iLC Apprentice II User manual

INTELLIGENT LIGHTING CONTROLS, INC.

5229 Edina Industrial Boulevard

Minneapolis, Minnesota 55439

Phone 952 829 1900

FAX 952 829 1901

1-800-922-8004

USER GUIDE

Version 1A

9/1/06

Class A FCC Device Statement

Warning: Changes or modifications to this unit not expressly

approved by the party responsible for compliance could

void the user’s authority to operate this equipment.

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reason-

able protection against harmful interference when the equip-

ment is operated in a commercial environment. This equip-

ment generates, uses, and can radiate radio frequency ener-

gy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio commu-

nications. Operation of this equipment in residential area is

likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

PM-I-905

ILC Apprentice II User Manual

Version 1A 9/1/06

Structure

The major components making up the

controller are:

•enclosure

•control transformer

•CPU board with integral keypad/display

•Input board(s)

•Output board(s)

•lighting relays

Enclosure –The enclosure is rated NEMA 1.

It contains a line voltage section for the con-

trol transformers and lighting relays and a low

voltage section. Enclosures are available in 3

sizes to accommodate 4, 8 and 16 inputs, out-

puts, and lighting relays.

Transformer –A 40 VA multi-tap control trans-

former (120 or 277/24 VAC) provides the 24 VAC

input to power the controller electronics and

input/output board(s).

CPU Board –The CPU board provides

the controller’s intelligence and memory.

Major components include:

•Keypad/display –4-line LCD display and six

durable, comfortable push buttons.

•Power Supply –converts the 24 VAC input

to the +5, -5 and +12 VDC required by the

controller logic and communications circuits.

A power switch provides the means of ener-

gizing/de-energizing all controller electronics.

•Communications –USB port, add-on card

expansion socket.

•Override Switches –push button override

switches turn relays all ON or all OFF.

•Microprocessor –executes the computer

code and coordinates all controller functions

including the controller real time clock.

•Flash Memory –contains the controller

operating system and basic tasks.

•the EEProm memory–store the user-entered

operating parameters.

•Real time clock –maintains time and date for

up to 30 days without power.

Input Board(s) –Each input board provides

four (4) switch inputs.

Major components include:

•Switch Inputs –can accept input from either

2- or 3-wire momentary or maintained dry

contact devices. Each switch input features

a switch pilot LED output, which can be pro-

grammed to track the state of a single relay,

relay group or preset. The inputs are optically

isolated, noise- and surge-resistant. A switch

and pilot may be located up to 1500 feet

from the controller, provided you use a mini-

mum of 18 gauge wire.

Output Board(s) –Each output board provides

four (4) relay outputs.

Major components include:

•Relay Outputs –Each optically isolated out-

put switches its associated lighting relay ON

and OFF. Each output has an associated LED.

The LED lights when the output switches the

relay ON.

•Relays –20A at 120 or 277 VAC

ILC Softcross™electromagnetically held relays

with Normally Open (NO) or Normally Closed

(NC) contacts.

Overview

The ILC Apprentice II lighting controller is a microprocessor-based, programmable

lighting controller capable of advanced lighting control in a master-slave application.

It is an economical controller that can link up to 48 control points and has the capability of using

hardwired or LightSync™data line switches. You can program the switch inputs to control any or

all of the relay outputs. The controller features ILC Softcross™relays with true zero-cross switching.

This User Guide outlines the capabilities of the controller and its add on modules.

The ILC Apprentice II is UL and FCC approved for commercial applications.

Section 1 Controller Description

1.0 Section Overview .......................................................................... 1-1

1.1 Controller Architecture.................................................................. 1-2

1.1.1 Enclosure ................................................................................ 1-2

1.1.2 Transformer ............................................................................ 1-2

1.1.3 CPU Board.............................................................................. 1-3

1.1.4 Input Board(s) ........................................................................ 1-4

1.1.5 Output Board(s)..................................................................... 1-4

1.1.6 Programming Buttons/Display ............................................. 1-8

1.1.7 Lighting Relays ....................................................................... 1-8

1.2 I/O Options...................................................................................... 1-9

1.2.1 Voice/DTMF Module ............................................................. 1-9

1.2.2 DMX 512 Module ................................................................... 1-9

1.2.3 N2 Module.............................................................................. 1-9

1.2.4 MODBUS Module................................................................... 1-9

1.3 Lighting Controller Network........................................................... 1-10

1.3.1 Communications Protocol and Transmission Media ......... 1-10

1.3.2 Network Architecture ........................................................... 1-10

1.3.3 Device Nodes ........................................................................ 1-10

Section 2 Installation

2.0 Section Overview .......................................................................... 2-1

2.1 Pre-Installation Checks .................................................................. 2-2

2.2 Mounting the Controller ................................................................ 2-2

2.2.1 Location ................................................................................. 2-2

2.2.2 Environmental Considerations............................................. 2-2

2.2.3 Distance From Hardwired Control Devices ........................ 2-2

2.3 Wiring the Controller ...................................................................... 2-2

2.3.1 Wire the Control Transformer ............................................... 2-2

2.3.2 Connect Line and Load ....................................................... 2-2

2.3.3 Wire Switch Inputs.................................................................. 2-2

2.4 Pre-Power Checks.......................................................................... 2-5

2.4.1 Check Controller Power Input ............................................. 2-5

2.4.2 Verify Supply Voltage ............................................................ 2-5

2.4.3 Double-Check Connections................................................ 2-5

4.4.4 External Monitoring and Control ......................................... 2-5

2.5 Power-Up and Check Out............................................................. 2-5

2.5.1 Power-Up the Controller ....................................................... 2-5

2.5.2 Verify the Lighting Relays ...................................................... 2-5

2.5.3 Perform Initial Programming Procedures............................ 2-5

2.5.4 Verify the Switching Function ............................................... 2-5

2.5.5 Verify the Timer Functions ..................................................... 2-5

ILC Apprentice II User Manual

Version 1A 9/1/06

Table of Contents

Table of Contents

ILC Apprentice II User Manual

Version 1A 9/1/06

Section 2 Installation, continued

2.6 Troubleshooting .............................................................................. 2-6

2.6.1 Controller Will Not Power-Up ................................................ 2-6

2.6.2 Lighting Relay(s) Will Not Function....................................... 2-6

2.6.3 Switch Input Will Not Function.............................................. 2-6

2.6.4 Timers Will Not Function Properly ......................................... 2-6

2.6.5 Entire Input or Output Board(s) Will Not Function............... 2-6

Section 3 Programming

3.0 Section Overview .......................................................................... 3-1

3.1 Hidden Menu Choices................................................................... 3-2

3.2 Clear All Memory............................................................................ 3-3

3.3 Configuring the Apprentice II Network........................................ 3-5

3.4 Relay Output Operations .............................................................. 3-6

3.5 Switch Operations .......................................................................... 3-11

3.6 Switch Pilot operations................................................................... 3-20

3.7 How to Set the Controller Clock ................................................... 3-22

3.8 Disable Daylight Savings Time ...................................................... 3-24

3.9 Adjust Daylight Savings Time Settings .......................................... 3-26

3.10 Time-Based Operations ............................................................... 3-28

3.11 Blink Alert/Alarms.......................................................................... 3-43

3.12 Off Hours Sweeps ......................................................................... 3-45

3.13 Input Active Times ........................................................................ 3-47

3.14 Preset Operations ......................................................................... 3-49

3.15 Edit Names .................................................................................... 3-52

3.16 How to Enter or Change a Password ......................................... 3-54

3.17 How to View the Firmware Revision ........................................... 3-56

3.18 Add-On Modules.......................................................................... 3-58

3.19 How to Enter the Photoccell Filter (Scan Rate) ......................... 3-59

Section 4 LightSync Device Switching

4.0 Section Overview .......................................................................... 4-1

4.1 Installation ....................................................................................... 4-1

4.2 How to Control Relays With a LightSync Switch ......................... 4-13

4.3 LightSync Switch Status.................................................................. 4-18

4.4 LightSync Switch Pilots ................................................................... 4-20

Table of Contents

ILC Apprentice II User Manual

Version 1A 9/1/06

Section 5 Appendix

A. Voice/DTMF Add-On Module......................................................... A-1

A.1 Overview .................................................................................. A-1

