Ignite MARGAY racing K3 User manual

IGNITE K3 SET-UP GUIDE BOOK

margayracing margayracing visit us online at margay.com

margayracing

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 1of 29

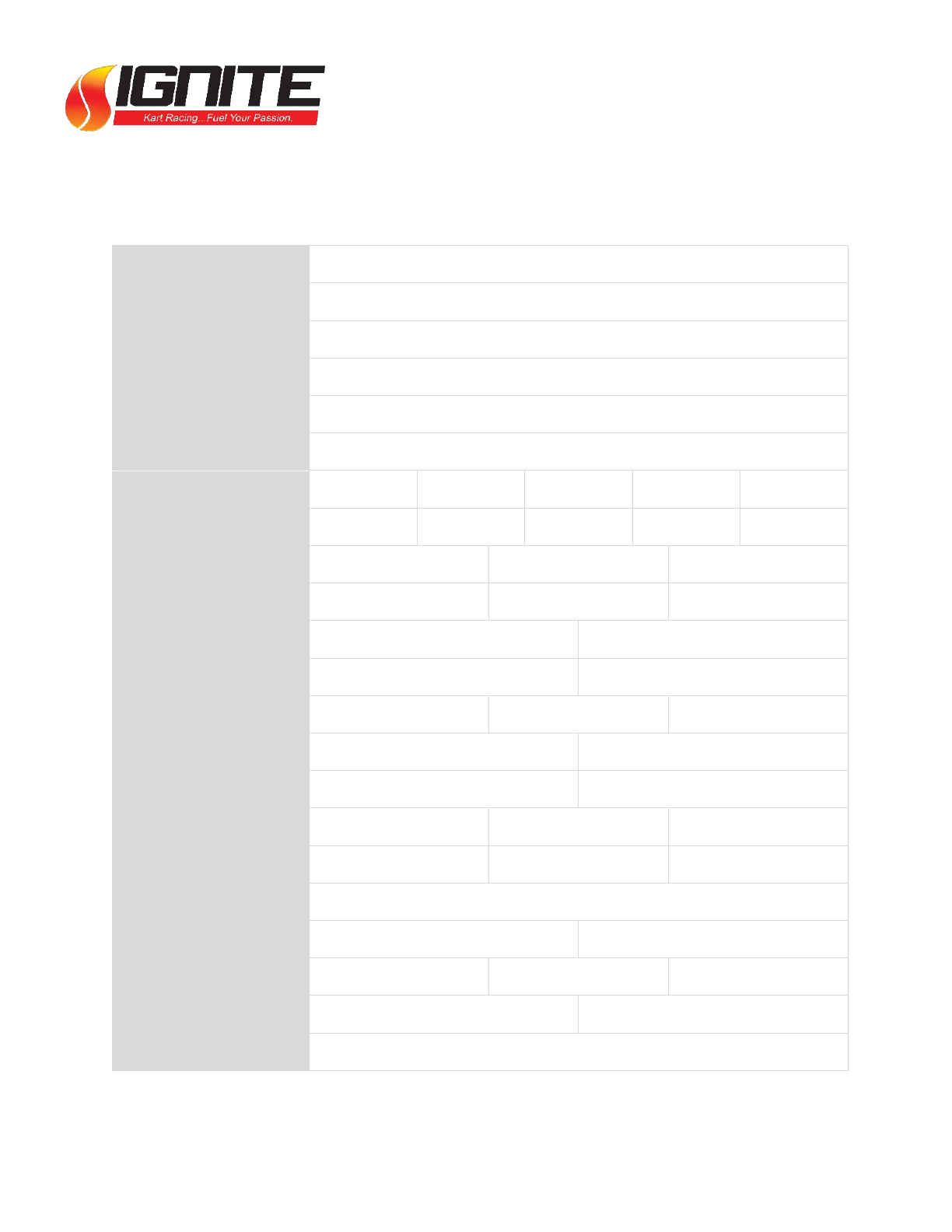

CONTENTS

2 Chassis Information

3 Quick Start Guide

4 Safety Guide

5 General Maintenance

7 Driving Lines and Terms

8 Tire Pressures

9 Wheels and Tires

8 Front Track Width

11 Front Torsion Bar

12 Front Ride Height

13 Caster/Camber/Toe

16 Rear Track Width

17 Rear Wheel Hubs

18 Rear Axle

19 Rear Ride Height

20 Supplemental Seat Struts

21 Seat Style and Positioning

23 Chassis Scaling

24 Wet Conditions

25 Adjusting for Understeer

27 Adjusting for Oversteer

28 Adjusting for Hopping

29 Adjusting for Flat Tight

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 2of 29

CHASSIS INFORMATION

Chassis Model:

2015 Ignite K3

Serial Number:

Chassis Color:

Welded by:

Assembled by:

Spindle heights:

Bodywork Style:

FP7

BDE

Duo

Evo Stilo

Stilo

Bodywork Color:

Black

Red

Blue

Silver

Yellow

Rear Bumper:

RS3

Tris

Metal

Steering Shaft:

