EXAKTOR EXOA-2 User manual

1/13/2005

EXOA-2

BLADE COVER/DUST COLLECTOR

Thank you for choosing the EXAKTOR®EXOA-2 Blade Cover. It has been designed to function

as a perfect upgrade for most contractor and cabinet-style table saws whose operators want to

eliminate dust thrown in the air by the saw’s revolving saw blade.

The EXAKTOR®EXOA-2 Blade Cover provides you with the following benefits:

xComplete with built-in dust collection capability and a four-inch hose connection.

xThe horizontal Boom is telescopic to suit table saws with up to 70” rip capacity.

xThe Guard Basket, Suspension and Boom have minimized weight for easy removal.

xAll metal parts have a baked-on powder coat paint surface for durability.

xQuick Release Levers for removal and/or attachment of the mast to the saw table.

xCounterbalance is located at the rear of the blade cover, out of your line of sight.

xTwo Rollers position the blade cover at the precise height above the work being processed.

xThe blade cover has shatterproof lens allowing for complete visibility of the saw blade.

Prior to installing the EXAKTOR®Blade Cover/ Dust Collector please take the time to read this

manual and then familiarize yourself with the parts that are used in its assembly. If you have

questions or if you feel there are parts of this manual that need clarification, you are encouraged

to let us know.

You can contact EXAKTOR Tools Ltd

326 Watline Avenue 210 South Eighth Street

Mississauga, Ontario L4Z 1X2 Lewiston, New York 14092

Canada USA

Tel: 905-568-4459 Tel: 800-387-9789

Fax: 905-568-4059 info.exaktortools.com

1

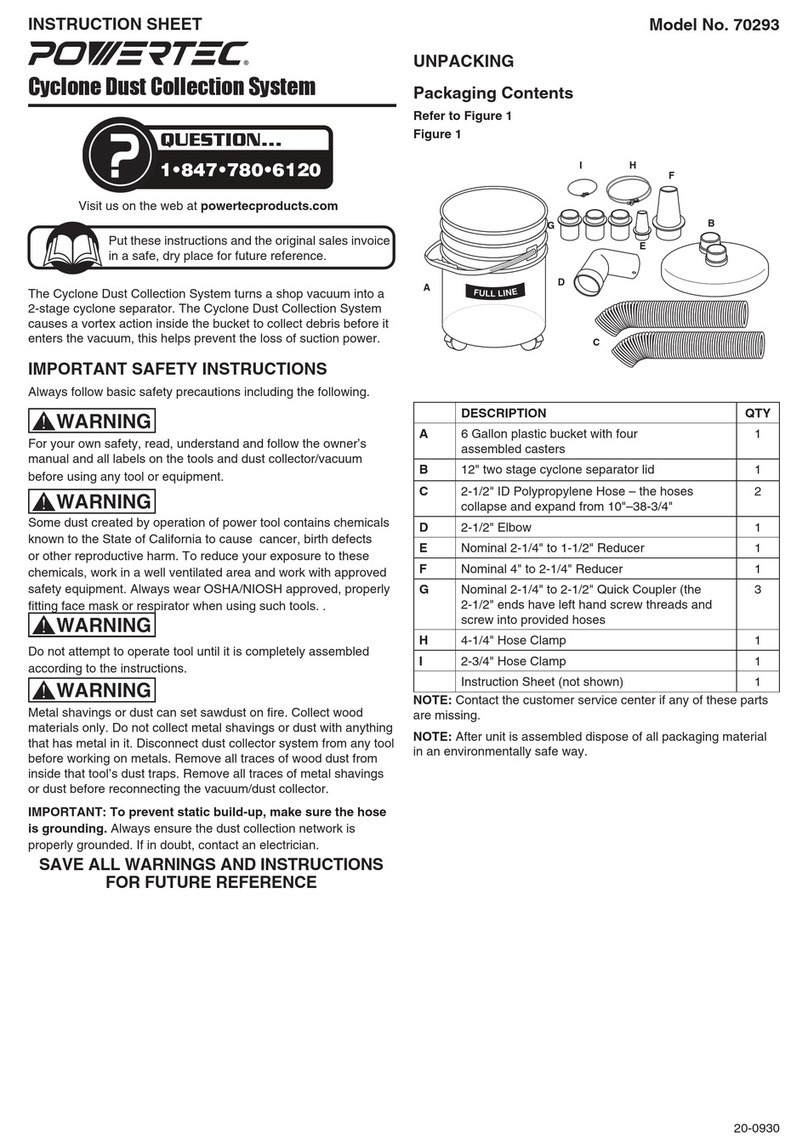

(34100)

