Ilsco IDT-12-N User manual

INSTRUCTION MANUAL

99945282 REV 6 © 2009 Ilsco Corporation Q.F.5.4.55 2/09

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

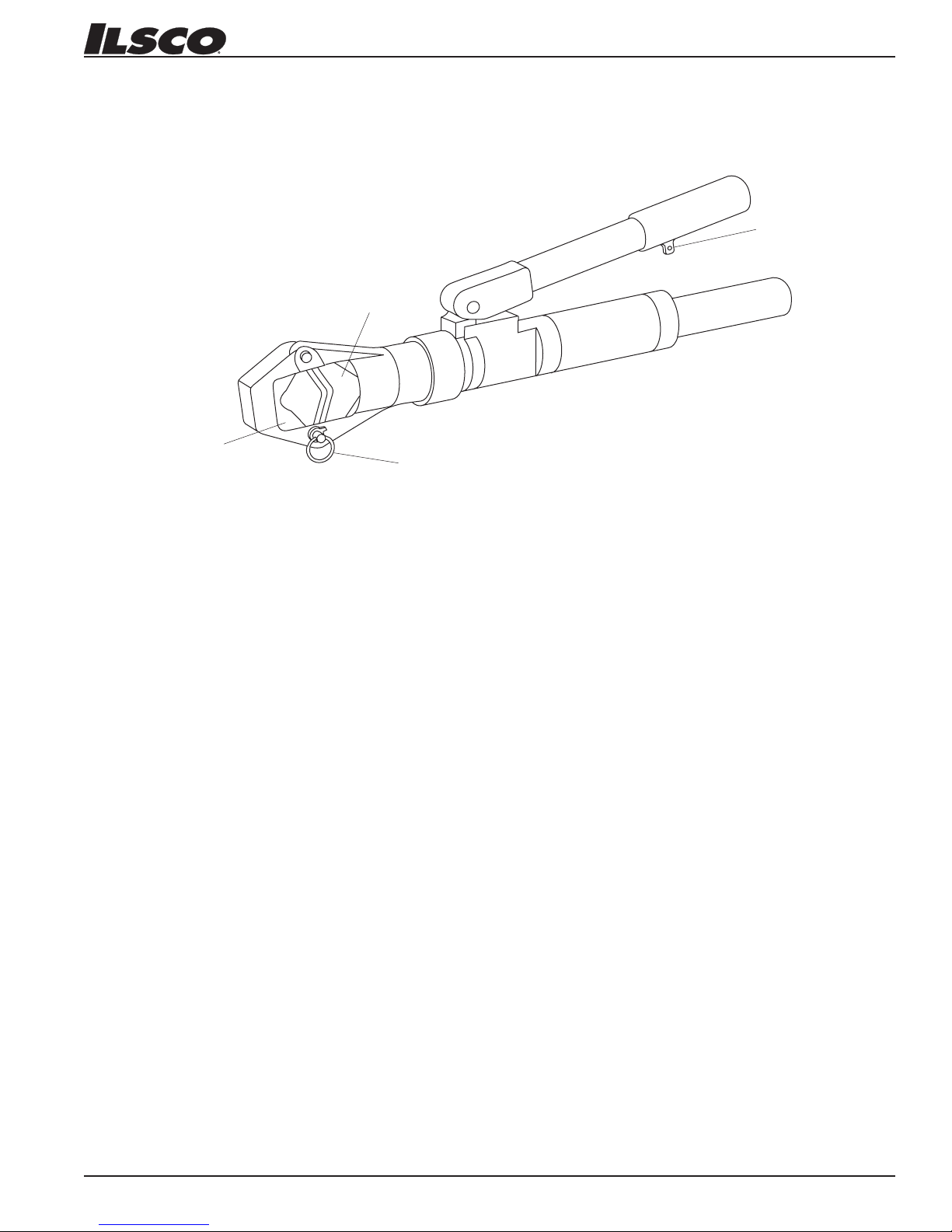

IDT-12-N

Hydraulic Crimping Tool

Ilsco Corporation 2 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

KEEP THIS MANUAL

Table of Contents

Description ..................................................................... 2