17”

19”

21”

Steering Wheel:

Standard Ignite flat top

King 330mm flat top

Steering Hub:

Flat

Angled

Torsion Bar:

None

Tube

Adjustable

Steering Bushing:

Standard (plastic)

Billet toe lock/fairing mount

Seat / Struts:

Standard

Bully adjustable

Axle:

40mm A (soft)

40mm B (std)

40mm C (hard)

Rear Hubs:

65mm wide

95mm wide

125mm wide

Front Wheels:

#75329 –AlumiLite 5” x 135mm DSM

Rear Wheels:

#75425 –AlumitLite 5” x 6.5”

#75415 –AlumitLite 5” x 7.75”

Tires Size:

4.5/10.0-5

6.0/11.0-5

7.1/11.0-5

Tire Compound:

Bridgestone YDS

Bridgestone YLC

Brakes:

MCP Cast system with 8.25” slotted rotor

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 3of 29

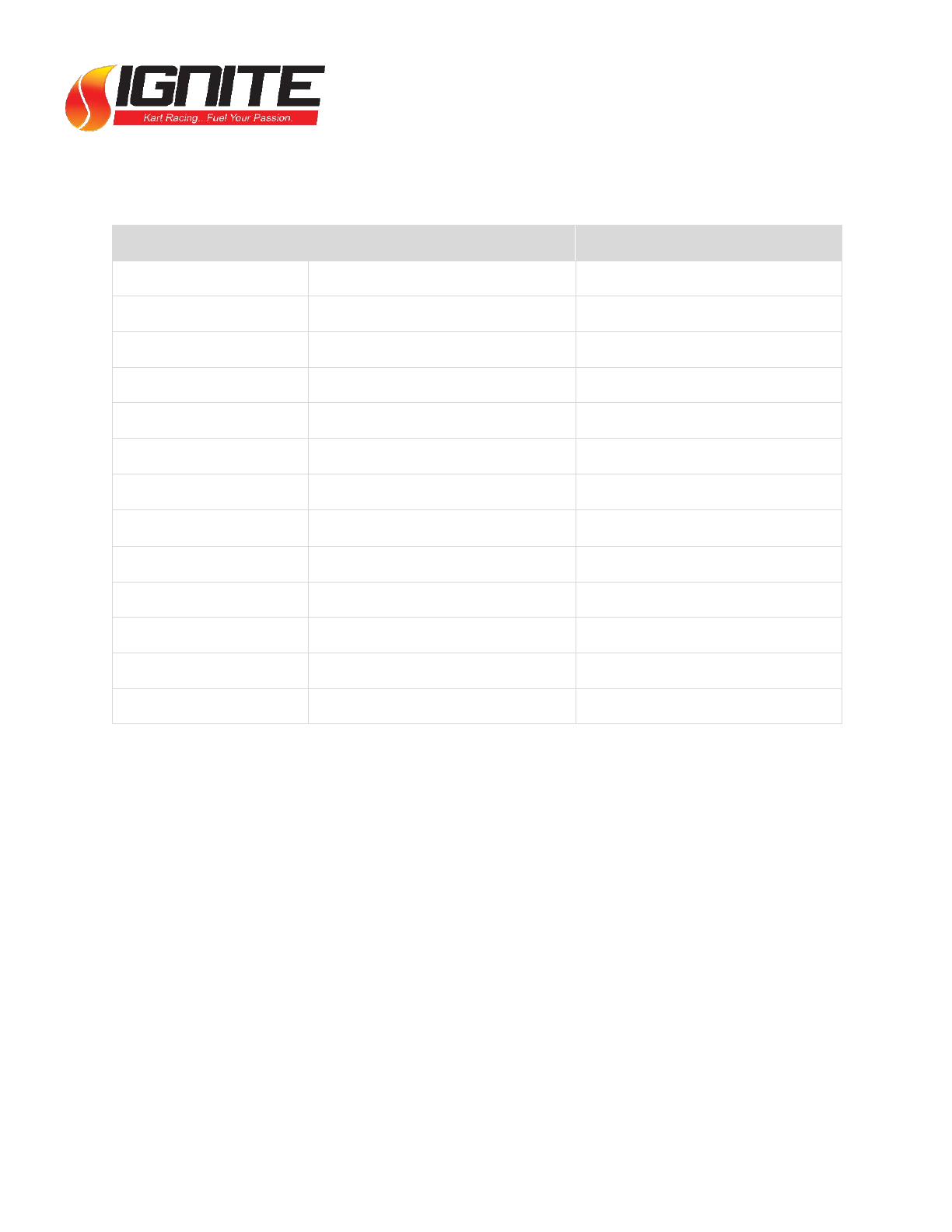

QUICK START GUIDE

Bridgestone YDS

Bridgestone YLC

Tire Pressure

25 –30 PSI

12 –14 PSI

Wheels

AlumiLite –135mm / 7.75”

AlumiLite –135mm / 7.75”

