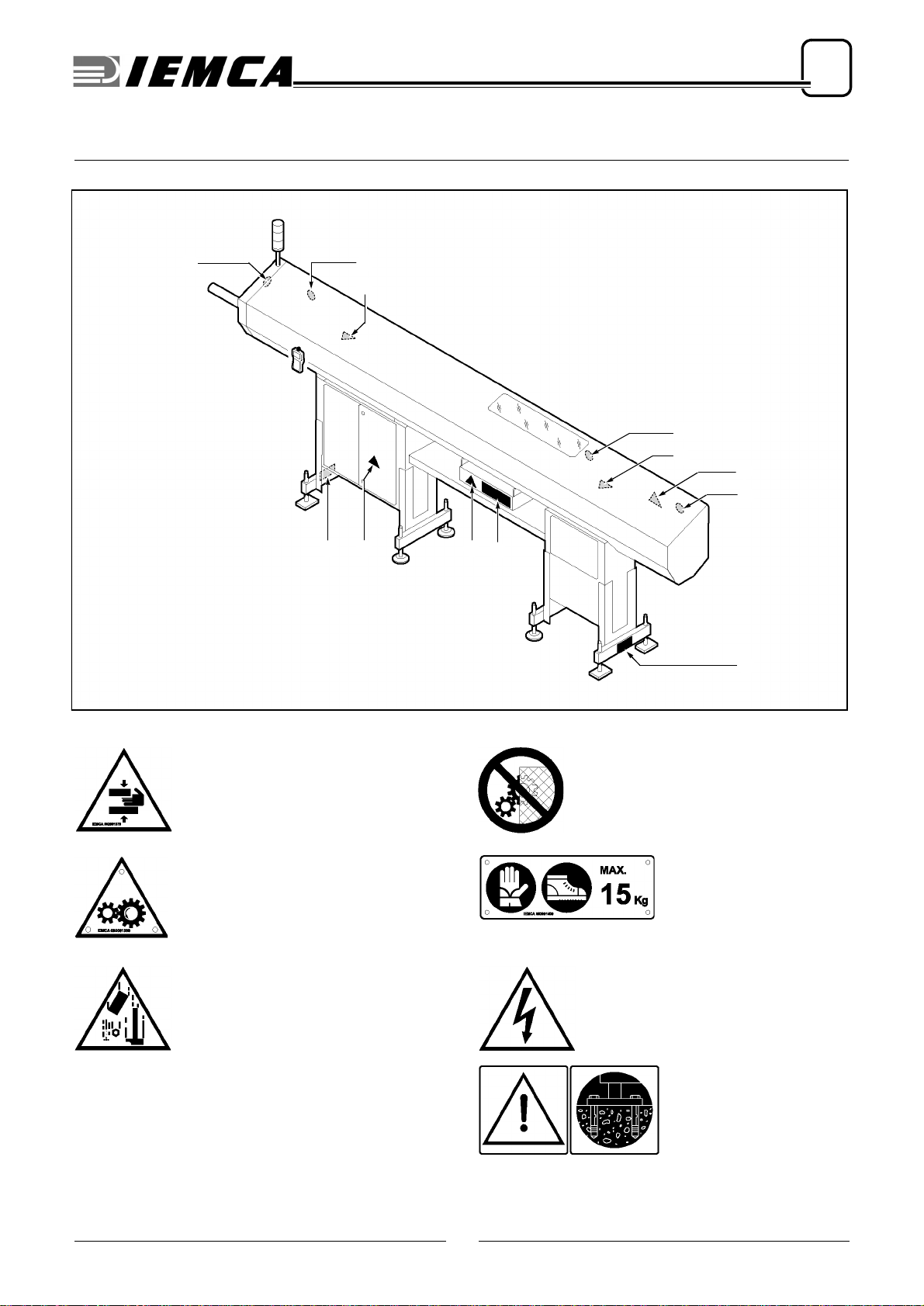

2.4. SAFETY PLATES - Position and description

A-Danger of arm crushing.

