Ihagee EXA 1 Operating instructions

1

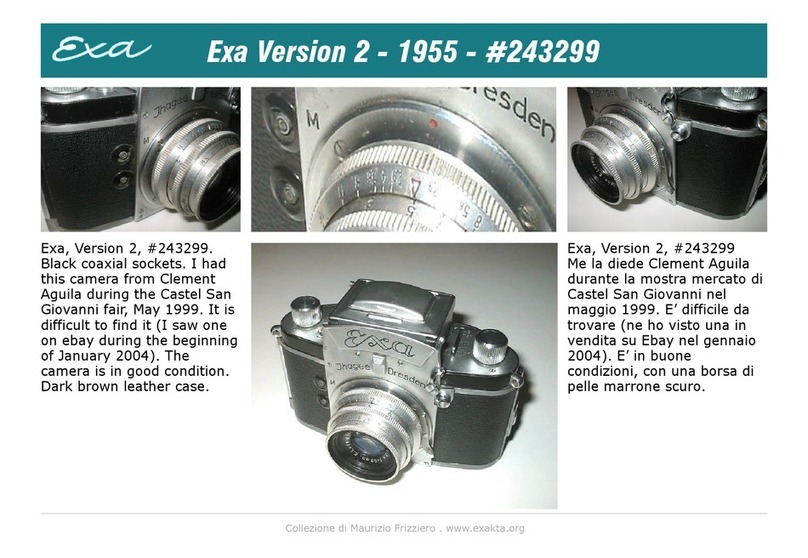

[Translated from the German Ihagee manual with the aid of QuickDic 7.2

(www.quickdic.de

)

. Notes in square brackets are mine – Steve Sheppard.]

2

EXA, EXA I Repair Manual.

Basic Remarks:

The camera under repair is placed with the lens mount 350.09 to the front, i.e. in the photograph

taking direction.

EXA

Right: Side with wind knob 350.07-23.

Left: Side with time setting lever 350.04 U 3.

EXA I/63

Right: Side with wind knob 350.17-24.

Left: Side with time setting disc 350.21 U 3.

All screws and nuts have right-hand threads. Never use force!

Before every repair remove the viewfinder (Do not touch the ground-glass screen).

A. Disassembly of EXA camera.

1. Remove the back 350.02

a) Withdraw the take-up spool 350.10.

2. Right side open.

a) Slacken the grub-screw in the wind knob 350.07-23, and withdraw the wind knob upwards.

b) Remove the two top-plate screws M1.2 DIN 91, take off the right top-plate 350.01-7, and

the rewind release button 350.01-6.

c) Refit the wind-knob. The grub-screw must be firmly tightened on the milled face of the

spindle. Take notice of the ratchet pawl 350.07-22 for the frame counter.

3. Left side open.

(This disassembly is not necessary to dismantle the inner parts.)

a) Remove the two top-plate screws M1.2 DIN 91.

b) Slacken the grub-screw in the wind knob 350.07-23, and withdraw the wind knob upwards.

Withdraw the rewind spindle 350.12-6 from below.

c) Take off the left top-plate 350.03-7.

d) Refit the rewind knob. Tighten the grub-screw firmly on to the milled face of the rewind

spindle.

4. Mechanism removal.

a) Cock the shutter.

b) Place the camera front upwards.

c) Remove the four fixing screws M1.7 x 6.5 DIN 91 from the lens flange 350.09, and remove

the flange (noting any shims 300.21-52/1).

d) Remove the shutter inhibit lever 300.21-46, the screws M1.2 for the front-plate, and the

front-plate 350.11 U1 (or 350.11 U3).

3

e) Remove the fixing screw M1.7 x 4 DIN 63 for the inner mechanism (in the milled area for

the lens flange).

f) Place the camera back side uppermost.

g) Remove the inner-mechanism fixing screws M1.7 x 4 DIN 85 in both cassette chambers.

h) Place the camera upright.

i) Remove drive-pinion 350.01-9 from sprocket spindle 350.01-4.

j) Set shutter speed lever 350.04 U 3 to B, and extract the inner mechanism from the outer

housing. Do not touch the mirror.