Front Width

30mm inside wheel

25mm inside wheel

Front Torsion Bar

soft position

soft position

Front Ride Height

neutral

neutral

Caster

neutral

neutral

Camber

-2mm / side

-2mm / side

Toe

+1mm / side

+1mm / side

Rear Width

52” outside / outside

52.5” outside / outside

Rear Hubs

40mm x 65mm

40mm x 65mm

Rear Axle

standard –‘B’

standard –‘B’

Rear Ride Height

axle in upper position

axle in upper position

Seat Struts

none

none

SCALING START GUIDE

Front Percentage: +/- 43%

Left Percentage: +/- 49%

Cross Percentage: +/- 50%

(cross percentage refers to RF and LR as a percentage of the total weight)

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 4of 29

SAFETY GUIDE

Always wear a helmet, neck support, driving suit and gloves while operating. Never

drive on public roads, highways or any place other than a sanctioned racing facility.

Karts can cause severe injuries, paralysis or death to the operator or others. Owner

assumes all responsibility for safe operation of the vehicle.

KART INSPECTION

It is the owner’s responsibility to carry out regular inspection of the kart components,

brakes, steering, etc. All steering components should be properly fastened and safety

clipped: steering shaft, tie rods, spindles and kingpins. All braking components should

be properly fastened and safety clipped: master cylinder, brake rod, brake caliper and

brake rotor. All nuts holding on wheels should be locking nuts. All nuts holding on

bodywork components should be locking nuts: front bumper, nerf bars and rear

bumper brackets.

KART MODIFICATIONS

Under no circumstances does Margay Racing authorize or recommend modifications

of any type to the chassis or components we manufacture and distribute. This

includes alternative methods of component assembly, chassis manufacturing, etc.

Altering the chassis or components is solely the responsibility of the owner.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 5of 29

GENERAL MAINTANENCE

Below are a list of items to keep your new kart running at maximum efficiency:

Change oil after Day 1 break-in, and every 2

hours following with 5w30 synthetic engine

oil (any brand).

Ensure front and rear sprockets are aligned

for a smooth chain. Lube chain before every

run with chain lube or a 90w gear oil.

Tension should be loose enough to show 2-3

teeth when pulled up on.

Lube between bearing wall and dust jacket

before every run with Tri-Flo or WD-40. Avoid

the use of white lithium grease.

Inspect and clean clutch components with

brake clean and emery cloth after every 2

hours of use.

FILL

DRAIN

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 6of 29

GENERAL MAINTANENCE (CONT)

At the completion of each days racing

sessions, be sure to pull the carburetor drain

plug screw to empty the float bowl. This will

help limit required maintenance on the

carburetor in the future.

Remove the float bowl on the carburetor and

break clean the brass jets that are screwed

into the housing. This will help ensure your

engine is running at the optimum level.

