ILX Lightwave LDM-4616 User manual

User’s Guide

16-Channel Laser Diode Mount

LDM-4616

70027604 May 2011

ILX Lightwave Corporation · 31950 Frontage Road · Bozeman, MT, U.S.A. 59715 · U.S. & Canada: 1-800-459-9459 · International Inquiries: 406-556-2481 · Fax 406-586-9405

ilx.custhelp.com ·www.ilxlightwave.com

TABLE OF CONTENTS

05_11 LDM-4616 i

TABLE OF CONTENTS

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety and Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Information and the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Marking Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Comments, Suggestions, and Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1 Introduction and Specifications

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shipping Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Available Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 Rack Mounting Instructions

Installation Instructions for Rack Mounting Kits . . . . . . . . . . . . . . . . . . . . . . . 5

TABLE OF CONTENTS

ii LDM-4616

Chapter 3 Operation

Connecting the LDM-4616 Mount to a Laser Diode Controller . . . . . . . . . . . . 9

Configuring the Pin Headers to Match Your Laser Pin-Out . . . . . . . . . . . . . 11

Front Panel Fiber Optic Mating Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Changing the Front Panel Mating Adapters . . . . . . . . . . . . . . . . . . . . . . . . . 15

Passing Fiber Through the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting Your Laser Diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inserting Your Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 4 Socket Numbering and Mount Modules

Numbering Sockets When Installing New Modules . . . . . . . . . . . . . . . . . . . . 21

Chapter 5 Maintenance and Safety

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LIST OF FIGURES

05_11 LDM-4616 iii

LIST OF FIGURES

Figure 2.1 Attach Pullout Members to Mount . . . . . . . . . . . . . . . . . . .5

Figure 2.2 Attach Drawer Slides to Frame Rails . . . . . . . . . . . . . . . .6

Figure 2.3 Mount Slide Assemblies to Rack . . . . . . . . . . . . . . . . . . . .7

Figure 3.1 Back Panel TEC Connector . . . . . . . . . . . . . . . . . . . . . .10

Figure 3.2 Back Panel Laser Connector . . . . . . . . . . . . . . . . . . . . . .10

Figure 3.3 Removing Screws and Pulling the Module Forward . . . .12

Figure 3.4 Configuring Pin Headers . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 3.5 Attaching Mating Adapters to the Front Panel . . . . . . . . .15

Figure 3.6 Attaching Mating Adapters Inside . . . . . . . . . . . . . . . . . .16

Figure 3.7 Rubber Grommets Protect Fiber Pass Through . . . . . . .17

Figure 3.8 Mounting the Lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 4.1 Correct Channel Numbering . . . . . . . . . . . . . . . . . . . . . .21

LIST OF FIGURES

iv LDM-4616

LDM-4616 v

SAFETY AND WARRANTY INFORMATION

The Safety and Warranty Information section provides details about cautionary

symbols used in the manual, safety markings used on the instrument, and

information about the Warranty including Customer Service contact information.

Safety Information and the Manual

Throughout this manual, you will see the words Caution and Warning indicating

potentially dangerous or hazardous situations which, if not avoided, could result in

death, serious or minor injury, or damage to the product. Specifically:

Caution indicates a potentially hazardous situation which can result in minor or

moderate injury or damage to the product or equipment.

Warning indicates a potentially dangerous situation which can result in serious injury or

death.

WARNING

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the

instrument until safe operation can be verified by trained service personnel:

•Visible damage

•Severe transport stress

•Prolonged storage under adverse conditions

•Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX

Lightwave distributor, for service or repair to ensure that safety features are

maintained (see the contact information on page ix).

All instruments returned to ILX Lightwave are required to have a Return

Authorization Number assigned by an official representative of ILX Lightwave

Corporation. See Returning an Instrument on page vii for more information.

SAFETY SYMBOLS

vi LDM-4616

SAFETY SYMBOLS

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within

the manual. See the Table of Contents to locate the specifications and other

product information. The following classifications are standard across all ILX

Lightwave products:

•Indoor use only

•Ordinary Protection: This product is NOT protected against the harmful ingress of moisture.