Safety ............................................................................. 2

Purpose of this Manual .................................................. 2

Warranty and Service ..................................................... 2

Important Safety Instructions ..................................... 3–4

Identication................................................................... 5

Specications................................................................. 5

Operation.................................................................... 6–7

Periodic Pressure Relief Valve Check............................. 8

Maintenance................................................................... 8

Troubleshooting.............................................................. 9

AirPurgingandOilFillingProcedure............................ 10

Illustration..................................................................... 11

Parts List ...................................................................... 12

Description

TheIDT-12-NHydraulicCrimpingToolisahand-held,

self-contained,dielesscrimpingtoolintendedtocrimp

aluminum and copper connectors onto electrical cable.

Thehingedcrimpinghead,whichallowseasyloading

andunloadingofspliceconnections,swivels180°for

maximumexibility.Thetwo-speedhydraulicsystem

automaticallyswitchesfromrapidadvance(forquick

snug-up)tonormaladvance(toaccomplishthecrimp).

An internal pressure regulating system automatically

sets the correct pressure for the connector.

Safety

Safety is essential in the use and maintenance of Ilsco

toolsandequipment.Thismanualandanymarkingson

the tool provide information for avoiding hazards and

unsafepracticesrelatedtotheuseofthistool.Observe

all of the safety information provided.

Purpose of this Manual

Thismanualisintendedtofamiliarizeallpersonnelwith

the safe operation and maintenance procedures for the

followingIlscotool:

IDT-12-NHydraulicCrimpingTool

Keep this manual available to all personnel.

Replacementmanualsareavailableuponrequestat

no charge.

Warranty and Service

ILSCOwarrantsthistooltotheoriginalpurchaserfora

periodofoneyearfromthedateofpurchase,provided

thetoolisoperated,maintainedandusedinaccordance

withILSCO’swritteninstructions.Ordinarywearand

tear,damagefromabuse,neglectoralterationsarenot

coveredbythiswarranty.Thiswarrantyisnullandvoid

if instructions and operating procedures are not

followed.ContactILSCOforallwarrantyandservice

issuesat800-776-9775.

DowCorningisaregisteredtrademarkandRTVSealant732isa

trademarkofDowCorningCorporation.

Univis is a registered trademark of Exxon Mobil Corporation.

