IKL ARINA User manual

Model: ARINA

USER MANUAL

IKL-INDUSTRIJSKI KOMBINAT LIVNICA DOO GUČA

Srbija,32230 Guča, Albanske spomenice bb

Tel/centrala:+381(0)32 306 000 ,

prodaja i servis;+381(0)32 854 305

Dear customer,

First of all we would like to thank you for having chosen us. You will be satisfied with your

choice, as our stove is in the leading category of the similar products due to its features

and design.

Yours sincerely,

GUČA

CONTENTS:

1. Introduction

2.Technical characteristics

3. Working principle of the stove

4. The flue

5. Wood

6. Cleaning of the stove

7. Consumables

8. Summer pause

9. Solutions of the problems

10. Technical description

11. Installation

12. Fire safety

13.Air entrance into the installation place during combustion

14. Admitted/not admitted fuel

15. Lighting

16. Normal operation

17. Operation in transition periods

18. Cleaning

1. INTRODUCTION

Read the instructions carefully and respect the rules and recommendations. Hereinafter

you will find the date regarding the stove itself, as well as the recommendations for the

installation and maintenance of the stove.

The efficiency of a stove depends on its correct installation, which must be carried out by a

professional following the highest standards and the safety regulations in force.

The place you intend to install the stove must have sufficient airspace and the floor and

surrounding object must be in a non-flammable material.

Moreover, if there is a flammable floor, it must be protected by an insulating plate (in steel,

brass, marble, stone, etc.), which extends at least 50 cm from the front and at least 15 cm

from the sides.

Do not place armchairs, seats, curtains or any flammable object within 100 cm from the

stove as well as within 50 cm on the sides, and 30 cm from the back side.

The cast iron parts are protected by heat resistant paint. The room has to be properly

ventilated.

The stove should work with the doors closed.

Take car that the fuel does not touch the glass, otherwise the glass shall get dirty.

The stove is heated during operation, so take the necessary measures of precaution.

Children should not be allowed to play near the stove.

Provide continuous flow of combustion air.

Parts of packing should be properly disposed. Elements from cardbox, wood or plastic

should be taken out before putting the stove into operation.

If you do not plan to use the stove for a certain period, store it in a suitable place

respecting the ecological regulations and local requirements for the storade of the waste

material.

IN CASE OF NON-OBSERVANCE OF THE INDICATIONS ABOVE-QUOTED, THE

MANUFACTURER DISCLAIMS ALL RESPONSIBILITIES FOR POSSIBLE DAMAGE.

2. TECHNICAL FEATURES

Definition: wood/coal-burning stove tested according to: EN 13240

Constructive System

*

Rating power in kW

10

Efficiency in %

84

Pipe diameter in mm

120 / 150

Maximum quantity of fuel-wood in kg

2

Mean content of CO to 13% O2in %

0.0691

Emission of exhaust gasses in C° - wood

253

Size of hearth opening in mm (W x H)

225 x 320

Hearth body size (W x H x D)

350 x 320 x 250

Grate type

Revolving grate

Stove height in mm

728 (with the upper output 775)

827 (with the upper output 872)

Stove width in mm

480

Stove depth (with handles) in mm

435

Weight in kg

115

Outer smoke output in mm

600

Equipment: glove

-□ * hearth door is closed automatically (there is the system for automatic door closing with

a spring)

□ * hearth door without the system for automatic door closing

3. WORKING PRINCIPLE OF THE STOVE

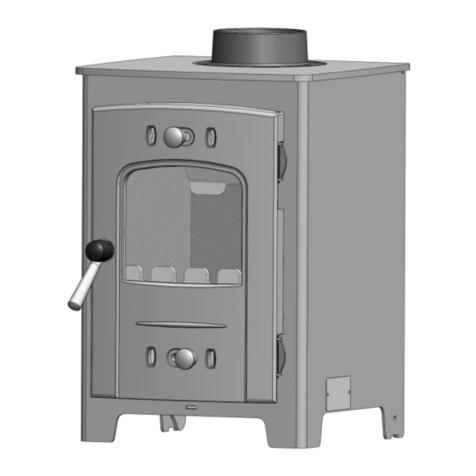

3.1 Description of the stove

The stove is designed to be used for indoor heating. The heat is diffused by radiation

through the panoramic glass and the parts of the stove made of cast iron.

