IMKO SONO-VIEW User manual

SONO-View

Manual

More Information:

www.imko.de

Moisture Sensor Experts

2

Thank you very much for your decision to purchase

this IMKO product

Should you have any queries please don´t hesitate to contact your local distributor or address

directly to IMKO.

SONO-VIEW:

Stand-alone display for the reliable control and configuration of processes using SONO moisture probes.

A total of up to 4 SONO probes can be monitored and the respective measurement values presented at

the LCD via a serial interface.

3

List of Contens

1General Notices................................................................................................................................4

1.1 Intended Use............................................................................................................................4

2Control Elements / Connections.......................................................................................................5

2.1Control Elements .....................................................................................................................5

2.2 Connections..............................................................................................................................5

3Initial Commissioning........................................................................................................................6

3.1 Safety Instructions....................................................................................................................6

3.2 Checking the Package Content for Completeness ..................................................................6

3.3 Connection ...............................................................................................................................6

4Operation..........................................................................................................................................8

4.1 Initial and New Installation........................................................................................................8

4.2Measurement Value Display ....................................................................................................9

4.3 Settings.................................................................................................................................. 10

4.3.1 New Installation ............................................................................................................. 10

4.3.2 Language....................................................................................................................... 10

4.3.3 LCD Contrast................................................................................................................. 11

4.3.4 Info................................................................................................................................. 11

4.3.5 USB/IMP-Bridge ............................................................................................................ 11

4.4 Probe Settings....................................................................................................................... 12

4.4.1 Sensor Info .................................................................................................................... 13

4.4.2 Material Calibration........................................................................................................ 13

4.4.3 Offset Balancing ............................................................................................................ 18

4.4.4 Averaging Mode ............................................................................................................ 19

4.4.5 Averaging Parameters................................................................................................... 20

4.4.6 Basic Balancing............................................................................................................. 22

5Technical Data............................................................................................................................... 23

6Safety Notes.................................................................................................................................. 24

4

1 General Notices

Please carefully read and get acquainted with these operating instructions.

Should any queries arise, please contact our service department under the contact data depicted above.

Do not, under no circumstances, attempt to open or repair the device yourself. In the event of any

warranty claims, please refer these to the retailer you purchased the device.

The device is subject to technical and optical change within the scope of product improvement.

1.1 Intended Use

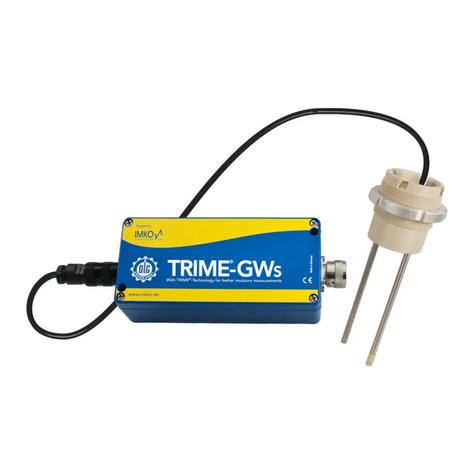

This device was developed to serve as a display and configuration device for various IMKO probes.

Only the respectively intended probes may be connected to the device. The connection of any probe

which is not intended for the device, can lead to damage or the destruction of this device and/or the

connected probe.

5

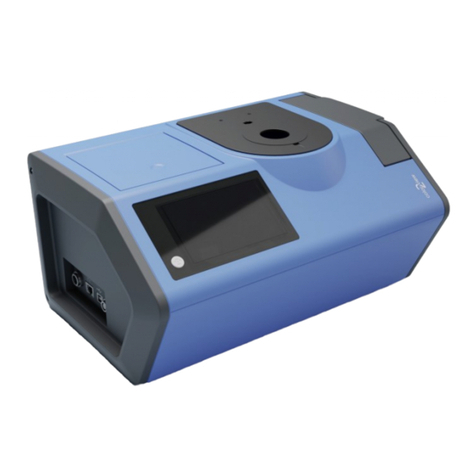

2 Control Elements / Connections

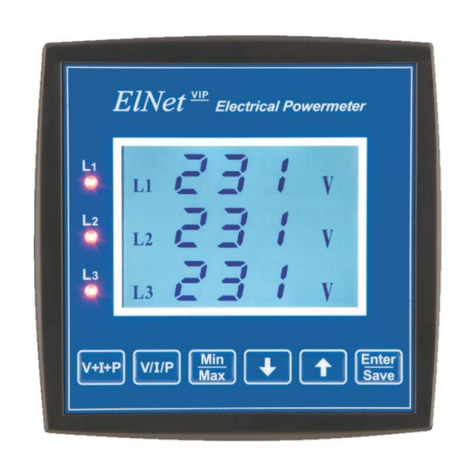

2.1 Control Elements

2.2 Connections

USB (Type-Mini B)

USB-IMP-Bridge

Firmware Update

Supply Voltage

Bus-Interface

6

3 Initial Commissioning

3.1 Safety Instructions

Attention: It is strictly necessary to read the General Notices contained under Item I at the beginning of

the operating instructions. Any not intended use of the device can lead to damage to this device.

3.2 Checking the Package Content for Completeness

•SONO-VIEW

•Terminal Block

•USB Cable (Type A →Mini B)

3.3 Connection

For operation, the SONO-VIEW requires a supply voltage of 7...24V (approx. 80..30mA). A joint ground

wire together with the probes is not required. For the connection with the probes, it is sufficient to merely

connect the two bus lines „RT“and „COM“.

