igus triflex R User manual

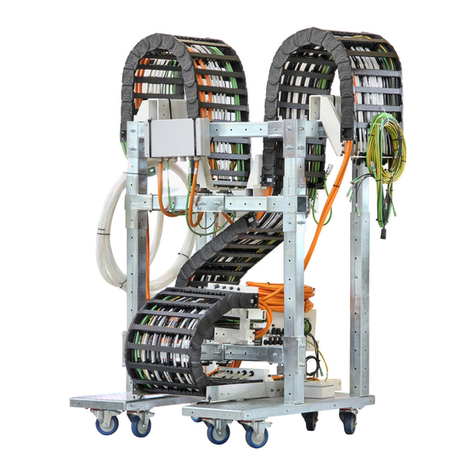

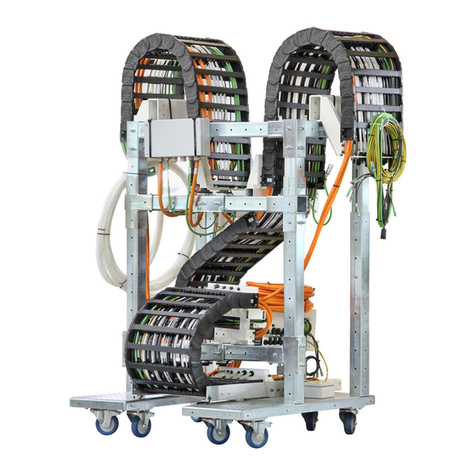

triflex®

retraction system

assembly instructions

www.igus.com/triflexr

plastics for longer life®

RSE

linear

RS

RSP RSE

Wheel

inside cover - blank

triflex®RSE Wheel 14

triflex®RS Modular 22

RSP shown

Table of Contents

triflex®RSE Linear 6

Linear retractions system that creates

tension through the use of elastic bands

triflex®RSE Wheel 14

Low payload retraction system that uses

elastic bands to create tension

triflex®RS Modular 22

Retraction system that utilizes tension

rods as resistance

triflex®RSP Pneumatic 26

Pneumatically driven retraction system

that allows for tension adjustment

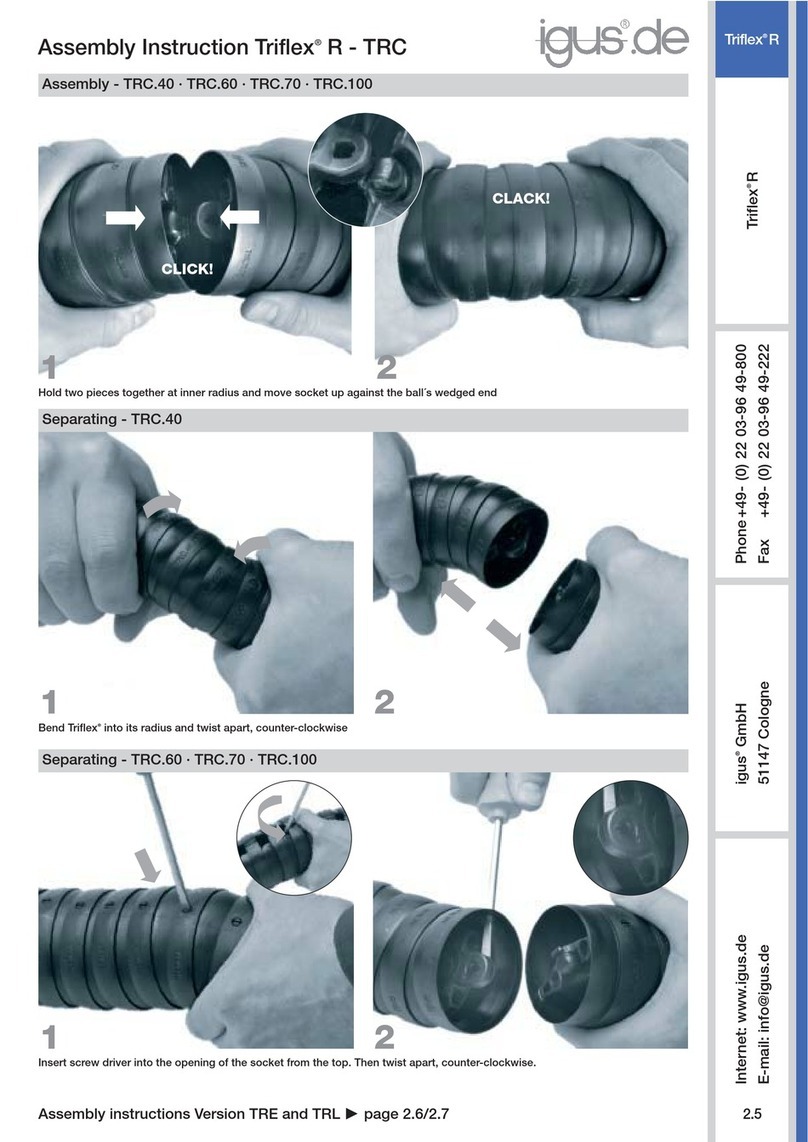

Installation checklist P

Make sure that the ball end of triflex®R is

run in the direction of the tool

1

Remember to use Lock Clips at every fixed bracket

2

Ensure that triflex®R is run straight, not twisted

3

For the end of arm bracket to be

installed correctly, triflex®R

must run into the bracket, not

across the pillow block support

plate

4

Make sure all cables and hoses are strain relieved

individually using tie-wraps or chainfix clamps

5

tie-wraps chainfix

clamps

General Troubleshooting

For system specific troubleshooting see the table at the end of each system

assembly instructions.