Ilsco Corporation 3 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

IMPORTANT SAFETY INFORMATION

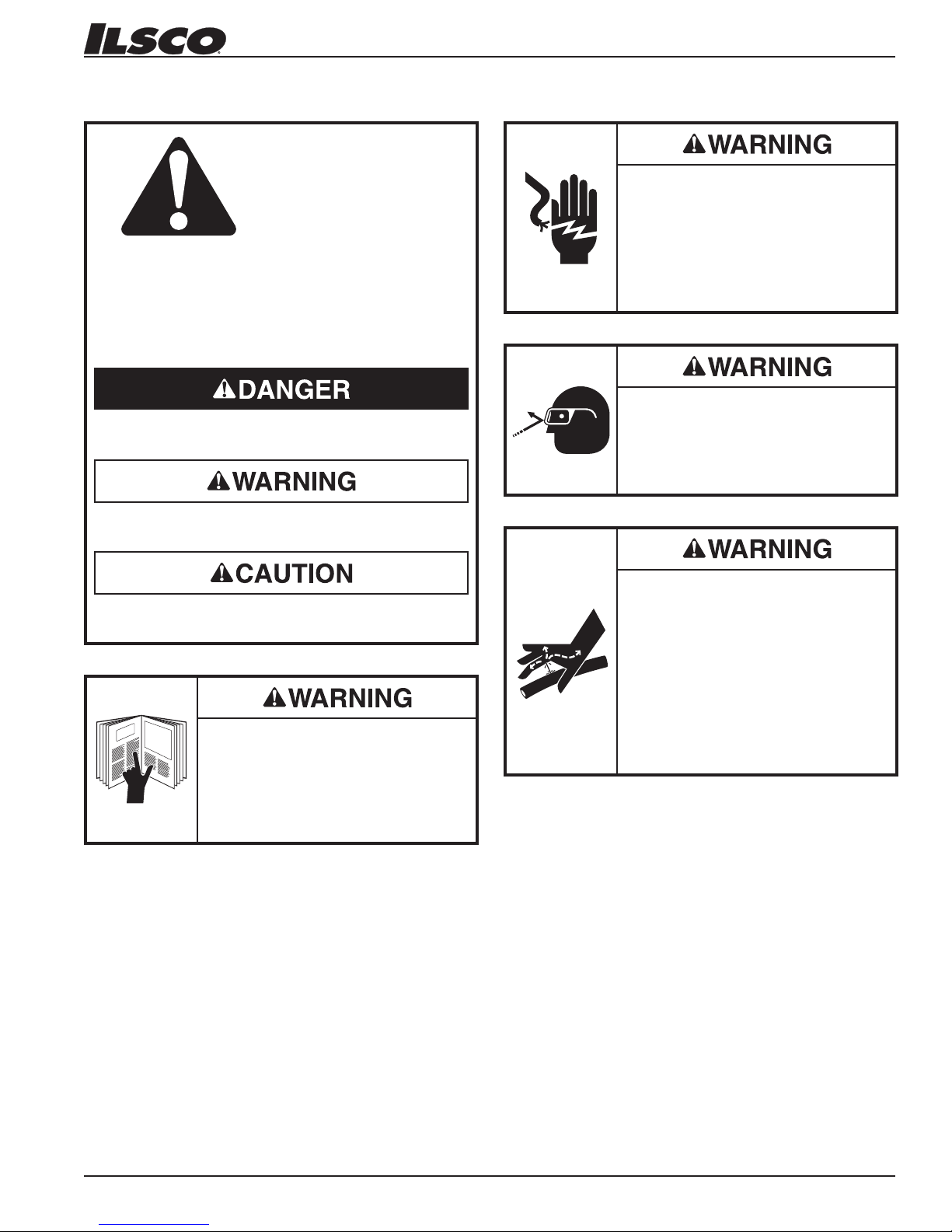

Electricshockhazard:

This tool is not insulated. When using

this unit near energized electrical

lines,useproperpersonalprotective

equipment.

Failuretoobservethiswarningcould

result in severe injury or death.

Weareyeprotectionwhenoperating

or servicing this tool.

Failuretoweareyeprotectioncould

result in serious eye injury from ying

debris or hydraulic oil.

Skininjectionhazard:

Do not use hands to check for•

leaks.

Depressurize the hydraulic system•

before servicing.

Oilunderpressureeasilypunctures

skincausingseriousinjury,gangrene

or death. If you are injured by

escapingoil,seekmedicalattention

immediately.

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards

orunsafepracticeswhichcouldresultinaninjuryor

propertydamage.Thesignalword,denedbelow,

indicates the severity of the hazard. The message

afterthesignalwordprovidesinformationfor

preventing or avoiding the hazard.

Immediatehazardswhich,ifnotavoided,WILLresult

in severe injury or death.

Hazardswhich,ifnotavoided,COULDresultin

severe injury or death.

Hazardsorunsafepracticeswhich,ifnotavoided,

MAY result in injury or property damage.

Read and understand all of the

instructions and safety information

in this manual before operating or

servicing this tool.

Failuretoobservethiswarningcould

result in severe injury or death.

Ilsco Corporation 4 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

IMPORTANT SAFETY INFORMATION

An incomplete crimp can cause a re.

Use proper connector and cable combinations.•

Improper combinations can result in an incomplete

crimp.

The relief valve sounds to indicate a completed•

crimp. If you do not hear the sound of the relief

valve,thecrimpisnotcomplete.

Failuretoobservethesewarningscouldresultin

severe injury or death.

Inspecttoolbeforeuse.Replaceanywornor

damaged parts. A damaged or improperly assembled

tool can break and strike nearby personnel.

