Watson McDaniel PMPNT Series Instruction manual

2

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Safety Considerations

Follow installation guidelines to ensure the product functions properly and as intended.

Improper installation and use may result in such hazards as damage to the product or malfunctions that

may lead to injuries or damage. Failure of the product to function may result in problems occurring in

the system, such as equipment flooding with condensate or improper drainage.

See page 9 & 10 for System Troubleshooting.

When disassembling or removing the product, wait until the internal pressure is relieved

and the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under pressure may lead to injuries or damage.

Do not excessively over tighten or torque when connecting piping to the product.

Over-tightening may cause cracks and damage to the product which may lead to fluid discharge, which

may cause injuries.

Each Watson McDaniel Company Product is warranted against defects in material and workmanship for one year from date of shipment. This warranty extends to

the first retail purchaser only. All defective material must be returned to the person from whom you purchased the Product, transportation prepaid, free of any

liens or encumbrances, and if found to be defective will be repaired free of charge or replaced, at the warrantor’s or seller’s option. If the material is replaced, any

replacement will be invoiced in the usual manner and after inspection of alleged defective material an adjustment will be made for depreciation caused by

purchaser’s use. In no event will Watson McDaniel Company be liable to do more than refund the original contract price. Incidental and consequential damages

are excluded, whether under this warranty or otherwise. All implied warranties, including warranties of merchantability and fitness for a particular purpose, are

disclaimed and excluded.