Part of the stove are made of cast iron, and the hearth is equipped with a panoramic door

with heat resistant glass.

The stove has the primary and secondary air control by which the combustion air is

adjusted. The primary air control must be completely opened during the lightning phase

(15 –20 minutes). During wood combustion, the primary air control is closed, otherwise

the wood burns fast. The secondary air control enables the glass to stay clean during

wood combustion and provides additional combustion. R

3.2 Installation

The installation of the stove must be carried out by qualified people who are aware

of the safety measures. A badly installed stove can cause serious accidents (chimney fires,

burning of insulating materials, etc).

3.3 Lighting the stove for the first time

The first time the stove is lit, there will be an odor given off due to the drying of the

protective color. That is normal, because the color stabilizes on temperatures over 350°C.

THE ROOM MUST BE PROPERLY VENTILATED.

Before the lighting, all parts should be cleaned with a dry cloth to remove dust and

impurities.

- Upon the first ignition of the stove, we suggest loading a reduced quantity of fuel and

slightly increasing the calorific value of equipment.

Positions 11 and 49 are free and are supported by the appropriate lateral bracing, position

49. Before the operation, control the positions 11 nad 49 which should be as in the picture.

3.4 Ventilation of the room

Good ventilation is essential in order to provide proper working without any risk to

people who use the room where the stove is installed, because during the combustion the

stove uses the oxygen from the air. It is necessary that the room has adjustable air

openings.

ATTENTION

In case of non-observance of the indications, the manufacturer disclaims all

responsibilities.

Modifications on the stove are not allowed.

4. THE FLUE

Special attention must be paid to the quality of the flue which must be made in accordance

with the standards. The flue must be regularly maintained. The stove is connected to the

flue through a connection on the upper or back side of the stove, by the appropriate smoke

pipes.

The draught in the flue

An inadequate draught is exclusively the main reason behind most complaints of poor

stove operation! Necessary draught for this type of stove is 12 Pa.

A lower value does not permit proper combustion with the consequent formation of carbon

deposits and excessive production of smoke, which, being unable to flow to the exterior

will escape through the grills or doors.

If the draught value is too high, combustion will be too fast, with the consequent dispersion

of the heat through the flue. If the draught is greater than 15Pa, the elements for draught

reduction should be installed.

The signs of a bad draught are:

dirty glass, boiling handle

smoke coming out into the room

4.1 General characteristics

To facilitate the draught in the flue, the chimney must be rising at least one metre

above the ridge of the roof.

The dimensions of the chimney may vary on the basis of the model of flue. However, to

guarantee good disposal of the fumes, the section of the air passage at its exit must

always be twice the section of the flue itself, and furthermore the cap of the chimney must

never obstruct the draught.

The chimney guarantees the conveyance of the fumes outwards even when there are high

horizontal winds and stops them from being blown back down the chimney.

Bad maintenance of chimney is the cause of flue obstruction, due to the breaking and

detachment of plaster, refractory bricks etc.

Chimney must have sufficient heat insulation, otherwise it can lead to condensation.

The internal parts of the whole flue should have a smooth surface, and the material used

should be refractory and resistant to their degree of acidity, and should be impermeable to

gases.

4.2 Chimney recommendations

The internal part of the whole flue should have a smooth surface, and the material used

should be resistant to heat and impermeable to gases.

.

Height of the flue

Round section

Square section

5 m

10 m

15 m

cm. 20/22

cm. 18/20

cm. 15/16

cm. 20 x 20

cm. 18 x 18

cm. 16 x 16

4.3 Connection of the stove to the flue

The metal tube connecting the stove to the flue must never have a smaller diameter

than the outlet hole of the appliance.