B-Beware of running parts.

C-Danger of material fall.

D-Do not remove safety barriers.

E-Wear working gloves

and shoes.

Do not lift manually

loads exceeding 15 kg.

F-Danger of electric shock.

G- Warning: fix the bar

feeder to the ground.

B

D

D

A

D D

A

CE

IDM - 3020870140.tif

G

FG

13

2

TECHNICAL INFORMATION

302.087

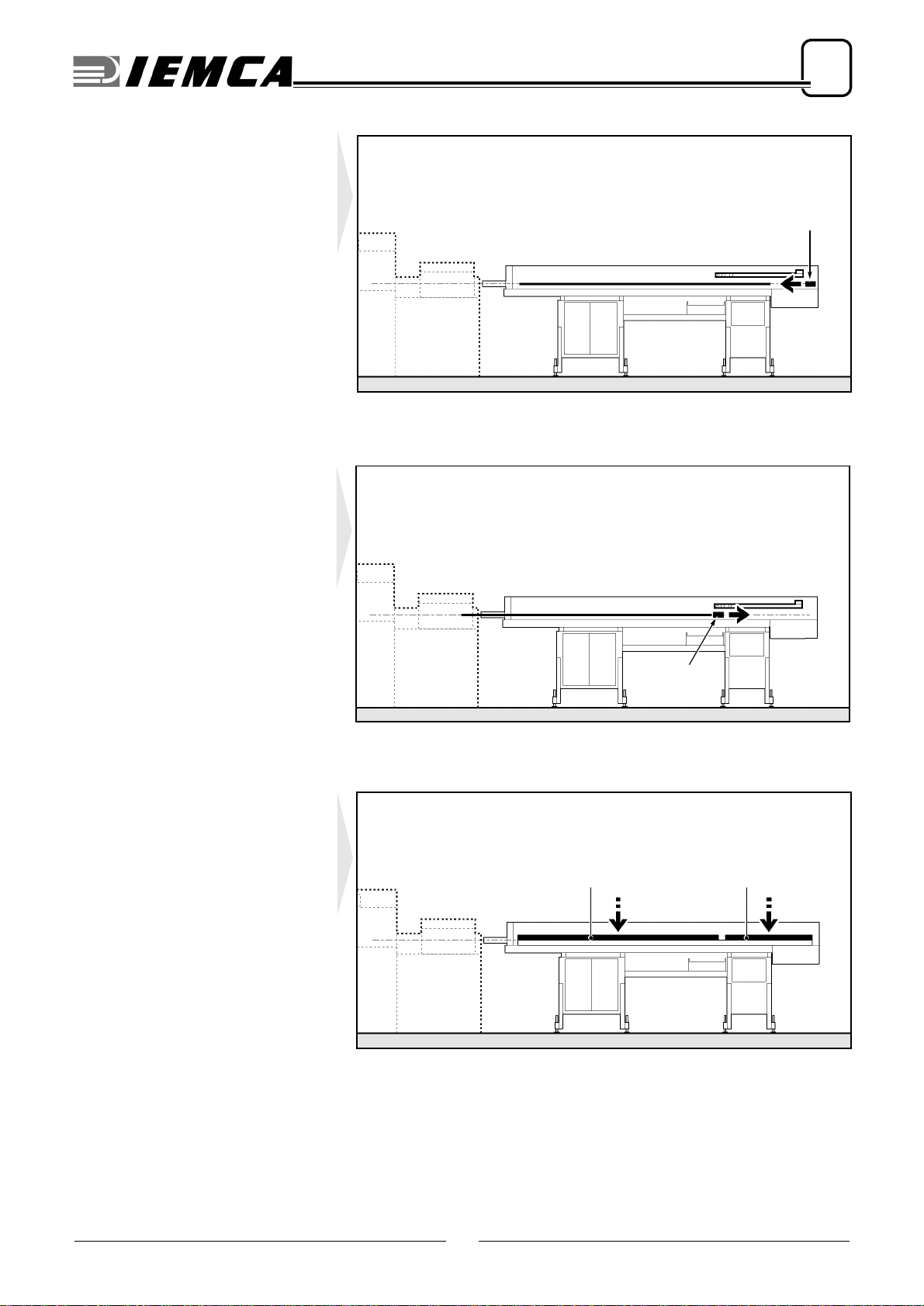

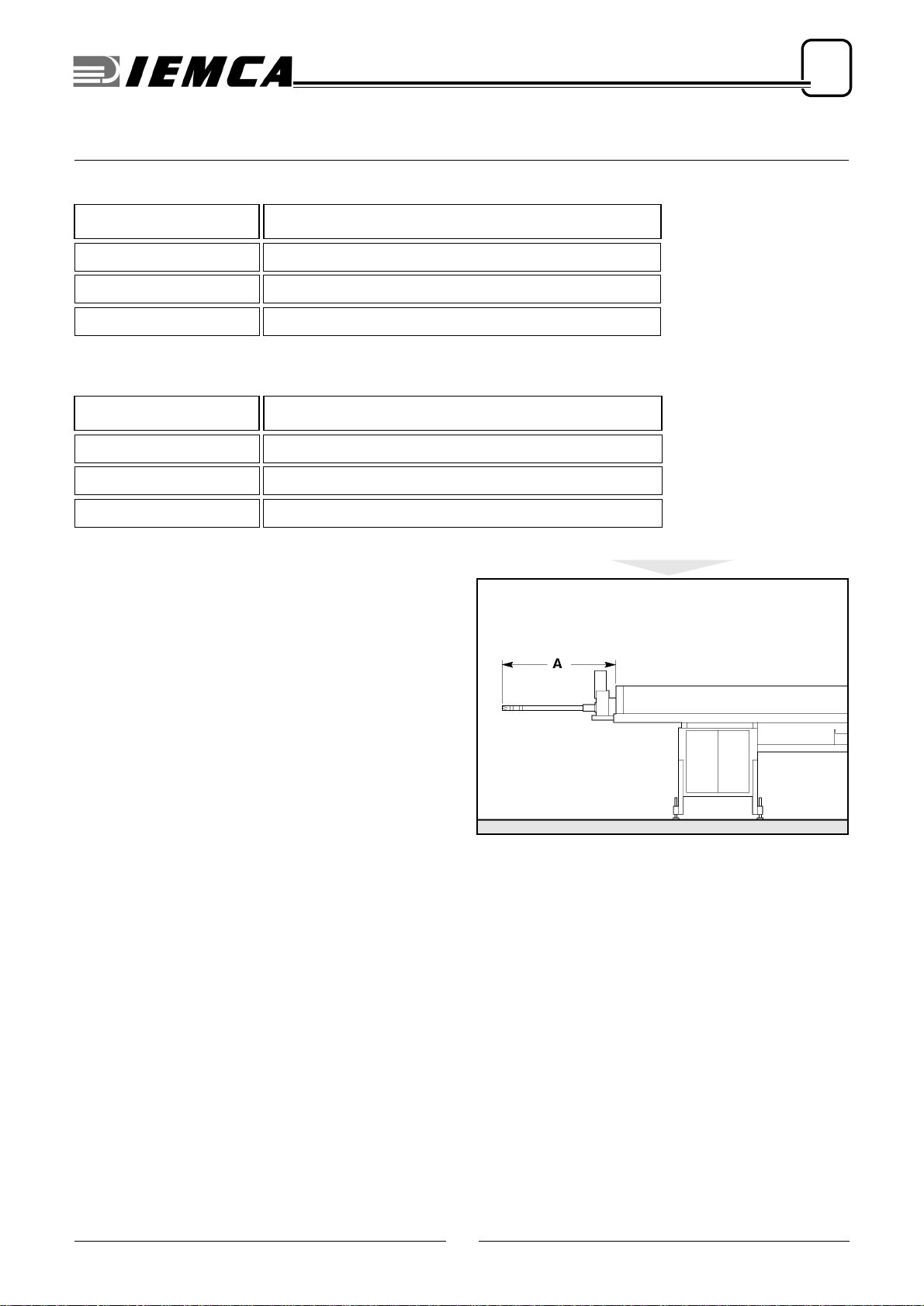

2.5. VERSION DESCRIPTION

Table 1. Maximum bar length

Version Max. length mm (ft)

32 3210 (10,5)

37 3730 (12,2)

42 4250 (13,9)

Table 2. Max. bar-pusher extension

Version

A

- Max extension (mm)