Problem Solution

triflex®R comes out of the end of arm bracket 1. Check to make sure Lock Clips are being

used

2. Check to make sure that triflex®R is run in

the correct direction with the ball end run in

the direction of the tool

3. Ensure that the bend radius of the triflex®

R is not being violated during the robot

motion. To relieve this condition, adjust the

end of arm bracket and axis 6 clamp

Cable breaks in the area of the end arm tool 1. Make sure strain relief has been properely

installed at the end of arm bracket

2. Confirm that the service loop from the end

of arm bracket to the tool connection is

sucient

3. Confirm that a torsion rated cable is being

used. If not, contact igus

Cable is coming out of the split opening of triflex®

R TRE

1. Make sure strain relief hs been properely

installed at the end of arm bracket

2. Confirm that the chamber inside triflex®R is

not overloaded

3. Ensure that the cables entering the fixed

end of the system at axis 3 are not pulled

too tight

triflex®R TRE is getting caught on the robot and

is damaged

1. Install a triflex®R protector in any location

that makes contact with the robot arm.

These should be installed 3-5 links apart

wire cutterallen keysscrewdriverwrenches

Tools needed for installation:

6

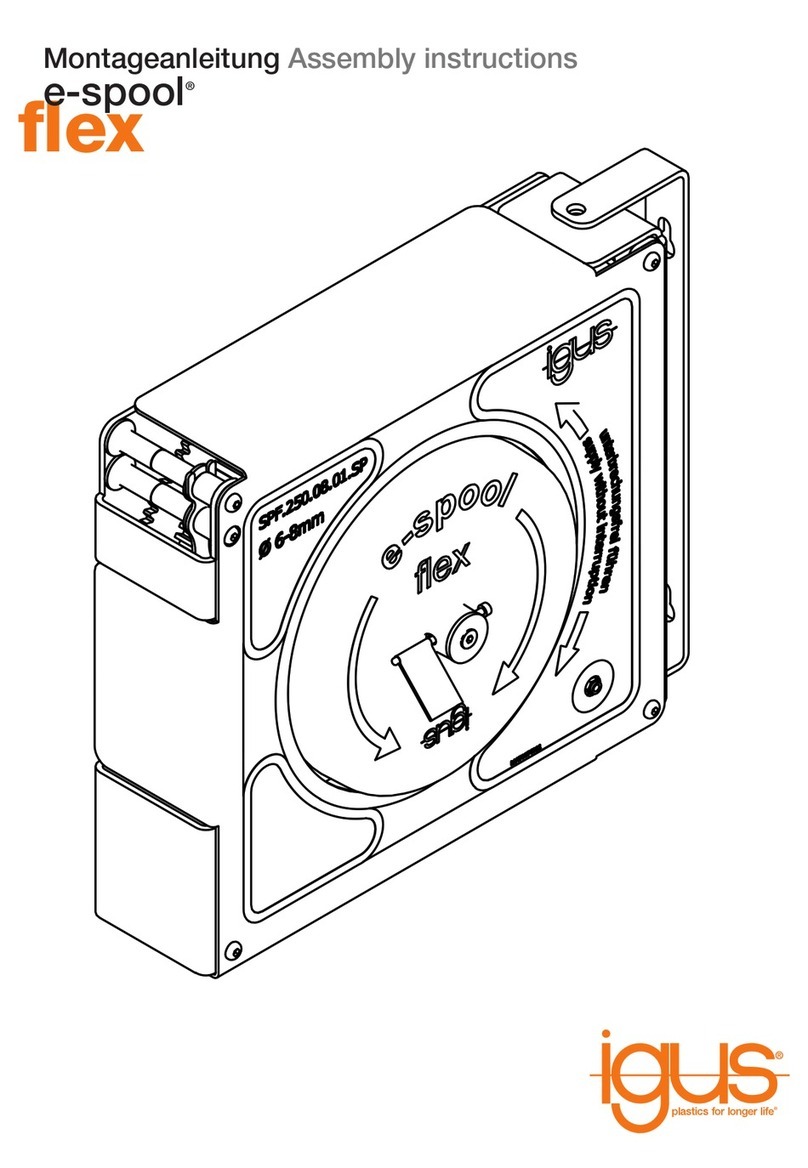

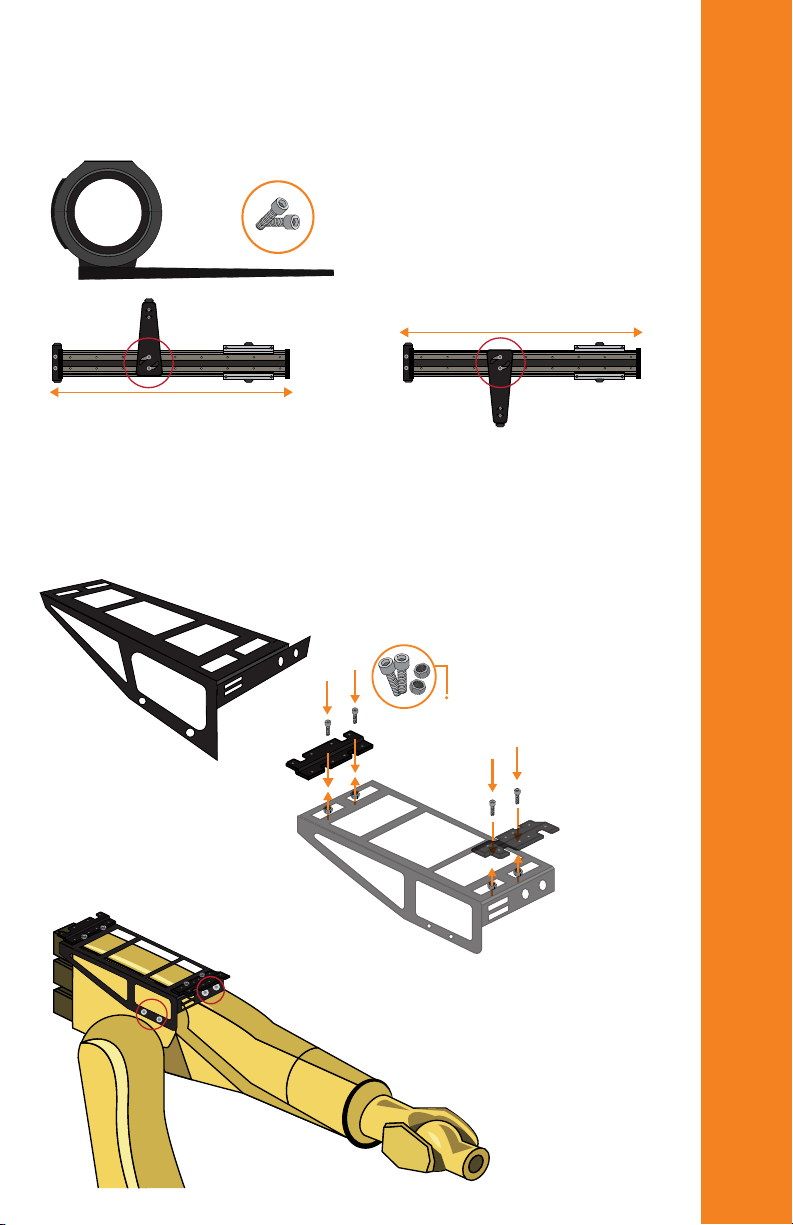

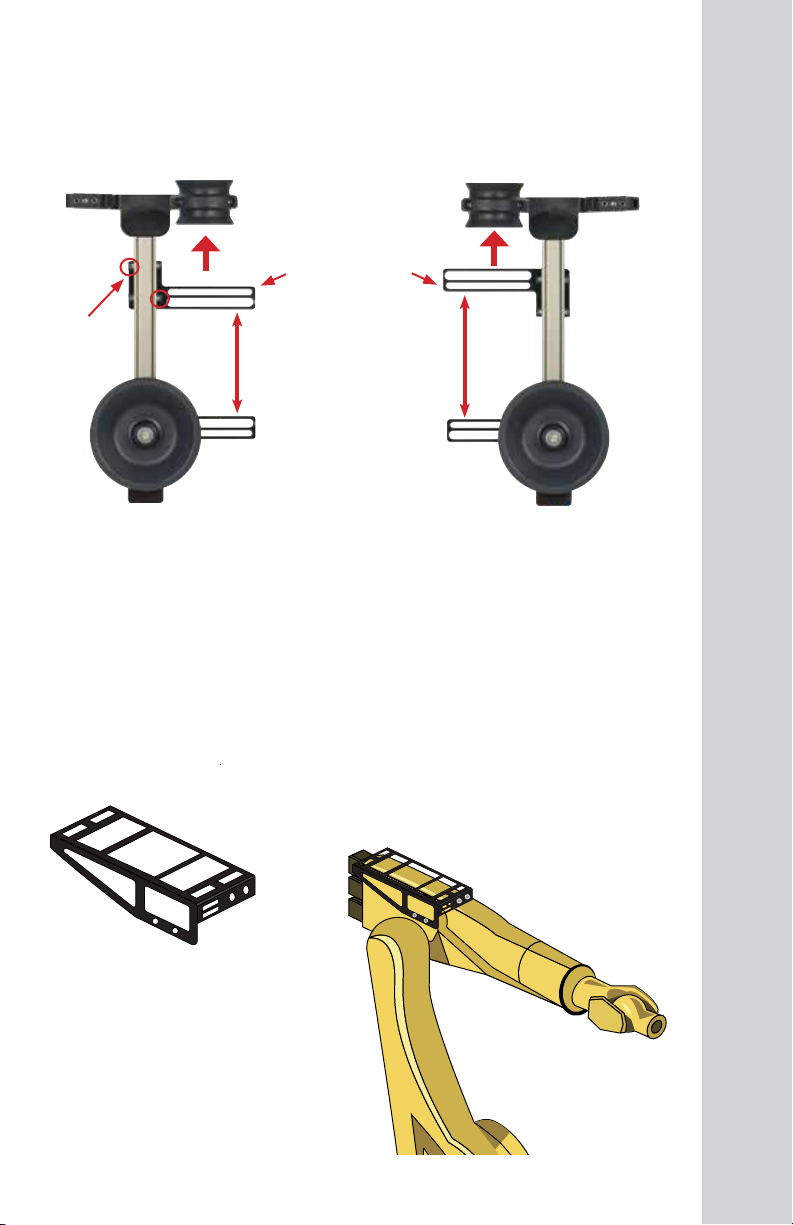

RSE linear retraction system