Try to avoid too many curves and horizontal sections; if this is impossible, ensure that

there is always a slope of at least 2/3 cm per linear metre as compensation.

The same flue must never be used for more than one appliance.

4.4 Cleaning the tubes and flue

Every time you notice the draught is becoming difficult, you should clean the stove, the

tubes, and the flue.

The removal of soot and carbon residues must be carried out to the highest standards

using appropriate means. Cleaning should be performed when the stove is cold.

The junction pipe for the connection to the chimney must be shortest possible and the

junstion points of the single pipes must be hermetic. The connection to the chimney must

be performed with stable and strong pipes (we recommend a thickness of 2 mm). The pipe

for smokes exhaust must be fixed hermetically to the chimney. The diameter inside the

connection pipe must correspond to the external diameter of the smokes exhaust small

trunk of the stove.

ATTENTION: Possible flammable pieces in the area of 20 cm round the connection pipes

must be changed with fireproof and not sensitive to heat materials.

For a good operation of the equipment it is essential that in the installation place, there is

sufficient air for combustion. This means that through suitable openings, air must

recirculate for the combustion, even with doors and windows closed.

The depression on the chimney should be 12 Pa –The measurement must be done

always with the equipment hot. When the depression exceeds 15 Pa it is necessary to

reduce the same with the installation of an additional flue adjuster (butterfly valve) on the

exhaust pipe or in the chimney.

5. WOOD

Only burn dry wood! You must not only select quality wood but it must also be dry at

the moment in which you use it.

Remember that the calorific power of the wood drops considerably as the presence

of humidity means that a large part of the heat produced is used to evaporate the water

and, furthermore, the risks of obstruction increase rapidly with the condensation of the

vapors in the flue.

Recommended humidity of wood is up to 20%.

5.1 DRYING

Damp wood not only burns badly but also makes the lighting of the fire difficult and

damages the flue. The water vapor transports condensible products such as acetic acid,

alcohol, methyl alcohol and tars which contribute to the formation of incrustations which

are detrimental for the efficiency of your stove.

Fresh cut wood is useless as a fuel. Actually a considerable part of the energy

produced is only used to evaporate the water, which is up to 75% in young wood without

bark.

To obtain dry wood (15%-20% humidity) you must cut the weak wood (in winter) to the

desire length and cut it again in pieces with a maximum diameter of 8-15 cm. You must

then put them in a ventilated shelter for at least 2 years 84 for oak, the first with exposure

to the rain to eliminate the tannin).

You must stack the wood without compressing it to allow the passage of air, which,

discharges the humidity and aids drying.

5.2 HOW TO SELECT THE RIGHT WOOD

To obtain combustion and optimum efficiency from your stove, you must use firewood

on the basis of the following list.

TYPE OF WOOD

QUALITY

HORNBEAM

EXCELLENT

OAK

EXCELLENT

ASH

VERY GOOD

MAPLE

VERY GOOD

BIRCH

GOOD

ELM

GOOD

BEECH

GOOD

WILLOW

BARELY SUFFICIENT

FIR

BARELY SUFFICIENT

ALDER-SCOTCH PINE

POOR

LARCH

POOR

IME

VERY BAD

POPLAR

VERY BAD

YOU SHOULD ABSOLUTELY NEVER USE:

Green or damp wood, treated wood (railway sleepers, plywood off-cuts, painted wood,

etc.), low-grade anthracite and coke.

THE USE OF THE ABOVE LISTED MATERIALS AND DAMAGES CAUSED BY THEM

ANNUL ANY FORM OF GUARANTEE AND THE MANUFACTURER DECLINES ALL

RESPONSIBILITY.

5. CLEANING THE STOVE

We recommend removing the ash produced every day. Never allow the ash

accumulate to the point where it touches the grate; this would obstruct the circulation of

primary air and slowly suffocate the fire.