A.2 Voice/DTMF Control Features................................................. A-2

A.3 Voice/DTMF Control Setup ..................................................... A-2

C. PC Control via USB Port................................................................... C-1

C.1 USB Programming Control and Monitoring .......................... C-1

C.2 USB Setup ................................................................................. C-1

E. DMX Control Feature ....................................................................... E-1

E.1 Overview ................................................................................... E-1

E.2 Objectives................................................................................. E-1

E.3 Programming Example ............................................................ E-4

M. MODBUS Communications ............................................................ M-1

M.1 Overview.................................................................................. M-1

M.2 Structure................................................................................... M-1

M.3 Transmission Modes................................................................. M-1

M.4 Transmission Mode Characteristics ....................................... M-3

M.5 Hardware Setup...................................................................... M-3

M.6 Required Parameter Entries ................................................... M-3

M.7 Framing .................................................................................... M-3

M.8 Supported Commands .......................................................... M-3

M.9 Additional Functions............................................................... M-3

M.10 Additional Information ......................................................... M-3

N. N2 Communications ....................................................................... N-1

N.1 Overview .................................................................................. N-1

N.2 Hardware Setup....................................................................... N-1

N.3 Point Map ................................................................................. N-1

O. Latitude and Longitude listings...................................................... O-1

P. Photo Control Applications ............................................................. P-1

P.1 Overview ................................................................................... P-1

P.2 Hardwired Model...................................................................... P-1

P.3 Programming ............................................................................ P-1

P.4 LightSync™Model ................................................................... P-1

P.5 Installation ................................................................................. P-4

P.6 Programming Example ............................................................ P-6

Section 1

Controller Description

ILC Apprentice II User Manual

Version 1A 9/1/06

12VAC

12VAC

CT

ILC APPRENTICE II

MON 08/07/06

04:19:44 PM

EDIT (C) 2006 ILC

ALL OFF OFF ON

POWER

77013466A

ALL ON

Controller Description

Section 1 Controller Description

1.0 Section Overview .......................................................................... 1-1

1.1 Controller Architecture.................................................................. 1-2

1.1.1 Enclosure ................................................................................ 1-2

1.1.2 Transformer ............................................................................ 1-2

1.1.3 CPU Board.............................................................................. 1-3

1.1.4 Input Board(s) ........................................................................ 1-4

1.1.5 Output Board(s)..................................................................... 1-4

1.1.6 Programming Buttons/Display ............................................. 1-8

1.1.7 Lighting Relays ....................................................................... 1-8

1.2 I/O Options...................................................................................... 1-9

1.2.1 Voice/DTMF Module ............................................................. 1-9

1.2.2 DMX 512 Module ................................................................... 1-9

1.2.3 N2 Module.............................................................................. 1-9

1.2.4 MODBUS Module................................................................... 1-9

1.3 Lighting Controller Network........................................................... 1-10

1.3.1 Communications Protocol and Transmission Media ......... 1-10

1.3.2 Network Architecture ........................................................... 1-10

1.3.3 Device Nodes ........................................................................ 1-10

Controller Description – Table of Contents

ILC Apprentice II User Manual

Version 1A 9/1/06

Objectives

In this Section you will learn about the

structure and configuration of the ILC

Apprentice II Controller.

Overview

The ILC Apprentice II is a microprocessor-

based lighting controller. You can program

the ILC Apprentice II to control lighting relays

in response to switch signals sensed by its

inputs and/or by time-based scheduling.

The ILC Apprentice II is UL approved and

FCC certified for commercial applications.

Section 1 –Controller Description

ILC Apprentice II User Manual 1-1

Version 1A 9/1/06

Controller Description

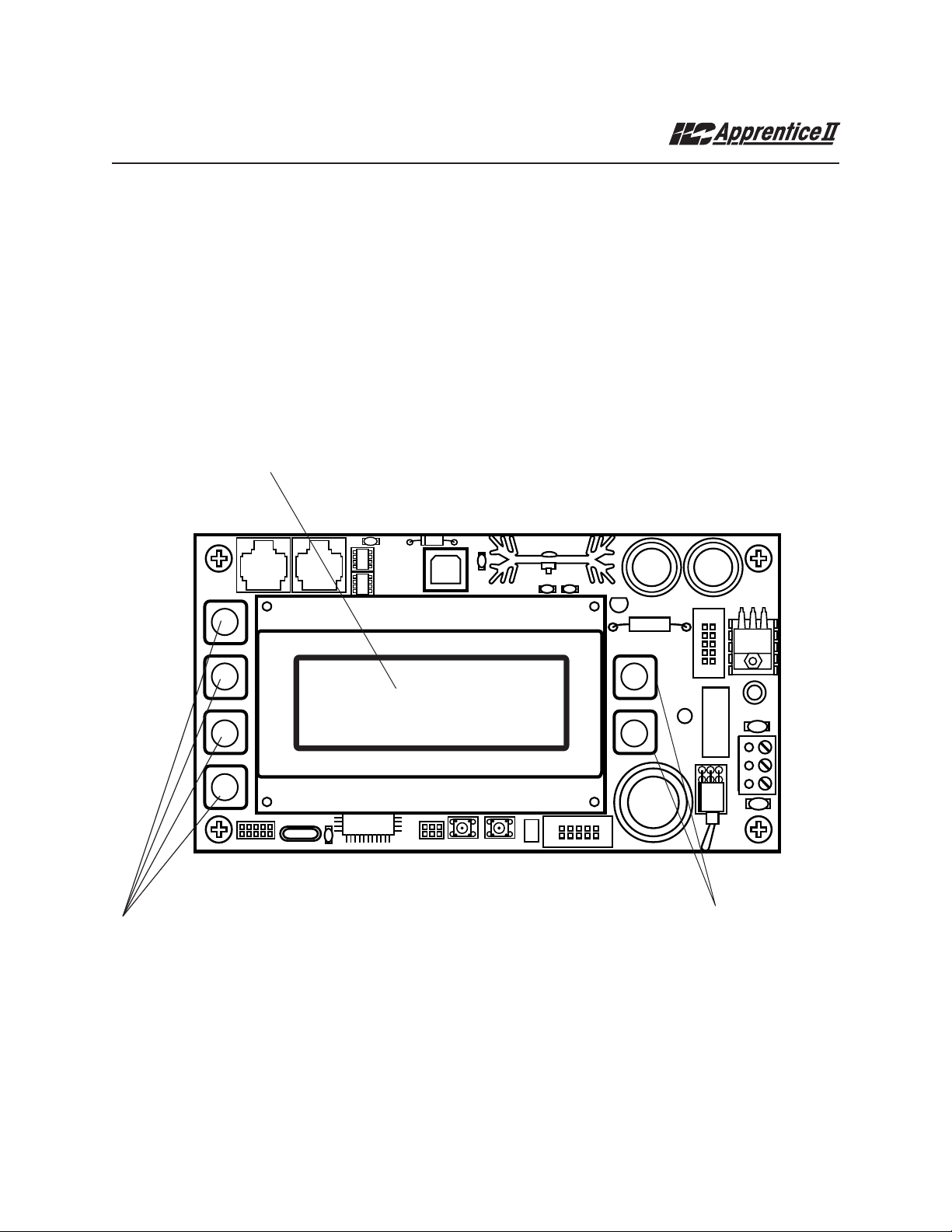

1.1 Controller Architecture

The major components making up the

controller are: (See Figure 1.1.)