Tip: Position of mounting feet will need to be adjusted to match the

mounting adapter

Remove mounting feet

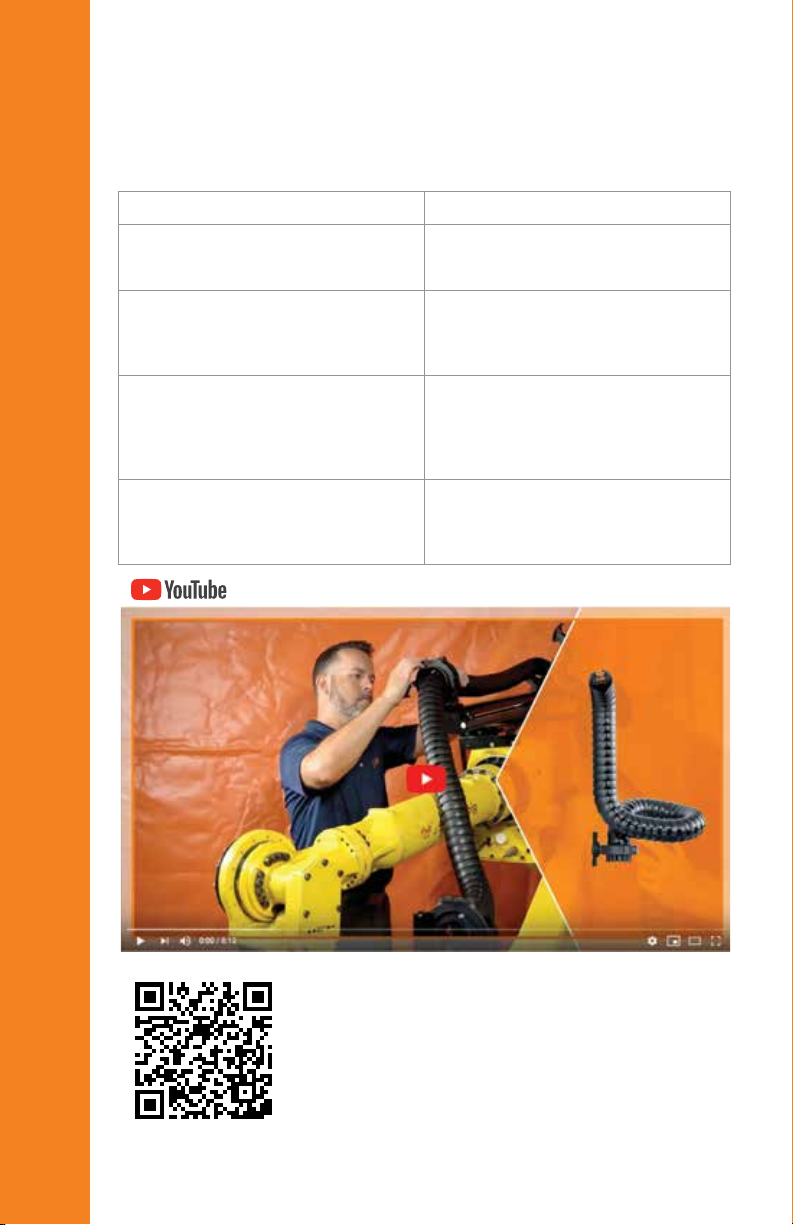

Visit https://toolbox.igus.com and

watch our video: How to install an

igus triflex RSE cable management

system on a six-axis robot

RSE linear installation guide

7

RSE linear installation guide

RSE support bracket

Mount the support bracket to the under-

side of the RSE linear system on either

side

Tip: Mount the support bracket in the middle of the RSE.

(support bracket not available for the 40mm and 50mm size)

Mounting adapter installation example

Note: Each robot model uses

a dierent mounting adapter.

Install the mounting

adapter on the robot

Fasten mounting feet and

adapter together.