Failuretoobservethiswarningcouldresultinsevere

injury or death.

Keephandsawayfromthecrimping

toolheadwhencrimping.

Failuretoobservethiswarningcould

result in severe injury or death.

Thistoolisintendedfortwo-handedoperation.•

Maintain a rm grip on both handles during opera-

tion. Using this tool in any other manner can result

in injury or property damage.

Do not perform any service or maintenance other•

than as described in this manual. Injury or damage

to the tool may result.

Failure to observe these precautions may result in

injury and property damage.

Note: Keep all decals clean and legible, and replace

when necessary.

Ilsco Corporation 5 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Identification

Specifications

Crimping Tool

Length .......................................................................................................... 673mm(26.5")

Width........................................................................................................... 26.3mm(2.87")

Mass/Weight ................................................................................................. 7.5kg(16.5lb)

HydraulicOil................................................................................................... 198cc(12in3)

Crimping Capacities

Crimping Range

Copper Connectors .................................. 25 mm2to 500 mm2(#4AWGto1000Kcmil)

Aluminum Connectors .............................. 16mm2to 500 mm2(#6AWGto1000Kcmil)

Maximum Crimping Tool Diameter ........................................................ 461mm(1.815")

CrimpingForce(maximum)........................................................................ 133kN(15tons)

Crimping tool adjusts automatically to connector size.

Movable

Pin Unit

Release

Trigger

Ram Die

Die Head

Ilsco Corporation 6 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Operation

Electricshockhazard:

This tool is not insulated. When using

this unit near energized electrical

lines,useproperpersonalprotective

equipment.

Failuretoobservethiswarningcould

result in severe injury or death.

Weareyeprotectionwhenoperating

or servicing this tool.

Failuretoweareyeprotectioncould

result in serious eye injury from ying

debris or hydraulic oil.

Skininjectionhazard:

Do not use hands to check for•

leaks.

Depressurize the hydraulic system•

before servicing.

Oilunderpressureeasilypunctures

skincausingseriousinjury,gangrene

or death. If you are injured by

escapingoil,seekmedicalattention

immediately.

An incomplete crimp can cause a re.

Use proper connector and cable combinations.•

Improper combinations can result in an incomplete

crimp.

The relief valve sounds to indicate a completed•

crimp. If you do not hear the sound of the relief

valve,thecrimpisnotcomplete.

Failuretoobservethesewarningscouldresultin

severe injury or death.

Inspecttoolbeforeuse.Replaceanywornor

damaged parts. A damaged or improperly assembled

tool can break and strike nearby personnel.

Failuretoobservethiswarningcouldresultinsevere

injury or death.

Keephandsawayfromthecrimping

toolheadwhencrimping.

Failuretoobservethiswarningcould

result in severe injury or death.

Ilsco Corporation 7 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Operation (cont’d)

Preparation

1. Selectapropersizeandtypeofconnectortocorre-

spondwiththewireorcable.

2. Stripthecabletoanappropriatelength.Followthe

instructions in the Ilsco stuffer sheet.

Note: Apply an oxide inhibitor, if required. Refer to

the Ilsco stuffer sheet.

Crimping

1. Insertthecablefullyintotheconnector.

2. Position the connector in the crimping head.

Note: Position the lug connectors so the tang is

perpendicular to the direction of ram travel, as

shown.

Direction of Ram Travel

Tang

3. Ifopen,closethedieheadandpushinthe

movable pin unit. Make sure the movable pin is fully

engaged.

4. Alignthetoolwiththealignmentmark(forlugs)or

centerstop(forsleeves)asshown.

OUTERMOST

BLADE OF DIE HEAD

LUG

ALIGNMENT

MARK

LONGER LUG

TANG

OUTERMOST

BLADE OF RAM DIE

LUG

ALIGNMENT

MARK

SHORTER LUG

TANG

OUTERMOST

BLADE OF DIE HEAD

CENTER

STOP

SLEEVE

5. Pump the handle to advance the ram. Continue to

pump until the pressure relief valve activates.

