Ilsco SSI SpecPRO SRM 14 Series User manual

PO Box 15732 Brooksville, FL 34604-5732- Phone: 888-987-8877/850-654-5559, Fax 850-654-3844 –www.surgesuppression.com

2018 SSI®. Rev Date 10/25/2018

Page 1of 2

Doc # SS06255

Description:

Parallel connected, AC power Surge Protective Device.

Application:

Designed for use at ANSI/IEEE location categories C, B and A.

Designed to protect all types of loads fed from individual

disconnects, sub panels, distribution panels and service entrance

locations.

Warranty:

10 Years

Unit Listings:

Listed to ANSI/UL 1449 by UL (E315947), CSA (MC#241804);

UL1283* (* Type 2 SPDs only)

Circuit Design:

Parallel connected, hybrid circuit design incorporating both

component level thermal fusing and internal over-current fusing. All

protection circuits are encapsulated in our high dielectric compound

to promote long component life and protection from the weather and

vibration.

Directly Connected

Protection Modes:

L-N, (Normal Mode), and N-G (Common Mode).

(Based on Wye configuration, L-G on Delta configuration.)

Input Frequency:

50-420 Hz (60 Hz typical)

EMI/RFI Filtering:

Up to 41 db normal mode, 39 db common mode

Circuit Diagnostics:

Super Bright LED, 1 per phase, normally on. See pg. 2 for additional

diagnostics options

Connection/mounting:

#10 Wire (pre-installed), hub (pre-installed on base models, installed

at time of installation on optional enclosures) and integral, multi-

point mounting feet.

Circuit Interrupt:

Internal component level thermal fusing and Patented internal over-

current fusing rated at 200,000 AIC short-circuit current rating

(SCCR = 200 kA)

Nominal Discharge

Current (In) Rating:

10 kA (SRMC14, SRMA14)20 kA** (SRMB14, SRMD14) (**Complies

with the requirements of UL 96A Master Label for Installation Requirements

for Lightning Protection Systems)

Designed for mission critical applications, the SRM series is an ideal choice for most

small electrical panel applications. The SRM series of Surge Protective Devices

provide the features, performance and value required by discriminating specifying

engineers. This device is intended for protection of general-purpose load

applications ranging from individual equipment disconnects and sub panels to

distribution panels and service entrance locations. It is extremely effective in limiting

externally generated lightning surges as well as internally generated transients.

The SRM series provides an effective blend of leading edge suppression design

technology, straight forward, no frills engineering and customer driven, value added

options. “Specify” the SRM with confidence.

Key Features:

Industry Leading Measured

Limiting Voltage Performance

Independent Verification of

Performance and Safety

Component-Level, Thermal

Fusing and Over-Current Fusing

No moving parts or springs - No

mechanical or electro-mechanical

thermal/over-current protection

Circuit Encapsulation

10 Year Warranty

SRMx14 Series

140 kA Per Phase

Peak Surge Current

ANSI/UL1449 UL

A = Type 2 SPD 10 kA

B = Type 2 SPD 20 kA

C = Type 1 SPD 10 kA

D = Type 1 SPD 20 kA

Voltage

Code

ANSI/UL 1449 (Fourth Edition)

Voltage Protection Rating (VPR)

L-N

HL-N

L-G

HL-G

N-G

L-L

HL-L

1P1

600

-

1200

-

600

-

-

1S1

600

-

1200

-

600

1200

-

3Y1

600

-

1200

-

600

1200

-

3D1

600

900

1200

1500

600

1200

1500

3Y2

900

-

1800

-

900

1800

-

3N2

-

-

1000

-

-

2000

-

3N4

-

-

1800

-

-

4000

-

Doc # SS06255

Page 2of 2

MEASURED LIMITING VOLTAGE PERFORMANCE AND ELECTRICAL SPECIFICATIONS

Voltage

Code

Circuit Type

Peak Surge

Current (Amps)

Per Mode

&

Per Phase

MCOV

Mode

ANSI/IEEE C62.41 & C62.45

6” External Lead Length Let-Through Voltage Test Results

A3

6 kV, 200 A100 kHz Ring Wave

90º Phase Angle

C3

20 kV, 10 kA Combination Wave

90º Phase Angle

1P1

120 V, Single Ø

(2 wire + ground)