AA. Disassembly of EXA 1/63 camera.

1. Remove the back 370.20.

a) Withdraw the take-up spool 370.09.

2. Removal of top-plate 350.21 U1.

a) Remove screw 350.21-24, bush 350.17-25 for frame-counter disc, frame-counter disc

350.17 U5, and spring-washer 350.17-27. Withdraw wind knob 350.17-24, pushing against

the end of the wind bush 350.17 U4 with two flats [Zweikant].

b) Withdraw the spool-retaining spring 300.15 U 12 from the rewind bush. Unscrew the

rewind bush [remove the screw] (pay attention to compression-spring 350.21-29, shim

beneath 300.15-34, and distance piece 370.21-21), and pull out the rewind spindle 350.21-

20 with rewind-knob 350.21-19.

c) Release circlip 6 DIN 6799, remove spring-washer 370.04-45, and take off time-setting disc

350.21 U 3.

d) Remove the four top-plate fixing screws M1.4 x 3 DIN 91, and take off the top-plate.

e) Refit the time-setting disc with spring-washer and circlip (pay attention to the contact disc

350.22-13 and setting slide on time plate 350.22-U1)[i.e. make sure the pin on time setting

disc engages with the paxolin disc and the sliding plate for speed setting below].

f) Refit the wind-knob, spring-washer and frame-counter disc with sleeve and screw (pay

attention to rewind latch 350.17-19).

3. Mechanism removal.

a) Cock the shutter.

b) Place the camera front side upwards.

c) Remove the four fixing screws M1.7 x 6 DIN 63 for the lens-flange 350.09, and take off the

lens-flange (noting any shims 300.21-52/1).

d) Remove the mechanism fixing screw M1.7 x 4 DIN 63 (in the milled area for the lens

flange).

e) Place the camera with the back side upwards.

f) Remove the inner mechanism fixing screws M1.7 x 4 DIN 84 in both cassette chambers.

g) Extract the inner mechanism from the outer housing. Do not touch the mirror.

B. EXA assembly.

1. Mechanism insertion.

As under disassembly of camera A.4, but in reverse order. Check for correct functioning.

2. Close left side.

As under disassembly of camera A.3, but in reverse order. Check for correct functioning.

4

3. Close right side.

As under disassembly of camera A.2, but in reverse order. Check for correct functioning.

4. Check and adjust the distance between the lens mount and the film plane.

Check along the film-path with a Meßuhr [means dial-gauge - should be depth-gauge, surely?].

The distance between the lens-mount and the film-guides must be 44.72 ± 0.01mm. The film-

path should be set accordingly [presumably by means of shims under the mount. There is no

way of setting the film-path itself].

5. Check and adjust the mirror position.

(Collimator is set to infinity).

a) Example 1:

The greatest sharpness lies before the infinity stop of the lens: hold the mirror retaining

spring 300.23 U 5 with the mirror hook (see diagram Fig. 1). Bend the chamfered rivet on

the mirror retaining spring downwards, until the greatest sharpness is obtained at the infinity

mark of the lens.

b) Example 2:

The greatest sharpness is not yet obtained at the infinity stop of the lens (i.e. the point of

sharpest focus would lie beyond the infinity stop): hook the mirror retaining spring (with a

screwdriver or knife) behind the chamfered rivet and bend it into the mirror chamber until

the greatest sharpness is obtained at the infinity mark on the lens.

5

BB. Assembly of camera EXA I/63.

1. Mechanism insertion.

As under disassembly of camera AA.3, but in reverse order. Check for correct functioning.

2. Top-plate 350.21 U 1 fitting.

As under disassembly of camera AA.2, but in reverse order. Check for correct functioning.

3. Check and adjust the distance between the lens mount and the film plane.

As under assembly of camera B.4.

4. Check and adjust the mirror position.

As under assembly of camera B.5.

C. Elimination of certain faults.

1. Shutter flap 350.04 U 5 falls back. [i.e. mirror is not caught by retaining spring]

a) Open right side (EXA) or remove top-plate 350.21 U 1 (EXA I/63).