RTD10000404AA

1/13/2005

2

EXAKTOR®INDUSTRIAL OVERARM

EXOA-2 BLADE COVER/DUST COLLECTOR

Your EXAKTOR®EXOA OverArm Blade Cover/Dust Collector can be used with most table

saws. Coupled to an appropriate dust collection system, the OverArm Blade Cover/Dust Collector

helps control airborne dust thrown up by the revolving saw blade.

The EXOA-2 features a counter-balanced Guard Basket that accommodates saw blades up to 16”

in diameter, raised up to 4” above the table and tilted for cuts to 45 degrees. You can be quickly

position the Guard Basket to suit the saw blade and the material being cut, and it is equipped to

accommodate the splitter and anti-kick-back pawls that are installed on your table saw. When you

are changing blades the telescopic Boom and Guard Basket will swing easily out of the way.

The top surface and sides of the steel framed Guard Basket have shatterproof Lexan¥lenses,

which give you a clear view of the saw blade at all times. The ‘baffling’ effect of the Guard

Basket and the flexible hose connecting the Guard Basket to the telescopic Boom makes dust

extraction very efficient.

Installation is exceptionally easy. The vertical mast stands on the floor and is adjustable to the

height of the saw table.

The mast is fastened to the side of the saw table or table extension with two quick release levers.

For quick removal, these levers release the upper part of the mast. The mast supports a telescopic

four-inch diameter boom equipped for coupling to a 4” vacuum hose. The boom length is

adjustable to allow the saw fence to be positioned up to 70” from the saw blade.

The EXAKTOR®EXOA-2 Blade Cover/Dust Collector has been carefully designed to fit and

work with your table saw. It will add an element of safety and its built-in dust collecting

capability will provide you with cleaner air to breathe.

Designed for Dust

Collection Only

The EXAKTOR®EXOA-2 OverArm Blade Cover/Dust Collector is sold for dust collection only.

It must be used with, and does not eliminate the need for, anti-kick-back and splitter devices.

These devices are not supplied with the EXOA-2 OverArm Blade Cover/Dust Collector. The

provision of a splitter and anti-kick-back device is the responsibility of the saw owner and/or

user.

1/13/2005

3

TABLE SAW SAFETY

1. To prevent accidents keep safety in mind while you work.

2. Use the safety guards installed on powered equipment. They are for

your protection.

3. When working on powered equipment keep fingers away from saw

blades and cutters.

4. Wear safety goggles to prevent injuries from flying wood chips and

saw dust.

5. Wear headphones to protect your hearing.

6. Consider installing a dust vacuum to reduce the amount of airborne

dust in your workshop.

7. Don’t wear loose clothing, such as neckties or shirts with loose

sleeves, or jewelry, such as rings, necklaces or bracelets when

working on power equipment.

8. Tie back long hair to prevent it from getting caught in powered

equipment.

9. Keep work areas clean. Cluttered areas invite accidents.

10. Do not force work though the machine. Tools work better and are

safer when they work at their own speed.

11. Do not overreach. Keep proper footing and balance at all times.

12. Do not reach behind the machine to grab a cutoff piece. If the wood

binds behind and against the blade or cutter it will kick back faster

than you can let go.

13. Disconnect the machine from electrical power before servicing and

changing accessories, such as blades and cutters.

14. Never leave the machine running unattended – turn the power off.

15. Do not leave the machine until it comes to a complete stop.

16. Do not operate the machine if you are mentally or physically

fatigued.

