ILMEG X-125 User manual

Warning

If the air coming out of the suction fan contains dust. Stop immediately the X-125 and check for

leakages. Never operate with dust coming out of the suction fan since the suction fan will be worn out.

This can cause severe damages.

Warning

Always turn the X-125 off while moving the equipment. Quick movements of the X-125 can cause

excessive forces on the suction fan. This can cause severe damages

Warning

The X-125 contains rotating and moving parts. When servicing the X-125 make sure the hydraulic

power is switched off, the pneumatic pressure is evacuated and the electric circuit is switched off.

Caution

Components are heavy. Please use lifting devises where necessary to avoid accidents and damages.

Further safety instructions

The X-125 can only be used for what it is intended for

Only qualified and trained personnel may operate the machine

Practice how to turn off the machine in case of emergency

The maximal air pressure cannot be exceeded

Always inspect the equipment before use

Never use the equipment if you suspect it is damaged

Always use good practice and sound judgment

Be alert on what you are doing

Never use the equipment when you are tired or under the influence of drugs, alcohol or

anything else that can affect you vision, your reactions or your judgment

Participate in safety training and other trainings applicable

Never hit the equipment and never misuse it

Store the equipment in a safe place and without reach of children

Make sure that all equipment is maintained in the right way

Make sure that warning signs and decals is readable and maintained.

Make sure that unauthorized personnel never comes within the working area of the equipment

Keep the workspace free from foreign objects

Never point compressed air against yourself or anybody else. To avoid damages, never use

compressed air to clean your clothes form dust and other dirt.

Safety regulations

These instructions contain important sections dealing with safety.

Special attention must be paid to all framed safety text that begins with a warning symbol (triangle)

followed by a signal word, as shown below.

Warning denotes a hazard or hazardous procedure which CAN lead to serious or life

threatening injuries if the warning is not observed.

Caution denotes a risk or risky procedure which CAN lead to personal injury or damage

to equipment if the warning is not observed.

Also observe the following general safety rules:

Before starting the machine, read through these instructions carefully.

Also read through the safety instructions before putting the machine to use.

For reasons of product safety, the machine must not be modified.

Use approved personal protective equipment.

Use ILMEG Genuine Parts only.

Always replace worn or damaged signs.

Specification X-125 Dust Collector System

Specification:

Max hole size: 127 mm (5”)

Filter area: 8 m²

Number of filters: 2

Oil flow requirement: 22 l/min

Oil pressure requirement: 200 bar

Width x depth x height: 740 x 957 x 1062

Approx weight: 160 kg

Filter cleansing system: Reversed air through filters in sequences while drilling.

Rec. working pressure: 7 Bar (100PSI)

Installation

Mechanical installation

Make sure the mechanical bracket used for the X-125 is sufficient to carry the full weight of the dust

collector in rock drilling applications. Correct mounting is as close to the feed beam/ rock drill as

possible to reduce the suction hose length. The suction hose should be as straight as possible.

Hydraulic installation

Contact a hydraulic specialist to design the hydraulic circuit for your application.

The hydraulic hoses for the pressure and return line must have the capacity of 22 l/min and

200 Bar pressure without excessive counter pressure. Recommended size is ؽ” or Ø13

mm.

The drain line size is recommended to be Ø ¼” or Ø 6mm and connected directly to tank. No

backpressure is allowed. With too high back pressure in the drain line the hydraulic motor axle

gasket will be damaged and leakage will occur.

Warning

Always use proper quality of hydraulic hoses and fittings to reduce risk of leakage. Hydraulic pressure

can cause severe damages.

Caution

Hydraulic oil leakages have a negative effect on the environment.

Attach the pressure line to the port marked P and the return line to the port marked T.

On top of the motor the drain line should be fitted.

The maximum speed for the fan is 4000 rpm which corresponds to appr 22 l/min hydraulic flow.

Warning

Do not install more hydraulic flow than specified. Over-speed of the fan can cause severe damages.

Cleansing pulse

Suction Capacity

0

10

20

30

40

50

60

70

80

90

100

1 2 3 4 5 6

Drill rod / Depth

Suction Capacity %

i-clean,

Normal

Air pressure installation for the filter cleaning system

Connect air supply for the filter cleansing function of the dust collector. Recommended pressure is 7

BAR or 100 PSI. To safeguard full filter cleansing effect a Ø1” or Ø25 mm hose is recommended.

Warning

Always use proper quality of pneumatic hoses and fittings to reduce risk of leakage. Pneumatic

pressure can cause severe damages.

The X- 100 cleansing system

i-clean a quantum leap when it comes to suction capacity in drilling applications.

The new filter cleansing function, i-clean, ensures

high suction efficiency, even under severe drilling

conditions. The system cleans each filter

independently and continuously during the drilling

sequence. The suction capacity remains

regardless of drill rod length and rock conditions.

The need for a pre-skimmer is reduced.

During the drilling sequence the closing

valves are open, thus letting air through the

filters creating the required suction. With

certain intervals one valve closes and a short

air pulse is introduced in the closed filter

compartment to clean the filter. After the

cleansing sequence both valves are open

again until the next cleansing sequence

comes in action on the next filter.

Electrical installation

The electric control system controls the cleansing sequence and opens and closes the air valves in

the dust collector

Connect the control box to 24 V DC and connect the drilling signal to the system giving 24 V DC as

“drilling signal “ i.e. the dust collector should suction.

See separate drawings for the electrical installation.

The control system is programmable and during operations the cleaning times can be changed.

