MICROGUARD RCI 510 TROUBLESHOOTING MANUAL i W450260D 03/10

TABLE OF CONTENTS

Introduction ..............................................................................................................................................................................1

1.1 Overview and Preparation ...........................................................................................................................................2

2.1 System Self-Test ...............................................................................................................................................................3

2.2 Display Console Problems .....................................................................................................................................4

2.3 Fault Reporting and Fault Codes ........................................................................................................................5

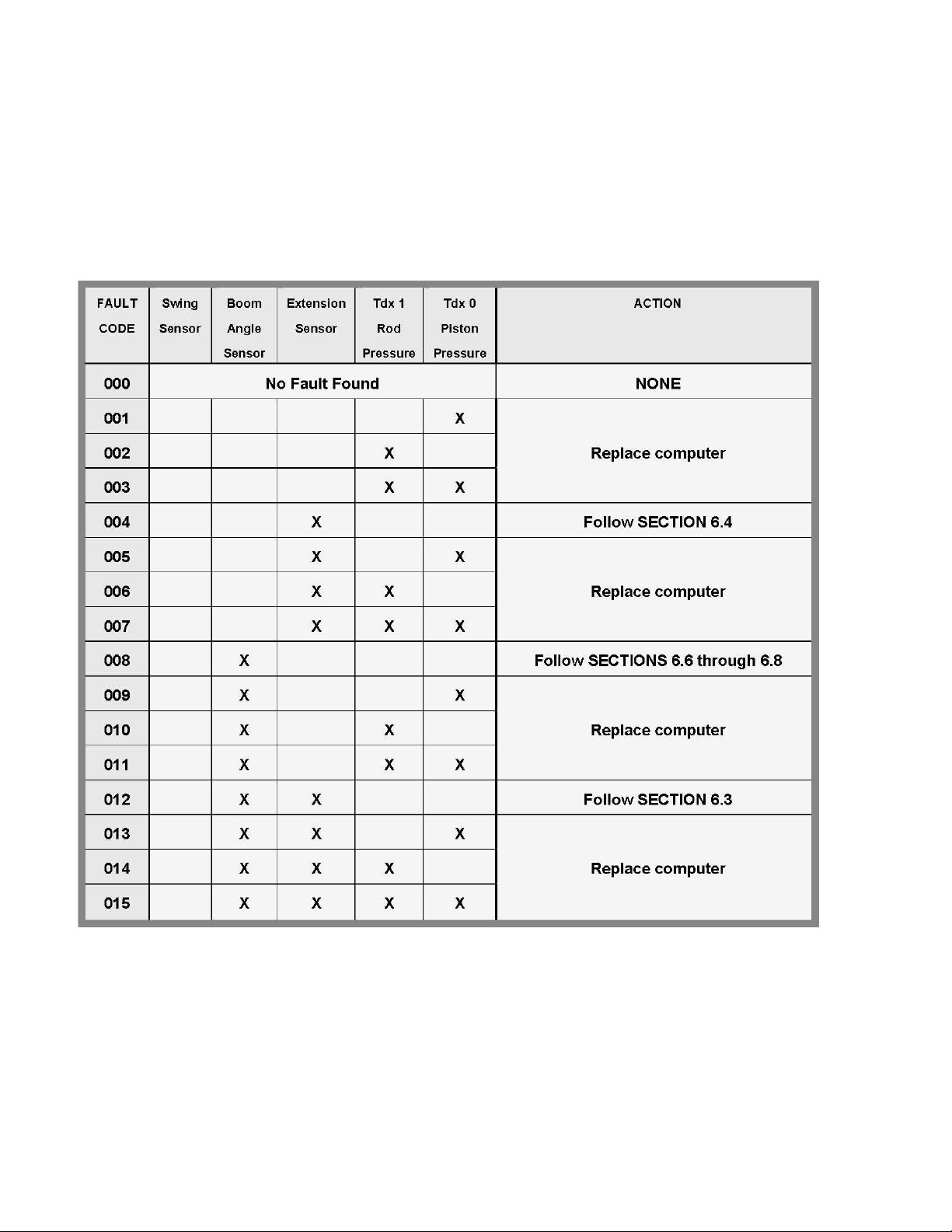

2.3.1 Group “A” Fault Codes ...........................................................................................................................................6

2.3.2 Group “B” Fault Codes ..........................................................................................................................................8

2.3.3 Group “C” Fault Codes ..........................................................................................................................................9

2.3.4 Group “D” Fault Codes ....................................................................................................................................... 10

2.4 “No Fault Code” Problems .................................................................................................................................... 11

2.4.1 Anti Two-Block Alarm (A2B) ............................................................................................................................ 11

2.4.2 Displayed Load or Radius Errors .................................................................................................................... 12