3

Watson McDaniel Company PMPNT Manual 2605100 Rev A

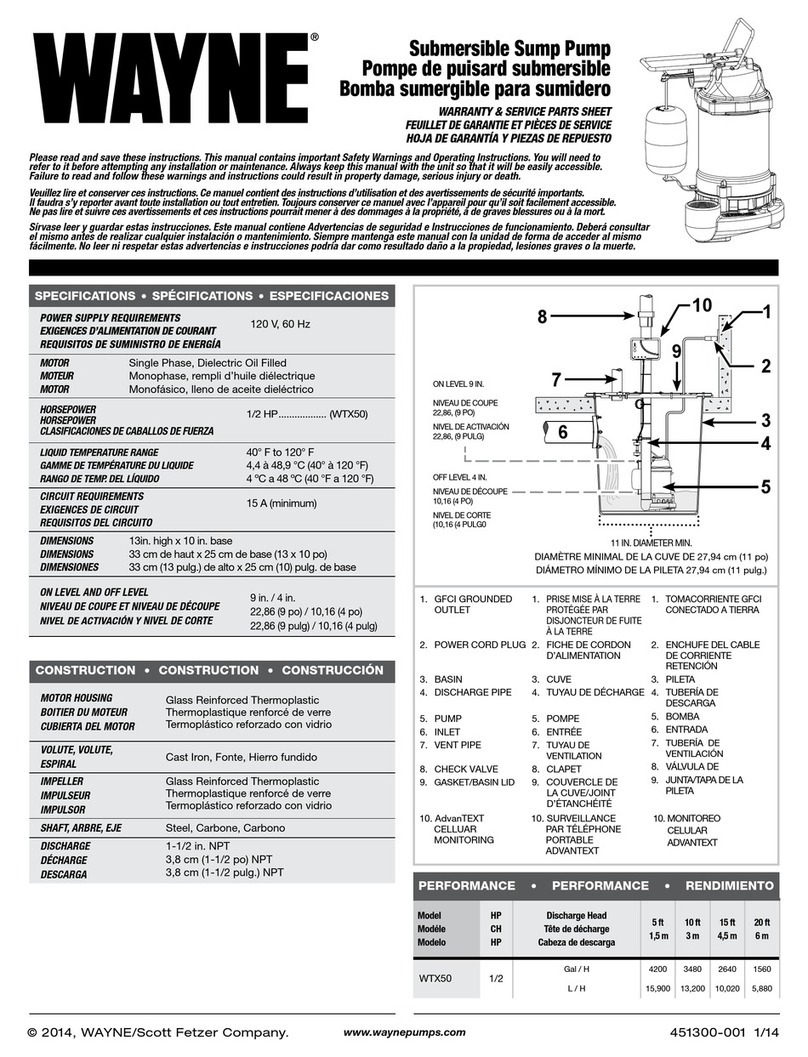

PMPNT Specifications PMPNTS Specifications

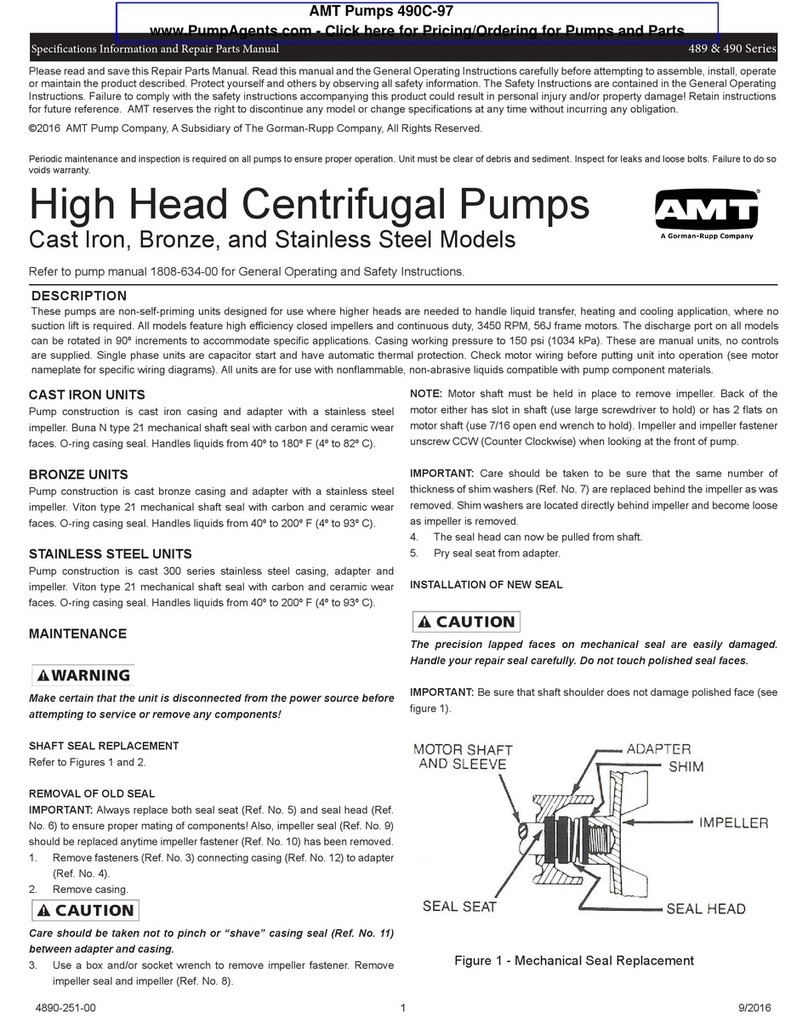

Figure 1: PMPNT Pump Figure 2: PMPNTS Pump

Operating Specifications

Average instantaneous discharge rate

16.1 gpm

Average pump discharge per cycle

1.9 gal

Average steam consumption

3 lbs. per 1000 lbs. liquid pumped

Average Air consumption

100 SCF per 1000 lbs. liquid pumped

PMPNT/S Pressure-Temperature Ratings

PMO Max. Operating Pressure

125 psig

TMO Max Operating Temperature

353°F

PMA Max Allowable Pressure

150 psig

TMA Max Allowable Temperature

450°F

Weight

1"

85 lb

1 ½"

95 lb

1 ½" SS

98 lb

Figure 3: PMPNT Cutaway View

Note: Pump overall length dimensions shown with 1½” check valves.

For 1” check valve overall length, subtract 2.86”.

Pump Serial Number and Date Code

can be located on the tag mounted to

the top of the pump cover.