140,000

150

150

L-N

N-G

261 V

491 V

729 V

991 V

1S1

120/240 V, Split Ø

(3 wire + ground)

140,000

150

150

L-N

N-G

261 V

491 V

729 V

991 V

3Y1

120/208 V, 3ØY

(4 wire + ground)

140,000

150

150

L-N

N-G

261 V

491 V

729 V

991 V

3D1

120/240 V, 3Ø

(4 wire + ground)

140,000

150

320

150

L-N

HL-N

N-G

261 V

392 V

491 V

729 V

1,374 V

991 V

3Y2

277/480 V, 3ØY

(4 wire + ground)

140,000

320

320

L-N

N-G

392 V

817 V

1,374 V

1,661 V

3N2

240 V, 3

(3 wire + ground)

140,000

320

L-G

376 V

1,414 V

3N4

480 V, 3

(3 wire + ground)

140,000

550

L-G

505 V

2,071 V

Measured Limiting Voltage Tests: Positive Polarity, All voltages are peak (±10%). All tests are static except 150V MCOV modes. Let-through voltages on static tests calculated by

subtracting sine-wave peak from let-through measured from zero. 150V MCOV mode let-through voltages measured from insertion point on sine-wave. Single-pulse surge current testing

for all modes at rated currents as recommended by NEMA LS1-1992. Single pulse surge current capacities of 200,000 amps or less are determined by testing all components within each

mode as a group. Present industry test equipment limitations require testing of individual components or sub-assemblies within a mode for single-pulse surge capacities over 200,000

amps. Scope Settings: Time Base = 10 microseconds, Sampling Rate = 500 megasamples/sec. These settings assure Let-through voltages test results are accurate.

Model Number Example: SRMB143Y2D3

Base Model:

SPD Rating:

PSC

Voltage Code:

Options:

SRM

A = Type 2 SPD 10 kA C = Type 1 SPD 10 kA

B = Type 2 SPD 20 kA D = Type 1 SPD 20 kA

14 (140 kA)

See Voltage Codes

3Y2

See Option codes

D3

Enclosure Dimensions

Inches

(mm)

Standard

Model

Enclosure Options

W

X

A

14.00

(356)

14.00

(356)

18.00

(458)

B

12.00

(305)

12.00

(305)

16.00

(407)

C

6.00

(153)

6.00

(153)

10.00

(254)

D

15.50

(394)

15.50

(394)

19.50

(496)

E

15.98

(406)

15.98

(406)

19.98

(508)

F

13.23

(309)

13.23

(309)

17.23

(411)

G

14.75

(375)

14.75

(375)

18.94

(482)

H

10.00

(254)

10.00

(254)

14.00

(356)

Type

NEMA

12

Steel

NEMA

4

Steel

NEMA

4X

Composite

lbs.

(kg)

14

(6.36)

14

(6.36)

32

(14.52)

Options

Description

AC10

Basic Internal Audible Alarm

AC11

Advanced Internal Audible Alarm

w/ on, off, and test

AC10S6

Basic Alarm/ Surge Counter

AC11S6

Advanced Alarm w/ surge

counter on, off, and test

D5 (CSA)

Integral Disconnect Switch **

D6 (CSA)

Integral Disconnect Switch (no

external handle) **

E1

Hub on side of enclosure

P

Flush Mount Plate

R2

Remote LED's in separate

enclosure

S

Internal Surge Counter

W

NEMA 4 Metal Enclosure

X

NEMA 4X Composite Corrosion

Resistant Enclosure (Box-in-box)

XS

NEMA 4X Stainless Steel

Corrosion Resistant Enclosure

Additional options may be available upon

request.