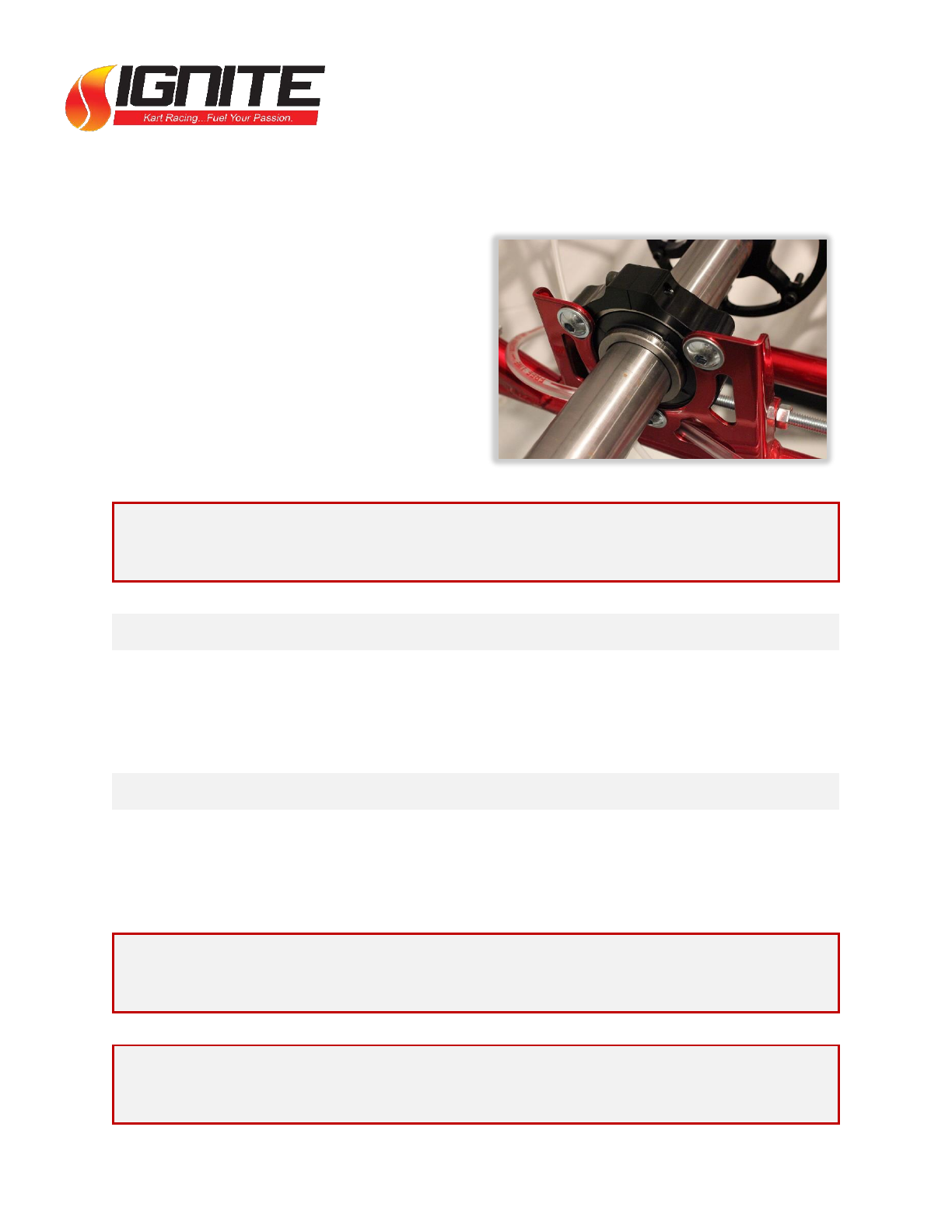

Check and tighten the axle bearing set

screws after each on track session. This helps

ensure that the axle stays in position and

doesn’t move under load on track.

Check header bolts after each run to ensure

they are always tightly fastened. Also check

header mounting bolts, brackets, silencer,

and silencer clamp.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 7of 29

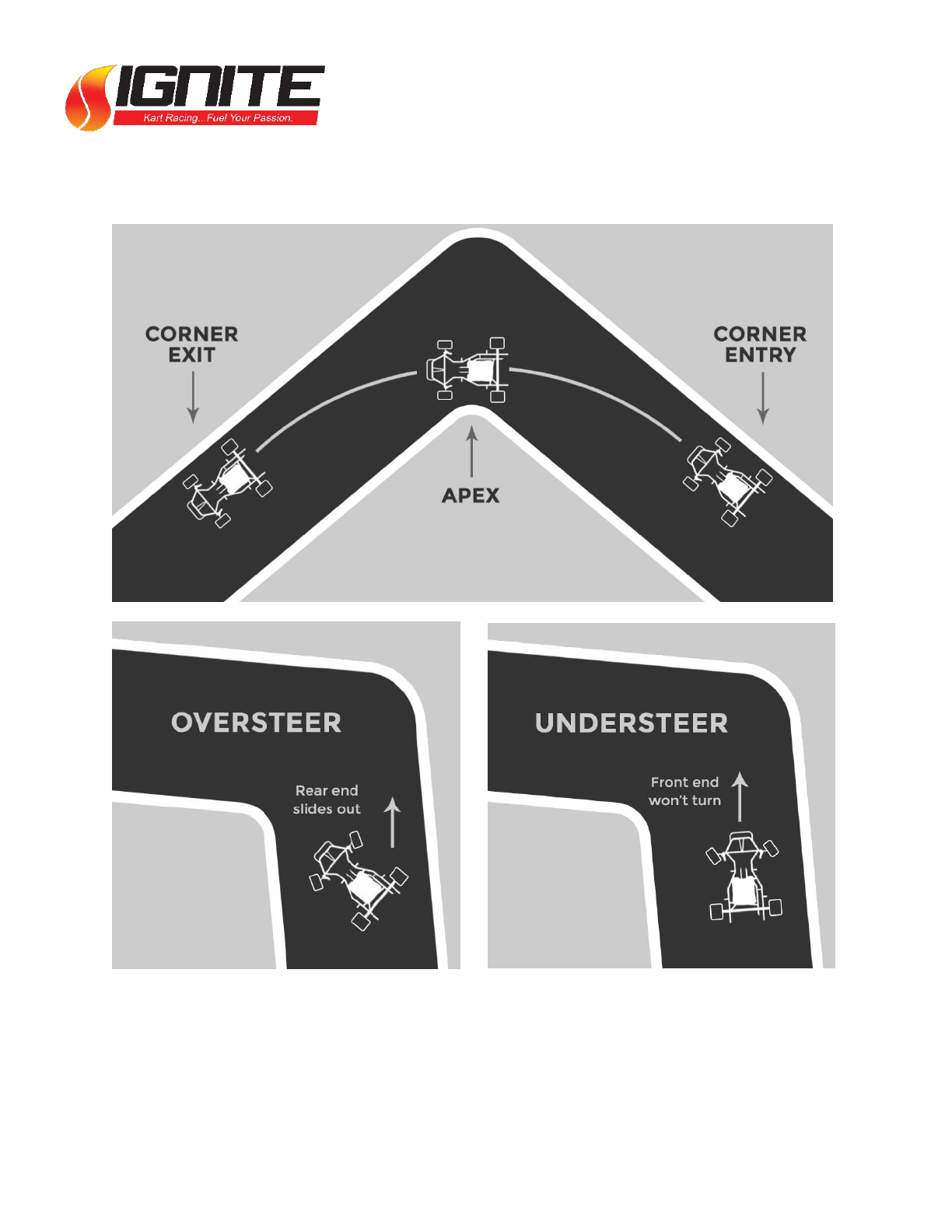

DRIVING LINE AND TERMS

Oversteer is when the rear of the kart

slides more than the front, causing the

driver to counter steer to avoid spinning.