Note: Pressure relief is indicated by an audible

“pop” and a sudden drop in handle force.

6. Toreleasethehydraulicpressure,pulltherelease

triggerbackwhilepressingdownonthehandle.

Note: To prevent the ram from retracting

completely, release the trigger. This speeds the

crimping process when a single connector requires

several crimps.

7. Complete the number of crimps specied in the

Ilsco stuffer sheet.

8. Toremovethetoolfromasplice,pullthemovable

pin on the die head and open the crimping head.

Ilsco Corporation 8 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Periodic Pressure Relief Valve Check

Test the crimping tool periodically to ensure that the

pressure relief valve activates at the proper pressure.

Orderacrimpingtooltestkit,Ilscopartnumber

50328913.

The pressure test slugs are manufactured to a precise

diameterandhardness.Donotre-usethetestslugs.

Discard each slug after use.

Testing the Crimping Tool

1. Centeranewpressuretestsluginthecrimping

head.

2. Pump the handles to advance the ram. Continue to

pump until the pressure relief valve activates.

3. Toreleasethehydraulicpressure,pulltherelease

triggerbackwhilepressingdownonthehandle.

4. RepeatSteps1through3ontwomoretestslugs.

5. Testthethreeslugsasfollowsagainstthe

GO/NOGOgaugeasshown.

• IftheGOslottsovertheslugandtheNOGO

slotdoesnot,thepressureiswithinthespecied

range.

• IftheGOslotdoesnotslideovertheslug,the

crimpingpressureistoolow.Sendthecrimping

tool to Ilsco.

• IftheNOGOslotslidesovertheslug,thecrimp-

ing pressure is too high. Send the crimping tool to

Ilsco.

Maintenance

Afterusingthetool,removeanydirt,grit,oroxide•

inhibitor from the tool.

Occasionallylubricatemovingparts.•

Storethetoolinitscasewiththeramfullyretracted.•

Perform the Periodic Pressure Relief Valve Check•

every500crimpsorevery90days,whichevercomes

rst.

GO Gauge NO GO Gauge

Check Point

(center depression of the three depression side)

6. Discard the slugs.

Ilsco Corporation 9 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Troubleshooting

Ramdoesnotadvance. Airinthehydraulicsystem. Referto“AirPurgingandOilFillingProcedure.”

Check valve or release mechanism. Return tool to Ilsco.

Ramadvancesslowly. Airinthehydraulicsystem. Referto“AirPurgingandOilFillingProcedure.”

Check valve or release mechanism. Return tool to Ilsco.

Ramadvanceserratically. Airinthehydraulicsystem. Referto“AirPurgingandOilFillingProcedure.”

Ramretractspartiallywith Airinthehydraulicsystem. Referto“AirPurgingandOilFillingProcedure.”

each stroke.

Check valve. Return tool to Ilsco.

Ramdoesnotfullyadvance. Hydraulicuidlevelislow. Referto“AirPurgingandOilFillingProcedure.”

Ramdoesnotfullyretract. Airinthehydraulicsystem. Referto“AirPurgingandOilFillingProcedure.”

Reservoirisoverlled. Referto“AirPurgingandOilFillingProcedure.”

Internal binding. Return tool to Ilsco.

Ram does not retract. Dies damaged. Return tool to Ilsco.

Release mechanism. Return tool to Ilsco.

Pressurebuildsslowly; Dischargecheckball. Flushvalveseatusingrapidpumpstrokes.

handlespringsback. Ifunitstilldoesnotwork,returntooltoIlsco.

Pressurebuildsslowly; Reliefvalveorreleasemechanism. ReturntooltoIlsco.

no response.

Nohighpressure. Checkvalve. Flushvalveseatusingrapidpumpstrokes.

Ifunitstilldoesnotwork,returntooltoIlsco.

Airinhydraulicsystem. Improperllprocedure. Referto“AirPurgingandOilFillingProcedure.”

Loose or missing reservoir plug. Replace plug.