As under camera disassembly A.2 or AA.2.

b) Bend apart the adjustable slot on the mirror cocking lever 350.04 U 2 (EXA), 350.04 U 7

(EXA I/63), see Fig. 2, until cocking stroke suffices and shutter flap goes past the retaining

spring 300.23 U 5 by about 0.5mm.

If the shutter flap falls back despite the adjustment of step b), then the mirror retaining spring

does not lie correctly in place in contact with the shutter release lever 350.04-8.

c) Remove the mechanism.

As under camera disassembly A.4 or AA.3.

d) Give the mirror retaining spring a bias [i.e. bend it down], being mindful of the mirror

setting.

e) Replace the mechanism.

As under disassembly of camera A.4 or AA.3, but in reverse order. Check for correct

functioning.

f) Close right side (EXA) or replace top-plate (EXA I/63).

As under disassembly of camera A.2 or AA.2, but in reverse order. Check for correct

functioning.

g) Check and adjust the distance between the lens mount and the film plane.

As under assembly of camera B.4.

h) Check and adjust the mirror position.

As under assembly of camera B.5.

6

2. Shutter does not engage (Shutter flap 350.04 U 5 runs closed) [i.e. second part of shutter

does not catch and runs with mirror]

Dismantle camera, as under Disassembly of Camera A.1 - A.4, or AA.1 - AA.3, and do as

described in Elimination of certain faults C.1 - Shutter flap falls back.

a) Verify the functioning of all the shutter levers together (i.e. levers must slide well and mirror

retaining spring must rest against the release lever 350.04-8). If Point a) is ensured, without

the fault being rectified, the shutter must be adjusted and/or readjusted.

b) Set the timing lever 350.04 U 3 (EXA) or 350.21 U 3 (EXAI/63) to B. Cock the shutter.

c) Restraining the first shutter flap with a finger, fire the shutter and let the first shutter flap run

slowly. Do not grasp the mirror. The release of the first shutter flap must occur about 2mm

before the shutter release lever stop. The release point is varied by the bend at the

adjustment slot in the shutter release lever.

d) Allowing the shutter release lever to move slowly outwards, the release of the second part of

the shutter flap must occur about 2mm before the edge of the plate [the plate above?]. The

release point is adjusted by bending the release nose of the shutter release lever [the lower

end].

e) Cock the shutter.

f) Release the shutter and pay attention to the second shutter flap. This must move in the

direction of the first shutter flap by about one millimetre before being stopped by release

lever 350.04-12 [the one at the bottom corner]. If this does not occur, the release lever must

be corrected [gerichtet] [i.e. bend the part turned inwards?].

g) Set the exposure time lever to 1/50 sec or 1/60 sec. Cock the shutter.

h) Holding the first shutter flap with a finger, fire the shutter and let the first shutter flap run

slowly, the release pin for the first shutter flap (see Fig.3) must now run towards the point

on the secondary lever on the exposure time lever. If this does not occur, the Anschlag

[?tab/stop?] on the secondary lever must be adjusted.

7

i) Set the exposure time lever to 1/150 sec or 1/175 sec. Cock the shutter.

j) Holding the first shutter flap with a finger, fire the shutter and let the first shutter flap run

slowly. The release pin for the shutter flap (see Fig.4), must now release the second shutter

flap in the indicated position. If this does not occur, the trip lever 350.04-13 [the long

vertical lever] must be bent at its lower end.

k) Control of the release at all shutter speeds.

The release of the second shutter flap must occur as described in Point j) at all shutter

speeds. If readjustment at the 1/50 sec (or 1/60 sec) or 1/25 sec (or 1/30 sec) should still be

necessary, then this is to be made at the curve of the trip lever over the half-round recess.

l) Check the shutter with a shutter time measuring device.

Example 1:

Shutter too light: Reduce the tension of the first shutter flap, or increase the tension of the

second shutter flap. [HOW?????????????????????????????????]

Example 2:

Shutter too dark: Increase the tension of the first shutter flap, or reduce the tension of the

second shutter flap. [HOW?????????????????????????????????]