Understeer is when the front slides more

than the rear, causing the kart to ‘push’

forward instead of turning.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 8of 29

TIRE PRESSURES

Tire pressure starting points (set before going on track):

Bridgestone YLB: 10 –12 PSI

Bridgestone YLC: 12 –14 PSI

Bridgestone YDS: 25 –30 PSI

Setting tire pressures for a cold tires is done so the tire can reach maximum

temperature near the last 25% of the race. It is important that you set tire pressures

cold with values that discourage them from becoming too hot during the session.

Using air, each tire should not rise more than 4 PSI during a normal session. We

recommend you check your tires after each session to ensure that they are not

overheating.

PROBLEM: The kart gets better as the race goes on, but by then it’s too late.

SOLUTION: Increase the tire pressures by 1 PSI per session. This will help get the tires

to temperature faster.

PROBLEM: The kart is really good in the first 3 laps, but gets slower from there.

SOLUTION: Decrease the starting tire pressures by 1 PSI per session. Your tires are

getting to temperature too quickly and are likely overheating from there. Decreasing

the starting pressures will allow them to heat slightly slower, making the kart become

progressively better instead of progressively worse.

Cold tire pressures can vary based on ambient temperature. On a cold day, increase

starting tire pressures. On a hot day, decrease starting tire pressures.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 9of 29

WHEELS AND TIRES

The relationship between wheels and tires is an important one, both for handling and

overall performance. The recommended wheels for the Ignite K3 are:

#75329 –AlumiLite 5” x 135mm DSM front wheel / for 4.5 front tires

#75425 –AlumiLite 5” x 6.5” Euro mount wheel / for 6.0 rear tires

#75415 –AlumiLite 5” x 7.75” Euro mount wheel / for 7.1 rear tires

There are also magnesium M-Series wheels available which are more porous than the

spun aluminum wheels. Because the magnesium are more porous, they are softer and

provide less overall grip.

Balancing tires each time they are mounted on the rim is important to ensure that

all rotational mass is properly balanced.

PROBLEM: The front tires are shaking at the end of the straight sections.

SOLUTION: Your front tires likely need to be balanced. Use stick on wheel weights to

ensure that the wheel/tire combination is properly balanced.

PROBLEM: The kart has too much overall grip.

SOLUTION: Switching to the M-Series magnesium wheel set will help the kart lose

some of its mechanical grip. Maintain the same wheel widths will ensure a true back

to back comparison.

The Ignite Series uses a spec wheel width and type for each class. Please refer to

the Ignite Series rule book for more information.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 10 of 29

FRONT TRACK WIDTH

Front track width can be adjusted by

moving spacers to the inside or

outside of the wheel. Adjusting front

track width can adjust the front

responsiveness on turn-in and also

the resulting inside rear tire lift.

Margay karts come with three spacer

sizes: 5mm (small), 10mm (medium)

and 20mm (large).

Baseline front track width settings:

Bridgestone YLB: 20mm inside the wheel

Bridgestone YLC: 25mm inside the wheel

Bridgestone YDS: 30mm inside the wheel

PROBLEM: The front end understeers on corner entry.

SOLUTION: Widen the front track width by 5mm per side, per session. This will

increase front end weight transfer and grip levels on corner entry.

PROBLEM: The front grips too much and causes the rear end to slide on entry.

SOLUTION: Narrow the front track width by 5mm per side, per session. This will

decrease the front end transfer on corner entry.

NOTE: Tighten the castle nut just enough so there is no lateral movement of the

wheel or spacers. Over-tightening will result in pressure being put on the wheel

bearings, causing them to not spin freely.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 11 of 29

FRONT TORSION BAR

Front torsion bars allow you to adjust

the front end rigidity of your kart.

Adjusting the rigidity of the front end

allows you to control the stability and

responsiveness on corner entry and

exit. A stiff front end will increase

turn in responsiveness and a soft

front end will cause the front end to

be slightly lazier.

NOTE: A softer front end will also help create a more stable straight line braking feel,

but at the expense of front end grip.

PROBLEM: The inside rear lifts too much, causing understeering in the front end.

SOLUTION: Use the adjustable torsion bar and set it in the stiff position (shown above).

This will increase front grip levels and reduce the rotation of the inside rear wheel.

PROBLEM: The front end is too “darty”.