When cleaning the outside surfaces of the stove, avoid abrasive products which would

damage the protective paint. Do not use chemicals that contain diluent, because the cast

parts are protected by heat resistant paint.

Panoramic door glass should be cleaned with normal detergent and exclusively after

getting cold. After cleaning, rinse with pure water and dry. To clean the parts in tiles use

non -abrasive detergents, water and a soft cloth which do not damage the glaze.

7. CONSUMABLES

The following are considered consumables and therefore not covered by the warranty:

all gaskets, the parts in ceramic hardened glass, the facing of the hearth, the paints, the

ceramics and the special treatments such as chrome plating. The warranty does not cover

damages caused by improper installation, incorrect connection not in compliance with the

instructions which accompany the product, or by tempering by unqualified or unauthorized

personnel.

8. SUMMER PAUSE

After you have cleaned the hearth, the chimney and flue, trying to eliminate completely

the ash and other residuals, you must close its openings in order to let work other

appliances that are connected to the same flue.

The cleaning of the flue should be done at least once a year. Check the state of

gaskets and replace them if necessary.

If there is dampness in the room where the stove has been placed, we advise you to

put absorbent salts into the hearth. If you want ti keep for long the aesthetic look of the

stove it is important to protect its internal walls in cast iron with neutral Vaseline.

9. SOLUTIONS OF THE PROBLEMS

9.1 The appliance does not work

Check that the entrance of the chimney has been carried out perfectly.

Check whether the dimensions of the chimney are correct and appropriate to the

appliance.

Check whether the flue is well isolated from thermo agents and made according to the

standards.

The doors of the stove must be well sealed.

9.2 Difficulty in lighting the fire

Open the primary air and the smoke register.

Use very dry wood.

Air the room in order to have a great quantity of oxygen.

The flue must be appropriated to the appliance used.

9.3 Smoke comes out

Check if the primary air register is opened.

Check if the entrance of the chimney presents leaks.

Check if the ash or other residuals have obstructed the draining pipe.

-Insufficient draught.

-Check the draught in the flue.

-Heck the gaskets.

9.4 The glass gets dirty in a short time

Damp wood: use dry wood (max.20% moisture)

Wrong fuels (see materials allowed)

Too much fuel

Draught insufficient (see connection to the flue)

Wrong regulation of the registers: if the secondary air register is closed, the glass gets

dirty in a short time.

9.5 Condensation

During the initial lightings the condensation is normal, because the covering materials

contain dampness.

If the problem goes on, check the wood you use; it must not be damp or badly

seasoned.

The chimney must not have defects and it must not cool down too quickly the draining

gas.

Attention: The manufacturer exclusively uses materials which are not health hazards.

The manufacturer reserves the right to make modifications to the appearance, to the

dimensions or to the models themselves without previous notice.

10. TECHNICAL DESCRIPTION

10.1 Description

The stove is suitable to heat living spaces or to support an insufficient centralized heating

system. As fuel, it is possible to use wood logs. The stove is made of cast iron and steel

plates. The hearth is internally sheathed with single sheets in cast iron and inside it there

is a turning and extractable grate. The hearth is equipped with a panoramic door (resistant

up 700 °C). This allows a wonderful view on the burning flames and maximum heat

distribution.

The heating of the environment is made:

Through the panoramic glass and the external hot surfaces of the stove, the heat is

radiated into the environment.

The chimney stove is equipped with registers of primary and secondary air by which the

combustion air is adjusted.

The stove can be attached from the back or through the heating plate.

10.2 PRIMARY air control

With the regulator on the stove door, the passage of air through the ash drawer and the

grate in the fuel direction is adjusted. The primary air is necessary for the combustion

process. The ash drawer must be regularly emptied, so that the ash does not obstruct the

primary air entry. Through the primary air fire is also kept alive.

During wood combustion, the register of primary air must be opened only for a while,

because otherwise the wood burns fast and the stove may overheat. The register

operation is shown in the picture.