•Class I Equipment (grounded type)

•Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

•Pollution Degree II

•Installation (overvoltage) Category II for transient overvoltages

•Maximum Relative Humidity: <80% RH, non-condensing

•Operating temperature range of 0 °C to 40 °C

•Storage and transportation temperature of –40 °C to 70 °C

•Maximum altitude: 3000 m (9843 ft.)

•This equipment is suitable for continuous operation.

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on

the instrument. These symbols provide information about potentially dangerous

situations which can result in death, injury, or damage to the instrument and other

components.

Caution,

refer to

manual

Earth

ground

Te r m i n a l

Alternating

current

Visible and/or

invisible laser

radiation

Caution, risk

of electric

shock

Protective

Conductor

Te r m i n a l

Caution, hot

surface

Frame or

chassis

Te r m i n a l

On: In position of a bistable push control.

The slash (I) only denotes that mains are on.

Off: Out position of a bistable push control.

The circle (O) only denotes that mains are off.

or

(I)

or

(O)

WARRANTY

05_11 LDM-4616 vii

WARRANTY

ILX LIGHTWAVE CORPORATION warrants this instrument to be free from

defects in material and workmanship for a period of one year from date of

shipment. During the warranty period, ILX will repair or replace the unit, at our

option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse,

modifications, or to use of the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any

implied warranty of merchantability or fitness for any particular purpose. ILX

Lightwave Corporation shall not be liable for any incidental, special, or

consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the

instrument's serial number, and thoroughly describe the nature of the problem.

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

1Obtain a Return Authorization number (RA) from ILX Customer Service.

2Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

3Attach the anti-static protective caps that were shipped with the instrument and place the

instrument in a protective anti-static bag.

4Place the instrument in the original packing container with at least 3 inches (7.5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

5Secure the packing box with fiber reinforced strapping tape or metal bands.

6Send the instrument, transportation pre-paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a

container with at least 3 inches (7.5 cm) of compressible packaging material on all

sides.

Repairs are made and the instrument returned transportation pre-paid. Repairs

are warranted for the remainder of the original warranty or for 90 days, whichever

is greater.

WARRANTY

viii LDM-4616

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or

shortages on the packing list. If the instrument is damaged, file a claim with the

carrier. The factory will supply you with a quotation for estimated costs of repair.

You must negotiate and settle with the carrier for the amount of damage.

WARRANTY

05_11 LDM-4616 ix

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that

you direct any product operation or service related questions or comments to ILX

Lightwave Customer Support. You may contact us in whatever way is most

convenient:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . (800) 459-9459 or (406) 586-1244

Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (406) 586-9405

On the web at: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ilx.custhelp.com

Or mail to:

ILX Lightwave Corporation

P. O. Box 6310

Bozeman, Montana, U.S.A 59771

www.ilxlightwave.com

When you contact us, please have the following information:

If ILX Lightwave determines that a return to the factory is necessary, you are

issued a Return Authorization (RA) number. Please mark this number on the

outside of the shipping box.

You or your shipping service are responsible for any shipping damage when

returning the instrument to ILX Lightwave; ILX recommends you insure the

shipment. If the original shipping container is not available, place your instrument

Model Number:

Serial Number:

End-user Name:

Company:

Phone:

Fax:

Description of what is

connected to the ILX

Lightwave instrument:

Description of the problem:

WARRANTY

x LDM-4616

in a container with at least 3 inches (7.5 cm) of compressible packaging material

on all sides.

We look forward to serving you even better in the future!

LDM-4616 1

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

This manual describes the LDM-4616 and LDM-4616DFB 16-Channel Laser

Diode Butterfly Mounts and related accessories and options, and explains their

operation.

Please read the entire manual to familiarize yourself with the operation of your

LDM-4616 Laser Diode Mount before installing laser diodes. In particular, you

should read the section on Electrical Connections before installing a laser diode.

The information contained in that section is necessary to provide correct electrical

connection to your particular laser

Note: When unpacking the mount, be sure to save the packaging in case you have to

return the mount to ILX Lightwave or ship is elsewhere. Shipping damage is not covered

under the standard warranty.