4

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Principle of Operation

The Pressure Motive Pump allows discharge of

high-temperature condensate for return to the

boiler. They can also be used to discharge water

and other liquids for transfer to other locations.

The PMPNT is for applications requiring compact

design due to spatial constraints and is used when

liquids must be moved to higher elevation, higher

pressure, or extended distances. The PMPNT is

intended to work in an open loop (vented) system.

A Pressure Motive Pump consists of a pump tank,

float with internal operating mechanism, and a set

of inlet and outlet check valves to control direction

of flow. The positions of the vent and motive

valves control the filling and discharge of the

pump. The vent valve must be open during the

filling cycle to allow air or steam in the pump to be

displaced as water enters the pump. Once the

pump becomes filled, pressurized gas enters the

tank through the motive line to push condensate

out of the pump and into the downstream return

line. Since water flows into the pump by gravity,

the pump tank pressure must be neutralized for

the pump tank to fill.

1. When the pump is in the normal start up

position, the float mechanism will be at its

lowest point with the vent valve open and the

motive pressure valve closed.

2. As condensate fills the pump, the float

mechanism begins to rise.

3. The float mechanism will continue to rise until

it reaches the upper trip point. When the spring

loaded mechanism reaches the trip point, it

snaps over the center and the motive pressure

valve opens and the vent valve closes.

4. When the motive valve opens, the pump

becomes pressurized under the motive

pressure, opening the outlet check valves and

discharging condensate out of the tank. A

check valve placed at the condensate inlet will

stop the condensate from being pumped back

into the receiver. As the condensate flows out

of the pump under the motive pressure, the

float begins to drop.

5. When the float reaches the low trip point, the

mechanism snaps over the center and the

motive pressure valve closes and the vent valve

opens. The pressure in the pump is released

and the condensate is able to once again flow

from the receiver down into the pump.