10.3 SECONDARY air control

Over the door of the hearth there is the secondary air control. The valve must be opened

(then moved to the right), especially for wood combustion, so that the unburnt carbon does

not undergo a post-combustion. Through this register it is possible to adjust the

combustion course of the stove.

Leaving it slightly opened, it is possible to keep the glass clean.

11. INSTALLATION

The stove must be connected with a junction to the existing flue. The junction must be, if

possible, straight, horizontal or positioned a little uphill. The connections must be tight. It is

obligatory to respect the National and European rules, local regulations concerning

building matter and also fireproof rules. Please apply to your chimney sweeper for

all information.

You should provide sufficient air entrance for the combustion in the installation place. The

siameter of the opening for the connection must correspond at least to the diameter of the

smokes pipe (Ø120 mm). The opening must be equipped with a wall connection for the

reception of the exhaust pipe.

Before installation, verify if your floor can support the weight of the stove.

The manufacturer is not responsible in case of modification of the product and for

the use of not original spare parts.

12. FIRE SAFETY

In the installation of the stove the following safety measures are to be followed:

a) In order to ensure sufficient thermal insulation, respect the minimum safety distance

from objects or furnishing components flammable and sensitive to heat (furniture, wood,

sheathing, fabrics etc.) and from materials with flammable structure. All the minimum

safety distances are shown on the product data plate and lower values must NOT

be used.

b) In front of the chimney stove there must not be any flammable object or building

material, sensitive to heat, at less than 100 cm distance.

c) If the product is installed on a non totally refractory floor, one must foresee a fireproof

background, for example a steel platform dimensions according to the local regulations.

The platform must stick out 30 cm sideways and 50 cm on the front side over the loading

door.

d) No flammable components must be present above the product.

The chimney stove must operate exclusively with the ash drawer inserted. The solid

residue of the combustion (ashes) must be collected in a hermetic container, resistant to

fire. The stove must never be ignited when there are gas or steam emissions (e.g. glue for

linoleum, gasoline, etc.). Never deposit flammable materials near the stove. During the

combustion will be spread thermal energy which warms up the surfaces, the door, the

fireplace glass, the handles and knobs, the smoke pipe and the front side of the stove.

Please avoid the contact of these parts without gloves or the relevant tools.

Warn children of the danger and keep them away during the operation of the stove.

The use of a wrong or wet fuel causes the formation of creosote deposits in the flue and

will fuel a chimney fire.

FIRST-AID MEASURES

Should any fire arise in the stack or in the flue:

a) Close the feeding door and the ash drawer door;

b) Close the controls of combustion air;

c) Extinguish the fire using carbon dioxide fire-fighting means (CO2 dust);

d) Seek immediate intervention of FIRE BRIGADE.

DO NOT EXTINGUISH FIRE USING WATER JETS.

When the fire has been extinguished, let the flue check by an expert to find possible

cracks and permeable points.

13. AIR ENTRANCE INTO THE INSTALLATION PLACE DURING COMBUSTION

As the stoves take their combustion air from the installation place, it is essential that a

sufficient quantity of air is introduced in the installation room itself. In case of tight doors

and windows (for example houses built according to the energy saving criteria) it is

possible that the air entrance is not guaranteed, compromising the draught, the welfare

and the security of the people. It is necessary to guarantee a further air entrance through

an external air intake, to be 3positioned in the nearby of the appliance or through air

connection towards outside or a near ventilated room, with the exception of thermal units

place or garages (FORBIDDEN).

The air entrance for combustion into the installation place must not be closed during the

operation of the stove. It is absolutely necessary that in the environment in which the

stoves operate with the natural flue of the chimney, it is introduced as much air as

necessary for the combustion, i.e. up to 20 m3/h.

An extraction hood (aspirating) installed in the same room or in a room nearby, causes

depression with output of combusted gases (smoke, smell). As consequence it is

necessary to ensure more flow of fresh air.

