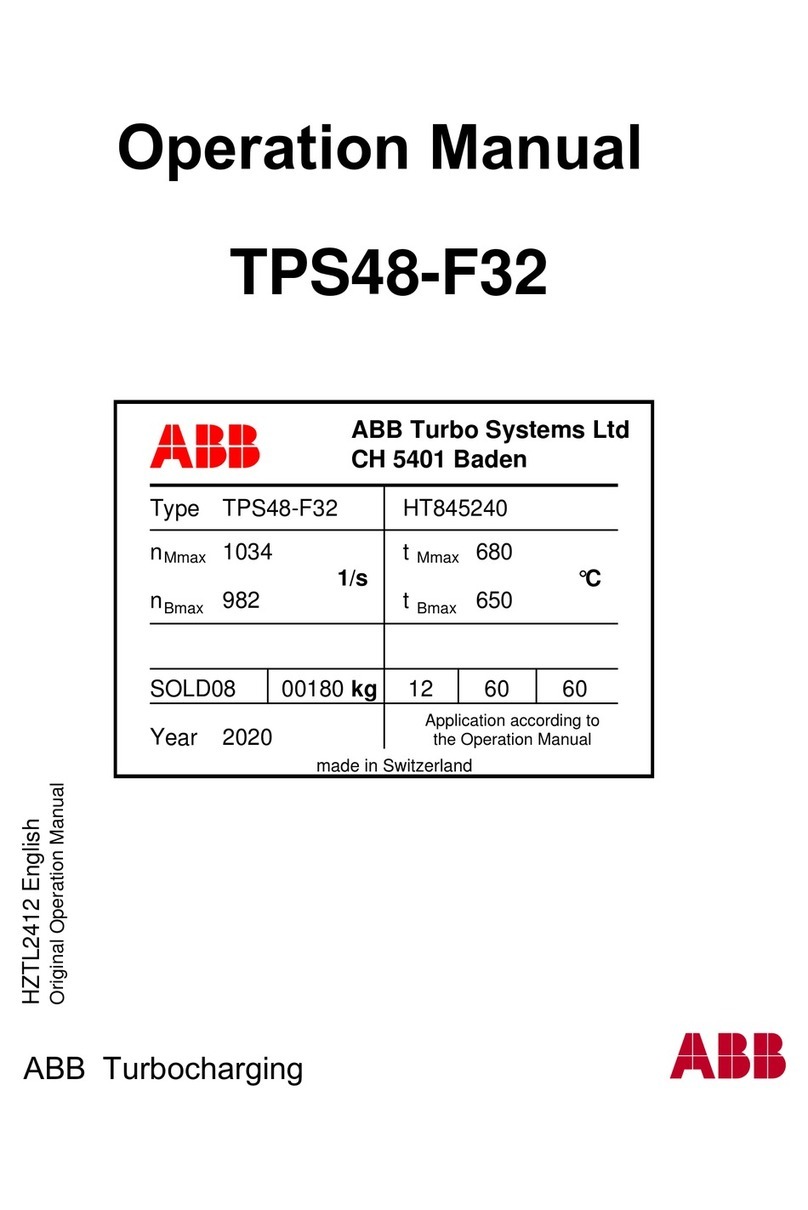

The handle can be removed by

loosening the locking screw.

To keep the handle mounted

permanently, make sure that

the locking screw is fully

tightened.