5

Watson McDaniel Company PMPNT Manual 2605100 Rev A

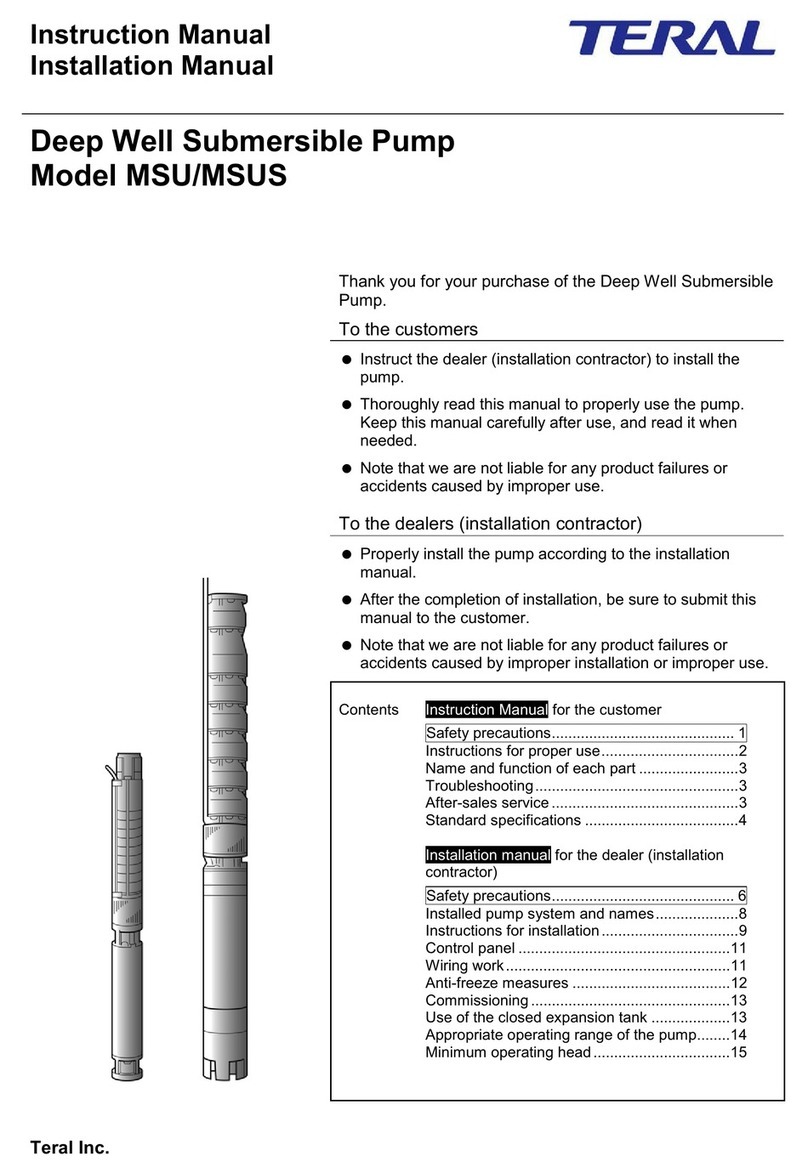

Installation –Open Loop (Vented) System

1. The pump must be installed standing in the

vertical position and located below an

atmospheric (vented) receiver. It is

important that the preferred operating

filling head be established from the top of

the pump body to the underside of the

receiver. A minimum of 6” filling head is

recommended. Note: Less fill head is

possible, but capacity will be reduced from

published values.

2. Vented Receiver: A vented receiver

should be installed before and above the

pressure motive pump. If you will be using

and existing tank or fabricated one, be

sure to verify that the vessel is properly

sized and vented for the application.

Please consult our sizing guide on Page 10

of this instruction.

3. Connect the inlet and outlet check valves

to the pump. Caution: Make sure that the

flow arrows on the check valves are

oriented in the proper direction. For

optimum performance, horizontal pipe runs

immediately before and after the check

valves should be kept as short as possible.

Pipe up the pump inlet check valve to the

receiver and outlet check to the discharge

line. It is recommended that full port

isolation valves be used for the pump,

matching the line size.

4. Connect the operating steam supply

pressure to the motive inlet connection

(1/2" FNPT) at the top of the pump head.

Motive pressure line should always be

equipped with an isolation valve, strainer

and a steam trap. The motive steam drip

trap condensate discharge may be piped to

the top of the receiver or pump

discharging line. A PRV may also be

considered in the motive piping to adjust

the pressure to optimum level.

5. Pump Vent/Exhaust Line: Install a pipe

line from the pump vent connection (1/2"

FNPT) to the top of the receiver. This

piping is extremely important to ensure

proper operation of the pump and system.

Figure 4: Open Loop Pump System

6

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Start up

1. Gradually open steam supply to provide

pressure at the pump motive inlet. Make

sure the motive trap is operational.

2. Completely open the full port isolation valves

in the pump condensate inlet and outlet lines

as well as any isolation valves in the pump

vent/exhaust line.

3. Open the isolation valve(s) ahead of the

pump receiver allowing condensate to enter

the vessel and begin to fill the pump body

below it. Pump will discharge when full.

4. Carefully observe the PMP unit. The pump(s)

should cycle periodically with an audible

sound at the end of each pumping cycle. If

any irregularities are observed, recheck

installation and start-up instructions for proper

procedure, or call the applications engineering

department for assistance.

5. If overflow piping has been provided (see

below), check that a water seal has been

established to prevent any steam from being

vented in normal operation. Prime piping if

necessary.

Figure 5: Open Loop Pump System with Overflow

7

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Maintenance

Close all pump isolation valves. Make certain no

pressure is trapped in the system. Allow unit and

piping to cool to room temperature.

1. Remove the motive pressure and vent piping

connections. Remove bolts from top cover

and lift complete mechanism out of pump

body.

2. Inspect mechanism for wear, dirt, and scale.

Make sure the mechanism moves as intended.

Remove check valves and inspect for any dirt

or debris that could be obstructing the valve.

Clean seating surfaces then reinstall or

replace if necessary.