•enclosure

•control transformer

•CPU board

•input board(s)

•output board(s)

•display/keypad

•lighting relays

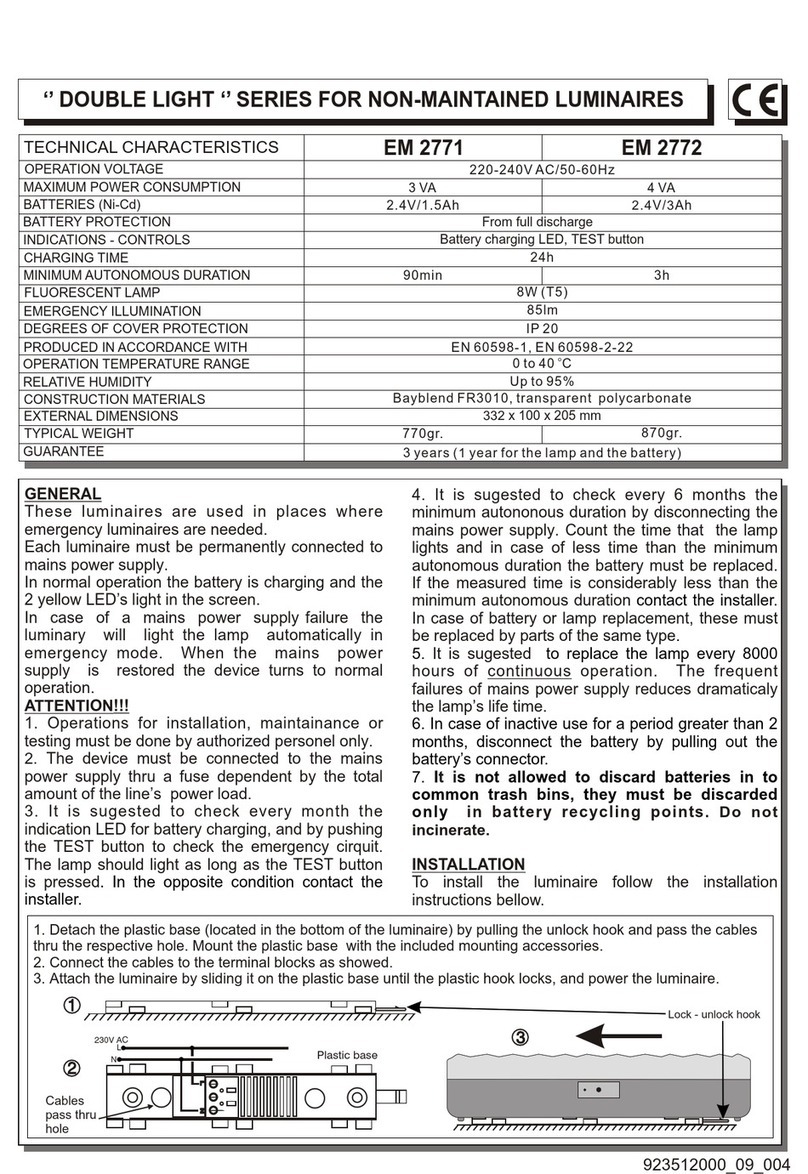

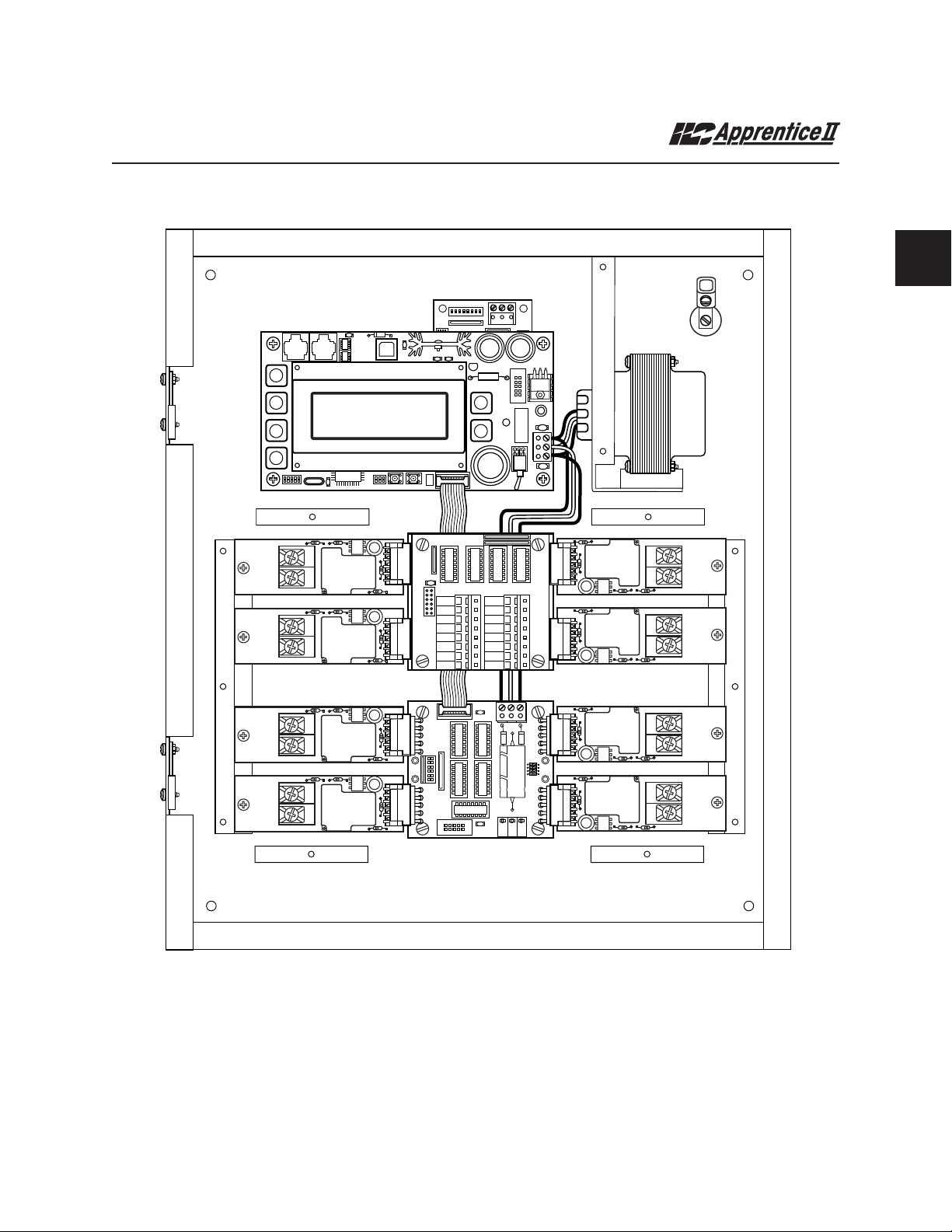

1.1.1 Enclosure - The enclosure is rated

NEMA 1. Enclosures are available in 3 sizes to

accommodate 4, 8, and 16 inputs, outputs,

and lighting relays. See (Table 1-1.) The ILC

Apprentice II is shipped to the job-site as a

complete assembly. (See Figure 1-1, which

illustrates a ILC Apprentice II 4.)

1.1.2 Transformer - A multi-tap transformer

(120 or 277/24 VAC) provides the 24 VAC input

to power the controller electronics.