17. If there is something that you do not understand, do not operate the

machine! Ask for help first.

These safety rules do not cover every situation in a workshop.

Consider your conditions when using your EXAKTOR®Blade Cover.

WARNING: NO PART OF THIS MANUAL MAY BE REPRODUCED IN ANY

FORM WITHOUT THE WRITTEN APPROVAL OF EXAKTOR®TOOLS LTD.

¤EXAKTOR®Tools Ltd, 2004

1/13/2005

4

Specifications:

Height of boom above the floor………………………56”

Height of boom above the saw table …………………20”

Length of telescopic aluminum boom .….……………min 49” to max 80”

Diameter of main boom tube …..……………………..4”

Diameter of inner boom tube ……………..…………..3½”

Guard Basket dimensions ..……………………………18½” x 4” x 4½” high

Clearance between guard basket and saw table………..7” max

Distance between the saw blade and vertical mast… …min 39” to max 70”

Weight …………………………………………………47 lb.

1/13/2005

5

EXOA-2

VIEW OVERALL

1/13/2005

6

EXAKTOR®EXOA-2 BLADE COVER

DUST COLLECTOR

Installation

The EXAKTOR®BladeCover/Dust Collector has been designed to fit most table saws with its vertical Mast installed at

either the right or left hand side of the machine. In most cases the vertical mast will be installed at the right hand end of the

saw’s table or table extension, close to the rear edge of the table.

Mast Assembly

1. With the Lower Mast (#1) resting on the floor, insert it into the bottom end of the Upper Mast (#2).

Adjust the overall length of the Lower and Upper Masts to where the top edge of the slotted Mounting Bracket,

that is welded on the side of the Upper Mast, will be just below the top surface of the saw’s table or table

extension. Lock the two Masts together with a Locking Knob (#3).

2. Carefully place the slotted mounting bracket against the edge of the saw table, or table’s extension, close to

the rear

edge of the table. Make sure there is clearance behind the edge of the table to accommodate the Backing Plate

(#15). Its two threaded holes must line-up with the slot in the mounting bracket.

3. Using the slots in the Mounting Bracket as a

template, drill a 1/4” hole at the top of each slot,

through the edge of the table. Using two Locking

Levers (#4) and the Backing Plate (#15), fasten

the Mounting Bracket to the edge of the table.

4. The diagonal brace is used to hold the

vertical mast in position. Use a ¼-20 x 1¼” Hex

Head Bolt (#6), Washer (#7) and ¼-20 Nut (#8)

to attach one end of the Mast Brace (#5) to the

bracket at the bottom end of the Lower Mast

(#1).

5. Position the assembled Lower and Upper

Mast so

that it is vertical to the floor and square to the

surface of the saw table. Determine where to

place the

unfastened end of the Mast Brace up under the

rear edge of the saw’s table, or table extension so

that when the brace is fixed in place, and the

turnbuckle is tightened, the assembled Mast will

be held vertical and square to the table surface

and will not shift from that position. Drill an

appropriate hole in the rear edge of the saw table

or table extension and attach the upper end of the

Mast Brace to the edge of the underside of the table.

Use Hex Head Bolt (#6), Washer (#7) and Nut (#8).

1/13/2005

7

Boom Assembly

Note: Thermoplastic and UHMW spacers are

used in the telescopic boom assembly. Their

purpose is to provide a smooth bearing surface

and to take up the play between the tubular

sections of the Boom. Pay close attention to how

the Small Boom Tube is inserted into the Large

Boom Tube, i.e. the Small Boom Tube can only

be inserted and extended one way.

6. The telescopic Boom is shipped with the

Small Boom Tube (#13) inserted into the Large

Boom Tube (#12). A ¼-20 x Ǫ” Button Head

Bolt (#21) and Nut (#22) are installed on the

underside the outboard end of the Small Boom

Tube.

7. There are two Ǫ” holes 6” apart, in the Large

Boom Tube for attaching the Boom Saddle (#9).