SOLUTION: Move the front bar to the soft position, or if already in the soft position,

remove it entirely. This will help create more chassis flex in the front and reduce the

aggressive turn in response.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 12 of 29

FRONT RIDE HEIGHT

Front ride height can be adjusted for

two reasons: to adjust cross weight

percentages and to adjust front end

responsiveness. A standard Ignite K3

has three adjustment shims on top of

the spindle, and three adjustment

shims on the bottom of the spindle.

Shims can be moved and adjusted

accordingly.

PROBLEM: The front end grips too much, creating oversteer through the corner.

SOLUTION: Dropping the spindle down 1 shim will help move the center of gravity

(C.O.G.) to the rear of the kart, reducing the front end responsiveness and increasing

rear end grip levels.

PROBLEM: I can’t get the front end to be as responsive as I want it to be.

SOLUTION: Raise the spindle 1 shim at a time. This will move the C.O.G. to the front of

the kart and increase your front weight percentage, resulting in an increase in front

end grip levels.

PROBLEM: While scaling, the front weights are off 10lbs from RF to LF.

SOLUTION: Drop the spindle 1 shim on the light side. This will raise that corner and

create a shift of an average of 6lbs and help balance out the front weight transfer.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 13 of 29

CASTER / CAMBER / TOE

Front end geometry is crucial in

creating the perfect handling kart.

Caster, camber and toe can be

adjusted to achieve almost any

desired handling characteristic.

Standard settings are:

Caster: Neutral (15 degrees)

Camber: -2mm per side

Toe: 1mm toe out per side

POSITIVE CASTER

NEGATIVE CASTER

PROBLEM: The kart sits flat and slides. The inside rear does not pick up on entry.

SOLUTION: Add positive caster using the adjustable caster/camber pills. Rolling the

top of the kingpin towards the rear of the kart increases the caster angle and increases

weight transfer and grip levels.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 14 of 29

CASTER / CAMBER / TOE (CONT)

PROBLEM: The kart is hopping through the center of the corner.

SOLUTION: The kart is trying to transfer more weight than the flex in the chassis will

allow. Decrease the caster angle to help settle the weight transfer down through the

middle of the corner.

NOTE: Increasing the caster will always help the kart turn better, but at the expense

of corner exit speed. Increasing the vertical weight transfer puts a larger burden on

the engine. An ideal caster setting would be as little as possible so that the inside

rear wheel lifts on entry but does not lift so much that the kart over-grips.

POSITIVE CAMBER

NEGATIVE CAMBER

PROBLEM: The kart understeers on entry, then grabs and becomes loose in the rear.

SOLUTION: Increase the positive camber in the kart. Standing the kingpin upright will

increase the contact patch of the tire and result in more front end grip.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 15 of 29

CASTER / CAMBER / TOE (CONT)

PROBLEM: The kart is “darty” and too responsive in the front end.

SOLUTION: Decrease the camber (increase the negative camber). This will reduce the

contact patch and reduce front end grip levels.

NOTE: While camber is generally used to adjust front end grip, it does effect the rear

end as well. Negative camber will encourage the inside rear tire to lift.