Controller Description

ILC Apprentice II User Manual 1-2

Version 1A 9/1/06

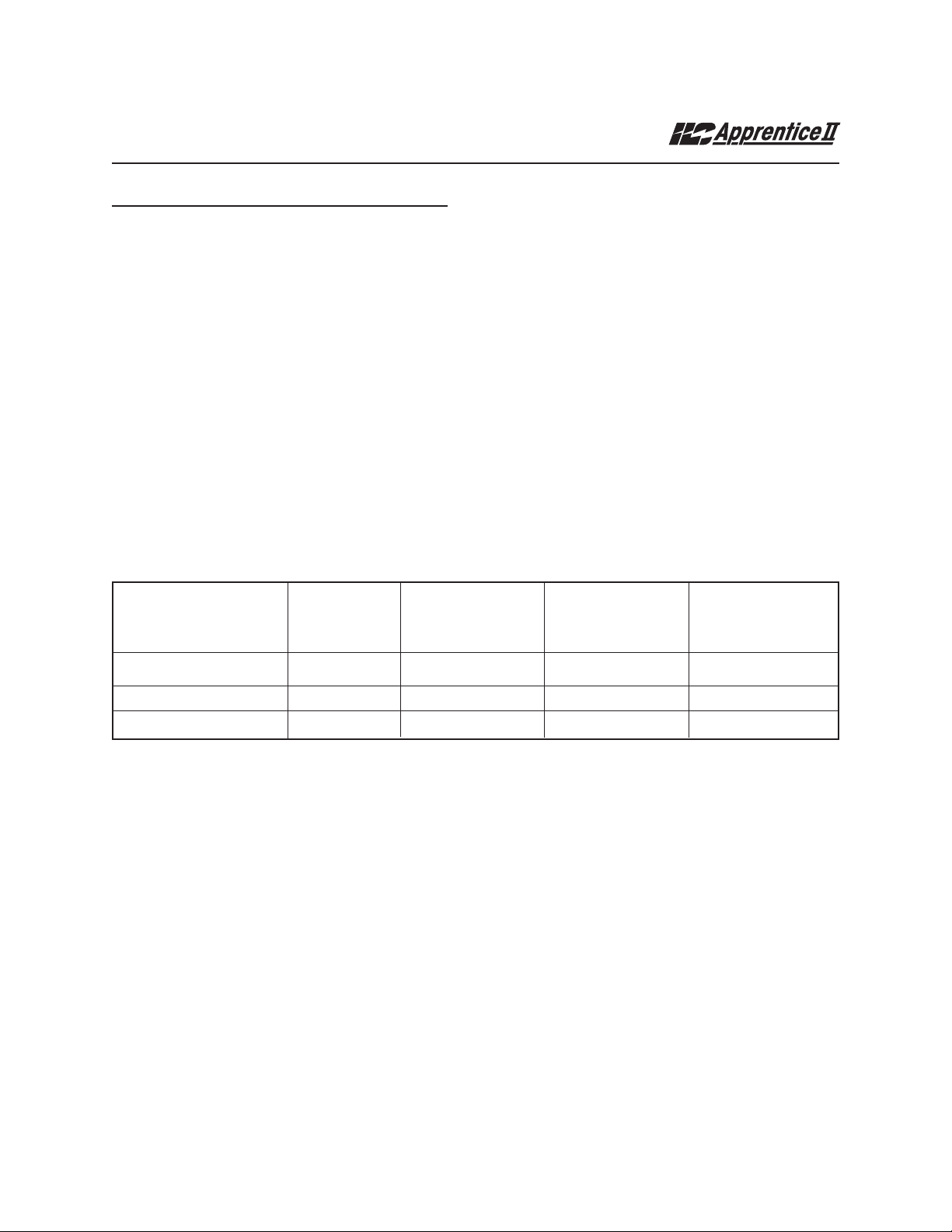

Model # of Relays

& I/O Points Width Height Depth

Apprentice II 4 4 14 Inches 12 Inches 4 Inches

Apprentice II 8 8 14 Inches 16 Inches 4 Inches

Apprentice II 16 16 14 Inches 24 Inches 4 Inches

Table 1.1 –ILC Apprentice II Configurations

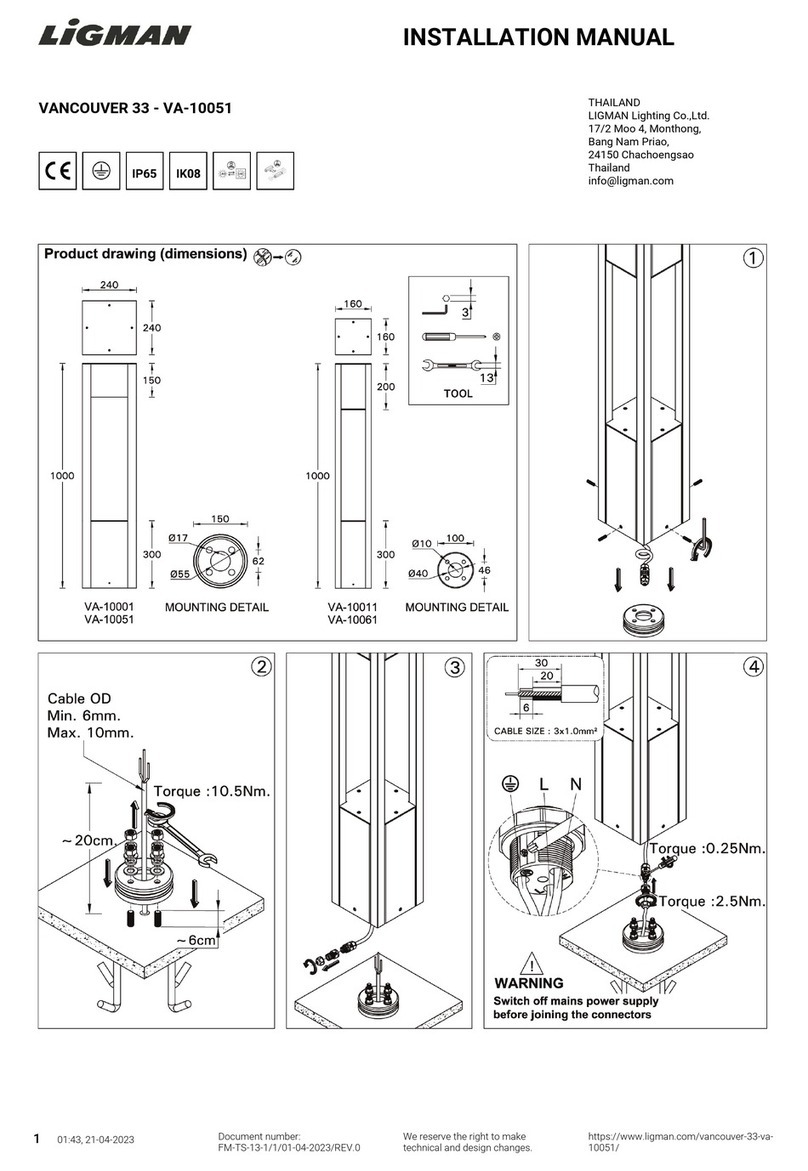

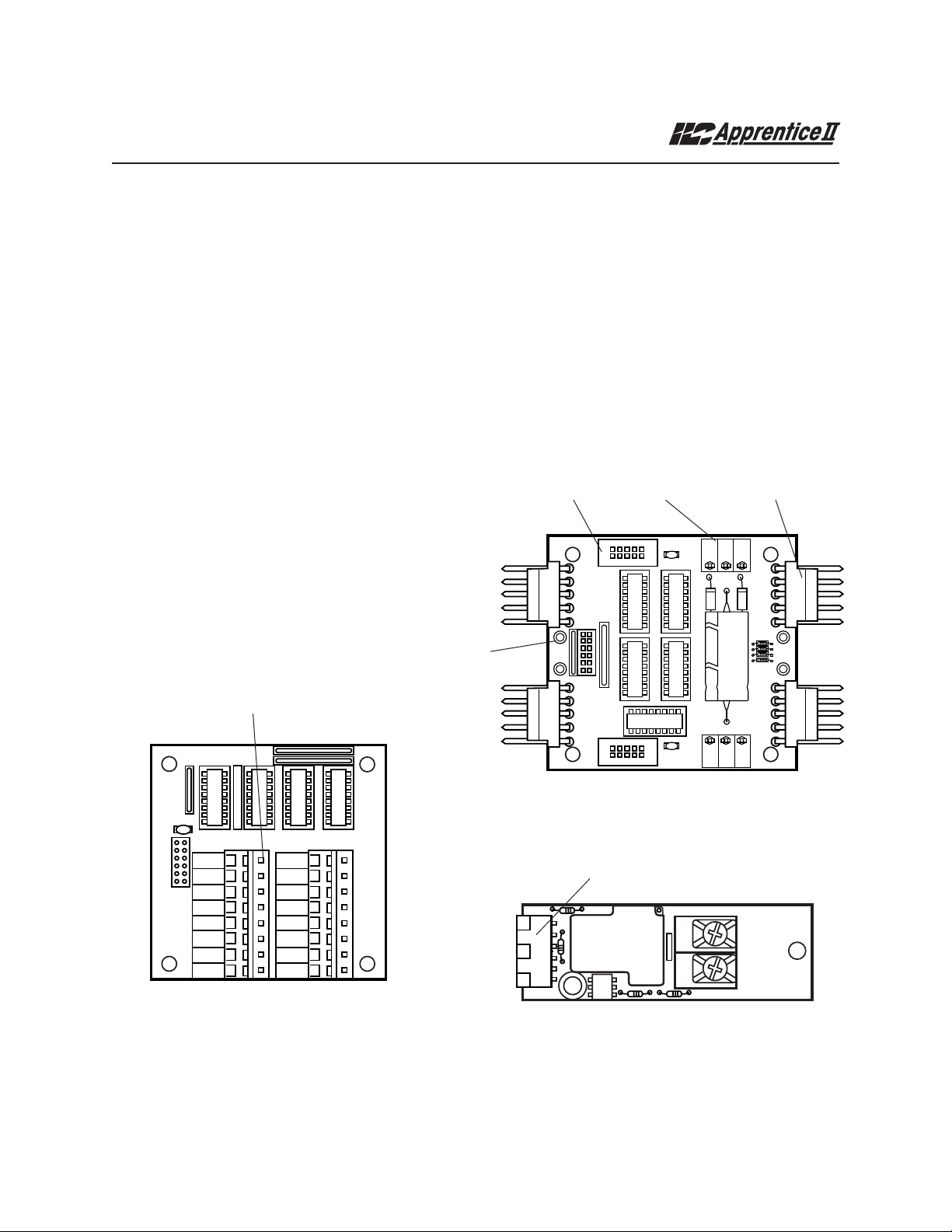

1.1.3 CPU Board –(See Figure 1.2.) The CPU

board provides the controller’s intelligence,

memory, and communications capabilities.

Major components include:

•Power Supply –converts the 24 VAC input

to the +5, -5 and +12 VDC required by the

controller logic and communications

circuits. A power switch provides the means

of energizing/de-energizing all controller

electronics.

•Communications –USB on-board port.

•Micro-Processor –executes the computer

code and coordinates all controller func-

tions including the controller real time clock.

•Override Switches –provided with All ON/All

OFF override pushbuttons.

•Flash Memory –contains the controller

operating system and basic tasks.

•EEProm memory–store the user-entered

operating parameters.

•Real time clock –maintains time and date

for up to 30 days without power.

Controller Description

ILC Apprentice II User Manual 1-3

Version 1A 9/1/06

77013452 REV A

97103452 REV

12VAC

12VAC

CT

ILC APPRENTICE II

MON 08/07/06

04:19:44 PM

EDIT (C) 2006 ILC

ALL OFF OFF ON

POWER

77013466A

ALL ON

LOAD LINE

N.O.

77013469A

1 ON

1 PILOT

1 OFF

1 COM

3 ON

3 OFF

3 COM

3 PILOT

2 ON

2 PILOT

2 OFF

2 COM

4 ON

4 OFF

4 COM

4 PILOT

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

Enclosure USB Port

Figure 1.1 –ILC Apprentice II 4 Controller