3. Check the (2) springs and pins. If either is

defective, remove and replace with new

springs and pins. Note: Disassemble and

replace one spring at a time

4. Inspect motive pressure inlet and vent

valves. Clean the valve and seats, and

replace if necessary. If pump is not cycling,

check motive pressure and adjust to 10 psi

min. above the backpressure. If the motive

pressure valve is leaking, the inlet valve may

be obstructed or damaged. With the pump

isolated, remove the cover and inspect.

Replace the inlet valve and seat assembly, if

necessary.

5. Make sure the pump mechanism is in the

proper orientation when reassembling.

Reconnect the motive and vent lines to the

pump, refer to the installation instructions.

After the pump is reinstalled, follow the

start-up procedures to bring the pump into

operation.

8

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Maintenance cont.

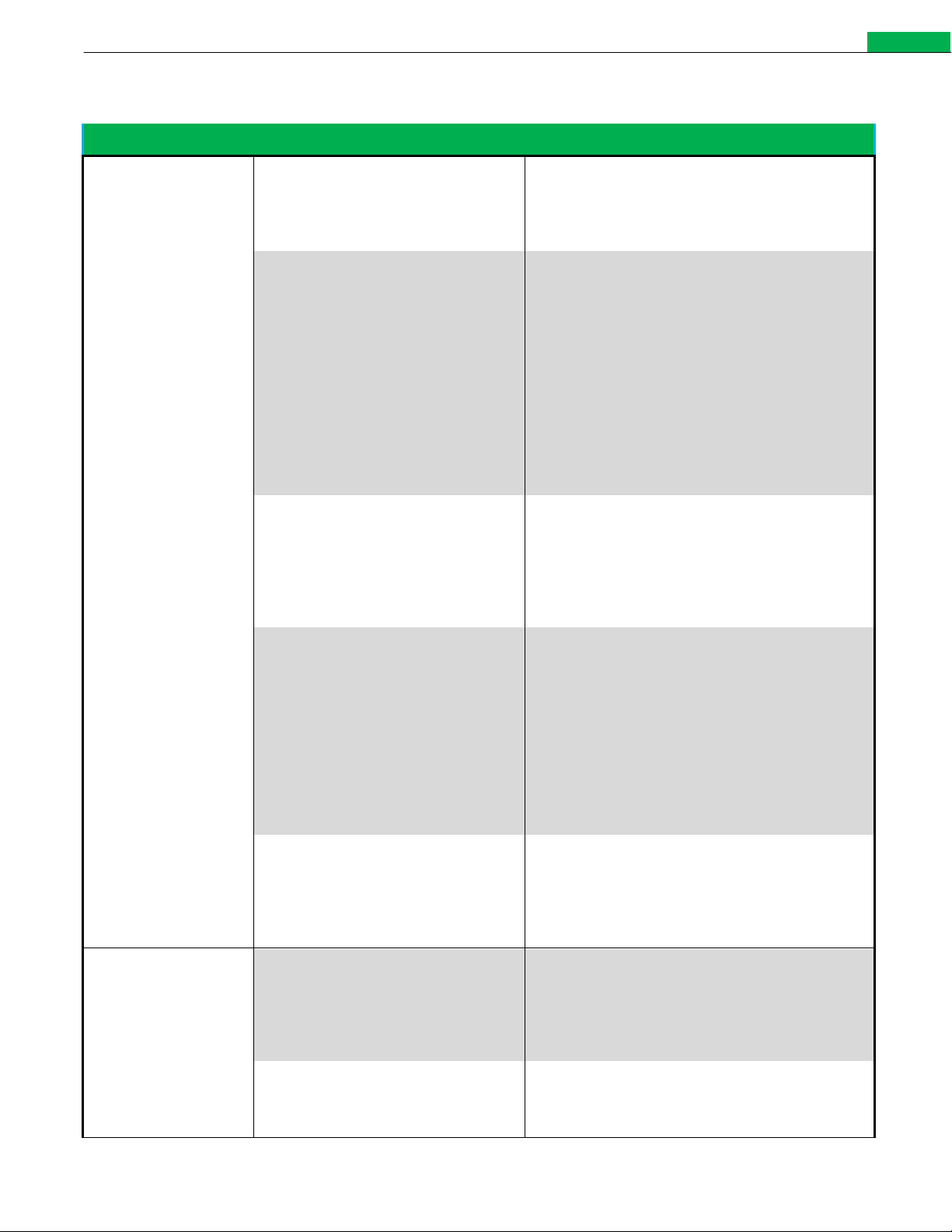

Model

Kit Order #

Description

PMPNT & PMPNTS

W-KIT-902-04

Cover Gasket

W-KIT-902-05

Inlet & Vent Valve Assembly

W-KIT-902-06

Float & Cover Gasket

W-KIT-902-08

Spring Assembly

W-KIT-914-03

Complete Pump Mechanism Assembly & Gasket PMPNT

W-KIT-914-03-SS

Complete Pump Mechanism Assembly & Gasket PMPNTS

VENT VALVE

OUTLET

MOTIVE VALVE

INLET

OUTLET CHECK

VALVE

CONDENSATE

INLET CHECK

VALVE

Figure 6: PMPNT(S) Cutaway View

GAUGE GLASS (OPTIONAL)

902-08

SPRING ASSEMBLY

902-04

COVER GASKET

902-05

INLET & VENT

VALVE ASSEMBLY

902-06

FLOAT

Ordering Spare Parts

Figure 7: PMPNT(S) Cutaway View

9

Watson McDaniel Company PMPNT Manual 2605100 Rev A

System Troubleshooting

PROBLEM

POSSIBLE

CAUSE CORRECTION

1. Pump fails to operate

on startup.

a) Motive pressure line closed

a) Open valves to supply motive pressure to

pump

b) Motive pressure insufficient to

overcome backpressure

b) Check motive pressure and backpressure.

Adjust motive pressure to 10 psi (min.)

higher than the backpressure

c) Liquid inlet line closed

c) Open all valves to supply liquid to the

pump

d) Liquid discharge line closed

d) Open all valves on the discharge side of

the pump

e) Pump vapor-locked

e) Break vent connection at pump cover.

Stand clear of vent connection. If pump