N958

L1218

LL 1478

IEMCA228510021

14

2

TECHNICAL INFORMATION

302.087

2.6. TECHNICAL SPECIFICATIONS

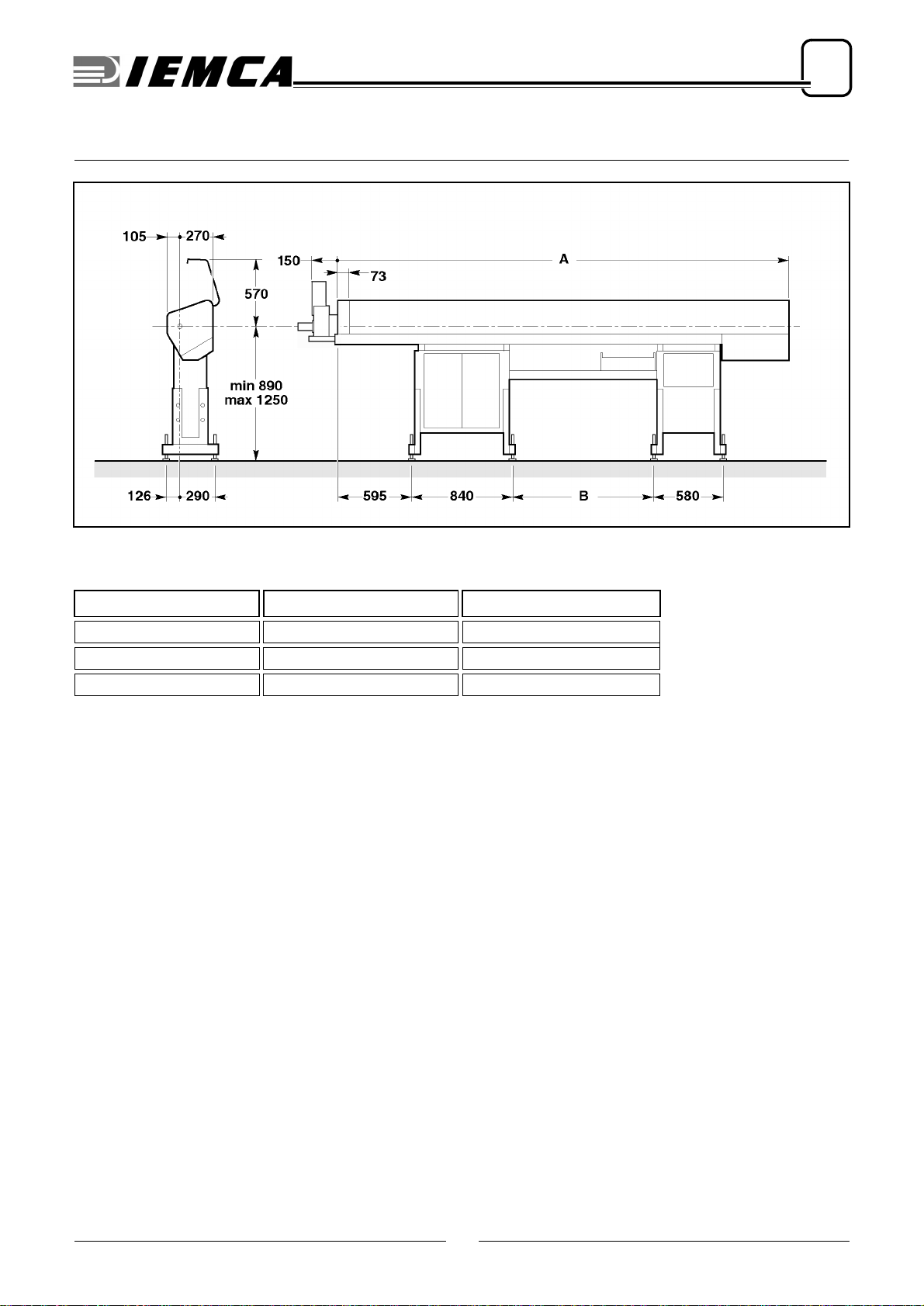

Table 3. Overall dimensions

Version

A

(mm)

B

(mm )

32 3755 1185

37 4275 1705

42 4795 2225

IEMCA228510031

15

2

TECHNICAL INFORMATION

302.087

Table 4. General technical data

Round bar diameter min 2 mm (5/64”) max 26 mm (1”)

Square bar side min 2 mm (5/64”) max 18 mm (45/64”)

Hexagonal bar height

(key socket) min 2 mm (5/64”) max 22 mm (7/8”)

Minimum bar length 1500 mm

Maximum bar length mod 32 - 3210 mm (10,5 ft)

mod 37 - 3730 mm (12,2 ft)

mod 42 - 4250 mm (13,9 ft)

Magazine capacity

(working width) 265 mm

(es: 22 barre da ø 12 mm)