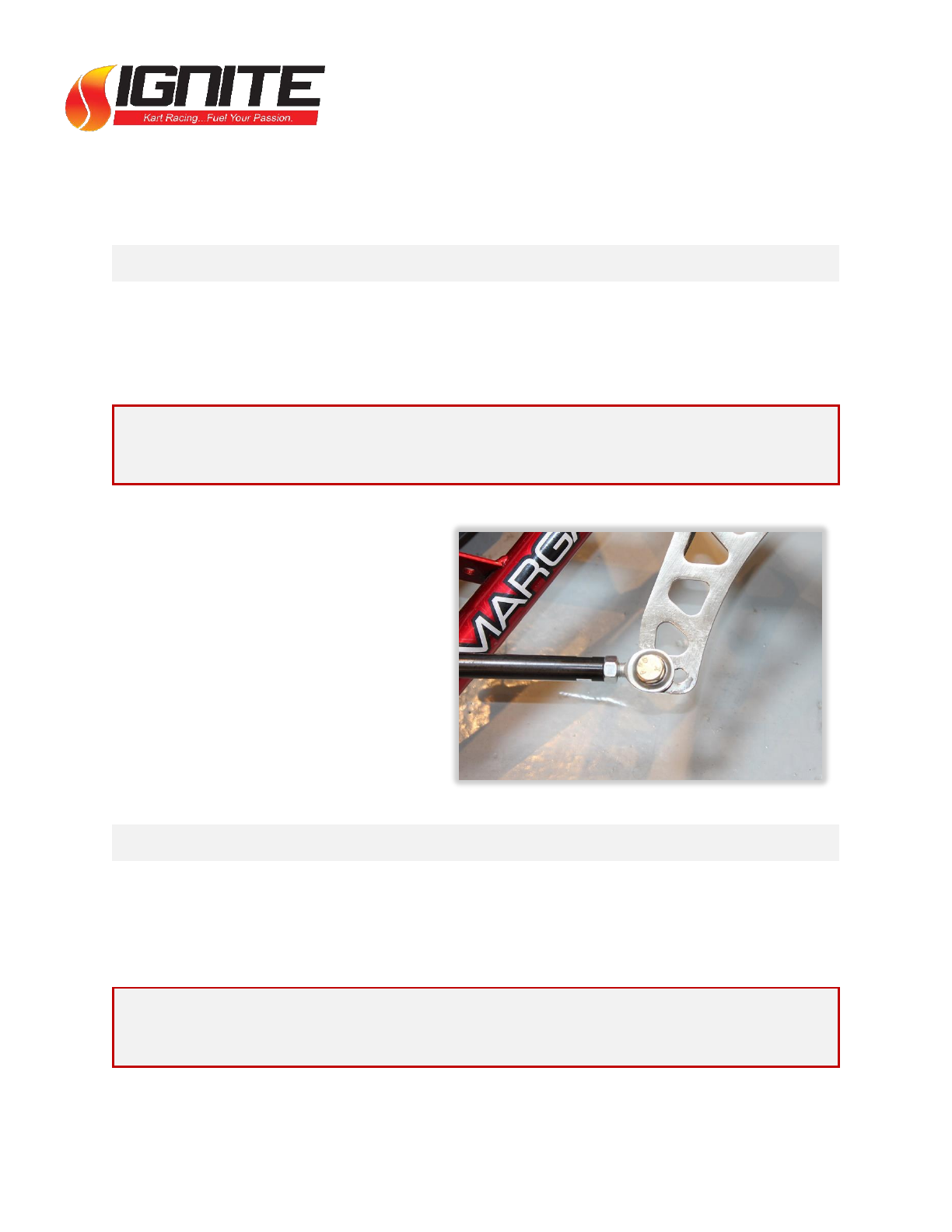

Steering Ackerman can be adjusted

to better suit a drivers required

steering input levels. There are two

adjustment holes on each spindle,

and a center adjustment on the

steering shaft. Recommended

starting positions:

Steering shaft: outer holes

Spindles: inner holes

PROBLEM: The kart lacks steering responsiveness through the corner.

SOLUTION: Increase the amount of Ackerman by moving the tie rods into the inner

holes on the spindle control arm.

NOTE: Any changes in caster, camber, toe or Ackerman will require a realignment of

the front end. The toe generally changes with every adjustment.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 16 of 29

REAR TRACK WIDTH

Rear track width is described as the measurement of the rear width, from the outside

edge of the LR wheel to the outside edge of the RR wheel. Adjusting the rear track

width helps determine the rear weight transfer of the kart. This can be adjusted by

loosening the rear hubs and sliding them in and out to meet your desired width.

Recommended starting positions are:

Bridgestone YLB: 53” outside to outside

Bridgestone YLC: 52.5” outside to outside

Bridgestone YDS: 52” outside to outside

PROBLEM: The rear end of the kart keeps sliding around, forcing oversteer.

SOLUTION: Narrow the rear track width by .25” per side, creating a .5” adjustment

overall. This will stiffen the rear end, and work the outside tire harder.

PROBLEM: The kart is hopping through the middle of the corner.

SOLUTION: Widen the rear track by .25” per side, creating a .5” adjustment overall. This

will soften the rear axle, creating a wider base for the kart through the corner.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 17 of 29