The depression in an extraction hood can at worst hypothesis, transforms the flue

into an external air intake, by sucking the smokes of the rooms with dangerous

consequences for the people.

14. ADMITTED/NOT ADMITTED FUEL

The fuel admitted is made of wood logs. One must use only logs of dry wood (water

content max. 20 %).One must load at maximum 2 or 3 logs of wood per time. The wood

pieces should have a length of 30-40 cm and a maximum circumference of 30-35 cm’s.

The wet wood makes ignition more difficult because it is necessary a greater quantity of

energy to evaporate the existing water. The humid contents has the disadvantage that,

with the temperature lowering, the water condensates first in the hearth and then in the

chimney. The unseasoned wood contains about 60 % of H20, and then it is not suitable to

be burnt.

Among the others, the following cannot be burnt: remainders of coal, cut-outs,

scraps of bark and panels, humid wood or treated with varnishes, plastic materials;

in this case the warranty on the equipment expires.

Variety

Kg/m3

Kwh/Kg moistness 20%

Beech

750

4,0

Oak

900

4,2

Elm

640

4,1

Poplar

470

4,1

Larch*

660

4,4

Spruce*

450

4,5

Scots pine *

550

4,4

*Resinous wood not suitable for burning

Paper and carton must be used only for ignition.

The combustion of wastes is FORBIDDEN and may damage the stove and the chimney,

causing health damages and claims by the neighbourhood owing to the bad smell.

The wood is not a fuel, which allows a continuous operation of the appliance, as

consequence the heating

all over the night is not possible.

ATTENTION: the continuous and protracted use of aromatic wood (eucalyptus, myrtle etc.)

quickly

damages the cast iron parts (cleavage) of the product.

.

15. LIGHTING

IMPORTANT: The first time that the appliance is lit, there will be an odour given off (due to

the drying of the adhesives of the junction chord), which disappears after a short use. It

must be ensured, in any case, a good ventilation of the environment. Upon the first ignition

we suggest loading a reducedquantity of fuel and slightly increasing the calorific value of

the equipment.

Therefore, it is extremely relevant to take these easy steps during the lighting:

1. Make sure that a strong air change is assured in the room where the appliance is

installed.

2. During the first starts, do not load excessively the combustion chamber (about half the

quantity

indicated in the instructions manual) and keep the product continuously ON for at least 6-

10 hours

with the registers less open than the value indicated in the instructions manual.

3. Repeat this operation for at least 4-5 or more times, according to your possibilities.

4. Then load more and more fuel (following in any case the provisions contained in the

installation booklet concerning maximum load) and, if possible, keep the lighting periods

long avoiding, at least in this initial phase, short ON/OFF cycles.

5. During the first starts, no object should be leaned on the appliance and in detail on

enameled surfaces. Enameled surfaces must not be touched during heating.

6. Once the «break-in» has been completed, it is possible to use the product as the

motor of a car,

avoiding abrupt heating with excessive loads.

To light the fire, it is suggested using small wood pieces together with paper or other

traded lighting means.

It is FORBIDDEN to use any liquid substance as for ex. alcohol, gasoline, oil and

similar.

Operation with wood :

Open the secondary air control, open the thermostat, open the ignition control, light up the

fire. After about 10 minutes, when the fire is lighted, close the thermostat and the ignition

control and adjust the combustion course with the controls.

The openings for air (primary and secondary) must be opened together just a little (you

must open the eventual butterfly valve placed on the pipe of smokes exhaust). Never

overload the stove (compare the technical table - max. quantity of loadable fuel). Too

much fuel and too much air for the combustion may cause overheating and then

damage the stove.

16. NORMAL OPERATION

IMPORTANT: due to the fact the door of the hearth has a remarkable size, we suggest you

to open the

door very slowly, to avoid the exit of smokes.

For safety reasons the door of the hearth can be opened only for the loading of the

fuel. The hearth

door must always remain closed during operation or rest.