Reservoir damaged. Replace reservoir.

ReservoirmissingO-ring. ReplaceO-ring.

DamagedO-ringonlowpressure ReturntooltoIlsco.

injector.

Probable CauseProblem Probable Remedy

Ilsco Corporation 10 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Air Purging and Oil Filling Procedure

FillthereservoirwithExxonUnivis®J26 all temperature

hydraulic oil only.

Donotllthehydraulicreservoirwithanyothertype

ofuid(suchasbrakeuid,glycerine,castoroil,etc.).

Fillingthereservoirwithanythingotherthanhydraulic

uidwilldamagethetoolandvoidthewarranty.

2. Retract the ram by pulling the release trigger back

whilepressingdownonthehandle.

3. Pump the handle one partial stroke.

4. Peelouttherubberplug(26)andremovetheset

screw(27)fromthereservoirhandle(1).

8. Pump the handle several times to advance the ram.

While holding a cleanshopclothoverthereservoir,

retract the ram fully. Repeat several times to purge

all of the air from the system.

9. With the pump handle vertical and the ram fully

retracted,llthereservoiruntilitoverows.

10. Replacetheplug(25)andwipeoffexcessoil.

11. Pumpthehandleonestrokeandinstallthereservoir

handle(1).Replacethesetscrew(27).

12. Coverthesetscrewwithasiliconerubbersealant,

suchasDowCorning®RTVSealant732™Multi-

Purpose Sealant.

1. Clampthetoolintoavisewithjawprotectorssothe

handlesareupward,asshown.

5. Unscrewthereservoirhandlefromthecrimping

tool.Removetheplug(25)fromthereservoir.

6. Retract the ram fully.

7. Addoiluntilthereservoiroverows.

Vise with Jaw

Protectors

Rubber

Plug (26)

Remove

set screw (27).

Reservoir

Plug

(25)