How to adjust the cleaning pulses and pauses between the pulses in the

control system:

Open the cover of the control system.

The display shows: Press “A” to set

parameters and “ESC” to go back

By pressing multiple on “A“you will toggle

between the menus.

By pressing once on “A” the menue for

setting the parameters / times during

drilling appears.

Paus means the time between the

cleaning pulse during drilling. (see i-clean

above) Factory setting is:

Pause: 1000 x 10ms = 10 seconds

Delay means tie to close one of the air

valves.

Factory setting 20 x 10 ms = 0,2 seconds

ON Means the cleaning pulses length

Factory setting 6 x 10 ms = 0,06 seconds

By pressing “A” once again you enter the

menu defining parameters when not

drilling. C1 = cleaning pulse length for

filter 1 and C2 = cleaning pulse length for

filter 2.

Factory setting for both is 1 x 100 ms =

0,1 second.

C1-C2 = time between cleaning pulses

Factory setting is 5 x 100 ms = 0,5

seconds

By Pressing “A” once again you enter the

menu number of cleaning pulses after

stop. Factory setting is 4 pulses per filter.

To change parameters

Select menu with the “A” button. Toggle up and down on the screen with “+” or “-“ and select

parameter. Press “OK” and increase or decrease parameter with the “+” or “-“ button. Press “OK”

again to confirm the new parameter.

The new parameter is now active and stored in the memory of the X-100 Control system

Suction hose installation:

The suction hose recommended for the X-125 is Ø5“or Ø125 mm. Mount the suction hose on the

machine avoiding bends on the hose to secure the best suction capacity.

LMEG Products AB, Sweden. Phone +46 155 220270 Fax +46 155 220277 mail: in[email protected] web: www.ilmeg.se

We reserve the right to change the specification without prior notice.

Table of contents

Other ILMEG Dust Collector manuals

Popular Dust Collector manuals by other brands

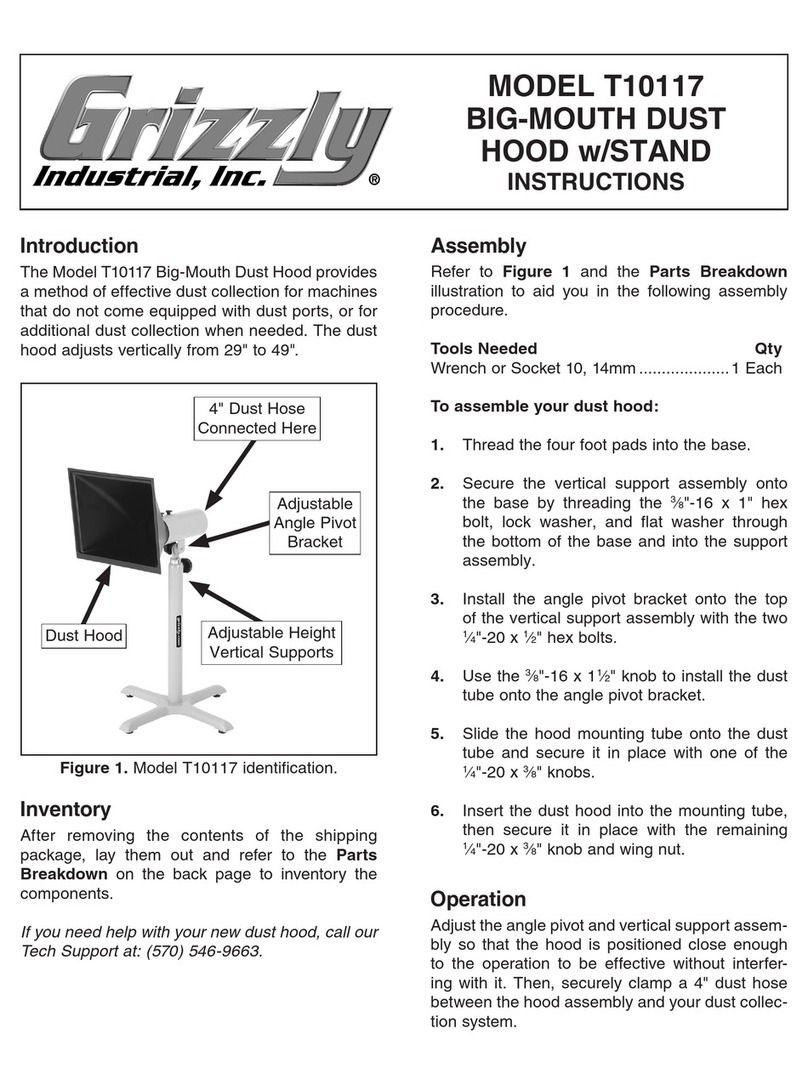

Grizzly

Grizzly G1030 owner's manual

Scheppach

Scheppach 5906301901 Translation of original manual

Nederman

Nederman FlexPAK 800 Installation and service manual

National Flooring Equipment

National Flooring Equipment DL6000P OPERATING & SERVICE MANUAL

Jet

Jet DC-650A Operating instructions and parts manual

CHICO

CHICO CKU-060AT3-ACC instruction manual

Oneida Air Systems

Oneida Air Systems XSK000114 owner's manual

Craftex

Craftex CSX Series user manual

Quatro

Quatro Jet-Stream Operation and maintenance manual

Donaldson Torit

Donaldson Torit Downflo Oval DFO 1-1 Installation and operation manual

Axminster

Axminster T-2000CK user guide

EXAKTOR

EXAKTOR EXOA-2 manual