INSTALLATION

IMPORTANT INSTALLATION

INSTRUCTIONS

The installer should note that the appliance that

side walls should be no higher than the hot plate

itself. Furthermore, the rear wall, the surfaces

surrounding and adjacent to the appliance must

be able to withstand an overtemperature of 75K.

The adhesive used to stick the plastic laminate

to the cabinet must be able to withstand a

temperature of not less than 150° C otherwise

the laminate could come unstuck. The appliance

must be installed in compliance with BS 6172

1990, BS 5440 part. 2 1989 and BS 6891 1988.

This appliance is not connected to a device able

to dispose of the combustion fumes. It must

therefore be connected in compliance with the

above mentioned installation standards.

Particular care should be paid to the following

provisions governing ventilation and aeration.

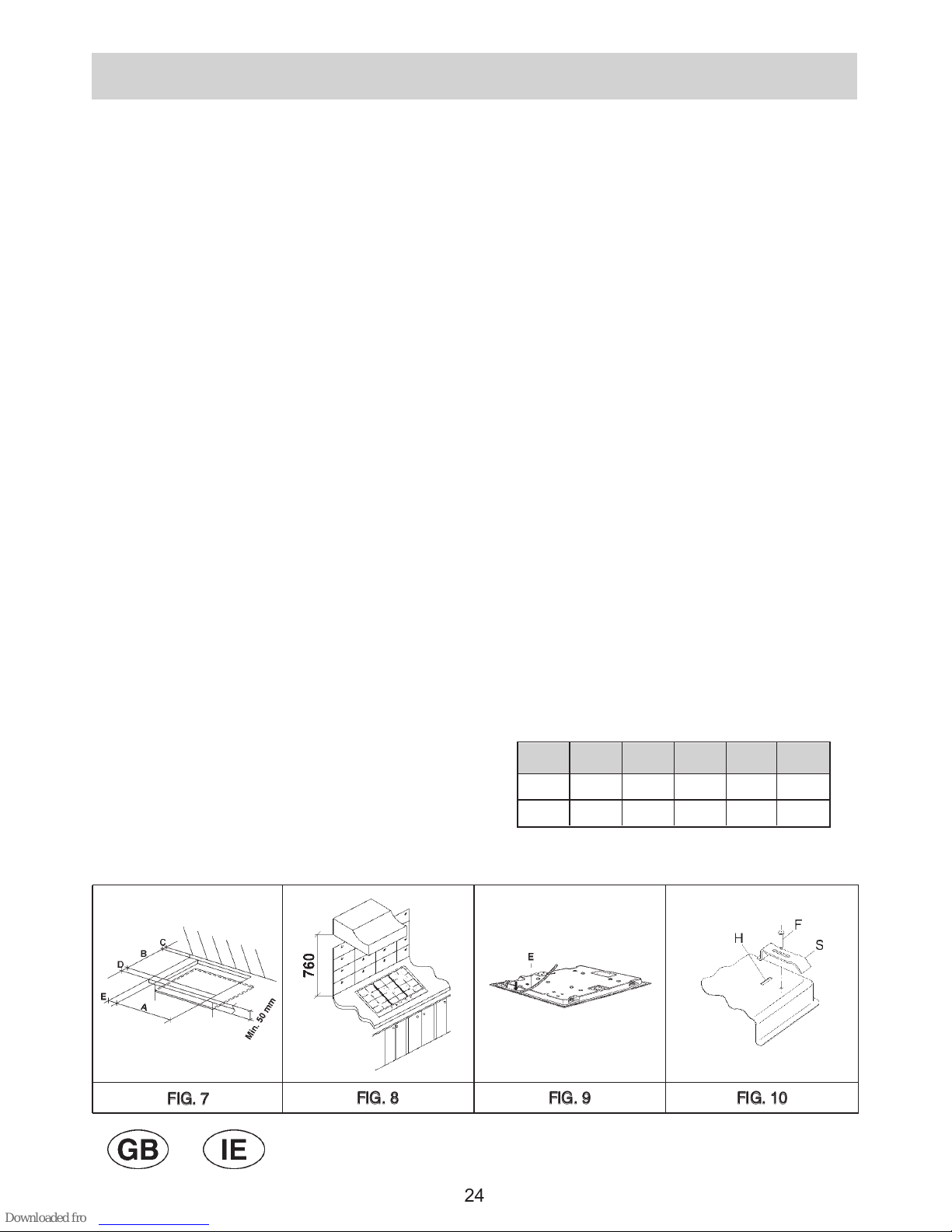

5) ROO VENTILATION

To ensure correct operation of the appliance, it is

important to ensure that the room where the hot

plate is installed has sufficient ventilation, as set out

in BS 5440 part 2. 1989. See table below.

Natural air flow must enter directly through

permanent openings in the walls of the room in

question. These must open towards the outside and

possess a minimum section of 100 cm2see fig. 3). t

must be impossible to obstruct these openings.

ndirect ventilation with air drawn from adjacent

rooms is permitted in strict compliance with the

provisions in force.

6) LOCATION AND AERATION

Gas cooking appliances must always dispose of

their combustion fumes through hoods. These must

be connected to flues, chimneys or straight outside

(see fig. 4). f it is not possible to install a hood, an

electric fan can be installed on a window or on a wall

facing outside (see fig. 5). This must be activated at

the same time as the appliance, so long as the

specifications in the provisions in force are strictly

complied with.

7) GAS CONNECTION

Before connecting the appliance, check that the

values on the data label affixed to the underside

of the hot plate correspond to those of the gas

mains in the home.

A label on the appliance indicates the regulating

conditions: type of gas and working pressure.

WARNIN :

a gas hot plate can only be connected by a CORG

Registered engineer.

nstallations should be carried out in accordance with

BS 6891 1988 and must comply with the Gas Safety

Regulations.

All hot plate installations must include an isolation

tap.

AS PRESSURE TEST

Some hot plates models have a test point fitted

under the control panel, to conduct a gas pressure

test proceed as follows:

- turn off the gas supply.

- Remove screw in the pressure test point, place

test gauge connecting tube on test point.

- Fit a burner ring and cap onto burner assembly,

replace control knob onto corresponding control

tap for the burner.

- Turn on gas and ascertain working pressure.

After test, turn off control tap, turn off gas supply,

disconnect test gauge connecting tube. Replace the

test point screw, turn gas back on and test for

soundness. Reassemble the hotplate.

IMPORTANT:

the appliance complies with the provisions of

the following EEC Directives:

- 90/396 + 93/68 regarding gas safety.

25