begins to cycle, vapor locking has

occurred. Re-check that the exhaust tie-

back line is unobstructed and completely

self-draining to a lower pressure area

with sufficient vapor space

f) Insufficient fill head to allow pump

to trip

f) Check that fill head is large enough for

condensate to drain freely by gravity into

the pump properly. Raise condensate

source or lower pump to achieve required

filling head

2. Liquid backup and

equipment flooded, but

pump appears to cycle

normally

a) Motive pressure is too low to

achieve required capacity

a) Check motive pressure setting and

maximum backpressure during operation.

Check against sizing table. Increase

motive pressure as required

b) Insufficient filling head to achieve

required capacity

b) Verify required filling head is large

enough for condensate to drain freely by

gravity into the pump properly. Raise

condensate source or lower pump to

achieve required filling head

c) Restriction in liquid inlet line

c) Check that only full ported fittings are

used. Clean the strainer. Verify that all

valves are fully open

d) Inlet check valve stuck open

d) Isolate inlet check valve and relieve

pressure. Remove cap and visually

inspect for debris. Clean seating surfaces

and reinstall or replace, if necessary

e) Pump undersized

e) Verify rated capacity in the sizing capacity

table. Increase check valve size or install

additional pump as required

3. Liquid backup and

equipment flooded, and

pump has stopped

cycling

a) Motive pressure low

a) If motive pressure is below backpressure,

increase motive pressure setting to 10 psi

(min.) above backpressure. Do not

exceed rated pressure limits of equipment

b) Discharge line closed via valve

blocked with debris

b) Compare motive pressure and

backpressure. If backpressure is higher

or equal, a closed or blocked discharge

line is possible. Check valves

downstream of pump

10

Watson McDaniel Company PMPNT Manual 2605100 Rev A

PROBLEM

POSSIBLE

CAUSE CORRECTION

3. (continued)

Liquid backup and

equipment flooded,

and pump has

stopped cycling

c) Outlet check valve stuck closed

c) After checking per step 3(b), isolate

discharge check valve and relieve line

pressure. Remove cap and visually inspect.