The options of the shutter time adjustment stated under l) are used alternatively by the

camera mechanic.

8

3. Mirror 300.21-53 replacement.

a) Remove the back 350.02 (EXA) or 370.20 (EXA I/63).

b) Place the camera front uppermost.

c) Remove the four lens-mount fixing screws M1.7 x 6.5 DIN 91 (EXA) or M1.7 x 6 DIN 63

(EXA I/63). Remove the lens-mount (noting any shims 300.21-52/1).

d) Guide the front edge of the shutter flap to the level of the gap in the round opening in the

outer casing. Bend outwards both the retaining tabs (left and right) for the mirror.

e) Slide the mirror out.

f) Insert the new mirror and bend the retaining tabs back inwards.

g) Replace the lens mount.

h) Check/adjust the lens mount to film path distance.

See under assembly of camera B4.

i) Check/adjust the mirror position.

See under assembly of camera B5.

4. Frame-counter failure.

EXA

a) Open right side, described in Disassembly of Camera A.2.

b) Cock and fire the shutter, observing the spring for the ratchet-lever 350.07-17.

c) Bend the spring for the ratchet-lever, near the mounting of the frame-counter disc 350.07-

21, so it engages with the teeth.

d) Close the right side. As in Disassembly of Camera A.2, but in reverse order.

e) Check the operation.

9

5. Synchronisation failure.

Adjusting the flash synchronisation.

EXA

Dismantle the camera, as under Camera Disassembly A.1 - A.4.

a) Set the exposure time lever to the 1/25 sec position and cock the shutter.

b) Holding the leading edge of the shutter flap with a finger, fire the shutter and let the leading

edge of the shutter flap run slowly. The X-contact must fire near the position shown in Fig.

5, and the F-contact near the position shown in Fig. 6. If they do not do so, the contact

spring must be bent at the flash contact accordingly.

c) Reassemble the camera, see Assembly of Camera B.1 - B.5.

Adjusting the flash synchronisation.

EXA I/63

Note:

The setting of both flash contacts (X and F) depends on the linkage between the time setting

disc 350.21 U 3 and the contact disc 350.22-13 on insulating-part I 350.22 U 4. Because of

this, setting the shutter times causes at the same time a changeover of the contacts.

The X-synchronisation takes place at shutter speeds of 1/60 sec and B.

The F-synchronisation will operate at shutter speeds of 1/175 sec, 1/125 sec and 1/30 sec.

10

Adjusting the insulating-part I. [the insulating block under the time-setting disc]

Dismantle the camera, as under Disassembly of Camera AA.1 - AA.2.

aa) At the F-synchronisation the contact spring of insulating-part I must touch the contact pin

(where the connection for the coupling wire 350.22-11 is). If necessary bend the contact

spring accordingly.

bb) Replace the top-plate 350.21 U 1, as under assembly of camera BB.1 - BB.2.

Adjusting the insulating-part II. [the block with the flash contacts on the right below the

wind mechanism]

Dismantle the camera, as under Disassembly of Camera AA.1 - AA.3. Check the F-contact:

cc) Set the time setting disc to 1/30 sec and cock the shutter.

dd) Restrain the shutter flap, release the shutter and let the shutter flap run slowly; the F-

contact must fire as shown in Fig. 7. If this does not occur, the contact spring for insulating-

part II must be bent accordingly.

11

Checking the X-contact.

ee) Set the time setting disc to 1/60 sec and cock the shutter.

ff) Hold [restrain?] the shutter flap, release the shutter and let the shutter flap run slowly; the

X-contact must fire as shown in Fig. 8. If this does not occur, the contact spring for

insulating-part II must be bent accordingly.

gg) Reassemble the camera, see Assembly of Camera BB.1 - BB.4.

6. Checking the film transport.

NB. Only use a faultless cartridge! When spools for daylight loading are used, these may only

be inserted in cassette cases of the same manufacturer. With film transport from cassette to

cassette, special attention must be paid to the wind-on cassette. If necessary the sliding surface

of the spool may be lightly rubbed with paraffin. The spool must slide easily into the case and

must not be at an angle. All these points being in order, the checking of the camera can begin.