Grounding Lug

CPU Board

Fishpaper

Barrier

Standoff

Control

Transformer

120/277 VAC

Controller Description

Add-on Module (optional)RJ-45 Data IN/OUT

Connections

LCD

Display

Programming

Buttons

All ON/All OFF

Overrride

Buttons

Input Board

Output Board

Power ON/OFF

Relay Board

Switch Inputs

and Pilot

Outputs

Controller Description

ILC Apprentice II User Manual 1-4

Version 1A 9/1/06

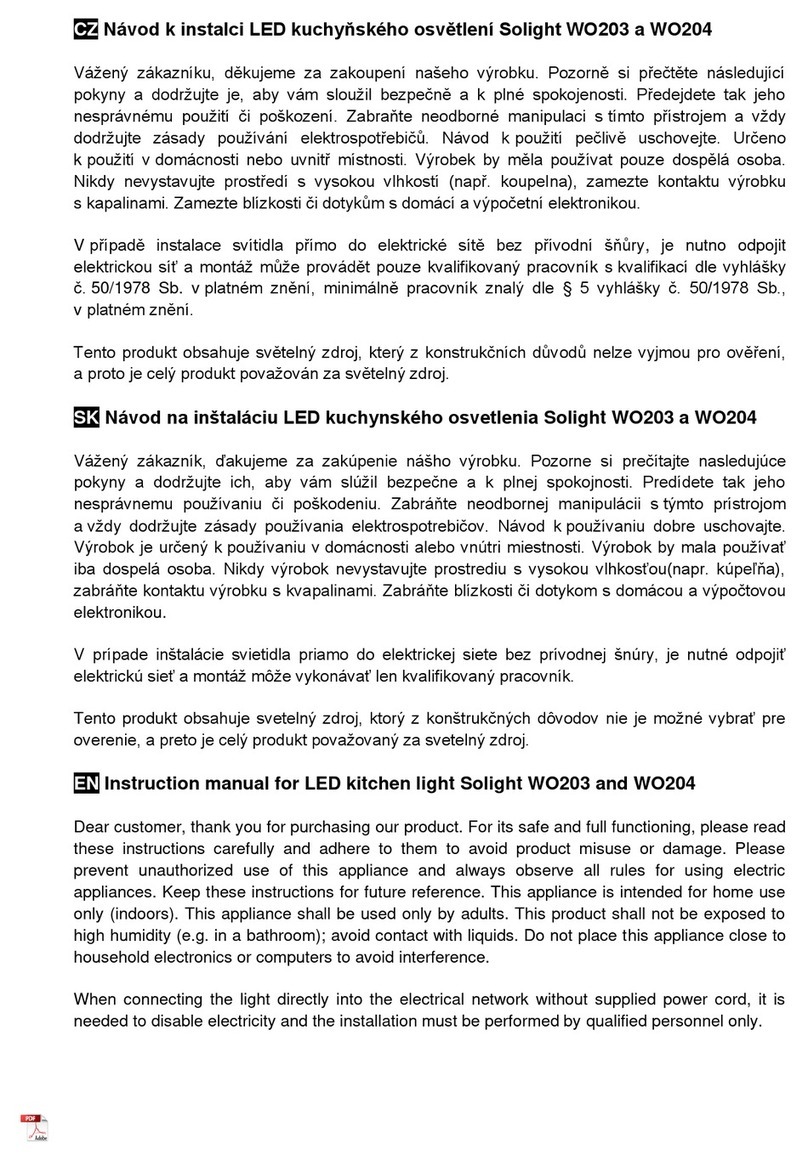

1.1.4 Input Board(s) –Each Input board adds

four (4) switch inputs and pilot outputs. The

inputs are all optically isolated. Additional

boards can be added to the enclosure to

provide a network capacity of up to 48

switch inputs. (See Figure 1.3, which illustrates

a ILC Apprentice II 8. Major components

include:

•Switch Inputs –The ILC Apprentice II is

designed to accomplish a wide variety of

switch input types. Each switch input has an

associated switch pilot LED output which

can be programmed to track the state of a

selected relay, relay group, or preset. See

the Table 1.2 (next page)for a description of

switch input types.

1.1.5 Output Board(s) –Each Output board

provides four (4) relay outputs that connect

to ILC Softcross™Relay boards. Major com-

ponents include:

•Relay Outputs - each output switches its

associated lighting relay ON and OFF.

Each output has an associated LED (light

emitting diode). The LED lights when the

output switches the relay ON.

12VAC

12VAC

COM

12VAC

12VAC

COM

77013469A

1 ON

1 PILOT

1 OFF

1 COM

3 ON

3 OFF

3 COM

3 PILOT

2 ON

2 PILOT

2 OFF

2 COM

4 ON

4 OFF

4 COM

4 PILOT

ILC Apprentice II Input Board

ILC Softcross™Relay

Switch inputs and pilot outputs

(4 per board)

Relay outputs

(4 per board)

Status LED

(4 per board)

LOAD LINE

N.O.