Clean seating surfaces and reinstall or

replace, if necessary

SAFETY NOTE TO

PREVENT INJURY:

For steps (d) through

(g), it is necessary to

disconnect the vent

line at the pump

head. It is possible

that hot condensate

may run out of the

vent connection

when broken.

d) Inlet check valve stuck closed

d) If mechanism is not heard to trip and fluid is

not running from the vent connection, it is

suspected that the fault lies in the

condensate inlet piping. Be sure that all

valves leading to the pump have been

opened. If so, this is a possible indication

that the inlet check valve is stuck closed.

Isolate the pump and check valve and

relieve line pressure. Remove the check

valve and visually inspect. Clean seating

surfaces and reinstall or replace, if

necessary. Reinstall exhaust/tie-back

connection and open line

e) Motive inlet valve leaking and/or

worn

e) Gradually open motive supply line, leaving

the condensate inlet and discharge lines

closed. Observe the vent connection for

steam or air leakage. If observed, inlet

valve is obstructed or damaged. With pump

isolated, remove cover and visually inspect.

Replace inlet valve and seat assembly

f) Mechanism failure

1. Ruptured float

2. Mechanism binding

f) Keeping motive line open, slowly open

condensate inlet line to the pump, allowing

pump to fill and observe vent connection. If

condensate runs out of vent connection, a

mechanism problem is apparent. Isolate

pump by shutting off motive supply and

condensate inlet, remove cover and visually

inspect. Examine float for defects. Stroke

mechanism and check for any binding or

increased friction. Repair or replace as

needed

g) Exhaust/tie-back causing vapor

lock

g) Recheck the vent/tie-back piping layout for

compliance with the installation instructions.

Check that the exhaust tie-back line is

unobstructed and completely self-draining

to a lower pressure area with sufficient

vapor space

4. Valve will not close

a) When a pump discharges a

significant volume of liquid into a

long horizontal return line with

rises and drops, the sudden

changes in velocity can develop a

vacuum

a) Install a vacuum breaker at high point in

return line. For pressurized return systems,

an air eliminator may be required down-

stream of the vacuum breaker

b) Pump is blowing by

b) Compare inlet and outlet pump pressure. If

the inlet pressure equals or exceeds the

backpressure, a "blow through" problem is

possible

11

Watson McDaniel Company PMPNT Manual 2605100 Rev A

PMPNT(S) Check Valve Capacities

Operating

Check Valve - Capacities

CAPACITIES - Condensate (lbs/hr) Using steam as motive pressure, (SCFM) Using air as motive pressure

Motive

Pressure

(PSIG)

Total

Back

Pressure

(PSIG)