Before opening the hearth door, open the ignition control, load the fuel, close the door and

after about 5 or 10 minutes close the control.

With the registers placed on the front of the appliance it is adjusted the emission of heat of

the stove. They

must be opened according to the calorific need. The best combustion (with minimum

emissions) is reached

when, loading the wood, most of the air for the combustion passes through the register of

secondary air.

Never overload the stove (compare the technical table - max. quantity of loadable fuel).

The warranty does not cover the damages due to overheating of the equipment.

You should always use the stove with the door closed in order to avoid damages due to

overheating (forge effect).

The adjustment of the registers, necessary to obtain a rating calorific performance with a

depression on the

chimney is the following:

Fuel

Secondary air (A1)

Primary air (B1)

Wood

Open

Closed

Mass of fuel hourly

2,0 kg/h

2,0 kg/h

Besides by the adjustment of air for the combustion, the intensity of combustion and then

the calorific value

of your stove is affected by the chimney. A good flue of the chimney requires a more

reduced adjustment of

air for the combustion, while a poor flue needs more an exact adjustment of air for

combustion.

To verify the good combustion of the stove, check if the smoke coming out from the

chimney is transparent.

If it is white, it means that the stove is not correctly adjusted or the wood is too wet; if on

the contrary the

smoke is gray or black, it means that the combustion is not complete (it is necessary a

greater quantity of

secondary air).

17. OPERATION IN TRANSITION PERIODS

During transition periods when the external temperatures are higher, if there is a sudden

increase of

temperature it can happen that the combustion gases inside the flue cannot be completely

sucked up.

The exhaust gases do not come out completely (intense smell of gas). In this case, shake

the grating more frequently and increase the air for the combustion. Then, load a reduced

quantity of fuel in order to permit a rapid burning (growing up of the flames) and the

stabilization of the draught.

Then, check that all openings for the cleaning and the connections to the stack are air-

tight. In case of doubt, do not operate the stove.

18. CLEANING

Let the installation of your stove, the connection to chimney and the ventilation check by

your chimney

sweeper.

For the cleaning of enamelled surfaces use soap water or not aggressive and not

chemically abrasive detergents.

IMPORTANT: It is possible to use exclusively spare parts clearly authorized and

offered by the manufacturer. In case of need please apply to your dealer!

THE APPLIANCE CAN NOT BE MODIFIED!

18.1 CLEANING OF THE FLUE

A correct lighting, the burning of a proper fuel, the loading of the suggested quantity of fuel,

the right adjustments of the secondary air control, the sufficient draught of the chimney

and the presence of air for the combustion, are essential for the good operation of the

appliance.

The appliance should be completely cleaned at least once a year or every time it is

needed (in case of bad working and low yield).The cleaning must be carried out

exclusively with cold equipment.

This operation should be carried out by a chimney sweeper who can simultaneously

perform an audit of the flue (checking of possible deposits). During the cleaning, it is

necessary to remove from the appliance the ash drawer and the smokes pipes. It is

possible to clean the space for the collection of smokes from the hearth or through the

smoke exhaust, by using a brush and a vacuum cleaner. Once the cleaning has been

completed, the same has to be positioned back in its seat.

18.2 CLEANING OF THE GLASS

Thanks to a specific entry of the secondary air the building of deposit on the glass of the

door is slowed down in a remarkable way. However the building of this deposit cannot be

avoided with the use of solid fuels such as wet wood, and this is not to be considered as a

defect of the appliance.

IMPORTANT:

The cleaning of the sight glass must be carried out only and exclusively with cold

appliance to avoid the explosion of the same. Do not use cloths, abrasive or chemically

aggressive products by

cleaning the hearth glass.

BREAK OF GLASSES:

Considering that the glasses are manufactured in glass-ceramic and resistant to heat

shock up to 750 ° they are not subject to thermal shocks. The break can be caused only by

mechanic shocks,

(bumps or violent closure of the door, etc.). Therefore, their replacement is not included in

the warranty.