ILC Apprentice II Output Board

Power supply

connection

Ribbon cable

connector

Connection to

Output Board

Controller Description

ILC Apprentice II User Manual 1-5

Version 1A 9/1/06

Momentary ON/OFF:

When momentary contact

is made between ON

and COM, relay outputs

controlled by this input

are turned ON. When

momentary contact is

made between OFF

and COM relay outputs

controlled by this input

are turned OFF.

Momentary Push- Button:

When momentary contact

is made between ON

and COM, relay outputs

controlled by this input

are turned ON and OFF

alternately each time

contact is made.

Photo Sensor Inputs:

ILC Apprentice controllers

can be connected to either

momentary or maintained

output photo sensors as

shown below.

Maintained ON/OFF:

When contact is made

between ON and COM

relay outputs controlled by

this input are turned ON.

When contact is broken

between ON and COM,

relay outputs controlled by

this input are turned OFF.

Maintained Multi-Way:

When contact is either

made or broken between

the ON and COM, relay

outputs controlled by this

input will be toggled

between ON and OFF

conditions. This function is

similar to that of standard

3- and 4-way switches.

Timed ON/Cleaning Switch:

When momentary contact

is made between COM

and ON, relay outputs

are turned ON. When

contact is broken, a timed

ON duration is started from

5-999 minutes. Contact

between OFF and COM will

turn relays OFF.

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

MOMENTARY

Set Preset:

When momentary contact

is made between ON and

COM, the selected preset

will be activated.

ON

COM

OFF

MOMENTARY

ON

COM

OFF

MOMENTARY

Two-Step Group:

When the switch is

activated, group A (relay

outputs) turn ON and

group B (relay outputs)

turn OFF. When the input is

activated again, group A

turn OFF and group B turn

ON. The pattern repeats

with successive switch

activations.

ON

COM

OFF

MOMENTARY

Input Disable:

When contact is made

between ON and COM,

selected input or inputs

will be ignored.

Four-Step Group:

The first time the switch is

activated, group A (relay

outputs) turn ON and

group B (relay outputs)

turn OFF. The second time

the switch is activated,

group A turn OFF and

group B turn ON. The third

time, both groups turn ON.

The fourth time, both

groups turn OFF. The fifth

actuation begins a repeat

of the 4 steps.

ON

COM

OFF

MOMENTARY

MAINTAINED MAINTAINED

ON

COM

OFF

MAINTAINED

Timer Disable:

While contact is made

between ON and COM,

selected timer or timers

will be ignored.

ON

COM

OFF

MAINTAINED

Output Override:

While contact is made

between ON and COM, relay

outputs controlled by this

input are turned ON, OFF or

held in their current state

and all other control com-

mands are ignored.

All inputs/timers are

ignored for controlled

relay outputs.

ON

COM

OFF

MAINTAINED

ON

COM

OFF

ON

COM

OFF

MOMENTARY

Programmed as “Momentary”

MAINTAINED

Programmed as “Maintained

ON/OFF input”

MOMENTARY

Fire Alarm System Inputs:

ILC Apprentice controllers

can be easily connected to

building Fire Alarm Systems

to force selected controlled

lighting circuits to the ON,

OFF or HOLD state and lock

out all other forms of con-

trol when a Fire Alarm sig-

nal is present (contacts

CLOSED).

Motion Sensor Inputs:

ILC Apprentice controllers

can be connected to either

momentary or maintained

output motion sensors as

shown below.

Dry Contact Interface:

Virtually any control sys-

tem or device can be inter-

faced to a ILC Apprentice

controller through the use

of a simple dry contact

interface utilizing any of

the available switch types.

Please consult factory for

any special requirements.

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

MAINTAINED

Programmed as

“Output Override input”

MOMENTARY

Programmed as “Momentary”

MAINTAINED

Programmed as “Maintained

ON/OFF input”

Force Timer:

A switch input can be

mapped to force a ILC

Apprentice Timer

activation.

ON

COM

OFF

MAINTAINED

HID Bi-Level:

Operation of Bi-level HID

Ballasts. First contact

between COM and ON will

turn ON power and

High/Low relay. (High/Low

relay is locked ON for 15

minutes for warm up peri-

od) Additional activations

of ON terminal will toggle

High/Low relay. Contact

between OFF and COM

will turn relays OFF.

ON

COM

OFF

MOMENTARY

NOTE: Switch Enable-Disable: Inputs may be enabled or disabled based on Time of day

Table 1.2 –ILC Apprentice Switch Input Types

Controller Description

Controller Description

ILC Apprentice II User Manual 1-6

Version 1A 9/1/06

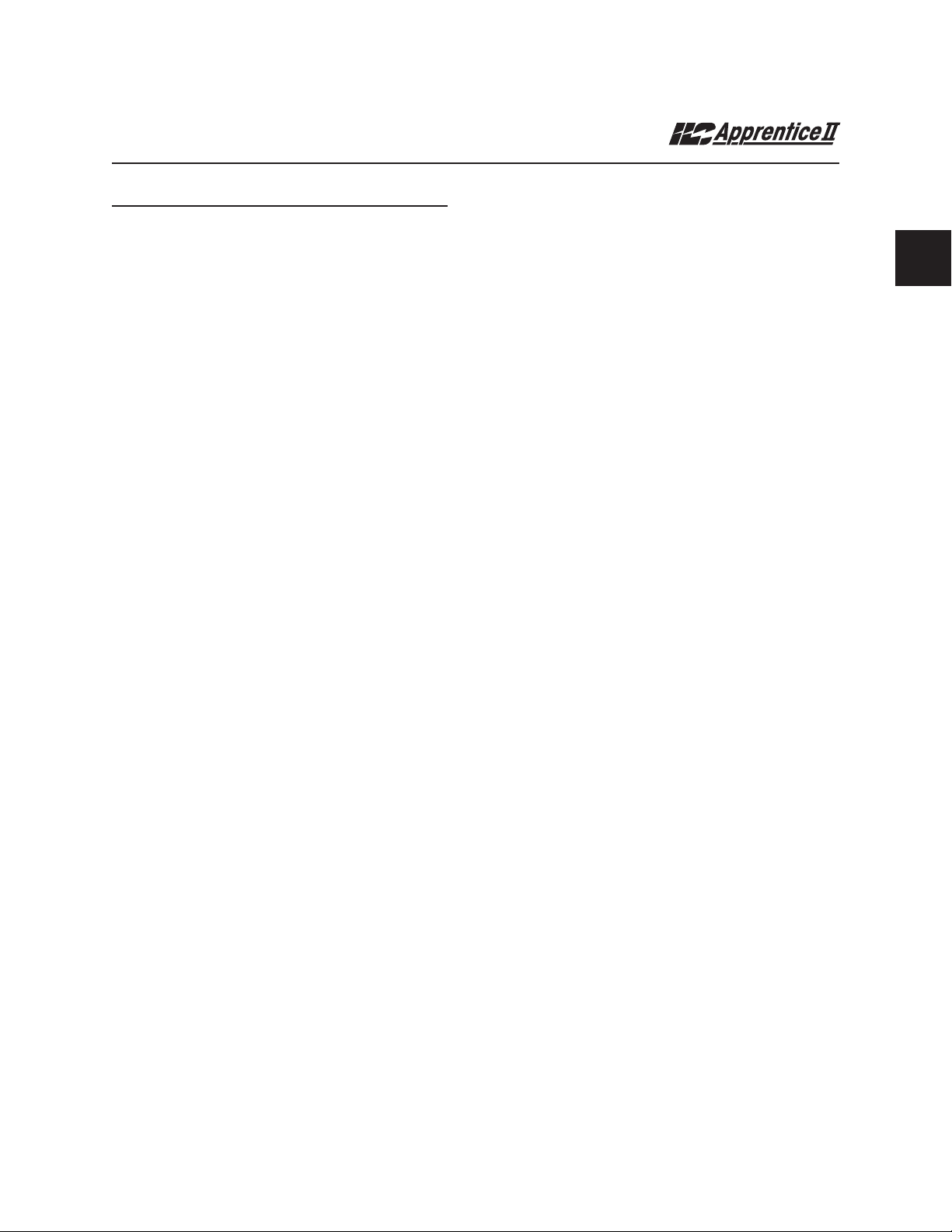

Figure 1.2 –Apprentice II CPU Board and I/O

77013452 REV A

97103452 REV

8VAC

8VAC

CT

ILC APPRENTICE II

MON 08/07/06

04:19:44 PM

EDIT (C) 2006 ILC

ALL OFF OFF ON

POWER

77013466A

ALL ON

LOAD LINE

N.O.

