INSTALLATION

1716

This appliance shall be installed only by authorised persons and in accordance with

the manufacturer’s installation instructions, local gas tting regulations, municipal

building codes, electrical wiring regulations, AS/NZS 5601 - Gas Installations and

any other statutory regulations.

Warning: the appliance is not suitable for connection with a exible hose

assembly.

There are two ways to carry out the connection to the main gas line:

A. The cooker can be connected with rigid pipe as specied in AS/NZS 5601.

B. The cooker can be connected with an Australian approved Limited Flexibility

Connector which complies with AS 4631. The Limited Flexibility Connector

used must be long enough to allow the appliance to be pulled forward when

service is required. Ensure the connector is not subjected to abrasion, crushing

or kinking during installation and that it is clear of the oor when the cooker

is in the installed position. A restraint device (typically chain) must be tted

by the installer. The device must restrict the appliance movement to no more

than 80% of the Limited Flexibility Connector length to prevent strain on the gas

connections when the cooker is pulled forward.

The cooker is factory tted with two chains at the rear of the appliance (one on the

left side and one on the right side) to prevent the appliance from tilting forward.

The installer must connect the chains to the wall, directly behind the chains as low

as possible using a method that suits the wall material and restrains the weight of

the cooker.If the appliance is installed between two cupboards,the installer should

drill a hole on each side of the cupboards, pass the chains through the holes and

anchor the chains within each cupboard.

Important: After xing the chains ensure they are taut and test that the cooker

does not tilt forward or sideways.

Check all connections for gas leaks with soap and water. DO NOT use a naked

ame for detecting leaks. Ignite all burners both individually and concurrently

to ensure correct operation of gas valves, burners and ignition. Turn gas taps to

low ame position and observe stability of the ame for each burner individually

and concurrently. When satised with the hotplate, please instruct the user on the

correct method of operation. In case the appliance fails to operate correctly after

all checks have been carried out, refer to the authorised service provider in your

area.

The ovens are supplied to function as indicated on the plate. Should a change be

necessary you should proceed with the adaptation to another gas as described in

the paragraph “Burner regulation”.

The Data Label is located in the appliance door recess.This appliance is suitable

for Natural Gas and Universal LPG; ensure that the available gas supply matches

the Data Label.

Any adjustment, maintenance, etc. must be performed by an authorized

technician after disconnecting the unit from the mains and from the gas supply.

INSTRUCTIONS

FOR INSTALLATION

Gas connection

Anti-tip device

Before leaving

Adapting for other gas

types

Data label

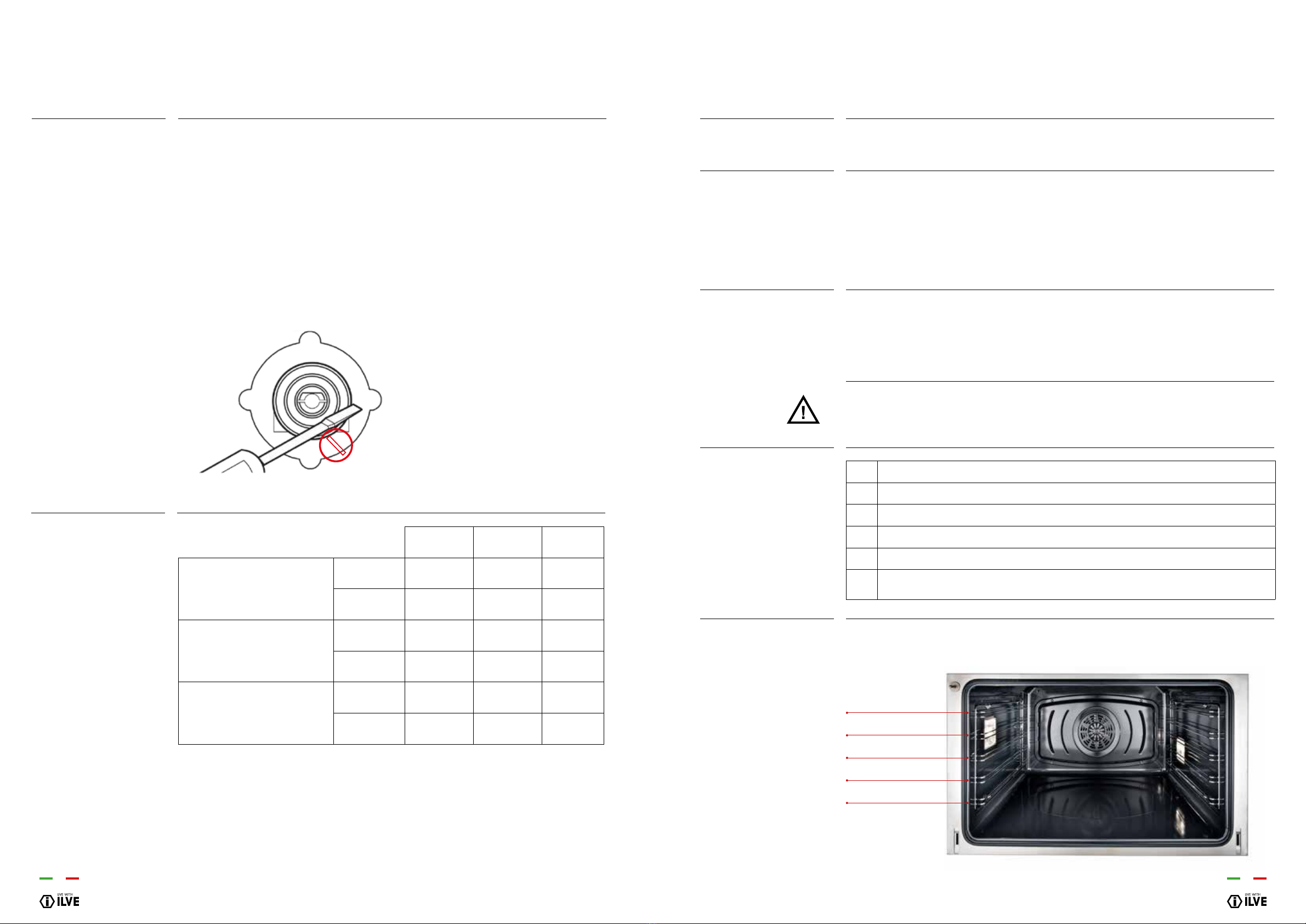

Replacing the injectors and air adjustment

IMPORTANT: Before carrying out these operations you must disconnect appliance

of electric power supply. After adjustments, the seals must be replaced by the

technician.The air adjustment our burners is not necessary.

The burners can be adapted to different types of gas by mounting injectors suited

to the user’s gas (see nozzle adjustment table).To do this you need:

1. Extract the pan stands, remove the head an cover of burners

2. With a 7 mm socket spanner unscrew and remove the nozzles from burners

(see g. below)

3. Replace the burner injectors according to the gas to be used (see nozzle

adjustment table)

4. Place the burners in the correct position

ADJUSTMENTS

Adapting for different

types of gas