Checking the friction-bush 300.15 U 3 (EXA) or 370.03 U 11 (EXA I/63).

a) Remove the rear cover 350.02 (EXA) or 370.20 (EXA I/63) and the take-up spool 350.10

(EXA) or 370.09 (EXA I/63).

b) Hold the friction bush with the left hand, and at the same time slowly cock the shutter. The

friction bush must give uniform resistance and not scrape, catch or run very much out of

true.

c) A faulty friction bush is to be removed, cleaned and re-lubricated.

**********************************

12

13

14

EXA Ia Repair Manual.

Basic Remarks:

The camera under repair is placed with the lens mount 300.21 U 6 to the front, i.e. in the photograph

taking direction.

Right: Side with wind-lever 750-005.00.

Left: Side with time-setting ring 750-004.00.

All screws and nuts have right-hand threads. Never use force! All screws secured with lacquer are to

be so secured on assembly.

A. Disassembly of camera

1. Take off the back cover 370.20.

a) Remove the take-up spool 370.09.

2. Remove the top-plate 750-001.00.

[Note there are 2 types of frame counter – first like Exa IIa – second like Exa IIb]

a) Set the time-setting ring 750-004.00 to B.

b) With the special tool undo the ring cover 370.41-21 [outer metal ring - use friction tool].

c) With the special tongues hold the frame-counter disc 370.41-25 and with the special tool

remove the screw 370.41-28 for the frame-counter disc.

d) Withdraw the frame-counter disc, if necessary note any washers.

e) Mark the position of the inter-ring 370.41-20 [the ring retaining the film-speed reminder],

and undo the three flat-head [cheese-head?] screws M1.4 x 2 DIN 84.

f) Take off the inter-ring with the film-type ring 370.41-20 and the spring shim 370.41-27.

g) Remove circlip 4 DIN 6799, shim 370.01-79 (as many as present), and the 3 fixing screws

M1.4 x 3 DIN 63 for the wind-lever 750-005.00. Withdraw the wind-lever (Note the

position of the wind-lever relative to the Schaltsegment 750-709.00 [the turning part on the

camera] and the shim 370.41-26).

Note:

With the modified film-type ring [like the Exa IIb] the disassembly is as in the following

sequence.

aa) Set the time-setting ring 750-004.00 to B.

bb) Remove glued-in cover disc (black) 750-000.37 (note position of index mark).

cc) With the special tongues hold the frame-counter disc 370.41-25 and with the special key

remove the screw 370.41-28 for the frame-counter disc.

dd) Withdraw the frame-counter disc, if necessary note any washers.

ee) Not applicable here.

ff) Not applicable here.

15

gg) Remove circlip 4 DIN 6799, shim 370.01-79 (as many as present), and the 3 fixing screws

M1.4 x 3 DIN 63 for the wind-lever 750-005.00. Withdraw the wind-lever (complete with

film-type ring 750-713.02, cover-ring 750-713.01 and spring shim 370.41-27). Note the

position of the wind-lever relative to the Schaltsegment 750-709.00[the turning part on the

camera] and the shim 750-713.04.

h) Remove the spool-retaining spring 300.15 U 12 from the rewind sleeve 750-000.02, and

unscrew the sleeve[centre screw] (pay attention to compression spring 370.01-90, shim

370.01-87/2 and spacer 370.01-69). Pull out the rewind spindle. Take off the disc 750-

000.31.

i) Remove the circlip 370.04-48 for the time-setting disc 750-004.00, the spring washer

370.04-45, and take off the time setting disc.

j) Undo the 4 fixing screws 350.21-32 for the top-plate, withdraw the lever for the shutter lock

750-012.00 with shim, and take off the top-plate.

k) Refit the time-setting disc with the spring washer and circlip (pay attention to the contact

disc 350.22-13 and setting slide on time plate 750-201.00)[i.e. make sure the pin on time

setting disc engages with the paxolin disc and the sliding plate for speed setting below].

l) Refit the wind-lever, complete, with three screws, shim and circlip.