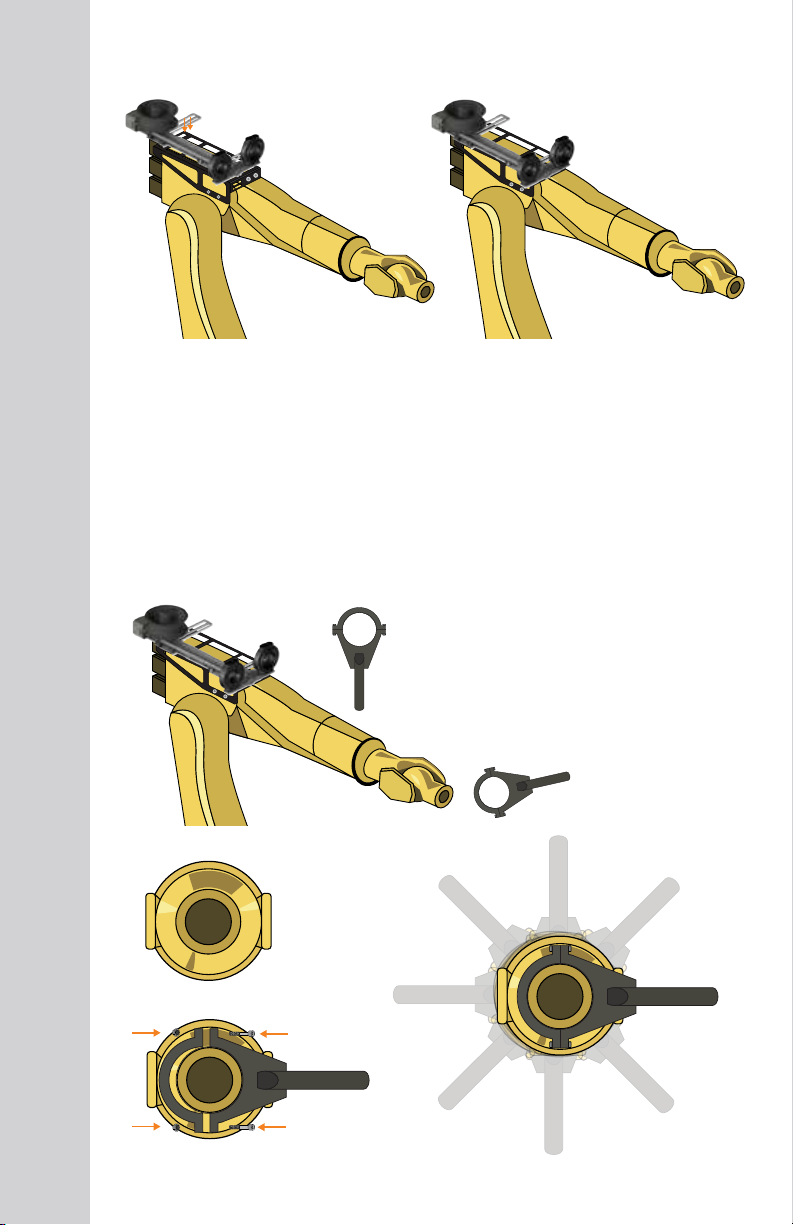

8

Bolts need to be tightened

Note: Tennis rackets available

for most robot models.

Bolts need to

be tightened

uniformly.

Note:

Can be mounted

in any direction

Retraction system installation

Tennis racket (axis 6 clamp) installation

9

Axis 6 bracket installation

Designed with

integrated

profile rail for

CFX clamp

Adjustable in four directions

Tip: Install the bracket as close to the end of the handle as possible and tighten the

bolts equally.