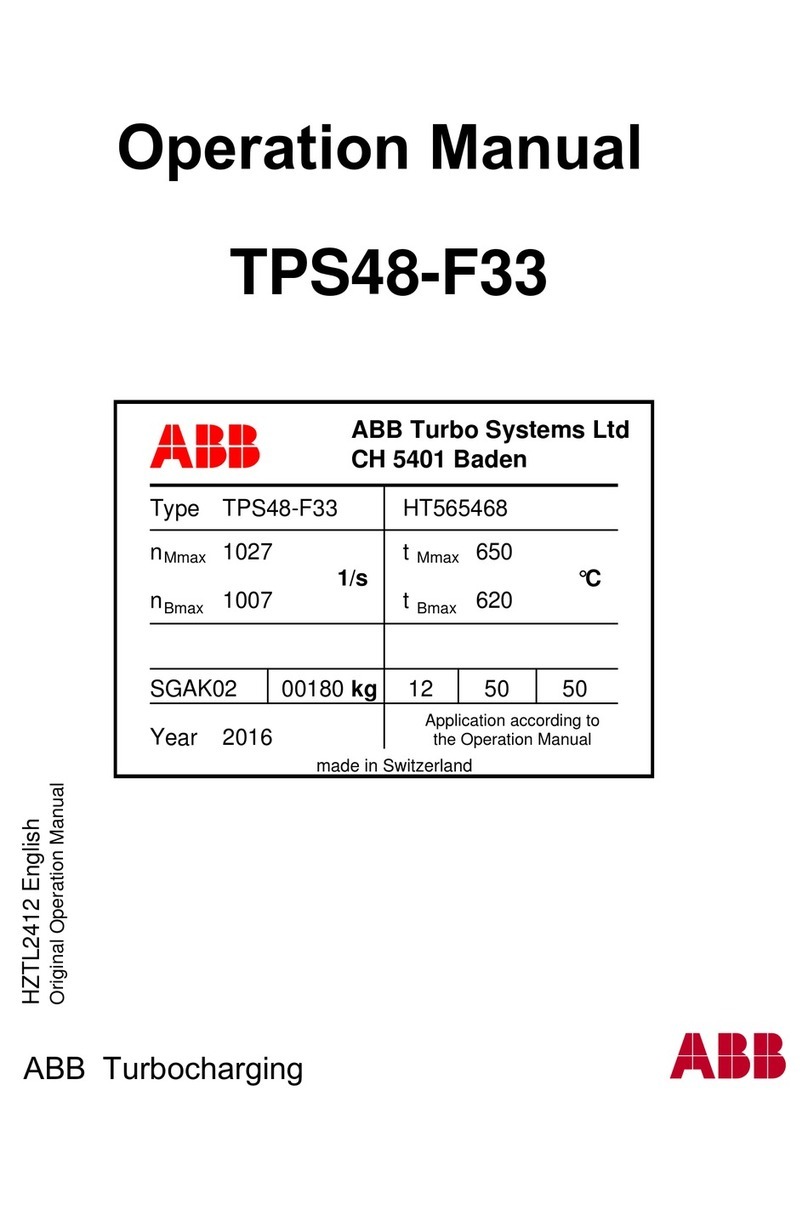

Part Number

Clamping

Direction

Clamping

Stroke

H1

Clamping Height

W1W2M1L2L1L3D M Dp H

QLSWH400R

CW

1.2 70~80 13 16

M 8×1.25

42 50 20 40

M6×1 Depth 12

28

120

QLSWH400L

CCW

QLSWH500R

CW

1.6 80~90 18 24

M12×1.75

48 60 25 50

M8×1.25 Depth 16

35

137

QLSWH500L

CCW

Part Number

W

H2D1H3R D2H4L4

Allowable Operating

Load (N) *)

Clamping

Force (kN)

Clamping

Mechanism

Weight

(kg)

QLSWH400R

40 22 38 16

125

23 30 39

600

3.5

Spiral Cam

Cam Angle: 2°

1.1

QLSWH400L

QLSWH500R

50 25 48 20

160

28 38 47 6.0 2.0

QLSWH500L

*) Allowable load to operate the handle

Clamp Arm

Tip Wrench

Adjustment Knob

Clamp Starting

Position

How To Use

When installing a tip on the clamp arm, lock the

clamp arm using a wrench to prevent it from

receiving any torque.

1. Load a workpiece. 2. Turn the adjustment

knob for the clamp

arm to rotate 90°.

3.

Continue turning the adjustment

knob for the clamp arm to go

down against the workpiece, for

temporary clamping.

4. Turn the handle for

full clamping.

(For unclamping, follow

the above steps back)

Countersink

When Handle Is Removed

L

4

Locking Screw

Continuing to next page

■Operation of CW Type (Invert the operation for CCW type.)

■Tip Installation