Maximum bar remnant

length 400 mm

Bar change time 30 sec

Maximum feed speed 1250 mm/sec

Supply voltage 230/400 Volt

Control voltage 24 Volt

Installed power 1.5 kW

Air pressure 6 bar

Quantity of oil 40 l

Dry weight mod 32 - 650 kg

mod 37 - 700 kg

mod 42 - 750 kg

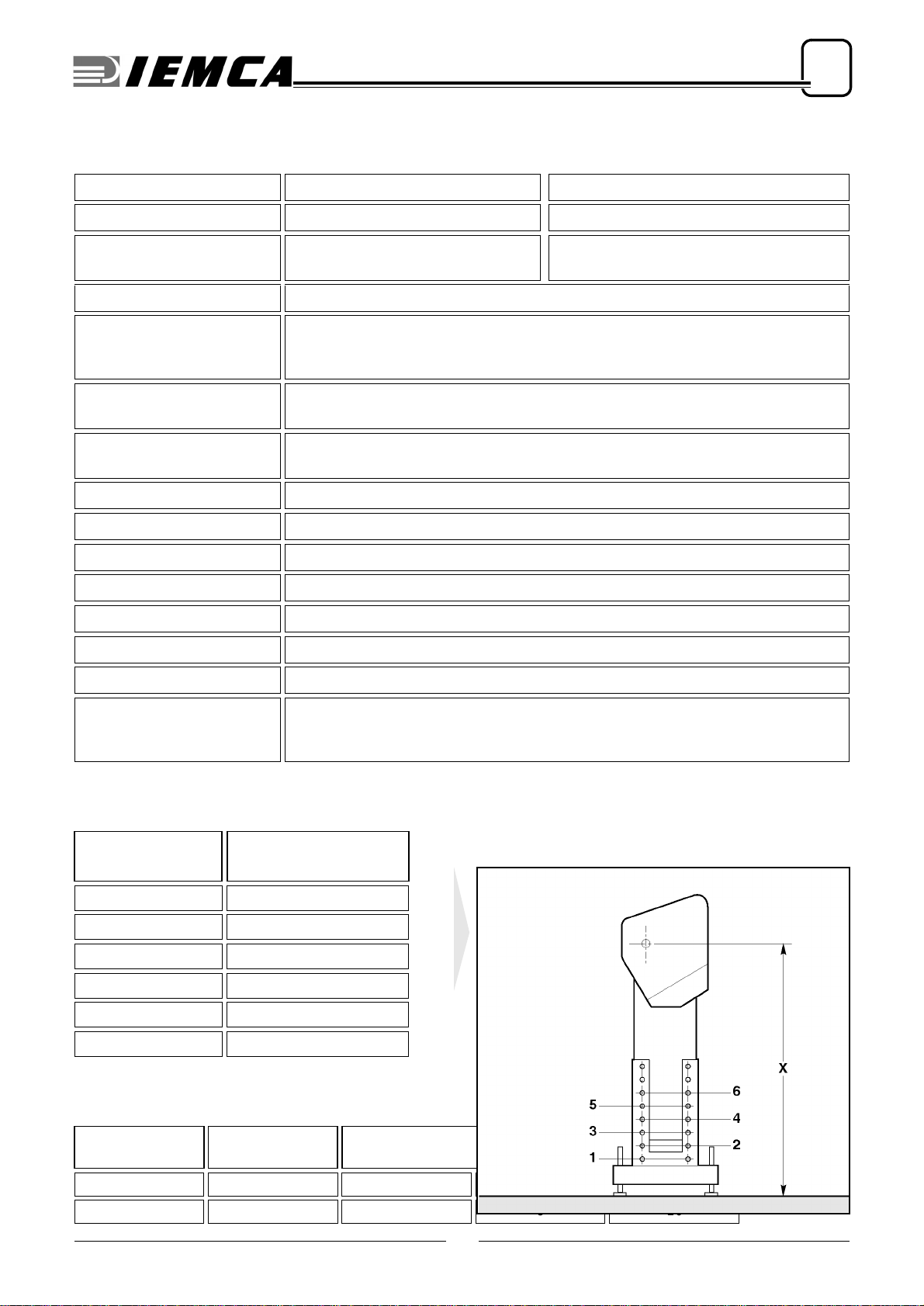

Table 5. Working axis height

Position of bottom

screws

X

(mm)