Standard bracket Heavy duty bracket

10

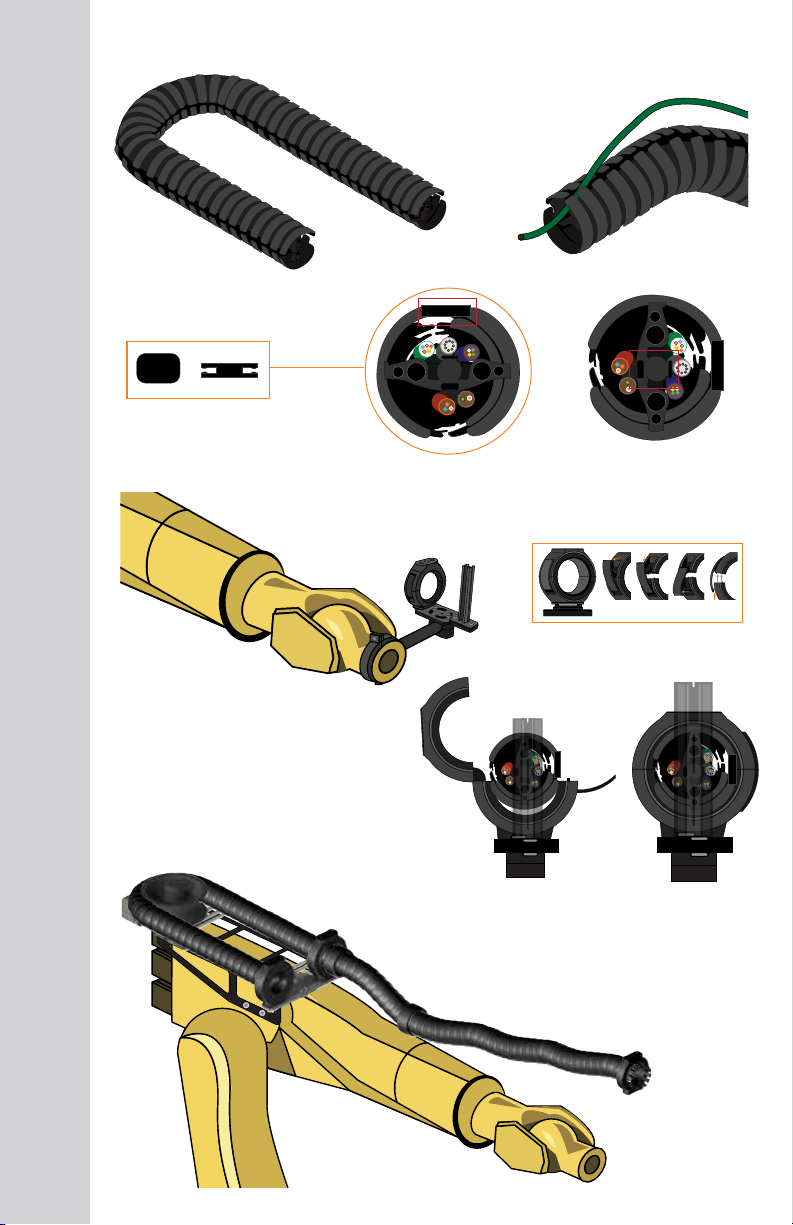

triflex®TRE only - install locking

clips at each fixed bracket

position Important: Ball end of

triflex®R at the EOAT

(End of arm tooling)

Install triflex®R in axis 6

mounting bracket first

Tip: Make sure triflex®R is

not twisted

triflex®R installation

Note: Easy cable installation

possible with triflex®TRE and

TRCF only. If using TRC,

cables will need to be fished

through individually

11

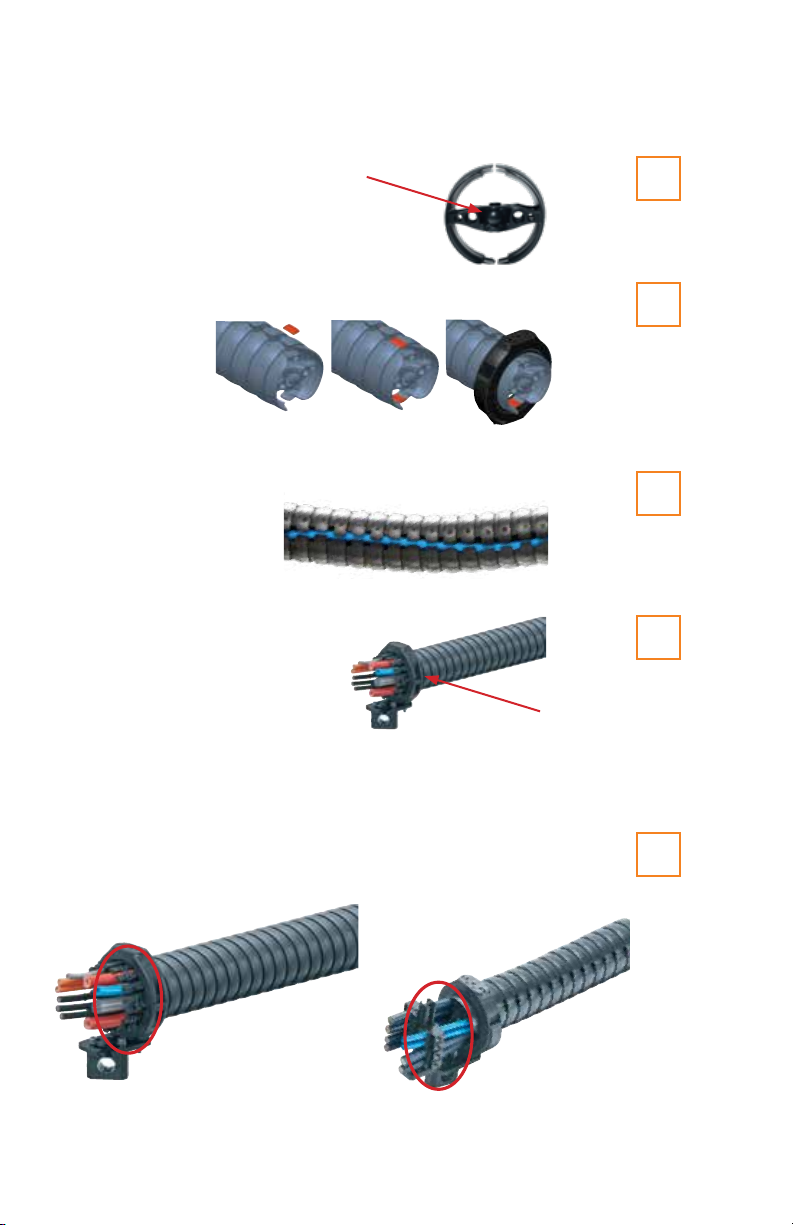

Installing CFX clamps to secure cables

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Protector:

To pretension the system, pull the triflex®forward two links

and install a protector at the exit of the moving end

Tip: For quick release protectors, use a flat

head screwdriver to pry the two halves apart

1

2

3

4

5

Installing protectors

Install protectors where triflex®R makes

contact with the robot

triflex®RSE linear

troubleshooting guide

Problem Solution

triflex®R is getting caught at the back of

the rail as it is extending

1. Install RSE support bracket at

midpoint of RSE rail

triflex®R breaks when RSE System is fully

extended

2. Install more triflex®R outside the RSE

System. The motion of the robot is

greater than the available travel of

the RSE System

RSE System does not function 1. Ensure the bands have tension

2. Confirm that the system is free of

debris

3. Reduce the length of triflex®R

outside the RSE System

Carriage slams when the robot returns to

the home position

1. Pull the system forward two links

and install a protector at the exit of

the pass-through bracket thereby

creating a stop

12

Scan the QR code to view the

triflex®RSE Linear assembly video

13

triflex®RSE linear

Installation examples

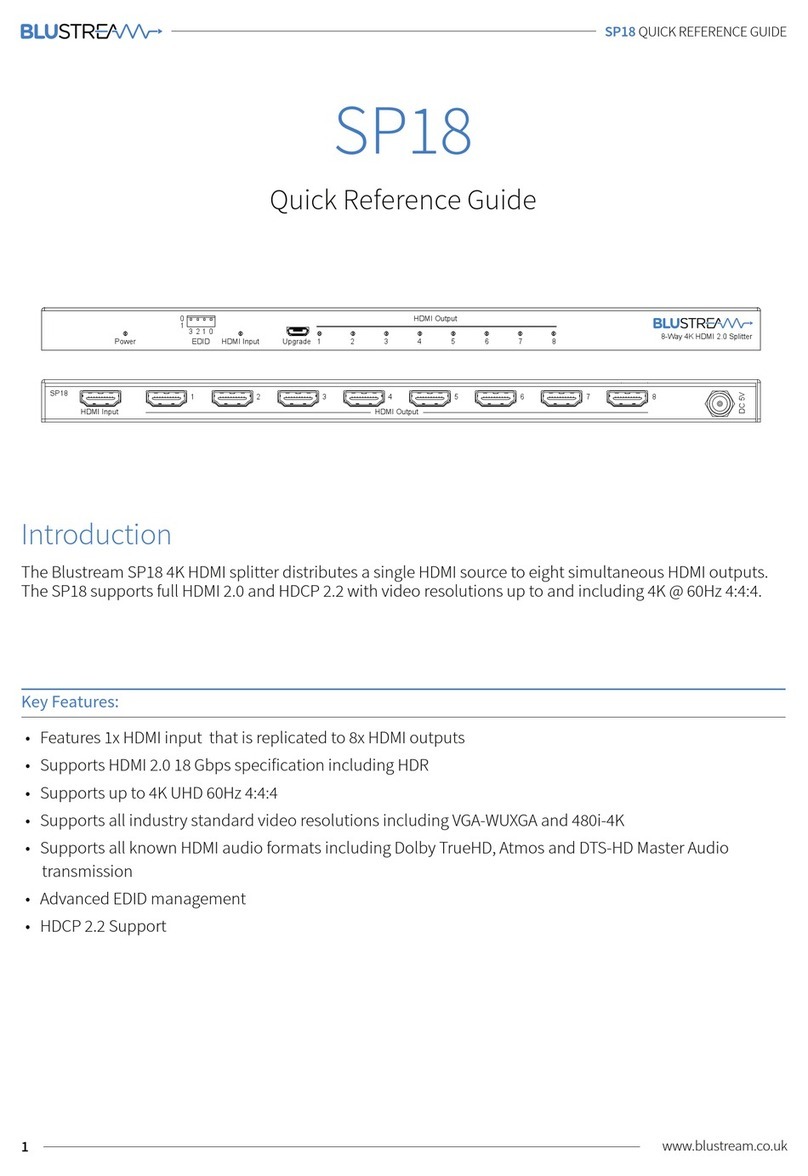

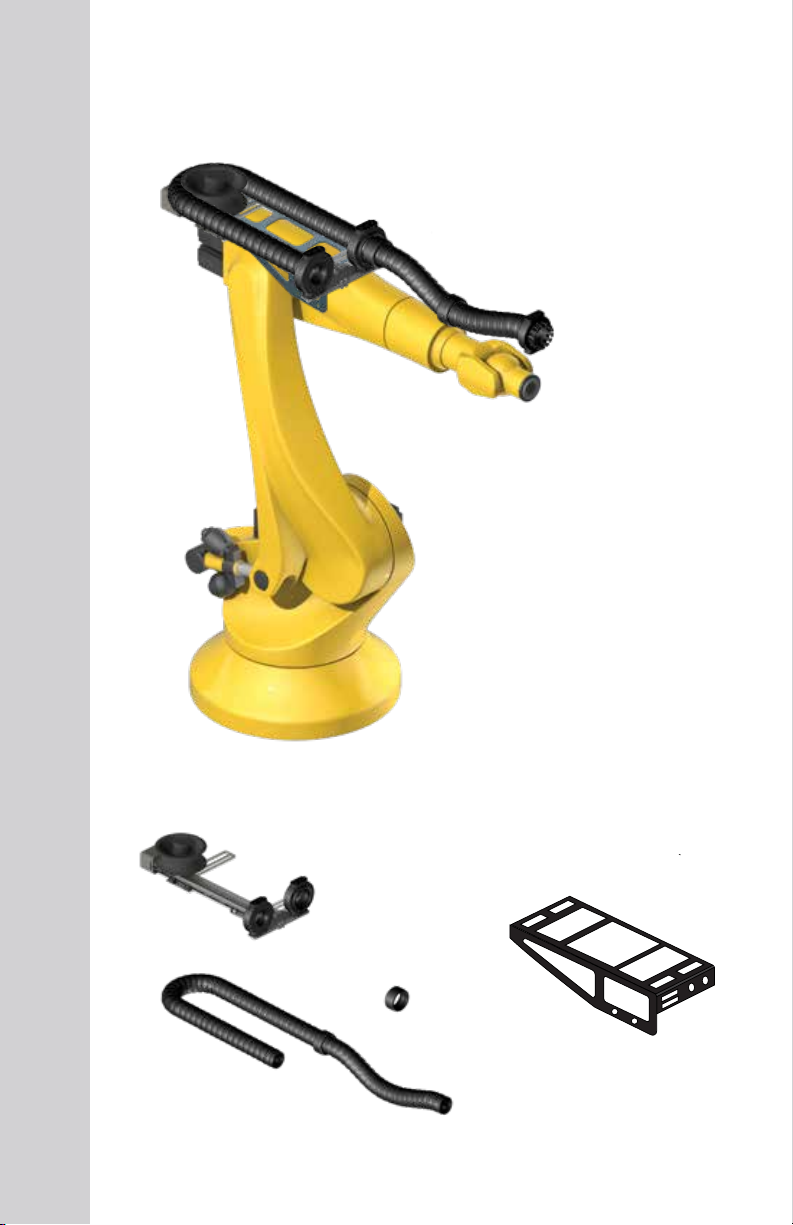

RSE Wheel installation guide

RSE Wheel retraction system

Mounting adapter

Note: Axis 3 mounting

adapters available for most

robot models

Protector

(Minimum 3 required)

14

Glide through bracket

must be on the same side

as the mounting feet

Adjustable

Adjustable

Configuring the retraction system

Mounting adapter installation example

Mounting adapter

15

Left hand system Right hand system

Easy to

adjust by

loosening

the bolts

Note: RSE wheel bracket

arrangement can be modified

to opposite side if needed.

Remember to keep mounting

feet on the same side as the

glide-through bracket

Retraction system installation

Bolt mounting feet

to mounting adapter

Align the mounting

feet with the

mounting adapter