Product Overview

The LDM-4616 Laser Diode Mount allows convenient mounting for up to 16 lasers

in 14-pin butterfly (“flat-pack”) packages. Configurable pin headers (terminal

blocks) must be wired properly to accommodate your particular laser pin

configuration, unless you have the LDM-4616DFB version which has a fixed pin

configuration. Four integrated fiber spools manage excess pigtail fiber. Fiber optic

mating adapters on the front panel can be changed to match your fiber connector

style. The mating adapters can be replaced with rubber grommets for feeding fiber

directly through the front panel. Any unused ports can be covered with the plugs

supplied in the shipping kit. The LDM-4616 was designed to install in a standard

19” rack with slide rils that allow easy access to your lasers. There is a large

finned heat sink and removable cover included.

Standard ILX Lightwave cables, which are terminated with paired 9-pin D-sub

connectors, connect easily to any ILX Lightwave current source and temperature

controller. The mount was specifically designed to enhance the value of ILX

Lightwave’s LDC-3916 16-Channel Laser Diode Controller. Electrical signals are

bussed from 9-pin D-sub connectors on the back of the mount to the configurable

INTRODUCTION AND SPECIFICATIONS

Product Overview

2 LDM-4616

CHAPTER 1

pin headers. Wiring is provided for controlling the lasers internal thermo-electric

modules as well as laser drive current.

The LDM-4616 mount housing is grounded through pin 3 on the 9-pin D-sub

connector for the Channel 1 current source. The housing tray includes a

grounding receptacle for a wrist strap, as well as a grounded laser tray cover.

Pin 3 of the 9-pin D-sub connector for Channel 1 laser current must be connected to

ground for the mount chassis to be grounded. Standard ILX Lightwave cables and

instruments will have the laser connector pin 3 connected to chassis ground.

Shipping Kit

When you receive your LDM-4616 or LDM-4616DFB Laser Diode Mount, verify

that the following items were included with the shipping kit:

•(1x) 5/64” hex socket wrench

•(1x) 3/32” hex socket wrench

•(1x) 2.5 mm x 2” screwdriver (LDM-4616 only)

•(32x) 2-56 x 3/16” screws

•(16x) metal plugs for front panel holes

•(16x) 9-wire packs for configuring pin headers (LDM-4616 only)

INTRODUCTION AND SPECIFICATIONS

Product Overview

05_11 LDM-4616 3

CHAPTER 1

Available Options and Accessories

Additional Configuration

In addition to the butterfly packaged laser mount shown in this manual, other

mounting options are available. Please contact ILX Lightwave for information on

other mount configurations, such as DIL packaged modules, etc.

DESCRIPTION MODEL NUMBER

16 Channel Laser Diode Butterfly Mount with configurable pins LDM-4616

16 Channel Laser Diode Butterfly Mount with fixed pin configuration LDM-4616DFB

Right Side DIL Laser Diode Mount Module LDM-4604/RDIL

Left Side DIL Laser Diode Mount Module LDM-4606/LDIL

Right Side Butterfly Laser Diode Mount Module LDM-4604/RBFY

Left Side Butterfly Laser Diode Mount Module LDM-4606/LBFY

Right Side Fixed Pin-Out DFB Butterfly Laser Diode Mount Module LDM-4604/RDFB

Left Side Fixed Pin-Out DFB Butterfly Laser Diode Mount Module LDM-4604/LDFB

16 Channel Laser Diode Mount Chassis LDM-4600

Slide Rail Rack Mounting Kit (20.5” hole spacing) RM-141

Slide Rail Rack Mounting Kit (25” hold spacing) RM-142

Mating Adapter:

FC-APC / FC-APC, Wide / Wide keys = N/N = 2.15mm / 2.15 mm MA-401

Mating Adapter:

FC-APC / FC-APC, Narrow / Wide keys = R/N = 2.05mm / 2.15 mm MA-402

Mating Adapter:

FC-APC / FC-APC, Narrow / Narrow keys = R/R = 2.05mm / 2.05 mm MA-403

Mating Adapter:

FC-APC / SC-APC, Wide key = N = 2.15mm MA-404

Current Source to Mount Interconnect Cable CC305S

Rack Optimized 8-cable Bundle (CS to Mount) CC316M

TEC to Mount Interconnect Cable CC505S

Rack Optimized 8-cable Bundle (TEC to Mount) CC516M

INTRODUCTION AND SPECIFICATIONS

Specifications

4 LDM-4616

CHAPTER 1

Specifications

In keeping with our commitment to continuous improvement, ILX Lightwave

reserves the right to change specifications without notice and without liability for

such changes.

Laser Package Styles Supported

14-pin Butterfly, DIL and Mini-DIL

Laser Package Socket

16 Zero Insertion Force (ZIF) sockets

LDM-4616 has user configurable pin-headers (terminal blocks) for configuring multiple laser pin-outs

LDM-4616DFB has the following fixed pin configuration:

Pin 1: Thermistor Pin 8: Laser Anode (case)

Pin 2: Thermistor Pin 9: Laser Anode (case)

Pin 3: Laser Cathode Pin 10: Laser Anode (case)

Pin 4: PD Monitor Anode (-) Pin 11: Laser Anode

Pin 5: PD Monitor Cathode (+) Pin 12: N/C (float)

Pin 6: TEC (+) Pin 13: Laser Anode

Pin 7: TEC (-) Pin 14: Lasr Anode (case)

Electrical Input Specifications

Maximum Laser Current 3 Amps

Maximum TEC Current 3 Amps

Input Connectors

Current Source 9-pin, D-Sub, female (16 on top)

Temperature Controller 9-pin, D-Sub, male (16 on bottom)

Thermal

Sockets are thermally connected to a finned heat sink.

Thermal Resistance: 0.41 oC/Watt (natural convection in open space)

0.17 oC/Watt (moving air in thermal chamber)

General

Size 3.38” x 18.97” x 23.9” (including drawer slides)

86mm x 482mm x 607mm

2U high in standard 19” rack

Tray Depth 17.52” plus 1” handle

Weight 12.7 kg (28 pounds)

LDM-4616 5

CHAPTER 2

RACK MOUNTING INSTRUCTIONS

The LDM-4616 Laser Diode Mount was designed to be installed in standard 19”

wide racks using slide rails for easy access. There are two different ILX Lightwav

rack mounting kits for two depths of racks. The RM-141 rack mounting kit is for

racks with 20.5” spacing depth on the rack frame. The RM-142 is for racks with

25% spacing depth on the rack frame.

Installation Instructions for Rack Mounting Kits

Remove the pullout members from both drawer slides by extending the inner most

section to its maximum and then depressing the retaining clip while sliding the

pieces apart. Attach the two pullout members to each side of the LDM-4616 with

the eight 8-32 x 3/16” pan head Phillips screws. See Figure 2.1.

Figure 2.1 Attach Pullout Members to Mount

RACK MOUNTING INSTRUCTIONS

6 LDM-4616

CHAPTER 2

Attach the drawer slides to the fram rails using four of the 8-32 x 3/8” pan head

Phillips screws and 8-32 hex nuts. Make sure the correct holes are lined up.

See Figure 2.2 You may need to push on the drawer slide latch to release the

sliding mechanism.

Figure 2.2 Attach Drawer Slides to Frame Rails

If you want to secure your LDM-4616 mount shut in the rack so it does not slide

open, install the two 10-32 speed nuts to the front vertical columns of the rack.

Mounting location would be in the same horizontal plane as the drawer/frame

slides. This allows the LDM-4616 to be secured shut in the rack with the two 10/32

x 1/2” ornamental screws when desired.

Next, mount the slide assemblies to the vertical columns of the rack using four of

the 8-32 x 3/8” pan head Phillips screws and 8/32 hex nuts. The slide mechanism

will have to be moved back and forth until you see the mounting hole in the frame

rail through the large hold in the drawer slide. See Figure 2.3.

Carefully insert the pullout members on the LDM-4616 into the drawer slides

within the rack. Note the initial insertion into the rack will seem tight. Smooth easy

travel should resume after initial insertion.