** Housed in a NEMA 4X Composite Enclosure

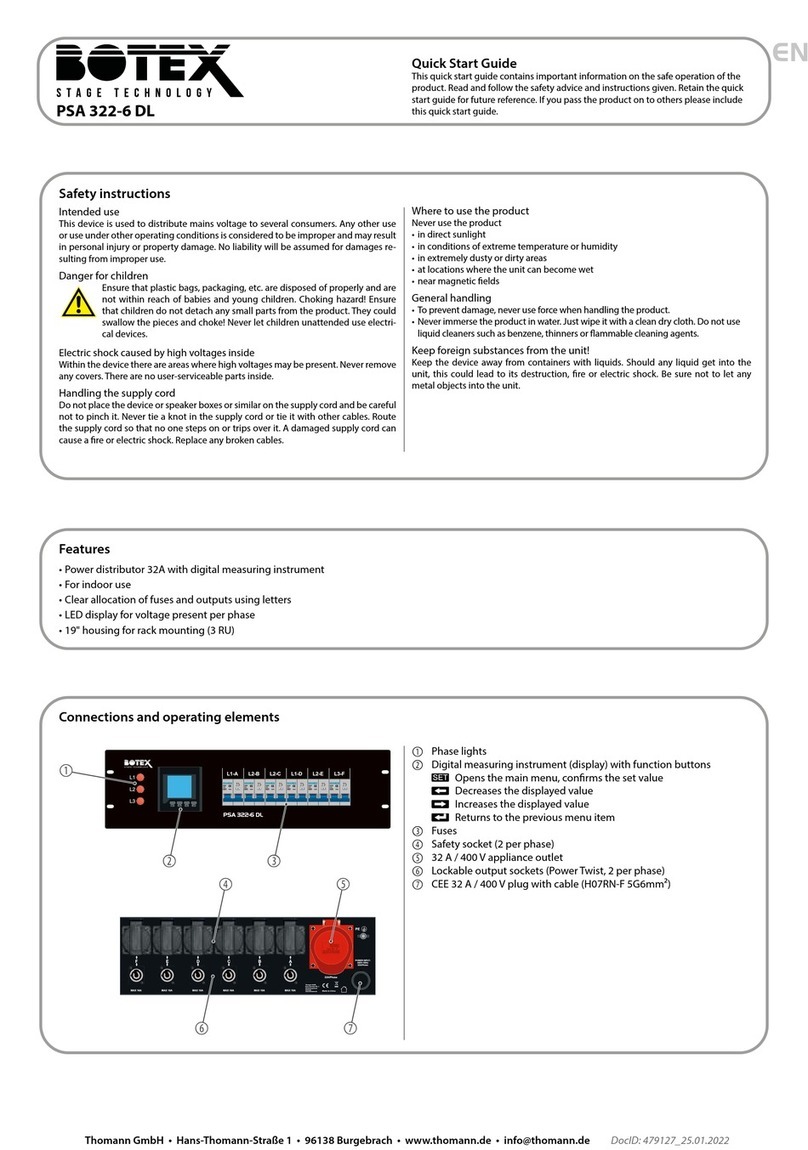

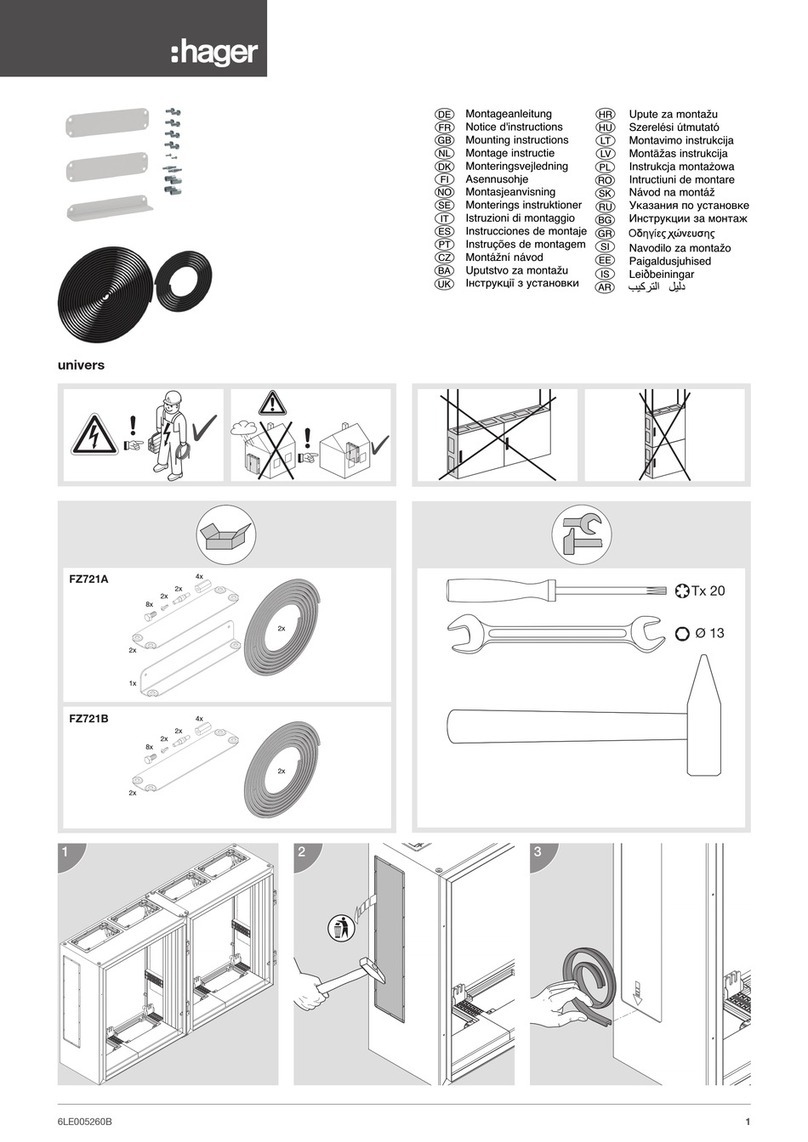

Integral

Disconnect

D5, D6 option

configuration

(Enclosure

24x20x10)

(CSA)

SPD

Inside

End View

Top View

ø0.30"

H

B

G

A

Mounting hub for X enclosure

options are placed at time of

installation

(3/4" hub provided)

Green LED status

indicators, one per

phase, normally on.

B

C

D

F

Pre-installed 3/4" hub for

standard models

End (normal hub location)

Side (E1 option)

Side (E11 option)

E

© 2017 Surge Suppression, LLC NN00139 Rev Date: 09/19/2017

WARNING - HAZARDOUS VOLTAGES ARE PRESENT. Improper installation may result in serious injury to the installer and/or damage to the

electrical system or related equipment. Read all instructions before beginning the installation. Safety equipment must be used as prescribed by

OSHA, whenever working around hazardous voltages.

Failure of unit and/or consequential equipment damage due to improper installation or misapplication is not covered by the product

warranty.

Voltage measurements and installation must be completed by a licensed/qualified electrician in accordance with the National and/or Canadian

Electric Code, State, and Local codes. These requirements supersede this instruction.

POWER MUST BE REMOVED FROM THE ELECTRICAL SYSTEM BEFORE INSTALLING THE UNIT.

INSTALLATION MATERIALS REQUIRED

The following is a list of materials that may be needed for proper installation of this Surge Protective Device (SPD). This list is intended to help the installer anticipate

materials needed for a successful installation. The installer should become familiar with the scope of work to avoid lost time and improper installation. Failure to use fittings

that are “Listed” will void the “Listing” of the SPD.

For Splices: 3 (or more) cable taps; such as: NSI IPCS- 2001 or 7501 (per Code).

Attachment Hardware: Use (four) screws or anchor toggle bolts, flat washers and lock washers.

¾” hub (included with most models).

Tools: Drill & bits, Mechanical Knock Out Set, Channel Locks™, Level, Screwdrivers, Appropriate Safety Equipment.

WIRING DIAGRAM

This device is suitable for use on a circuit capable of delivering not more than 200,000 RMS symmetrical

Amperes for the respective models’ (max.) nominal voltage shown in the Table of Maximum Suggested

Operating Voltages on page 2.

The SPD is equipped with integral fuses. This allows the device to be installed directly to the system bus

bars, to the main lugs in a panel or disconnect, or to a circuit breaker. Consult NEC/CEC, State and Local

Codes to assure compliance†.

In the event that one or more of the LED status indicators fail to illuminate, the entire device should be

returned for warranty replacement. If service of the device is a consideration (i.e.: removal and

replacement), and there is no means to remove power from the SPD without removing power from the entire

system, the installer may consider incorporating a disconnect device between the SPD and the system

connecting point.

The design of these units provides superior protection for sensitive/critical equipment connected to

distribution panels, sub-distribution panels or individual equipment disconnects. These units are designed

for use at IEEE C62.41 Location Categories A, B, and C. “Voltage Responsive” type units are designed to

be used in 50 to 420 Hz applications. NOTE: SPDs with model numbers beginning with the letter “C” are

“Frequency Responsive” (Sinewave tracking) units and are designed to be used in 50 to 60 Hz applications

only and shall not be used at locations where the voltage frequency fluctuates (i.e.: on the output of variable

frequency drives).

When inspecting the panel prior to installation, make a visual check that there are no Neutral to Ground

bonds that violate the NEC/CEC.

Note: Pre-existing breakers of the rated load size (30 amp, etc.), that are serving existing loads, may be

utilized if the breaker is “Listed” for this application (see NEC) and provided the owner/tenant has authorized

multiple conductor termination.

†[ex.: NEC ‘10-foot tap rule’ for direct bus tapping.].

NOTE FOR ISOLATED GROUND

If the electrical system uses an isolated ground, connect the SPD ground to the isolated ground bus. EXCEPTION FOR METAL ENCLOSURES AND/OR METALLIC

HUBS –For metal enclosures and/or metallic hubs, the SPD ground wire is bonded to the enclosure internally. If the system uses an isolated ground, the SPD enclosure

must be isolated from the panel or load it is being connected to through the use of an insulated conduit fitting or other “Listed” fitting. In this installation, the ground wire

from the SPD must terminate at the isolated ground bus.

BEFORE INSTALLATION

For proper performance, the SPD must be installed with the shortest lead length possible. Sharp bends should be avoided.

No position-oriented components are used in the units. Devices can be mounted upside down or sideways allowing for shortest possible lead lengths. There are a few basic

principles for surge suppression installation. They are:

1. For proper performance, the SPD must be installed with the wires as short and straight as humanly possible. Any sharp bend in the wire is unacceptable!

This applies to phase, neutral, and ground leads. The objective is to reduce the lengths of wire provided on each unit, not add to it. The priority is to the

phase leads, then the neutral, and then the ground lead.

2. Install the SPD on the side of the panel closest to the neutral bus, if present, and use a breaker on the same side.

3. Use a breaker close to the neutral bus and the SPD to keep the wires as short and straight as humanly possible.

4. The ground wire may be connected to the panel by using a ground lug installed near the SPD in the can or frame as they are grounded. (See exception

above for Isolated Grounds).

Installation Instruction for

Split Phase, 4-wire Suppressors

with Internal Fusing

(2 phases, neutral and ground)

PO Box 15732

Brooksville, FL 34604

Phone (888) 987-8877

Fax (352) 799-6987

info@surgesuppression.com

© 2017 Surge Suppression, LLC NN00139 Rev Date: 09/19/2017

Table of Maximum Suggested Operating Voltages and Model Wire Colors

Split Phase

1Sx

Phase

Phase

Phase

*Neutral

Phase A

Phase B

Neutral

Ground

Nominal

Model Voltage

To

To

To

To

Wire

Wire

Wire

Wire

System Voltage

Code

Neutral

Phase

Ground

Ground

Color

Color

Color

Color

120/240

1S1

132 V

264 V

132 V

< 132 V

Black

Black

White

Green

120/240

1S12

132 V

264 V

132 V

< 132 V

Black

Black

White

Green

220/380

1S22

242 V

418 V

242 V

< 242 V

Black

Black

White

Green

230/400

1S23

253 V

440 V

253 V

< 253 V

Black

Black

White

Green

240/415

1S24

264 V

457 V

264 V

< 264 V

Black

Black

White

Green

240/480

1S2

264 V

528 V

264 V

< 264 V

Black

Black

White

Green

*NOTE: If Neutral to Ground voltage is greater than 5 VAC, a problem may exist in the electrical system. The SPD may be installed; however, a

qualified electrician or Power Quality Engineer should be consulted to correct the problem. Contact SSI with specific questions.

INSTALLATION STEPS

STEP 1: Check Voltages

Confirm that the nominal system voltage does not exceed the maximum suggested operating voltage for the model to be installed according to the Table above. All

voltage measurements should be made with an RMS voltmeter. DO NOT INSTALL THE SURGE SUPPRESSOR IF THE MEASURED VOLTAGE EXCEEDS THE

MAXIMUM SUGGESTED OPERATING VOLTAGE OF THE DEVICE.

CAUTION: Do not proceed further until power has been removed from the electrical system.

STEP 2: Mounting the Unit

Non-lug type SPDs are provided with 18-24 inches of #10 AWG/TEW stranded wire. For best performance, mount the SPD so that all wires (phase, neutral, and ground)

can be cut and connected in the shortest, straightest path possible, the goal being 6 inches of wire length or less. For every inch of conductor longer than 6-inches, you

increase the let-through voltage of the SPD by 21.7 volts for an ANSI/IEEE Category B, 6 kV, 3 kA impulse and reduce the performance of the SPD.

No sharp bends should be made in the installation. If bends are unavoidable, make them smooth and flowing. The device contains no position-dependent

components; therefore, the device can be mounted upside down or sideways, etc.

Do not cut any wires until SPD has been mounted. Units with plastic hubs must be installed with the non-metallic flexible conduit and extra hub.

While holding the SPD on the wall, determine the shortest, straightest distance between the hub on the suppressor and hub to be installed on panel. Cut the flexible

conduit to the shortest length possible to fit securely over both hubs.

Twist the trimmed flexible conduit onto the extra hub. Slide conduit and hub over wires of SPD and twist the conduit onto the hub of the SPD.

Connect the extra hub to the panel and mount the SPD to the wall.

STEP 3: Connecting “Optional Form C” Dry Relay Contacts (Applies to only to SPDs with optional Dry Relay Contacts)

Make sure power is removed from surge suppressor.

Open surge suppressor lid and note encapsulant height prior to drilling or punching enclosure. (Allow internal clearance for locknuts).

Drill 0.5” diameter clearance hole through side, top or bottom of unit and install a watertight strain relief (i.e.: Altech #225-A00).

NOTE: Surge suppressor is equipped with two sets of contacts. The first set (labeled 1 & 2, N/C) is normally closed and the other set (labeled 3 & 4, N/O) is

normally open with power applied. The DRC terminal header block is located on the inside of the suppressor cover lid.

Contacts are rated at 60 W (from 30 VDC @ 2 A to 150 VDC @ 0.4 A) or 100 VA (from 50 VAC @ 2 A to 220 VAC @ 0.45 A).

Alarm contacts accept AWG #26 (0.14mm2) to AWG #16 (1.5mm2) wire. Wire size must be in compliance with NEC/CEC, State or Local codes for power on circuit.

Follow rules for the class of wiring used when routing alarm leads. To maintain NEMA-4 (IP66) rating use appropriate cable and watertight strain relief.

Connect alarm circuit(s) to Normally Open (N/O) or Normally Closed (N/C) terminals as needed & the alarm contact wires to alarm control panel.

Upon replacing front cover of suppressor, certain models allow various lid rotations (90° to 180°) for improved label orientation. (model specific)

STEP 4: Wire the SPD into the Electrical System

Carefully lay out the wires keeping them as short and straight as possible. (Wires may be slow-twisted together thereby reducing RF-impedance.) After a satisfactory

layout has been made to the appropriate termination points as described below, cut the wires and connect them as instructed.

Connect the GREEN ground wire from/to the SPD to the system Ground bus bar or to a lug mounted in the can or frame close to the SPD if the Ground bus bar is not

close following the current the NEC/CEC. Refer to earlier sections for systems utilizing an isolated ground. Connect the WHITE neutral wire from/to the SPD to the

system Neutral bus bar.

You may connect the Phase wires or “hot” wires (see table above for wire colors) from/to the SPD to the Phase conductors or buses of the electrical system through

any required circuit interrupts (fuses or breakers) described above. Note the SPD has internal fusing and does not require external circuit interrupts. The Phase

conductors may be directly connected to the system buses after the main disconnect

Before energizing, measure the voltage again to ensure it is within the levels in the table above.

Immediate failure of the SPD will occur if installed on voltages higher than shown in the Table at the top of this page.