77013469A

1 ON

1 PILOT

1 OFF

1 COM

3 ON

3 OFF

3 COM

3 PILOT

2 ON

2 PILOT

2 OFF

2 COM

4 ON

4 OFF

4 COM

4 PILOT

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

Switch inputs

and pilot outputs

Line

Relay output

status LED

4-line LCD display

12 VAC

Center tap

12 VAC

Terminal block for

processor transformer

Add-on Module

(optional)

24 VAC

USB Port

Main power switch

Data cable

to I/O board Softcross Relay

Board

Power LED

Programming

buttons

Programming

buttons

RJ 45 Connectors for

data line devices

All ON/All OFF

override pushbuttons

Load

Controller Description

ILC Apprentice II User Manual 1-7

Version 1A 9/1/06

77013452 REV A

97103452 REV

9

12VAC

12VAC

CT

OFF

ILC APPRENTICE II

MON 08/07/06

04:19:44 PM

EDIT (C) 2006 ILC

ALL OFF OFF ON

POWER

77013466A

ALL ON

8VAC

8VAC

COM

8VAC

8VAC

COM

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

77013469A

1 ON

1 PILOT

1 OFF

1 COM

3 ON

3 OFF

3 COM

3 PILOT

2 ON

2 PILOT

2 OFF

2 COM

4 ON

4 OFF

4 COM

4 PILOT

LOAD LINE

N.O.

LOAD LINE

N.O.

LOAD LINE

N.O.

Figure 1.3 –ILC Apprentice II 08 with standard 4-inputs

Controller Description

Controller Description

ILC Apprentice II User Manual 1-8

Version 1A 9/1/06

12VAC

12VAC

CT

ILC APPRENTICE II

MON 08/07/06

04:19:44 PM

EDIT (C) 2006 ILC

ALL OFF OFF ON

POWER

77013466A

ALL ON

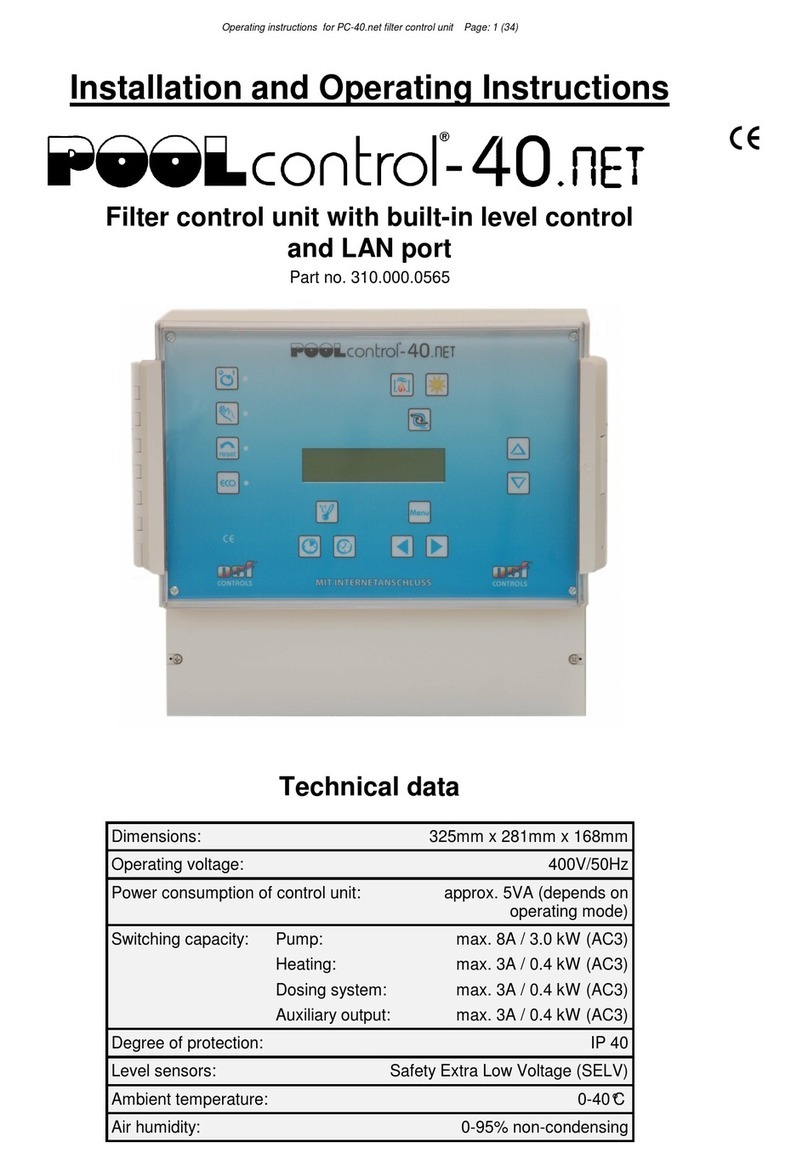

Figure 1.4 –ILC Apprentice II Programming Buttons and Display

4-line, 32-character Display Screen

Scrolling Buttons

Selection Buttons

(Used to select

displayed options)

1.1.6 Programming Buttons/Display - (See

Figure 1.4.) The ILC Apprentice provides

you with programming buttons and a LCD

display to enable programming and view

controller data.

1.1.7 Lighting Relays - ILC Softcross™relays are

electromagneticall held relays with Normally

Open (NO) or Normally Closed (NC) contacts.

They control the live voltage loads and can

control 120 or 277 VAC loads rated up to 20

amps. The relays are connected to the output

board by means of a five-pin push-on con-

nector hele in place with a retaining screw.

1.2 I/O Options

The ILC Apprentice II controller can be

equipped with the following add-on

devices:

1.2.1 Voice/DTMF Module –You can equip

the controller with a DTMF (Dual Tone Multi

Frequency) interface, which allows you to

activate switch inputs via commands from a

touchtone telephone.

(See Appendix A.)

1.2.2 DMX 512 Module –Provides for direct

control of ON/OFF lighting or other loads from

any DMX 512 control device. Any of the avail-

able 512 DMX control channels may be

mapped to control individual relays. (See

Appendix B.)

1.2.3 N2 Module –Provides for direct control

of control devices in building automation sys-

tems using N2 protocol . (See Appendix N.)

1.2.4 MODBUS Module –Provides for direct

control of control devices in building automa-

tion systems using MODBUS protocol . (See

Appendix M.)

Controller Description

ILC Apprentice II User Manual 1-9

Version 1A 9/1/06

Controller Description

Controller Description

ILC Apprentice II User Manual 1-10

Version 1A 9/1/06

1.3 Lighting Controller Network

ILC Apprentice II controllers can be net-

worked together in a Local Area Network

(LAN) to form a comprehensive lighting con-

trol system for a faciltity.

1.3.1 Communications Protocol And

Transmission Media –Devices that operate

on ILC’s LightSync CAT-5 data line include

Apprentice II lighting controllers, LightSync

switches, photocells, and interfaces like the

LightSync D-6 and SIB-4. A standard 24

gauge CAT-5, CAT-5E or CAT-6 cable is used

for the data line and provides both data

and power to these devices. See Figure 1.5

which details cable specifications. The cable

terminates to ports on each Apprentice II

controller (or expansion panel) as shown in

Figure 1.7. The total data line end to end dis-

tance may not exceed 3000 feet without the

addition of a Power Supply Repeater (PSR)

(See Figure 1.8) to the data line. Only a PSR

will extend the data line. A PSR has one

incoming and two outgoing RJ45 ports to split

the line into two different directions. See Figure

1.8 for an example of possible project layout.