1-1/2" x 1-1/2" Check Valve Size

0" Fill Head

6" Fill Head

12" Fill Head

18" Fill Head

Cap•Air

Cap•Stm

Cap•Air

Cap•Stm

Cap•Air

Cap•Stm

Cap•Air

Cap•Stm

5

2

1721

1375

2592

2071

3059

2445

3417

2731

10

5

1678

1369

2495

2036

2932

2393

3266

2665

10

2

1794

1528

2758

2349

3278

2792

3677

3132

25

15

1628

1354

2385

1983

2788

2318

3095

2574

25

10

1721

1489

2592

2242

3059

2647

3417

2956

25

5

1794

1601

2758

2461

3278

2925

3677

3281

50

40

1495

1196

2095

1676

2409

1927

2647

2118

50

25

1678

1455

2495

2164

2932

2543

3266

2833

50

10

1794

1638

2758

2518

3278

2992

3677

3357

75

60

1495

1203

2095

1685

2409

1938

2647

2129

75

40

1662

1443

2460

2136

2886

2506

3212

2788

75

15

1794

1653

2758

2541

3278

3020

3677

3388

100

80

1495

1207

2095

1690

2409

1944

2647

2136

100

60

1628

1397

2385

2047

2788

2392

3095

2656

100

40

1721

1542

2592

2322

3059

2741

3417

3062

100

15

181 1

1690

2795

2608

3327

3104

3736

3486

125

115

1359

1046

1803

1388

2032

1564

2204

1697

125

100

1495

1209

2095

1693

2409

1947

2647

2140

125

80

1606

1367

2336

1989

2724

2319

3019

2570

125

60

1687

1492

2515

2225

2959

2618

3298

2917

125

40

1752

1597

2662

2426

3151

2872

3526

3214

125

15

1820

1713

2817

2650

3356

3157

3770

3547

Note: For 1” x 1” Check Valve, multiply capacity by 0.58

12

Watson McDaniel Company PMPNT Manual 2605100 Rev A

Vented Receiver Sizing

Vented Receiver Sizing

Flash Steam

up to --

Receiver

Vent Line

Dia.

Dia.

Length

75 pph

4”

36”

1”

150 pph

6”

36”

2”

300 pph

8”

36”

3”

600 pph

10”

36”

4”

900 pph

12”

36”

6”

1200 pph

16”

36”

6”

Below figures are approximate for 4” X 4”

Packages

2000 pph

20”

60”

8”

3000 pph

24”

60”

8”

4000 pph

26”

60”

10”

5000 pph

28”

60”

10”

6000 pph

30”

72”

12”

7000 pph

32”

72”

12”

8000 pph

36”

72”

14”

When sizing a Pressure Motive Pump for an

atmospheric return system, the amount of flash

steam to be vented through the receiver must be

calculated. Vent sizing is critical to maintain zero

psig in the receiver tank to allow free drainage of

low pressure systems. Undersized vents will cause

gradual pressure increase in the receiver. This

impedes drainage from the condensate source, and

can cause water logging of the system.

To Size Receiver & Vent:

Usually the condensate load to be pumped comes

from multiple sources. For each source determine

the pressure and load. Then go into the "Percent

Flash" table with the condensate pressure and

move right until under the appropriate tank

pressure to read the percentage of condensate

that will flash into steam. Now take that source

load and multiply it by the decimal value of the

percentage to calculate the amount (lbs/hr) of

flash steam. Repeat this for all condensate

sources and total the flash steam. Enter the

"Vented Receiver Sizing" table with the total flash

steam load to determine the correct sizes for

receiver and vent.

Percent Flash Steam

Condensate

Pressure

(PSIG)

Flash Tank Pressure (PSIG)

0

2

5

10

15

20

30

40

60

80

100

5

1.6

0.9

0

10

2.9

2.2

1.3

0

15

3.9

3.3

2.4

1.1

0

20

4.9

4.2

3.3

2.1

1

0

30

6.5

5.8

5

3.7

2.6

1.7

0

40

7.8

7.2

6.3

5.1

4

3

1.4

0

60

10

9.4

8.5

7.3

6.2

5.3

3.7

2.3

0

80

12

11

10

9.1

8.1

7.1

5.5

4.2

1.9

0

100

13

13

12

11

9.6

8.7

7.1

5.8

3.5

1.6

0

125

15

14

14

12

11

10

8.8

7.5

5.3

3.4

1.8

150

16

16

15

14

13

12

10

9

6.8

4.9

3.3

200

19

18

17

16

15

14

13

12

9.4

7.6

6

250

21

20

19

18

17

16

15

14

12

9.8

8.2

300

23

22

21

20

19

18

17

16

13

12

10

350

24

24

23

22

21

20

18

17

15

13

12

400

26

25

24

23

22

21

20

19

17

15

14

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Flotec

Flotec FPZS50RP owner's manual

Wilo

Wilo Yonos PICO1.0 Installation and operating instructions

Becker

Becker BASIC VASF 2.80/1-0.AC230 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Wayne

Wayne WTX50 Warranty & service parts sheet

CET

CET PFP-20HP-HND-1D Instruction handbook