Push the Small Boom Tube out through the Large

Boom Tube to gain access to these two Ǫ” bolt

holes from inside the Large Boom Tube

8. With the threaded hole in the tubular section

of the Boom Saddle (#9) facing in the direction

of the Small Boom Tube, use two ¼-20 x Ǫ”

Button Head Bolts (#21) and ¼-20 Lock-nuts

(#22), to firmly attach the Boom Saddle to the

Large Boom Tube.

9. Place the tubular section of the Boom Saddle

(#9), over the top end of the Mast assembly.

10. Use a Locking Knob (#3) to secure the Boom

Saddle to the Mast.

11. N/A

1/13/2005

8

Guard Basket Assembly

12. Position the large Roller Wheel (#41) at the front end of the Guard Basket and attach it with a ¼-20 x1-1/4”

Shoulder Bolt (#6) and 10-24 Ny-Lock Nut (#44) with a 6mm washer (#19) placed under the head of the Bolt

and under the Ny-Lock Nut.

13. Position the small Roller Wheel (#45) at the back end of the Guard Basket and attach with a ¼-20 x 1¼”

Shoulder Bolt (#6) and 10-24 Ny-Lock Nut (#44) with a 1/4” washer (#19) placed under the head of the Bolt

and under the Ny-Lock Nut.

14. Use 20 Button ¼-20x Ǫ”Head Bolts (#21) and ¼-20 Nuts (#22) to assemble the Guard Basket Frame (#16)

with the Top Lens (#20) and the two Side Lenses (#19).

1/13/2005

9

Suspension Assembly

15. Use Ǫ-18 x 1¼” Shoulder Bolts (#31) and

5/16-18 Ny-Lock Nuts (#40) to secure the rear end

of the Long Arm (#25) and the Short Arm (#26)

to the Boom Clamp (#29).

16. With a Star Washer (#33) under the head of a

Shoulder Bolt (#31), secure the forward end of

the Long Arm (#25) to the top of the Vertical

Arm (#27) using 5/16-18 TPI T-Knob (#28).

17. Secure the forward end of the Short Arm

(#26) to the middle of the Vertical Arm (#27)

with a Ǫ-18 x 1¼”Shoulder Bolt (#31) and 5/16-

18 TPI Ny-Lock Nut (#40).

18. Insert the plastic End Caps (#34) into the

forward end of the Long and Short Arms. If the

Caps tend to be a loose fit, you can use a rubber

band stretched around the ribs of the cap to

eliminate any play.

1/13/2005

19. Use a Hose Clamp (#24) to secure one end of the

Flexible Hose (#23) to the top of the Guard Basket

Frame.

20. Use a Locking Lever (#35) and the Slide Bar (#18)

to attach the Vertical Arm to the channel located

on the top surface of the Guard Basket Frame.

21. With the bottom edge of the Guard Basket seated

squarely on the saw table, position the Boom Clamp

(#29) approximately 2” in on the open end of the

Small Boom Tube (#13). Secure by using a T-Knob

(#30) with ¼-20x3½” Carriage Bolt (#39).

22. Use a Hose Clamp (#24) to secure the open end of

the Flexible Hose (#23) to the open end of the Small

Boom Tube (#13).

23. Insert the Counter Weight (#32) into the tail end of

the Long Arm (#25) and secure with the counter

weight Locking Knob (#3).

Adjusting and using the EXOA-2

Blade Cover

24. Adjust the length of the Boom Tubes to position

the Guard Basket over the saw blade. Lock the Tubes

in position with Knob (#3). Adjust the ¼-20xǪ”

Button Head Bolt (#21) installed on the underside the

outboard end of the Small Boom Tube to take-up any

play between the Small and Large Boom Tubes and

secure with the ¼-20 Jam Nut (#22).

25. N/A.

26. Position the Guard Basket forward or backward,

over the saw blade, so that the opening to the Flexible

Hose is centered above the saw blade. Secure the

Guard Basket using the blade cover Lever (#35).

27. The rear of the Guard Basket has two vertical slots

to allow the basket to come down over a splitter

located behind the saw blade. Use the four 6-32x½”

Pan Head Screws (#46) to attach a Cover Plate (#36 or

#37) to cover one or both slots as desired.