1890÷949

2950÷1009

31010÷1069

41070÷1129

51130÷1189

61190÷1250

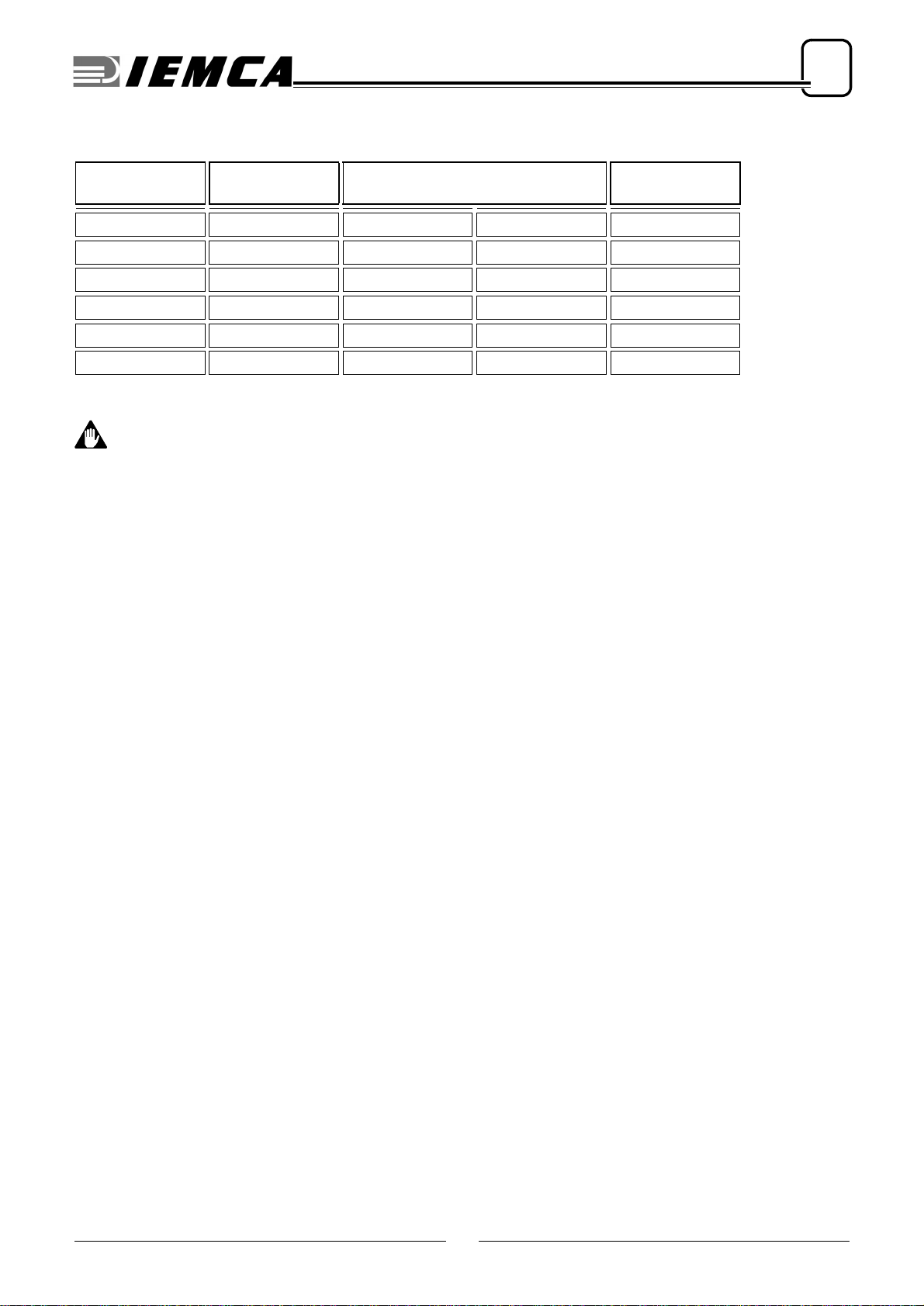

Table 6. Diameters of guides, bar-pusher, bars and pipes

Guide

diameter (mm) Bar-pusher

diameter (mm) Bar diameter (mm) Largest pipe

diameter (mm) (*)

87,5 26,5 7

11 10 3 9 10

16

2

TECHNICAL INFORMATION

302.087

(*) valid also for prepared bars or normal bars machined with front remnant ejection

CAUTION: Barstock diameters for any guide

channel are only given as an example. A barstock

diameter approximately 5 mm smaller than the

guide channel diameter may cause vibration and

failure to the bar feeder. Therefore, it may be nec-

essary to slow down the bar rotation speed or to

change the guide channel diameter in order to ob-

tain the best performance for a specific applica-

tion.

13 12 411 12

18 15 513,5 17

22 20 518,5 20

26 25 823 25

28 27 825 26

30 29 826 26

Table 6. Diameters of guides, bar-pusher, bars and pipes

Guide

diameter (mm) Bar-pusher

diameter (mm) Bar diameter (mm) Largest pipe

diameter (mm) (*)

Table of contents

Popular Industrial Equipment manuals by other brands

Eaton

Eaton CODMV Series Instruction leaflet

ABB

ABB HT608847 Operation manual

GREER Company

GREER Company MicroGuard RCI 510 troubleshooting manual

Berker

Berker RolloTec 2911 operating instructions

Zaber Technologies Inc.

Zaber Technologies Inc. VSR-E Series user manual

Siemens

Siemens SINUMERIK 808D ADVANCED T user manual