This product is designed as a general industrial device. Do not use for other applications. We do not take any

responsibility for any damage that may result from the disregarding of these warnings.

In the event that an accident results from the use of this product, we do not compensate for any damage,

including abnormalities of equipment, connection devices, and/or software, any damage resulting from

malfunctions, and/or any other secondary damage.

Caution : Installation, operation and usage of ITOH DENKI MDRs in combination with a control card designed by a

third party could result in fatal phenomena such as fire, electric shock, injuries, etc. which are out of the

responsibility of ITOH DENKI.

introduction

notes on industrial property rights:

disclaimer:

There are some examples of parts that need to be prepared by customers, as explained within this manual.

However, this does not provide any guarantee against the existence of any rights, such as our industrial

property rights, or those of other companies.

*

1

:

International Organization for Standardization

*

2

:

This indicates that even though events that would result in serious injury occur infrequently under

assumed risk environment, there is a high probability to avoid danger if you observe the safety contents

described in this manual.

This product is based on the performance level “C”*2 in ISO-13849-1*1.

notes on technical support:

We respond to technical inquiries based on the contents described within this manual, and on this product

within the range of general items for this product unit.

There are some descriptions in this manual, about parts, equipment, and wiring arranged by customers, as

well as the controls and operation under such circumstances. However, these are not included in the

guaranteed operating range and/or support.

When in use, please check and perform the aforementioned based on your responsibility according to

operation.

About the performance level (PL) for this system:

*

1

:

Insulation coordination for equipment within low-voltage supply systems - Part 1 of the

International Standard

*

2

:

Non-conductive pollution will occur, but it is assumed that condensation will happen to generate

conductive property temporarily.

This product is not equipped with special dust proof/waterproof countermeasures, and is intended to be

used in environments of “Pollution Degree 2”*2 , as defined in IEC60664 -1*1.

installation environment:

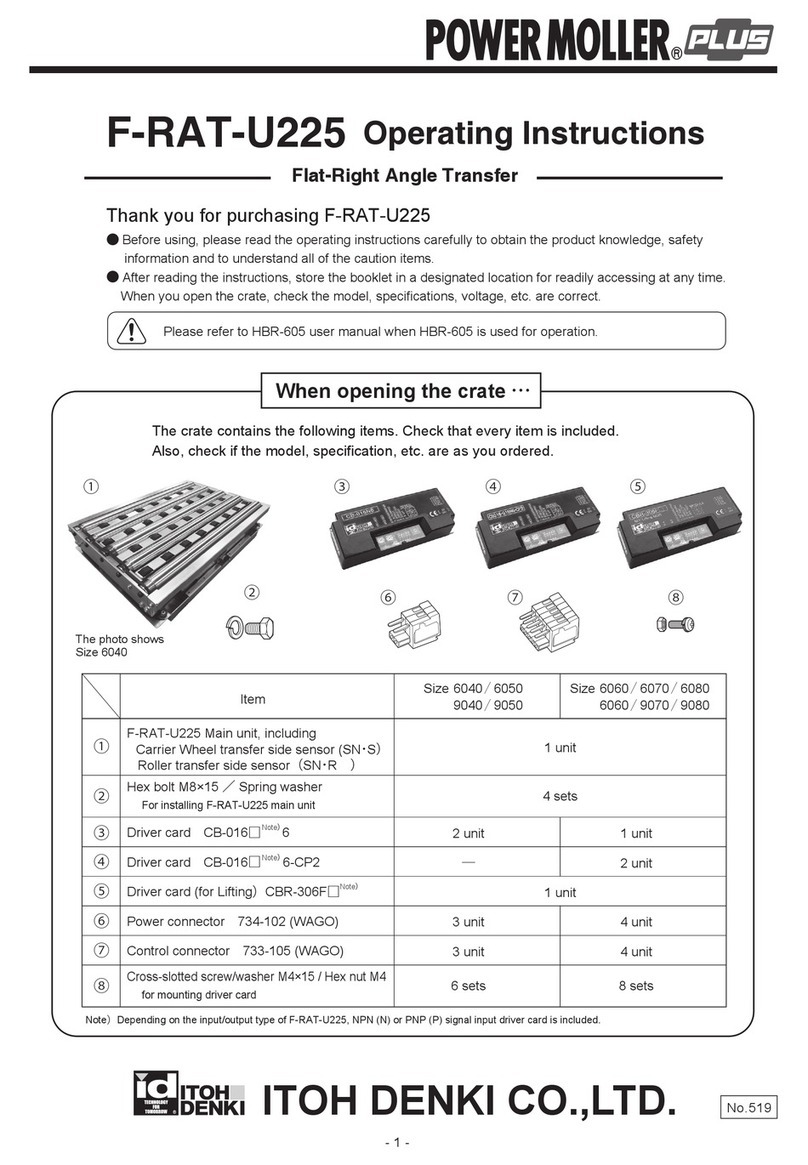

Depending on the signal type (NPN/PNP) specified by customers, different models of controllers are

supplied as being the standard for this product.