Ilsco Corporation 11 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

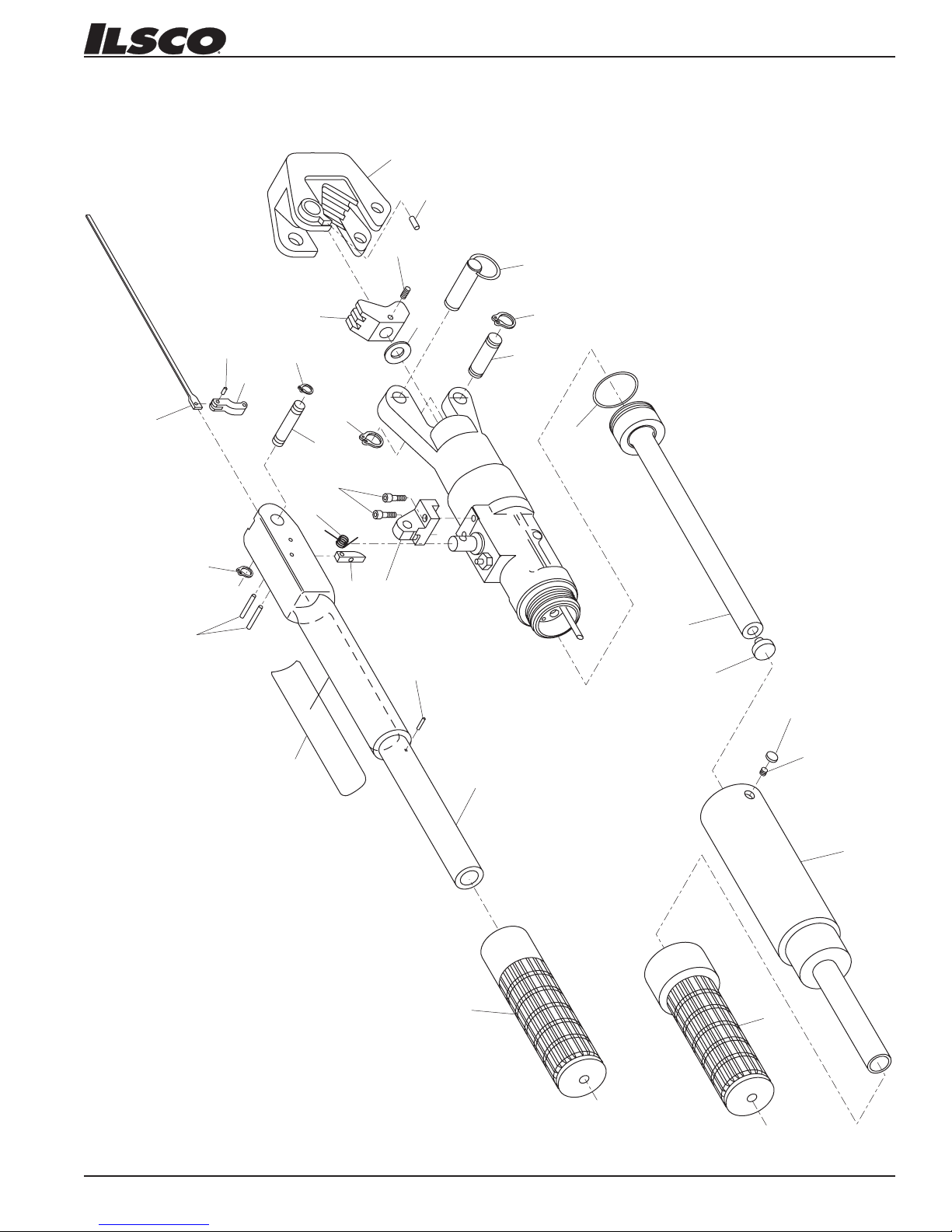

Illustration

7

17

29

5

4

2

3

23

24

25

22

16 21

27

26

1

18

19

20

28

15

16

14

13*

10

11

12

8

15

6

9

Torque cap screws (13)

to 20.3 Nm (15 ft-lb).

Ilsco Corporation 12 4730MadisonRd.•Cincinnati,OH45227-1426•800/776-9775

IDT-12-N Hydraulic Crimping Tool

Parts List

Key Part No. Description Qty

U.S. TECHNICAL SUPPORT

1-800-776-9775

IlscoCorporation•4730MadisonRoad,Cincinnati,Ohio 45227-1426

Phone(800)776-9775,(513)533-6200•Fax(513)871-4084

1 50014501 Handle,reservoir.................................................................................1

2 50356895 Grip,reservoirhandle .........................................................................1

50014480 Handleunit,pump(includesitems3–11) ...........................................1

3 50356887 Grip,rubber ........................................................................................1

4 50014498 Handle,pump .....................................................................................1

5 90510488 Pin,roll,.125x.625............................................................................1

6 90534751 Pin,roll,.156x1.375..........................................................................2

7 50356984 Rod,pressurerelease.........................................................................1

8 90504585 Pin,roll,.125x.375............................................................................1

9 50034278 Trigger,release....................................................................................1

10 50033344 Spring,torsion,.187x.280x.312 .....................................................1

11 50356976 Bar,pressurerelease ..........................................................................1

12 50324934 Lever,pivot .........................................................................................1

13 90512650 Screw,cap,1/4–20x.750sockethead .............................................2

14 50356763 Pin,fulcrum.........................................................................................1

15 90523369 Ring,retaining,.312Truarc.................................................................2

16 90513797 Ring,retaining,.500Truarc.................................................................2

17 50325140 Die,ram ..............................................................................................1

18 50356771 Head,die ............................................................................................1

19 52047204 Detent,ball .........................................................................................1

20 90523385 Screw,set,#10-32x.250socket .....................................................1

21 50356780 Pinunit,movable ................................................................................1

22 50356739 Pin,pivot,.468x2.05.........................................................................1

23 90538145 O-ring,1.47x1.71x.118...................................................................1

24 50356860 Reservoir.............................................................................................1

25 50324888 Plug,rubberreservoir .........................................................................1