28. Position the Counter Balance so that the weight of

the Guard Basket is easily raised when material can be

passed under the front Roller Wheel. For thicker

material raise the Guard Basket and place it on top of

the material. The roller wheels should just touch and

roll on the top surface of the material being cut.

29. If cutting work taller than the Guard Basket when

it’s raised to its highest position above the saw table,

the Guard Basket and Boom can be swung out of the

way by loosening the Locking Knob (#4) in the Boom

Saddle.

30. If the Mast is in the way when crosscutting longer

material, the Upper Mast and Boom assembly can be

easily removed by loosening the two Locking Levers

(#4) and the Locking Knob (#3) in the lower end of the

upper mast.

Optional Casters

An optional pair of casters is available for those who

want to have the ability to move the location of the

their table saw with the EXOA-2 Blade Cover

remaining attached to the saw. The plate at the bottom

of the mast has two holes in which the casters (#50)

can be easily installed.

10

1/13/2005

Parts for EXOA-2

Mast & Boom Assembly

Part# Description Qty.

OA01 Lower Mast 1

OA02 Upper Mast 1

OA03 T-Knob 4

¼ -20 x ǫ”

OA04 Locking Lever 2

¼-20 x1ǩ”

OA05 Mast Brace 1

OA06 Hex Head Bolt 2

¼-20x1¼”

OA07 Washer ¼”2

OA08 Hex Nut 2

¼-20 TPI

BC09 Boom Saddle 1

BC12 Large Boom Tube 1

BC13 Small Boom Tube 1

BC14 Rubber Seal 1

OA15 Backing Plate 1

OA21 Button Head Bolt 3

¼-20 x ½”

OA22 Lock Nut 3

¼-20 TPI

OA38 EXAKTOR® Logo 1

BC50 Casters (optional) 2

Suspension Assembly

Part# Description Qty

OA25 Long Arm 1

OA26 Short Arm 1

OA27 Vertical Arm 1

OA28 T-Knob 1

5/16-18 TPI

BC29 Boom Clamp 1

OA30 T-Knob 1

¼-20 TPI

Part# Description Qty

OA32 Counter Weight 1

OA33 Star Washer Ǫ” 1

OA34 End Caps 2

OA35 Locking Lever 1

¼-20 x ǫ”

OA39 Carriage Bolt 1

¼-20 x 3½”

OA40 Ny-Lock Nut 3

5/16-18 TPI

Guard Basket Assembly

Part# Description Qty.

BC06 Shoulder Bolt 2

¼” x 1¼”

10-24 TPI

ST19 Washer 6mm 4

BC16 Guard Basket Frame 1

BC18 Slide Bar 1

BC19 Side Lens 2

BC20 Top Lens 1

OA21 Button Head Bolt 18

¼-20 x ǫ”

OA22 Lock Nut 18

¼-20 TPI

BC23 Flexible Hose 1

3½” Dia.

BC24 Hose Clamp 2

BC36 Full Cover Plate 1

BC37 Half Cover Plate 1

BC41 2½” Large Wheel 1

BC44 Ny-Lock Nut 2

10-24 TPI

BC45 1Ǭ” Small Wheel 1

BC46 Pan Head Screw 4

6-32 x ½”

OA31 Shoulder Bolt 4

Ǫ-18 x 1¼”

11

1/13/2005

12

If You Need to Call Customer Service

Please complete the following information for future reference:

Model Number: EX26, EX26X, EX26S, EX26SX, EX40, EX60, EXOA-2,

E100 (Circle your model number)

Invoice Number: ……………………………………………………

Date of Purchase: ………………………………………………….

Place of Purchase: …………………………………………………

Retain this Owner’s Manual with your sales receipt as a permanent record

of your purchase, in the event of theft, fire or warranty service.