3. Mechanism removal.

See Repair Manual for EXA I/63.

B. Assembly of camera.

1. Mechanism insertion.

See Repair Manual for EXA I/63 AA.3 but in reverse order. Check functioning.

2. Fitting top-plate 750-001.00.

As under disassembly of camera A.2 but in reverse order. Check functioning.

3. Check and adjust the distance between the lens mount and the film plane.

See Repair Manual for EXA B.4.

4. Check and adjust the mirror.

(Collimator is set to infinity.)

a) Example 1:

The greatest sharpness lies before the infinity stop of the lens: Bend upwards the adjustment

tab (on the left side of the upper shutter flap), until the sharpest focus is obtained at the

infinity stop of the lens.

b) Example 2:

The greatest sharpness is not yet obtained at the infinity stop of the lens (i.e. the point of

sharpest focus would lie beyond the infinity stop): Bend downwards the adjustment tab (on

the left side of the upper shutter flap), until the sharpest focus is obtained at the infinity stop

of the lens.

16

C. Elimination of certain faults.

1. Shutter flap 750-401.00 falls back.

a) Remove the top-plate 750-001.00. As under disassembly of camera A.2.

b) Bend apart the adjustment slot in the mirror lifting lever 350.04 U 7, until the lift stroke

suffices and the shutter flap passes the mirror holding lever 750-400.05 by about 0.5mm.

Should the lift stroke not be sufficient in spite of this adjustment, then check and if necessary

replace the Schaltsegment 750-709.00 [the assembly the wind lever fixes to?] and

Aufzugsgetreibe 750-704.00 [the lift linkage].

c) Replace the top-plate. See under Disassembly of Camera A.2 but in reverse order. Check

functioning.

2. Shutter does not engage (Shutter flap 750-401.00 runs closed) [ie. second part of shutter

does not catch and runs with mirror?].

Disassemble camera, as described under Disassembly of Camera A.1 - A.3. For repair method,

see Repair Manual for EXA/EXA I C.2.

3. Mirror 300.21-53 replacement.

See Repair Manual for EXA/EXA I C.3.

4. Frame counter failure.

See Repair Manual for EXA IIa C.6.

5. Synchronisation failure.

See Repair Manual for EXA/EXA I C.5. - Adjusting the flash synchronisation EXA I/63.

6. Checking the film transport.

See Repair Manual for EXA/EXA I C.6.

**********************************

17

18

EXA II Repair Manual.

Basic Remarks:

The camera under repair is placed with the lens mount 300.21 U 6 to the front, i.e. in the photograph

taking direction.

Right: Side with wind-lever 370.01 U11.

Left: Side with time-setting ring 370.01-67.

All screws and nuts have right-hand threads. Never use force! All screws secured with lacquer are to

be so secured on assembly.

A. Disassembly of camera.

1. Take off the back cover 370.10.

a) Remove the take-up spool 370.09.

2. Remove the top-plate 750-001.00.

a) Set the time-setting ring 370.01-67 to ½ sec.

b) Remove screw 370.01-81, frame-counter disc 370.01 U4, and frame-counter knob 370.01-

70 (press against the end of the frame-counter shaft with two flats [Zweikant]).

c) Remove circlip 4 DIN 6799, shim 370.01-79 (as many as present), and the three fixing

screws M1.4 x 4 DIN 63 for the wind-lever 370.01 U11. Withdraw the wind-lever (Note the

position of the wind-lever relative to the pawl carrier 370.01 U8).

d) Remove the spool-retaining spring 300.15 U 12 from the rewind bush 370.01-21, and

unscrew the sleeve[centre screw] (pay attention to compression spring 370.01-90, shim

370.01-87/2 and spacer 370.01-69). Pull out the rewind spindle 370.01 U14. [NB. It’s not

necessary to take out the screw on top holding the film reminder]

e) Remove the circlip 370.04-48 for the time-setting disc 370.01-67, remove shim 370.01-87/1,

loosen [it is a snug fit] and remove the time-setting disc from the two flats of bush 370.04

U8 (press against the end [Zweikant] in order that the gear mesh is not changed).

f) Remove the 2 fixing screws M1.4x3 U91 from the top cover.

g) Lift off the top cover and remove rewind button 370.01 U10 with spring 370.01-89.

h) Refit the wind-lever with 3 screws, shim, and circlip.

i) Mark the mesh of the time-setting wheel (gear-wheel on sleeve 370.04 U8) to the gear on the

mechanism and refit the time-setting disc.