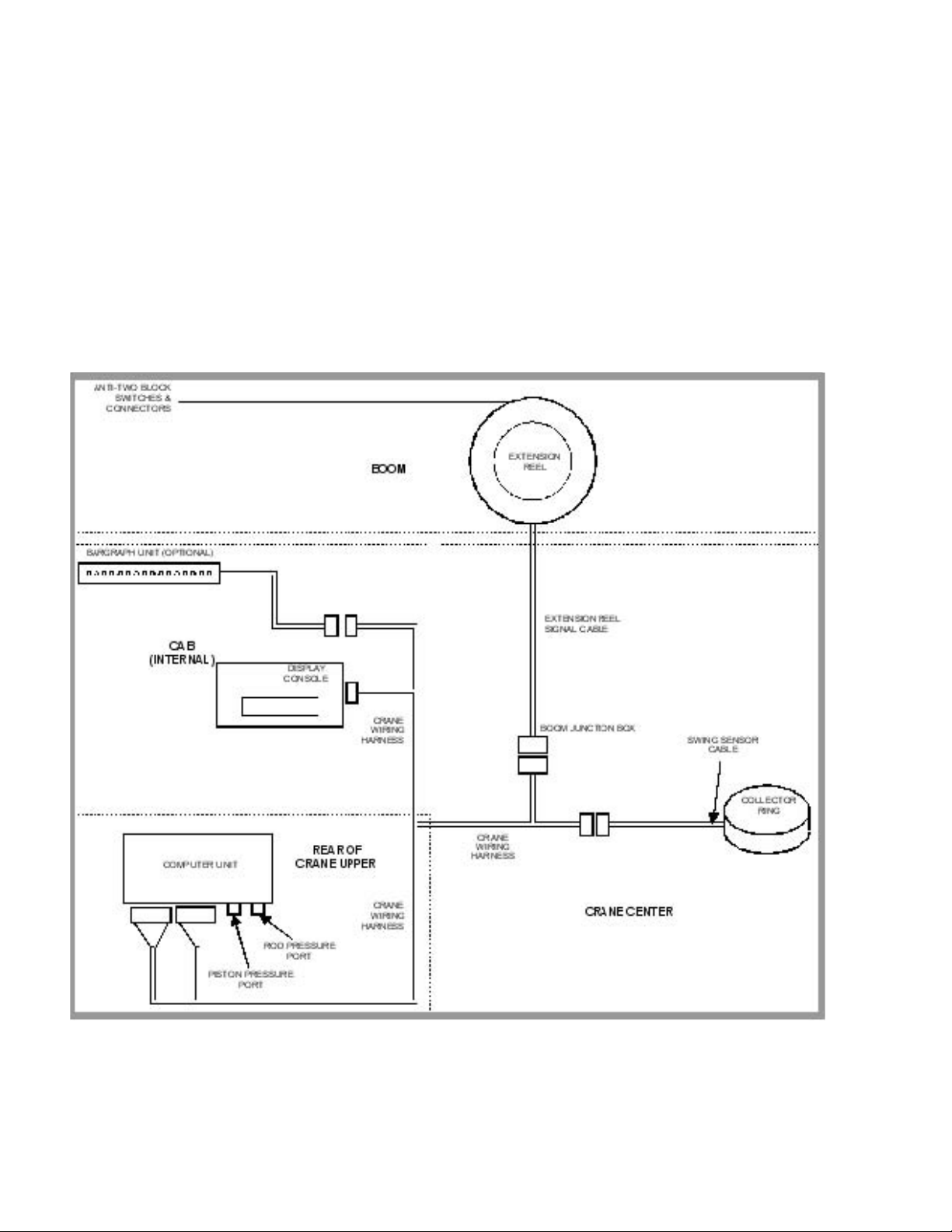

3.1 Computer Unit Overview .......................................................................................................................................... 14

3.2 Computer Unit Layout .......................................................................................................................................... 15

3.3 Internal Status Indicators ................................................................................................................................... 17

3.4 The COMM Indicator ............................................................................................................................................ 18

3.5 Computer Unit Replaceable Part ..................................................................................................................... 19

3.5.1 Function Kickout Fuse (FUS1) ......................................................................................................................... 19

3.6 Pressure Sensors ..................................................................................................................................................... 20

3.7 Replacing the Computer Unit ........................................................................................................................... 21

4.1 Display Console Overview ........................................................................................................................................ 22

4.2 Display Console Models ....................................................................................................................................... 22

4.3 Checking the Display Console ........................................................................................................................... 22

4.3.1 Reading the LCD ................................................................................................................................................. 22

4.3.2 Unresponsive Buttons ....................................................................................................................................... 23

4.3.3 Connectors ............................................................................................................................................................ 23

4.3.4 Horn ......................................................................................................................................................................... 23

4.3.5 Moisture ................................................................................................................................................................ 23

4.4 Replacing the Display Console .......................................................................................................................... 24

5.1 Remote Bar Graph Overview ..................................................................................................................................... 25

5.2 Checking the Remote Bar Graph ..................................................................................................................... 25

5.2.1 Lamps ..................................................................................................................................................................... 25

5.2.2 Brightness Control ............................................................................................................................................. 25

5.2.3 Cable and Connector ....................................................................................................................................... 26