18.3 CLEANING OF THE ASH DRAWER

The stove has a hearth grate and an ash drawer for the collection of ashes. We suggest

you to empty periodically the ash drawer and to avoid filling it up totally, in order not to

overheat the grate. Furthermore, we recommend letting always 3-4 cm of ash in the

hearth.

ATTENTION: The ashes removed from the hearth have to be stored in a container made

of fire-resistant material equipped with an air-tight cover. The container has to be placed

on a fire-resistant floor, far from flammable materials up to the switching off

and complete cooling.

18.4 SUMMER PAUSE

After you have cleaned the hearth, the chimney and the flue, trying to eliminate

completely the ash and others residuals, you must close the doors of the hearth and its

registers; in case you disconnect the appliance from the chimney, close its opening in

order to let work other possible appliances connected to the same flue.

The cleaning of the flue should be done at least once a year; in the meanwhile check the

state of the

gaskets, which if not perfectly intact, that is to say that they are not more close-fitting with

the stove, do not guarantee the good working of the stove! In that case the gaskets must

be replaced. In presence of dampness in the room where the stove has been placed, we

advise you to put absorbent salts into the hearth.

We hope that you have read this instruction thoroughly and that you will not have any

problems while using the stove.

In case of any complaints call the local vendor or the manufacturer.

19. Recommendations for environmental protection

Product

-The device is made of recycable material. Before storing to waste, observe the valid

laws on protection of environment.

-Use only the recommended types of fuel.

-The incineration of organic and inorganic waste is forbidden (plastic, textile, oiled

wood, painted wood etc.) because it discharges carcinogenic and other detrimental

materia.

Packaging:

-Packaging material is 100% recyclable.

-When storing to waste, oibserve the local regulations.

-Packaging material (plastic bags, styrofoam etc.) should be held out of the reach of

children.

25.

P.025

4

63.

P.037

24.

P.024

1

61.

DIN 1481, ISO 8752

1

23.

P.023

1

56.

DIN 660

1

22.

P.022

1

55.

DIN 660

1

21.

P.021

1

50.

P.036

1

20.

P.020

1

49.

P.035

1

19.

P.019

1

48.

1

18.

P.018

1

47.

1

17.

P.017

4

46.

1

16.

P.016

1

45.

1

15.

P.015

1

44.

1

14.

P.014

1

43.

DIN 137 A –M10

2

13.

P.013

1

42.

DIN 923

1

12.

P.012

1

41.

P.034

1

11.

P.011

1

39.

DIN 965, ISO 7046

1

10.

P.010

1

38.

DIN 1481, ISO 8752

1

9.

P.009

2

37.

P.033

1

8.

P.008

1

36.

P.032

1

7.

P.007

1

35.

P.031

1

6.

P.006

1

34.

P.030

4

5.

P.005

1

30.

DIN 7985, ISO 8752

1

4.

P.004

1

29.

P.029

1

3.

P.003

1

28.

P.028

1

2.

P.002

2

27.

P.027

1

1.

P.001

1

26.

P.026

5

Poz.

Oznaka

Kom.

Poz.

Oznaka

Kom.

IKL

Table of contents

Other IKL Stove manuals

Popular Stove manuals by other brands

Primus

Primus Himalaya MultiFuel manual

Arada

Arada Aarrow DEFRA Installation and user guide

Ravelli

Ravelli Aria brochure

Charnwood

Charnwood Cove 2B Operating & installation instructions

Morso

Morso 8140 Installation and operating instructions

hergom

hergom EB-1 SE Installation, use and maintenance instructions

Guca

Guca THERMO LAVA Instructions for installation and operation

Jolly Mec

Jolly Mec AMBRIA2 Instructions for installation, use and maintenance manual

SCAN

SCAN A10 Instructions for installation and use

Nordpeis

Nordpeis N-21A Exclusive user manual

Travis Industries

Travis Industries Spirit DV owner's manual

Drolet

Drolet WOODSTOVES owner's manual