In this manual, IB-E06F-N-UL-M1 and IB-E06F-P-UL-M1 are described as IB-E06F-M1, and IB-E06F-N-UL-M1

and IB-E06F-P-UL-M1 are described separately, when needed.

Illustrations and wiring images in this manual are described under the assumption that two units of this

product are to be synchronized and controlled. When the number of synchronized units is different, or

multiple units of this products are to be controlled separately, perform wiring and control according to

the respective conditions.

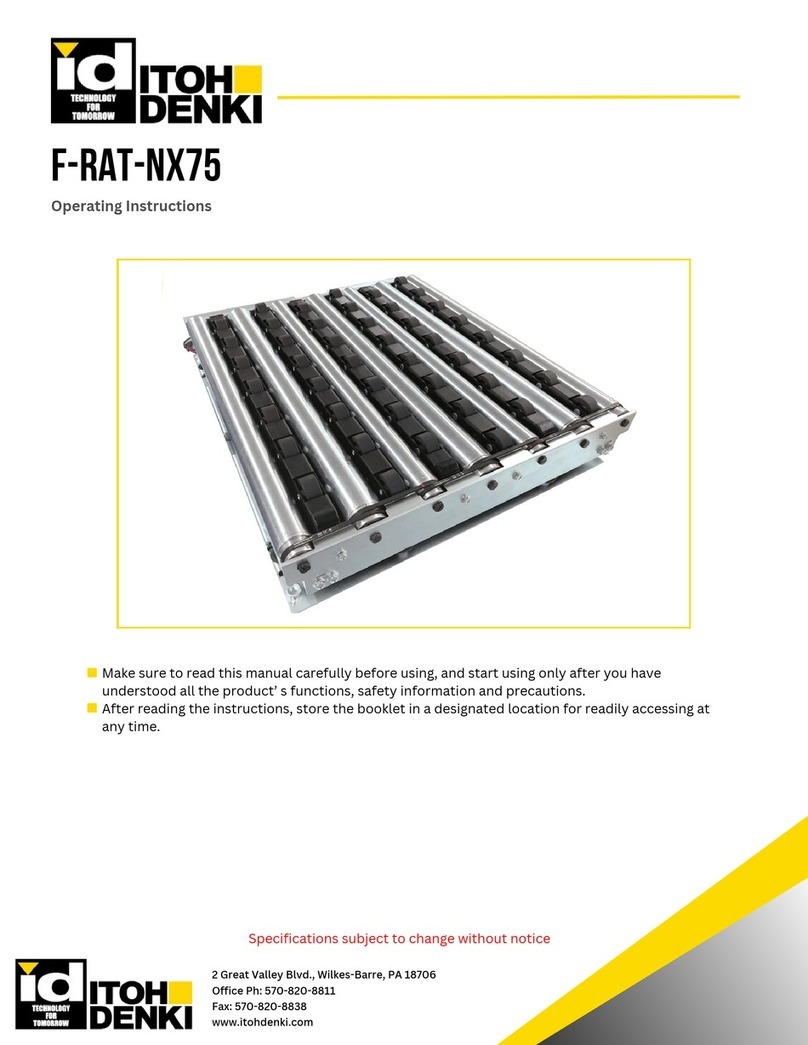

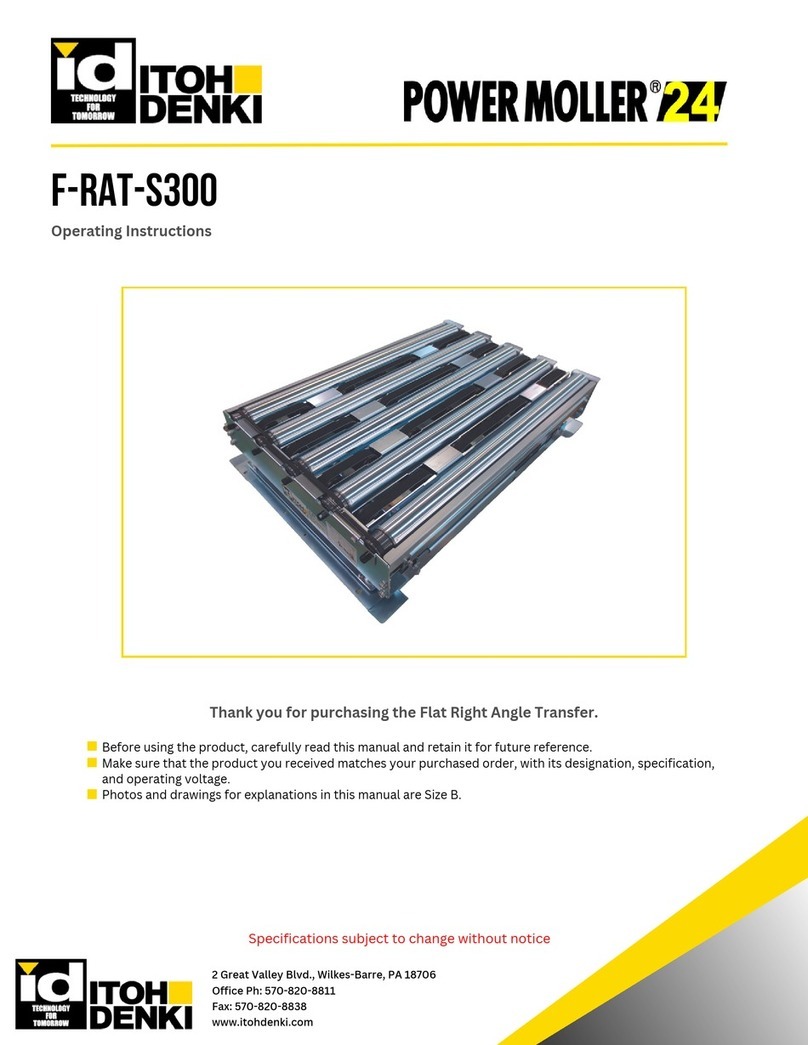

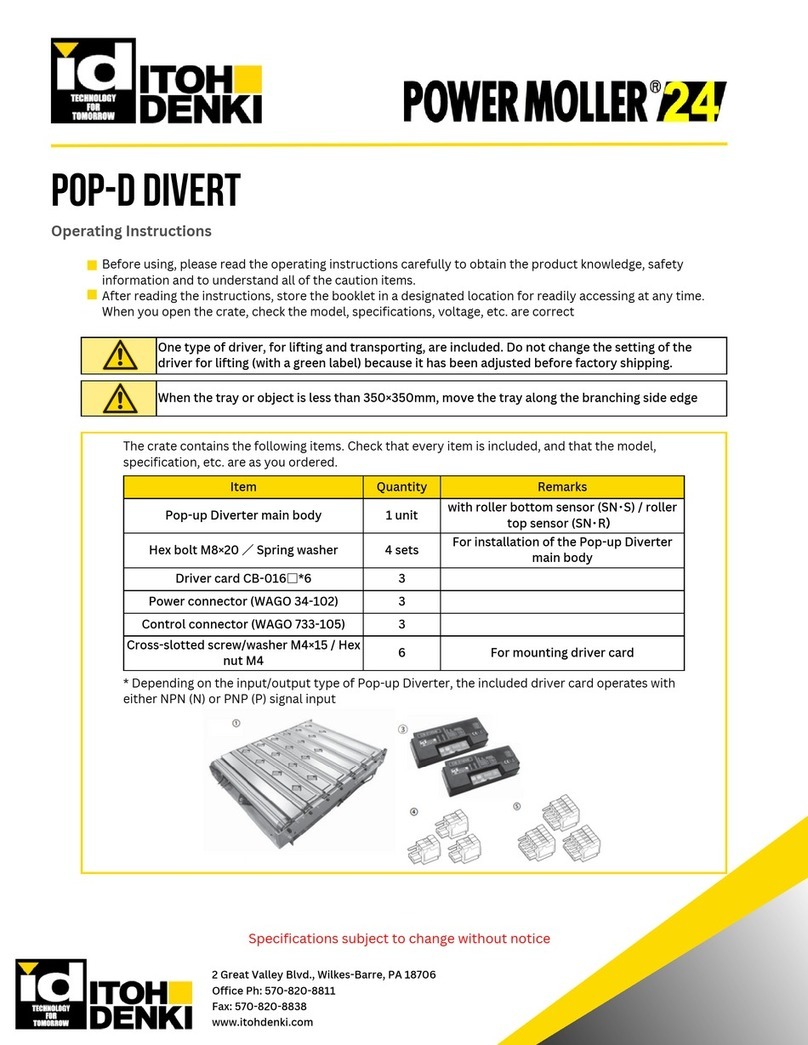

description of the product: