41-VL500-OC-01

Issued 8/01 7

Vista Control System Programming Procedures (contd)

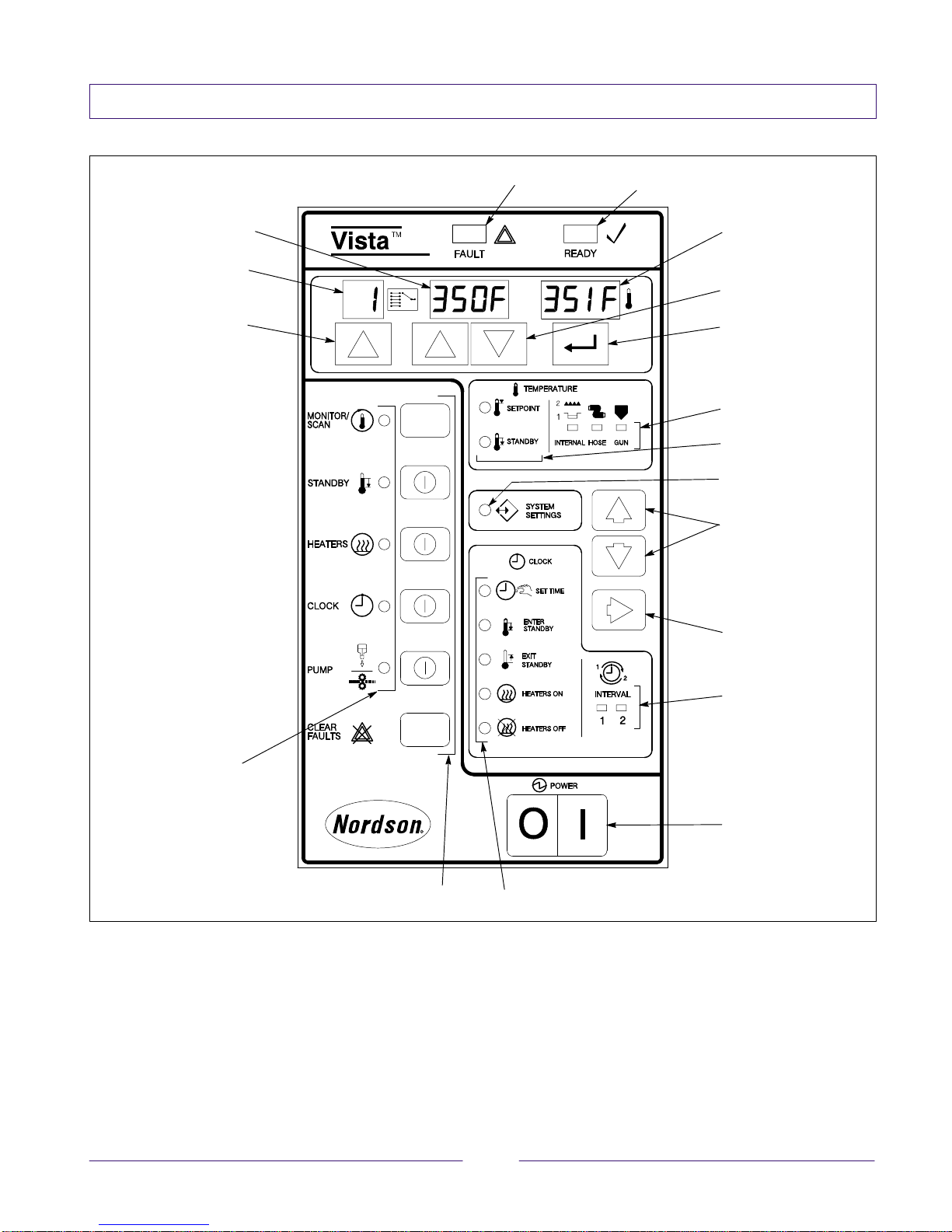

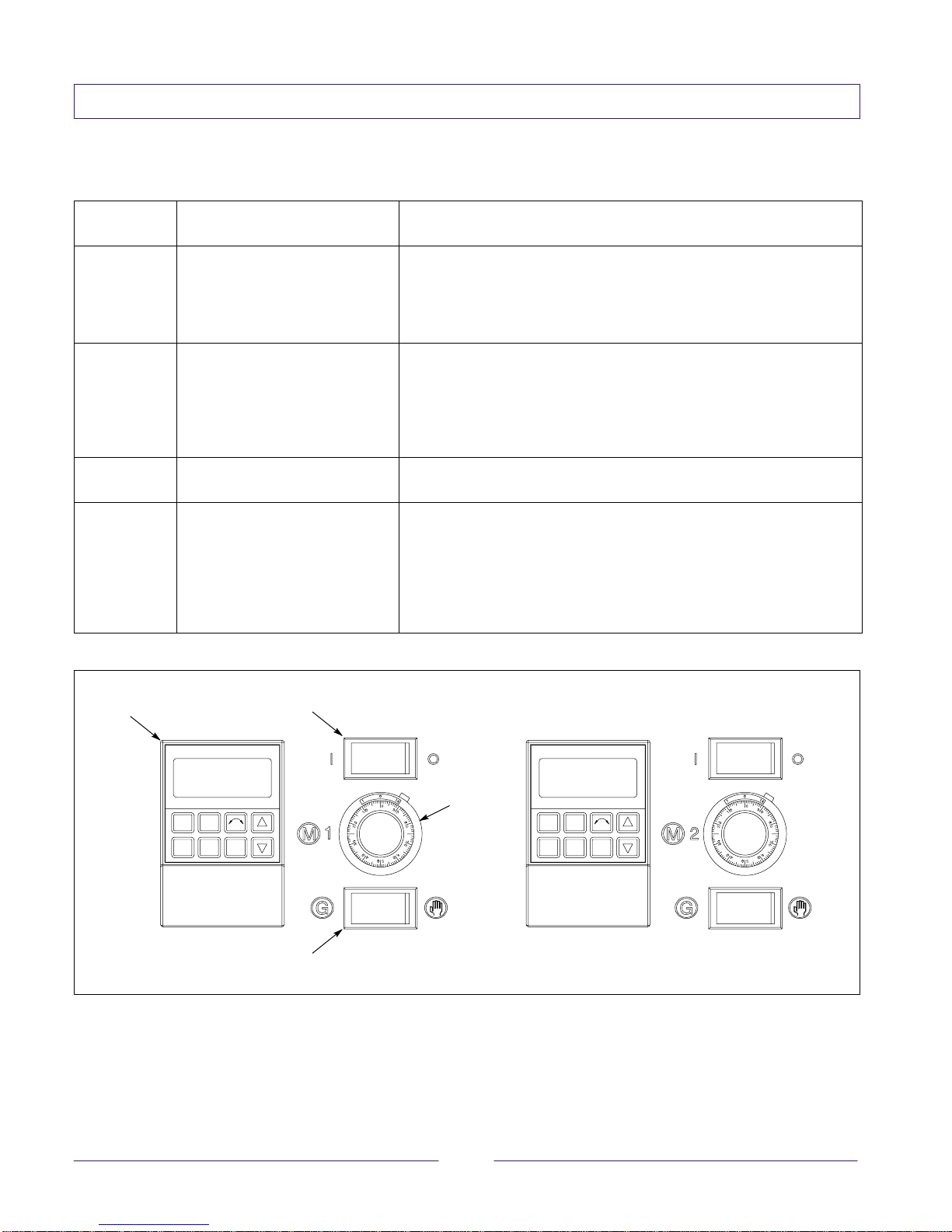

NOTE: See Figure 4 for the location of the displays,

keys, and lights on the Vista control panel.

Setting the Clock

1. Press the up or down arrow keys next to the

SYSTEMS SETTINGS light until the SET TIME

light turns on.

2. Press the up arrow key under the selector display

until the correct day code is shown (1=Monday,

2=Tuesday, and so on); then press enter.

3. Press the up or down arrow key under the

multipurpose display until the correct hour is

shown in the left side of the display; then press

enter.

4. Press the up or down arrow key under the

multipurpose display until the correct minutes are

shown on the right side of the display; then press

enter.

5. Press the MONITOR/SCAN key to exit the

clock-setting mode.

Setting Heaters On/Off or Enter/Exit

Standby Times

1. Press the up or down arrow keys next to the

SYSTEM SETTINGS light until the HEATERS ON,

HEATERS OFF, ENTER STANDBY, or EXIT

STANDBY light turns on.

2. Press the right arrow key (under the up/down

arrow keys) until the INTERVAL 1 or INTERVAL 2

light turns on. You can program two sets of times

for each feature (heaters on/off or enter/exit

standby).

3. Press the up arrow key under the selector display

until the correct day code is shown (1=Monday,

2=Tuesday, and so on); then press enter.

4. Press the up or down arrow key under the

multipurpose display until the correct hour is

shown in the left side of the display; then press

enter. If you wish to delete a time, press the key

until four dashes appear in the display; then press

enter and skip to step 7.

5. Press the up or down arrow key under the

multipurpose display until the correct minutes are

shown on the right side of the display; then press

enter.

6. Repeat steps 1–5 for each interval time you wish

to program.

7. Press the MONITOR/SCAN key to exit the heaters

on/off or enter/exit standby setting mode.

Using the Automatic Functions

If you want the automatic, clock-related functions to

occur (heaters on/off and enter/exit standby), press

the CLOCK key to turn the clock on. The CLOCK light

turns on when the clock is on.

Checking the Warning or Fault Log

1. Press the up or down arrow keys next to the

SYSTEMS SETTINGS light until the light turns on.

2. Press the up arrow key under the selector display

until feature number 35, 36, 37, (first, second, and

third most recent warnings) or 26, 27, or 28 (first,

second, and third most recent faults) appears.

3. The multipurpose display will show two numbers:

one that represents the affected zone and one that

represents the type of warning or fault that

occurred. Refer to Table 2.

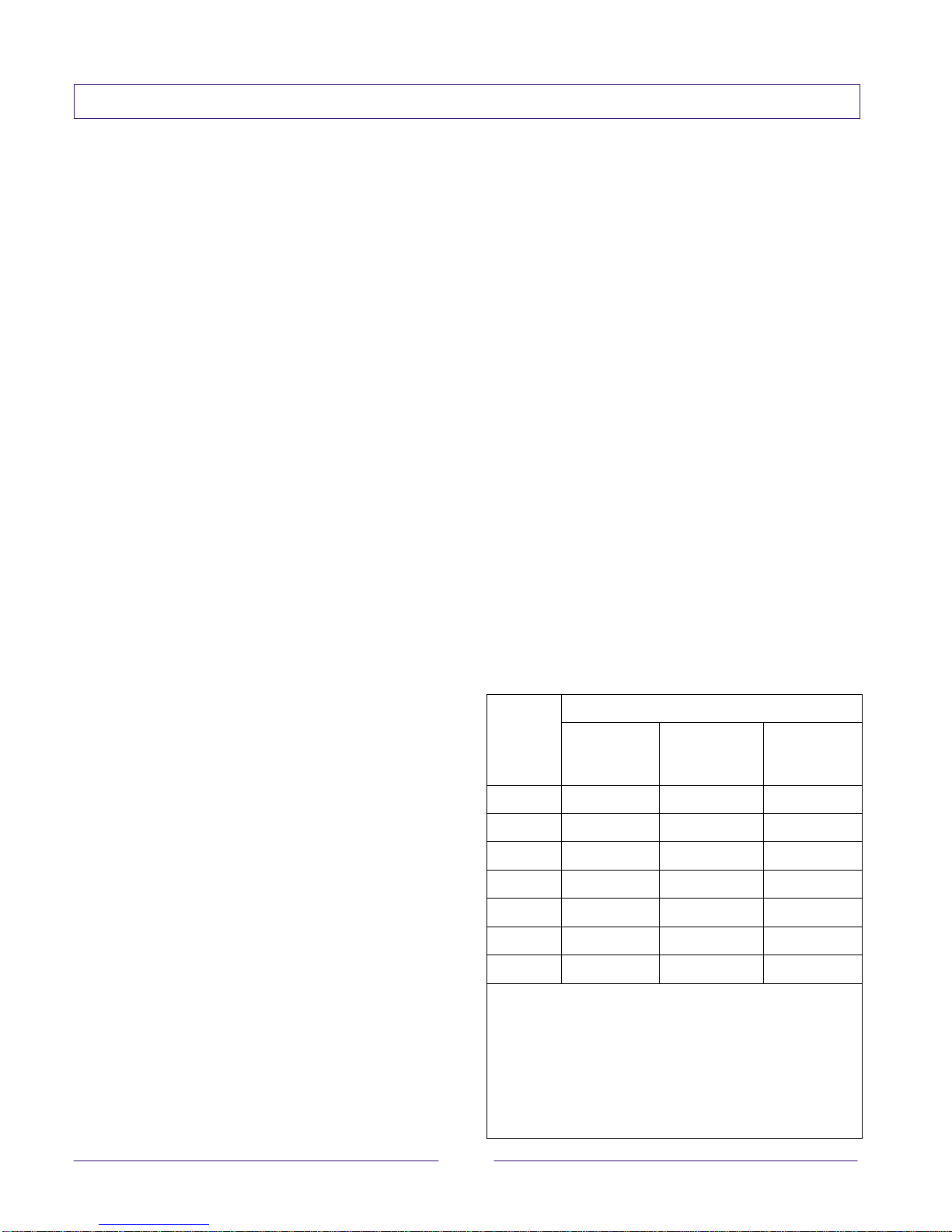

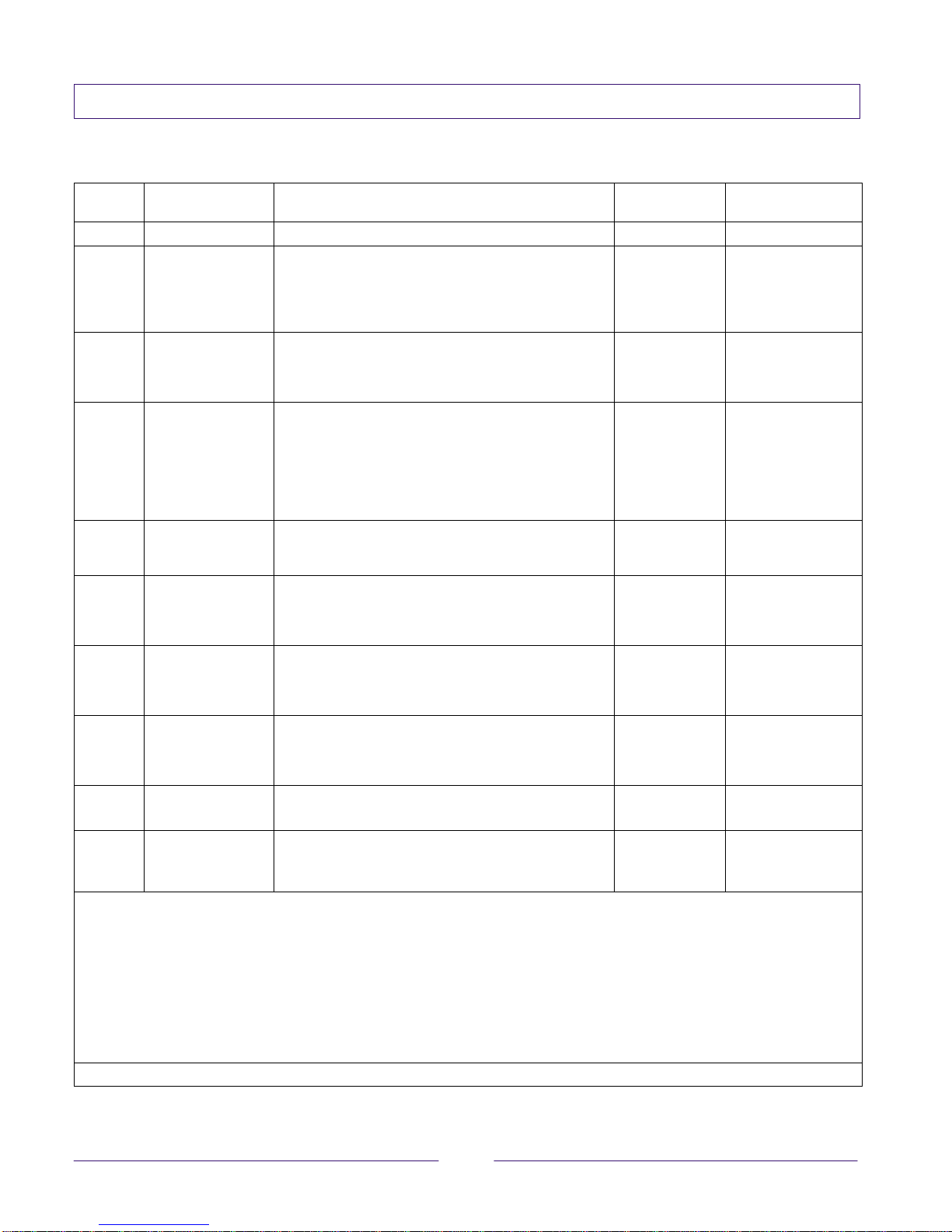

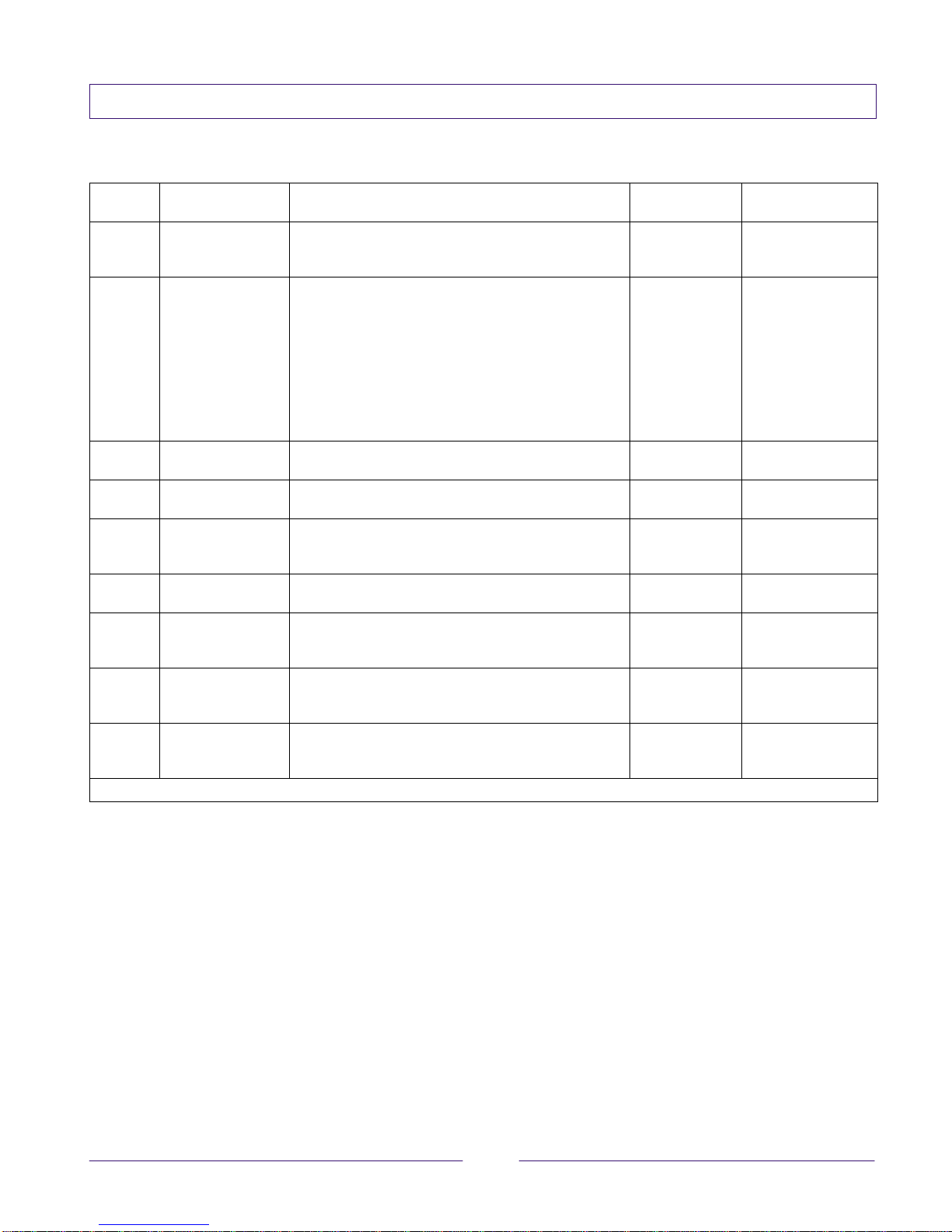

Table 2 Warning/Fault Log Numbers (See Note)

Warning

Number Fault

Number Meaning

not used 0No fault

not used 1Zone below operating

temperature setpoint

2 2 Open RTD

3 3 Shorted RTD

4 4 Zone out of band or

undertemperature

not used 5Defective control board

not used 6Brownout occurred

NOTE: The first number in the multipurpose display

represents the affected zone: 0 = reservoir, 1 = grid,

2–7 = hoses 1–6, and 8–13 = applicators 1–6.

Remember that if you have heated-air zones, that zone

number will be represented as one of the hose or

applicator zone numbers. The second number in the

multipurpose display represents the warning or fault

number.