26 DowCorningSilastic732RTV(clearorblue)......................as needed

27 90512413 Screw,set,#10–32x.187socketatpoint........................................1

28 50337300 Spacer,.549x.997x.025...................................................as needed

50014277 Carryingcase......................................................................................1

50062468 Calibrationtestkit(includes30testslugsandgauge).......................1

50353730 Exxon Univis J26 hydraulic oil.............................................as needed

50328921 Gaugepressuretest ...........................................................................1

503 28930 Slug pressure test...............................................................................7

Decals

29 50014293 Decal,warning....................................................................................1

50014765 Decal,case .........................................................................................1

50062433 Decal,instruction/operating ...............................................................1

50062336 Decal,safety .......................................................................................1

50014463 Decal,toolidentication .....................................................................2

Printed in the USA

Table of contents

Other Ilsco Power Tools manuals

Popular Power Tools manuals by other brands

Buffalo Tools

Buffalo Tools Pro Series instruction manual

LF

LF Style Selections 15094L manual

jbc

jbc pulsmatic user manual

Concrete Tool Importers

Concrete Tool Importers surspider ZKZ-25A owner's manual

TE Connectivity

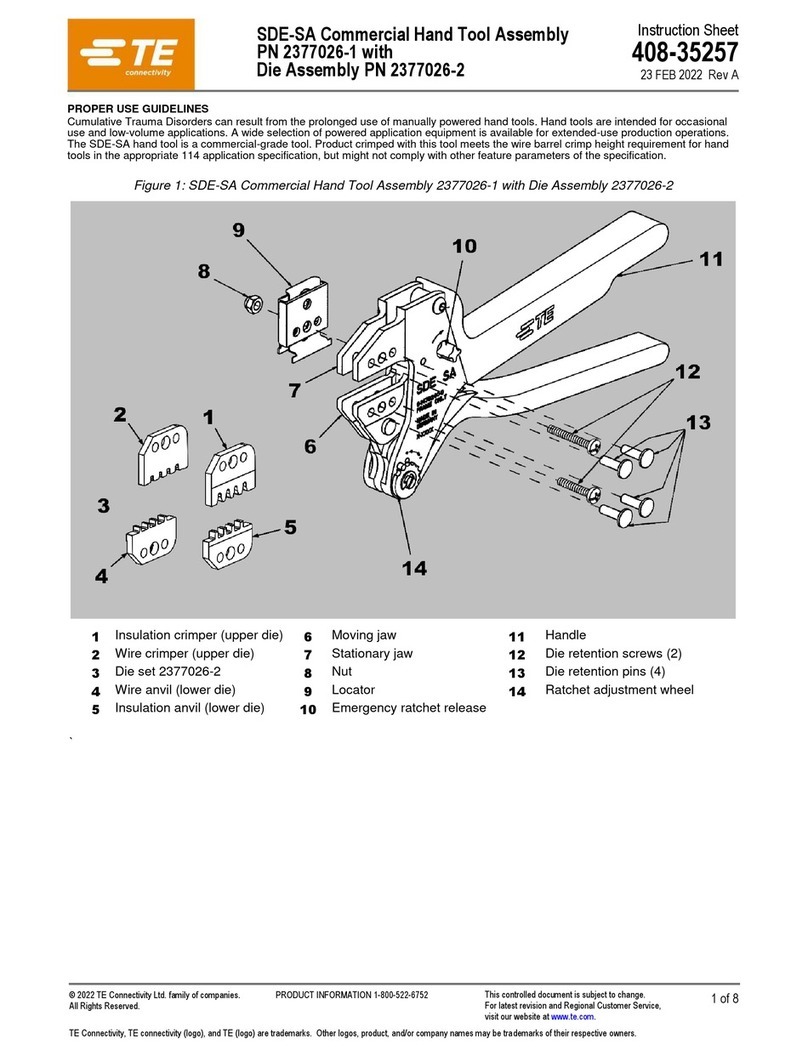

TE Connectivity 2377026-1 instruction sheet

Powercraft

Powercraft 67000 instruction manual