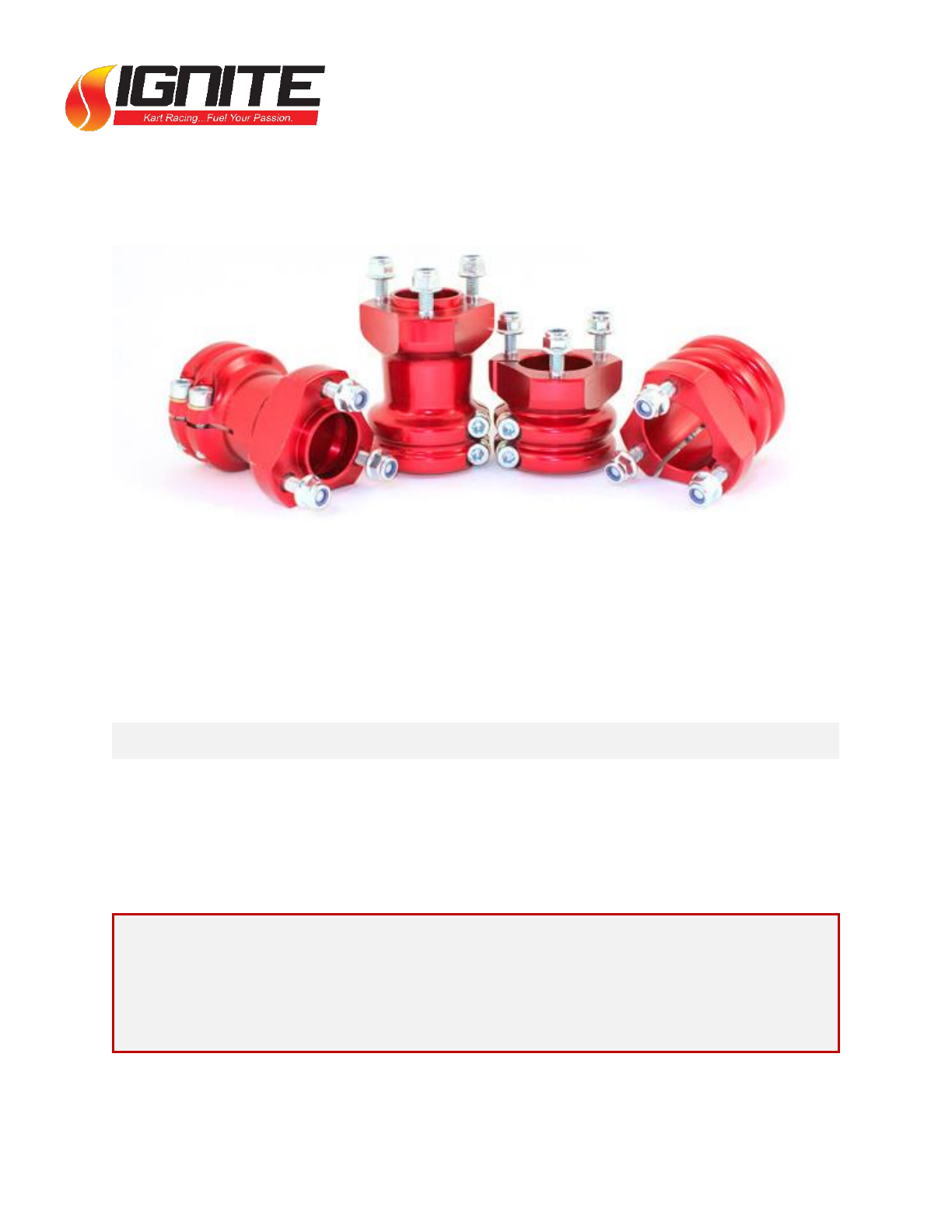

REAR WHEEL HUBS

Rear hubs come in variable lengths, which can be used to adjust rear end stiffness and

rear track width. If rear track width remains the same, and a longer hub is installed,

the leverage point on the axle decreases, causing it to become stiffer and thus working

the outside rear tire harder. Wider hubs can also be used to achieve a wider track

width, because part of the hub can extrude beyond the end of the axle.

PROBLEM: The rear end of the kart keeps sliding around, forcing oversteer.

SOLUTION: Add a longer hub while maintaining the same rear track width. This will

narrow the leverage point of the axle and create a stiffer rear end. A stiff rear end will

ultimately produce more rear grip.

NOTE: Rear hub pinch bolts must remain overlapped with the axle itself. Having

pinch bolts extend beyond the end of the axle can cause them to come off during a

session. Always make sure pinch bolts are tight. If hubs slide in, locking collars can

be added to prevent future movement.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 18 of 29

REAR AXLE

Rear axle stiffness can be adjusted to

create more or less flex in the rear end.

Ultimately, the rule of thumb is: softer

axles create less grip and stiffer axles

create more grip. There are three axle

options available in the 40mm:

40mm ‘A’ Soft

40mm ‘B’ Medium (standard)

40mm ‘C’ Hard

PROBLEM: The rear end of the kart is loose through the middle of the corner.

SOLUTION: Change to a stiffer rear axle. This will direct more weight transfer to the

rear end of the kart, and provide more rear end grip.

PROBLEM: The kart lays flat though the corner with little to no inside rear lift.

SOLUTION: Change to a softer rear axle. This will encourage flex through the rear end

and result in the inside rear lifting easier and with less effort.

PROBLEM: The kart hops through the middle of the corner.

SOLUTION: Change to a stiffer rear axle. This will help keep the kart from flexing too

much through the center, and provide a more stable base throughout the corner.

NOTE: Always tighten axle set screws when changing axles. If needed, use blue

LocTite on each set screw before tightening.

2015 IGNITE K3 SET-UP

BASELINE SET-UP INFORMATION FOR THE IGNITE K3

Page 19 of 29

REAR RIDE HEIGHT

Rear ride height can be adjusted to raise

or lower the center of gravity toward the

rear end of the kart. The Ignite K3 comes

with two vertically adjustable axle

positions. The standard placement is with

the axle in the highest position, which

keeps the rear end of the frame low.

NOTE: Rear ride height positions must be the same for both of the bearing cassettes

to ensure proper alignment of the axle.

PROBLEM: The kart hops through the middle of the corner.

SOLUTION: Drop the rear axle down to the lower ride height holes. This will move the

C.O.G. towards the front of the kart, giving the front end more weight percentage.

PROBLEM: The kart understeers through the center of the corner.

SOLUTION: Make sure your axle is in the upper mounting holes, which will push the

C.O.G. toward the rear of the kart, creating an increase in rear grip.

NOTE: Before changing the axle ride height positions, loosen the bearing set screws.

Occasionally, if left tight, the set screws will cause the axle to bind.

NOTE: Always tighten axle set screws when changing axles. If needed, use blue

LocTite on each set screw before tightening.

Table of contents