3. Removal of mechanism 370.03.

a) Remove the 2 screws M1.7x8 DIN 84 in each film chamber.

b) Lift out the mechanism from the body-shell 370.08.

B. Assembly of camera.

1. Insertion of mechanism 370.03.

As under Disassembly of Camera A3 but in reverse order, engaging with the pinion on the

sprocket-spindle 370.01-35. Check for correct functioning (including flash contact).

19

2. Fitting the top-plate 370.01 U2.

As under Disassembly of Camera A2 but in reverse order. Check for correct functioning.

3. Check and adjust the distance between the lens mount and the film plane.

The film-path is checked with a Meßuhr [means dial-gauge - should be depth-gauge, surely?].

The distance between the lens-mount and the film-guides must be 44.72 ± 0.01mm. The film-

path should be set accordingly [presumably it means by means of shims under the mount - no

way of setting the film-path itself].

4. Check and adjust the mirror position.

(Collimator is set to infinity).

a) Example 1:

The greatest sharpness lies before the infinity stop of the lens: Bend upwards the adjustment

tab on the mirror base 370.03 U 13 (see Fig 1) until the greatest sharpness is obtained at the

infinity mark of the lens.

b) Example 2:

The greatest sharpness is not yet obtained at the infinity stop of the lens (i.e. the point of

sharpest focus would lie beyond the infinity stop): Bend downwards the adjustment tab on

the mirror base (see Fig 1) until the greatest sharpness is obtained at the infinity mark of the

lens.

C. Elimination of certain faults.

[NB. There seem to be two versions of the spring spindles. The illustrations are evidently the earlier

version. See the “Notes” for method for the later version.]

1. Cocking fails or is blocked.

Dismantle camera, as under Disassembly of Camera A.1 to A.3.

In the following only the disassembly of the cocking side will be described. The camera

mechanic determines which parts must be replaced and/or readjusted. No attention need be

paid to the position of the gear wheels relative to each other.

20

Disassembly of the cocking side:

a) Take off the wind-lever 370.01 U11 and pawl carrier 370.01 U8 (Pay attention to the wind-

lever return spring 370.01-110). [The circlip may have formed burrs on the top of its

groove. Dress them with a needle file so that the pawl-carrier slides off easily]

b) Remove the locking wheel 370.01 U6 and shims 370.01-87/1. [One above, one below]

c) Remove the circlips 1.5 DIN 6799, the cocking spindle 370.04 U6 and the transport spindle

370.04 U7. Both spindles come out downwards (note shims).

d) Undo the 4 fixing screws 300.21-59 for the intermediate plate 370.04 U4, and lift off the

intermediate plate.

Assembly of the cocking side:

As described under C.1.a) to C.1.d) but in reverse order (take care to replace shims).

2. Cocking segment 370.07 U5 is damaged.

Dismantle camera, as under Disassembly of Camera A.1 to A.3.

a) Mark the position of both curtain-rods in the un-cocked condition on the shutter plate

(right), and the mesh of the teeth of both pinions 370.03-27 with the shutter wheels, 370.07

U7 and 370.07 U8.

b) Remove the two pinions 370.03_27.

c) Undo and remove all the fixing screws for the right shutter-plate (4 screws) and for the

shutter cover-plate 370.03 U14 (1screw) (see Fig2) as well as for the right cover-plate

370.03-24 (3 screws) [inside]. Remove the shutter plate, springing the shutter cover-plate

backwards.

This manual suits for next models

6

Table of contents

Other Ihagee Digital Camera manuals