STEP 5: Apply Power to the SPD

The LED status indicators should be illuminated. If not, remove power from the SPD and contact Surge Suppression, LLC at: 1-(888)-987-8877.

© 2018 Surge Suppression, LLC

Page | 1 Doc # SS05788

PO Box 15732

Brooksville, FL 34601

Phone 888-987-8877

Fax 850-654-3844

TEN YEAR LIMITED WARRANTY –SpecPRO™ FOUR MODE PRODUCTS

Surge Suppression, LLC warrants for a period of ten (10) years from date of retail purchase

that if its product ceases to properly function as a direct result of any electrical anomaly,

including lightning, Surge Suppression, LLC will repair or replace the product without charge,

subject to the terms and conditions set forth herein. If, in the sole subjective opinion of Surge

Suppression, LLC the product has been modified, altered, tampered with, misused or

misapplied or repaired by any entity other than Surge Suppression, LLC, or subjected to

abuse, the warranty is void. The warranty shall not apply unless the product is installed by a

qualified licensed and/or bonded electrician. The warranty period for repaired or replacement

products shall be only the remaining portion of the original limited warranty. Any defect

appearing more than ten (10) years from the date of delivery to purchaser, shall be deemed to

be due to ordinary wear and tear. Surge Suppression, LLC, however, assumes no risk or

liability resulting from the use of its products, including but without limiting the generality of the

foregoing: (1) The use of this product in combination with any electrical or electronic

components, circuits, systems, assemblies or any other materials or substances; (2) The

improper application or unsuitability of this product for use in any circuit or assembly. All

warranty inspections and parts must be obtained at Surge Suppression, LLC. The giving of, or

failure to give, any advice or recommendations by Surge Suppression, LLC shall not constitute

any warranty by or impose any liability upon Surge Suppression, LLC. THIS WARRANTY

DOES NOT GUARANTEE UNINTERRUPTED ELECTRIC SERVICE. REPAIR OR

REPLACEMENT OF THIS PRODUCT IS THE EXCLUSIVE REMEDY OF THE RETAIL END

USER PURCHASER. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR USE OR

PURPOSE; ALL OF WHICH ARE HEREBY EXCLUDED AND EXPRESSLY DISCLAIMED.

SURGE SUPPRESSION, LLC SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES OF ANY KIND OR

CHARACTER, INCLUDING, WITHOUT LIMITATION, THE EXPENSE OF INSTALLATION OR

REMOVAL OF THIS PRODUCT, LOSS OF REVENUE OR PROFITS, FAILURE TO REALIZE

SAVINGS OR OTHER BENEFITS, LOSS OF COMPUTERIZED OR OTHER DATA, DAMAGE

TO ANY ELECTRIC OR ELECTRICAL EQUIPMENT, INCONVENIENCE AND/OR FOR THIRD

PARTY CLAIMS MADE AGAINST THE WHOLESALE OR RETAIL PURCHASER OF THIS

PRODUCT, EVEN IF BEFORE OR AFTER PURCHASE SURGE SUPPRESSION, LLC HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SURGE SUPPRESSION,

LLC’S TOTAL LIABILITY FOR ANY CLAIM MADE AGAINST IT SHALL IN NO EVENT

EXCEED THE PURCHASE PRICE PAID TO SURGE SUPPRESSION, LLC FOR THE

DEFECTIVE PRODUCT. As a condition precedent to SURGE SUPPRESSION, LLC’s

performance pursuant to this Warranty, Purchaser must return this product within the Warranty

period FOB SURGE SUPPRESSION, LLC’s place of business in Brooksville, Florida. Please

call 888-987-8877 for warranty return procedures. Return authorization is required.

Table of contents

Other Ilsco Power Distribution Unit manuals

Ilsco

Ilsco SSI CSM 40 Series User manual

Ilsco

Ilsco SSI SpecPRO CSM 36 Series User manual

Ilsco

Ilsco SSI SpecPRO CSM 20 Series User manual

Ilsco

Ilsco SSI SpecPRO SRM Series User manual

Ilsco

Ilsco SSI SpecPro SSM 48 Series User manual

Ilsco

Ilsco SSI SpecPRO SSM 12 Series User manual

Ilsco

Ilsco SpecPRO CRM 26 Series User manual