EXAKTOR®Numbers

The Exaktor Solutions Center is our one-stop resource for all of your Exaktor tool

needs. You can download the latest Assembly Manuals, read FAQ’s and trouble-

shooting tips. Visit us at:

http://solutions.exaktortools.com

For Customer Service

1-800-597-1343 (Voice – North America)

1-905-568-4459 (Voice – Outside North America)

1-905-568-4059 (Fax)

Authorized Dealers

For the name of an Exaktor authorized dealer, call 1-905-568-4459

Important:

We recommend that you keep all original packing materials, in the event

that you ship this product.

1/13/2005

13

EXAKTOR®ULTIMATE WARRANTY and EXCHANGE SERVICE

Following your thirty (30) day-trial period, this warranty gives you certain rights in addition to other rights

you may have that may vary from jurisdiction to jurisdiction. This warranty is given only to the first end use

purchaser of the accompanying product (referred to in this warranty as “this product”).

What is covered: EXAKTOR®Tools Ltd, (“Exaktor”) warrants to you for the Warranty Period, that there are no defects in the

materials or workmanship of this Product. The “Warranty Period” begins on the date you purchased this product and lasts as

long as you are the original end use purchaser.

What is not covered: Warranty WILL BE VOID by Exaktor for repairs or replacements made necessary due to the following: (1)

the Product was not purchased from an authorized Exaktor reseller, (2) the Product has been modified by anyone other than an

Authorized Service Representative of Exaktor, (3) any damage caused by accident, neglect, abuse or misuse of the Product, (4)

Damages caused as a result of modification or alteration of the Product, (5) NOT COVERED UNDER WARRANTY ARE

reasonable wear and tear where no defects in material and workmanship are found in the Product.

What to do if you think your Product is defective: Call our Customer service Hotline at 1-800-597-1343. During the Warranty

Period, supply Exaktor’s representative with information from your dated bill of sale showing that this product was purchased

from an Authorized Exaktor Reseller. After contacting the authorized service center, you may be required to deliver or send the

Product properly packaged, freight prepaid, to Exaktor’s Service Center together with a photocopy of your bill of sale.

What Exaktor will do: Exaktor will evaluate your report of a possible defect to determine whether a defect exists, and if it does

exist, Exaktor will repair or (at Exaktor’s option) replace the Product with a product that performs the same functions and

performs as well as the original Product. Exaktor reserves the right to supply refurbished or remanufactured replacement parts

provided that the replacement parts conform to the manufacturer’s specifications for new products. The repaired or replacement

product will be returned to you at no cost.

Exchange Service: When an exchange is authorized, Exaktor will exchange your non-working product with a refurbished or

remanufactured product that conforms to the manufacturer’s specifications for new products. The refurbished or remanufactured

Product you receive will be covered by the balance of the warranty period remaining on the original Product.

You will keep the replacement Product that is sent to you and you must return (or be billed up to the cost of the new product)

your original non-working product, which shall become the property of Exaktor. You must call Exaktor Customer Service and if

the representative cannot correct the product’s malfunction over the telephone and you elect the exchange service, you must

provide information pertaining to this Product and must also provide a valid credit card (Visa, MasterCard or AMEX) number.

Your credit card will be charged up to the cost of a new Product if: (1) you do not return your original Product within ten (10)

business days; (2) the malfunctions of your original Product are not covered by the warranty; (3) the Product was not properly

packaged and has caused damage to the Product; (4) the original Product has not been sufficiently validated with a copy of the

proof of purchase (bill of sale). The Exaktor Customer Service Representative will ship the exchange Product the next business

day, with return instructions. You must return the original Product, Freight Prepaid, in the same shipping carton in which the

exchanged Product was received and include a copy of proof of purchase (bill of sale). Retain your original accessory items and

a copy of the courier’s bill, signed by the courier.

Limitations : Repair or replacement as described above is your sole and exclusive (that is your only) remedy if this Product is

defective. Exaktor shall not be liable for any direct, indirect, incidental or consequential damages or specific relief. Because

some jurisdictions do not allow the exclusion or limitation of consequential or incidental damages, the above limitation may not

apply to you.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES, WRITTEN OR ORAL, WHETHER EXPRESSED BY

AFFIRMATION, PROMISE, DESCRIPTION, DRAWING, MODEL OR SAMPLE, AND ANY AND ALL WARRANTIES OTHER

THAN THIS ONE, WHETHER EXPRESSED OR IMPLIED, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED.