holes

Note: Tennis rackets available

for most robot models.

Tennis racket (axis 6 clamp) installation

Bolts need to

be tightened

uniformly

Note:

Can be mounted

in any direction

16

Axis 6 bracket installation

17

Tip: Install the bracket as close to the end of the handle as possible and tighten the

bolts equally.

Designed with

integrated

profile rail for

CFX clamp

Adjustable in four directions

Standard bracket Heavy duty bracket

Important: Ball end of

triflex®R at the EOAT

(End of arm tooling)

Tip: Make sure triflex®R is

not twisted

triflex®R installation

18

Install triflex®R in axis 6

mounting bracket first

triflex®TRE only - install locking

clips at each fixed bracket

position

Note: Easy cable installation

possible with triflex®TRE and

TRCF only. If using TRC,

cables will need to be fished

through individually

Installing CFX clamps to secure cables

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Install protectors where triflex®R makes

contact with the robot

Tip: For quick release protectors, use a flat

head screwdriver to pry the two halves apart

1

2

3

4

5

Installing protectors

19

Protector:

To pretension the system, pull the triflex®forward two links

and install a protector at the exit of the moving end

20

triflex®RSE WHEEL

troubleshooting guide

Problem Solution

triflex®R breaks when RSE System is fully

extended

1. Install more triflex®R outside the RSE

System. The motion of the robot is

greater than the available travel of

the RSE System

RSE System does not function 1. Ensure the bands have tension

2. Confirm that the system is free of

debris

3. Reduce the length of the triflex®R

outside the RSE System

Carriage slams when the robot returns to

the hom position

1. Pull the system forward four links

and install a protector at the exit of

the pass-through bracket thereby

creating a stop

This manual suits for next models

4

Table of contents

Other igus Cables And Connectors manuals