1.3.2 Network Architecture

The network can consist of a Master panel

and a number of Expansion (slave) panels

that add up to a maximum of 48 relay out-

puts. The Master panel is always Node 1 and

controls the Expansion panels. The Expansion

panels are adddressed with a unique node

address ranging from 2 to C. The data line

exits the Master panel’s RJ-45 OUT port and

enters the IN port of the Expansion panel.

As an alternative to programming from the

Master Controller Keypad, programming may

be done from a personal computer (PC)

equipped with proprietary ILC Apprentice II

Pro software. See Appendix C for details.

1.3.3 Device Nodes –Apprentice II Networks

also feature Device Nodes. These are data

switches, photocells and other I/O devices

connected to the CAT-5 data line. (See Figure

1.8). There can be a maximum of up to 32

device nodes in a the lighting control network.

There are limitations to the distance data

can travel over CAT-5 cable without loss,

and distance limitations due to voltage drop

associated with cable length and number of

devices on the LightSync data line. These

limitations are addressed by the addition of

a Power Supply Repeater, Power Supply or

LightSync Hub (see Figure 1.6), depending

on the application. The specific use of these

devices depends on the project layout.

Each controller will power up to 8 device

nodes without a Power Supply Repeater

(PSR), Power Supply (PS) or LightSync Hub

(HUB). Each of these will supply power to an

additional 20 devices. If "T" connections are

required, or if data needs to be extended, a

PSR is necessary. A LightSync Hub (See Figure

1.9) provides “home run”wiring capability.

Consult factory for details.

Each device node is addressed via address

dials that are part of the device. Possible

addresses for device nodes are 01-20. These

are a different set of addresses from the con-

troller node addresses.

If your project features device nodes,

consult Section 4 for details.

Figure 1.5 –Data Cable Requirements

Data Cable Requirements

Definitions:

Category 5 Cable (UTP-Unshielded Twisted Pair)- A 4 pair high performance cable that consists of

twisted pair conductors, used mainly for data transmission. Basic CAT-5 cable was designed for

characteristics of up to 100 MHz. NOTE: The twisting of the pairs gives the cable a certain amount of

immunity from the infiltration of unwanted interference.

Category 5E Cable (Enhanced)- Same as Category 5, except that it is made to somewhat more

stringent standards (see comparison chart below). The Category 5E standard is now officially part

of the 568A standard. Category 5 E is recommended for all new installations, and was designed for

transmission speeds of up to 1 gigabit per second.

Below you will find a list of the required properties your selected cable must meet. You will also find a

list of cables, which meet these criteria from several different manufacturers. At your option you

may utilize one of the below-suggested cables or have your cable supplier provide you with a suit-

able alternative, which meets the listed criteria.

Category 6 Cable- Same as Category 5E, except that it is made to a higher standard (see

comparison chart below). Category 6 is now part of the 568A standard.

Standard 24-gauge Data Cable Performance Specification Chart:

Parameter Category 5 Category 5E Category 6

Specified frequency range 1-100 MHz 1-100 MHz 1-250 MHz

Attenuation 24 dB 24 dB 36 dB

NEXT 27.1 dB 30.1 dB 33.1 dB

Power-sum NEXT N/A 27.1 dB 30.2 dB

ACR 3.1 dB 6.1 dB -2.9 dB

Power-sum ACR N/A 3.1 dB -5.8 dB

ELFEXT 17 dB 17.4 dB 15.3 dB

Power-sum ELFEXT 14.4 dB 14.4 dB 12.3 dB

Return loss 8 dB 10 dB 8 dB

Propagation delay 548 nsec 548 nsec 546 nsec

Delay Skew 50 nsec 50 nsec 50 nsec

Suggested Manufacturers and Data Cables:

Manufacturer Part Number Cable Type Phone

Belden 7854A CAT-5 non-plenum 800 235 3361

1583A CAT-5E non-plenum

7811A CAT-5 plenum

1585A CAT-5E plenum

General 2137113 CAT-5 non-plenum

5133299E CAT-5E non-plenum

5131413 CAT-5 plenum

6131278 CAT-5E plenum

Hitachi 38696-8 CAT-5 non-plenum

38993-8 CAT-5E non-plenum

39419-8 CAT-5 plenum

38891-8 CAT-5E plenum

If you have any questions or would like our engineers to approve your cable selection please feel

free to contact our applications department at 1-800-922-8004.

Contact

Cassidey

Technolgies

(800 464 9473),

manufacturer,

or local

distributor

Controller Description

ILC Apprentice II User Manual 1-11

Version 1A 9/1/06

Controller Description

Controller Description

ILC Apprentice II User Manual 1-12

Version 1A 9/1/06

Figure 1.6 –LightSync Network Cable Run Distance Detail

LightSync™Network Cable Run Distance Detail

Devices that operate on ILC’s LightSync CAT-5 , 5E, 6 data line include LightSync switches, photocells,

and interfaces like the LightSync D-6 and SIB-4. A standard CAT-5 , 5E, 6 cable is used for the data line

and provides both data and power to these devices. There are limitations to the distance data can

travel over CAT-5 , 5E, 6 cable without loss, and distance limitations due to voltage drop associated

with cable length and number of devices on the LightSync data line. These limitations are addressed

by the addition of a Power Supply Repeater, Power Supply or LightSync Hub (see chart), depending on

the application. The specific use of these devices depends on the project layout.

There are four main areas of limitation to be addressed:

1. Total Data Line Overall Distance: The total data line end to

end distance may not exceed 3000 feet without the

addition of a PSR to the data line. Only a PSR will extend the

data line.

2. Total number devices (Lightmaster panels and LightSync

devices): Total number of devices without a PSR is 32. A PSR

will add 31 more devices (PSRs are counted as a device).

3. Total number of LightSync devices powered: No Apprentice II

controller panel can power more than eight (8) LightSync

devices on the data line without a PS, PSR or LightSync Hub

(each can power up to 20 additional LightSync devices).

4. Total Power Cumulative Distance: The cumulative distance

from each device to its power supply may not exceed 2000

feet if powered by a Apprentice II panel, or 3000 feet if pow-

ered by a PS, PSR or LightSync Hub.

INTELLIGENTLIGHTING CONTROLS, INC. MINNEAPOLIS, MN 800 922 8004

25 feet

Total cumulative distance is equal to the

total of the run to EACH device,

25 + 50 +50 = 125 feet in this example

ILC Power and Data Repeating Devices

A Power Supply Repeater (PSR) is both a power supply and data repeater and its primary purpose is to

repeat data and provide a bridge to another data line capable of 3000 feet end to end. This device

also has one incoming and two outgoing RJ45 ports to split the line into two different directions. The PSR

also adds power to LightSync devices for an additional 3000 cumulative feet.

A Power Supply (PS) provides additional power as needed to the LightSync data line. This is the

most efficient option to compensate for voltage drop from multiple LightSync devices on the data

line. Note that a PS provides power only and does not repeat data.

A LightSync Hub (HUB) is a device that allows a home run configuration by providing RJ45 ports for

up to 20 LightSync devices, supplying power and data up to 1500 feet per each port.

ILC Power and Data Total Data (end No. of LightSync Cumulative Power

Repeating Device to end) Distance Devices Powered Distance

Apprentice II Panel 3000 feet 8 2000 feet

Power Suppy (PS) N/A 20 3000 feet

Power Supply 3000 feet 20 3000 feet

Repeater (PSR) (combined)

LightSync Hub 1500 feet 20 total 1500 feet

(HUB) per port per port

INTELLIGENTLIGHTING CONTROLS, INC. MINNEAPOLIS, MN 800 922 8004

3000 feet end to end

1000 feet

PSR

2000 feet

INTELLIGENTLIGHTING CONTROLS, INC. MINNEAPOLIS, MN 800 922 8004

Up to 20 addi-

tional devices

PSR

AP II 16

AP II 04

25 feet

Counts as 2

AP II 08

Table of contents