This Warranty is the only warranty that Exaktor is giving for this Product. It is the final expression and the exclusive and only

statement of Exaktor’s obligations to you. It replaces all other agreements and understandings that you may have with Exaktor

or its representatives.

This warranty (and Exaktor’s obligations to you) may not be changed in any way unless you and Exaktor sign the same piece of

paper in which we (1) refer to this product and your bill of sale date, (2) describe the change to this warranty and (3) agree to

make that change.

This manual suits for next models

1

Table of contents

Popular Dust Collector manuals by other brands

CHIKO AIRTEC

CHIKO AIRTEC CHV-030AD-HC-V1 instruction manual

Grizzly

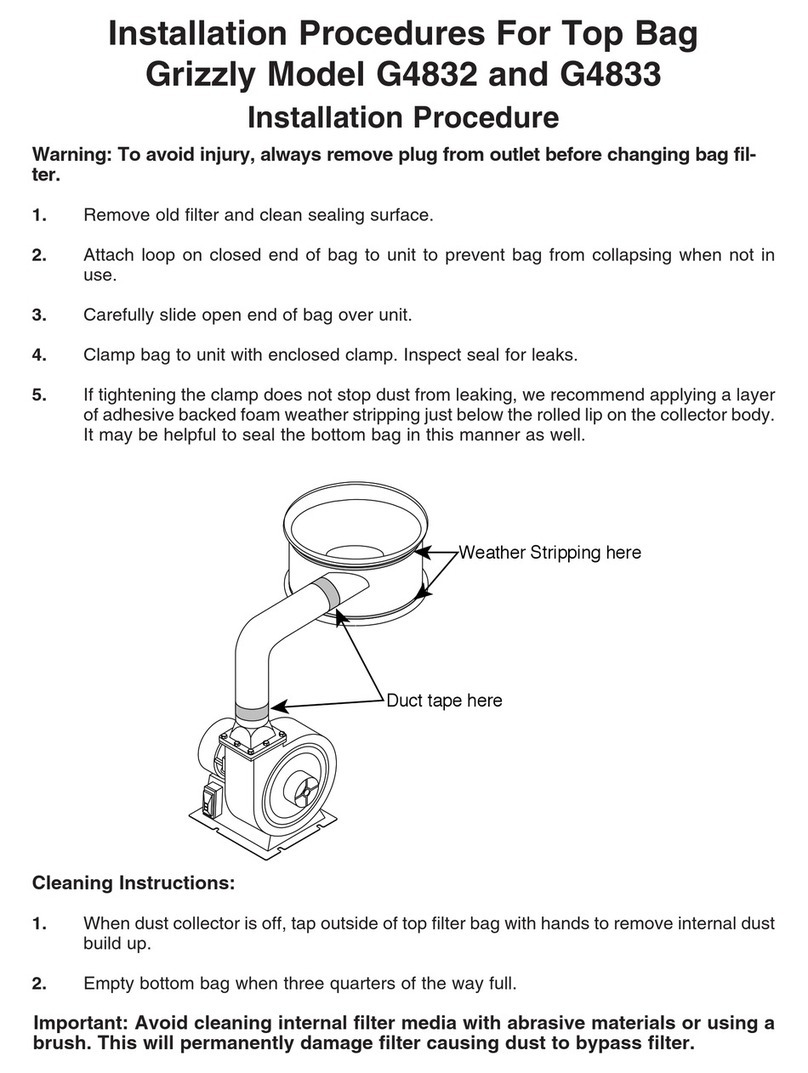

Grizzly G4832 Installation procedures

Jet

Jet JCDC-1.5 operating instructions

Vaniman

Vaniman V-SIX SE quick start guide

Esta

Esta TK-4 operating instructions

National Flooring Equipment

National Flooring Equipment DL6000P OPERATING & SERVICE MANUAL