RACK MOUNTING INSTRUCTIONS

05_11 LDM-4616 7

CHAPTER 2

If removal from the rack is required, pull the LDM-4616 out to its maximum

extension and depress the retaining clips which are exposed on each pullout

member, allowing for removal.

Figure 2.3 Mount Slide Assemblies to Rack

RACK MOUNTING INSTRUCTIONS

8 LDM-4616

CHAPTER 2

Table of contents

Popular Computer Hardware manuals by other brands

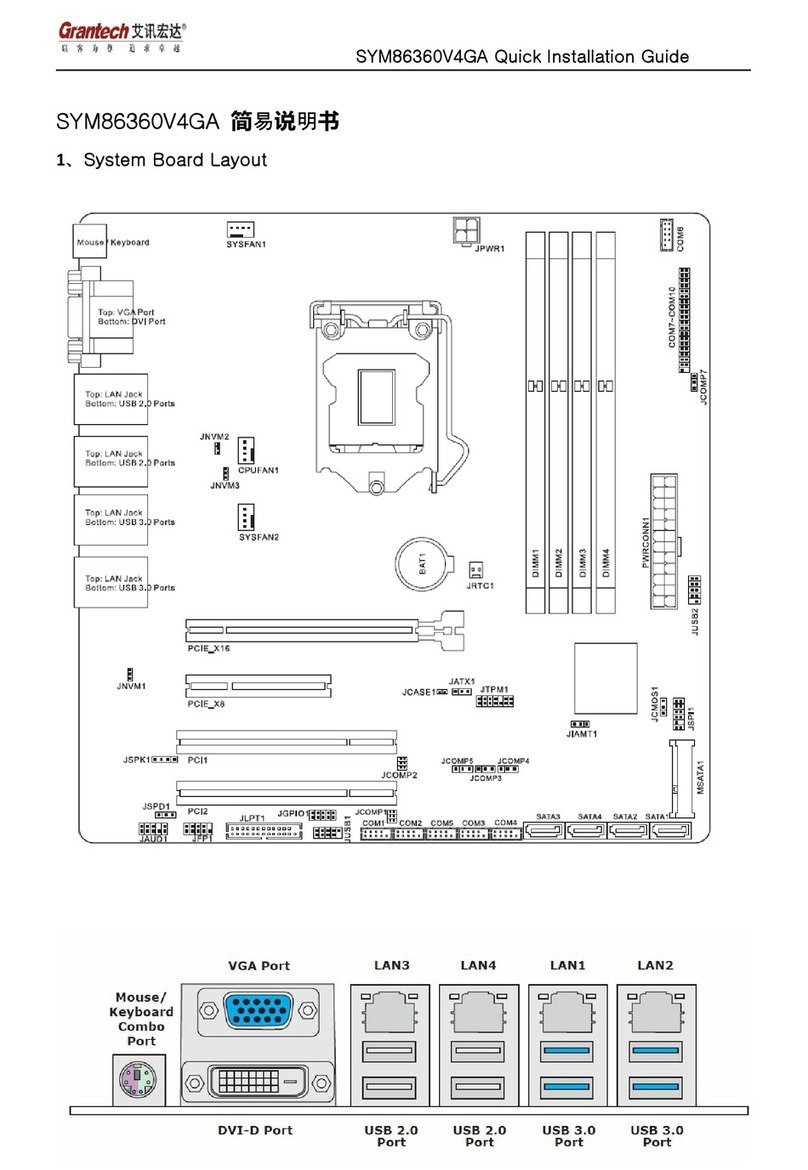

Grantech

Grantech SYM86360V4GA Quick installation guide

Koolance

Koolance EX2-755 user manual

Sony Ericsson

Sony Ericsson CM-42 Integrator's manual

Rabbit

Rabbit 2000 Designers handbook

Moxa Technologies

Moxa Technologies Industrial Serial Board CI-132 Quick installation guide

NXP Semiconductors

NXP Semiconductors Androidi.MX 8M Mini quick start guide