NOTE:

The SONO-VIEW is suited for the display and configuration of up to four probes. Should more

than four probes be connected, an error message will be generated, and the device cannot

operate correctly.

0V

+7..24V

(RT) IMP-Bus

(COM) IMP-Bus

7

Example 1:

Connection of the SONO-VIEW with two SONO probes and one joint voltage supply source.

Example 2:

Connection of the SONO-VIEW with 2 SONO-probes merely via IMP-bus. SONO-VIEW and the probes

dispose of their voltage supply. This may be useful, if the distance between the measuring equipment

and the display device is considerable.

8

4 Operation

4.1 Initial and New Installation

At the initial connection to your probe-network, it is necessary to set the same up, respectively follow an

installation procedure at the SONO-VIEW.

For this purpose, the device will scan the IMB bus for

connected probes.

Initiate the installation with the button .

After an instant, the serial numbers of all connected

probes are listed in the display.

In order to maintain the clarity within the administration

of the probes, the SONO-VIEW operates on the basis

of assigned probe numbers (1...4).

These must be allocated to the detected serial numbers

in the next step. For each probe number, select a serial

number using the / buttons and subsequently

acknowledge the same with the button .

Repeat this procedure until all serial numbers have

been allocated a probe number.

After completion of the above steps, all probe numbers

will be presented once more together with the

respectively allocated serial numbers in ascending

order.

Complete the installation process with the button .

9

NOTE:

The SONO-VIEW is suited for the display and configuration of up to four probes. Should more

than four probes be connected, an error message will be generated, and the device will not be

able to operate properly.

After completion of the installation process, the SONO-VIEW will re-start, verify the connected probes,

and will immediately commence to call up the measurement values.

4.2 Measurement Value Display

The SONO-VIEW immediately commences to call up and display the measurement values after start-

up. This is performed in a 500 ms cycle. Depending on how many probes are connected, from one to

four, the following displays will be presented.

The moisture value in percent and the respective probe number is always presented. If two or three

probes are connected, the temperature measured by the probe is additionally also presented. In the

event that only one probe is connected, the calibrated radar run-time is also presented.

If more than one probe is connected to the SONO-VIEW, there is an option to change the display. For

this purpose, actuate the buttons / . Subsequently, all connected individual probes are presented

consecutively.

For the purpose of allocation, the probe number is always also presented in the upper section. If this

form of display is maintained for a longer period, the same will be assumed as „Standard“. In this case,

the SONO-VIEW will present this set measurement display form after a re-start.

10

4.3 Settings

Actuate the button while the measurement display is active and you will reach the setup menu. Here,

you are enabled to perform various settings and call up information regarding the SONO-VIEW.

The setup menu features the following structure:

Setting

Description

New Installation

Enables a new detection of connected probes

Language

Setting of the language

LCD Contrast

Setting of the display contrast

Info

Serial number and further information regarding your SONO-VIEW

USB/IMP-Bridge

Enables the comfortable configuration of your probes via PC

Set the desired setting using the buttons / . By actuating the button , you can subsequently enter

the selected setting. Actuate the button again in order to exit the setup menu.

4.3.1 New Installation

See Section 4.1 „Initial and New Installation “

4.3.2 Language

The selection of the language is performed with the buttons / . By actuating the button , the

selected language is set as the standard language. To exit the menu item “Language”, actuate the

button .

11

4.3.3 LCD Contrast

A bar containing a grey colour gradation will appear.

4.3.4 Info

4.3.5 USB/IMP-Bridge

As soon as this menu item is called up, the SONO-VIEW changes into a transparent data mode. All data

packets will be now redirected from the USB interface directly on to the IMP-bus and vice versa. This

enables a comfortable configuration of the probes via a connected PC without the necessity of additional

hardware. For this purpose, please download the free software „SonoConfig“as well as the respective

operating instructions available on the IMKO-homepage.

Connect the SONO-VIEW to the PC using the provided USB cable. The SONO-VIEW will connect with

the PC as a virtual serial interface (COM-Port). The respectively required driver is usually automatically

installed by all currently used Windows versions. Should the driver not be automatically installed, please

download the driver under:

http://www.ftdichip.com/Drivers/VCP.htm.

NOTE:

As long as the SONO-VIEW is in the USB-IMP-Bridge modus, no measurement values are queried

by the probe. The probes however continue to measure and issue the measurement value at the

analogue output.

Actuate the button in order to exit the menu item „USB/IMP-Bridge“.

Set the contrast using the buttons / in a manner

that enables you to recognise all grades. Store the set

value with the button . To exit the menu item „LCD

Contrast“, actuate the button .

The device will present the serial number, the HW-

version, the IBT version, as well as the firmware version.

By actuating the button , the device will present further

status information such as the currently connected probes

and system voltage values. To exit the menu item „Info“,

actuate the button .

12

4.4 Probe Settings

The SONO-VIEW offers the option to comprehensively configure the connected probes even without

PC. Settings such as offset displacements or the selection of a material-specific calibration can be

simply adjusted with the buttons / .

The menu “Probe Settings” respectively offers the following options:

Setting

Description

Sensor Info

Presents information regarding the connected probe

Material Calibration

Selection of a material-specific calibration

Offset balancing

Displacement of the measurement value

Average Mode

Setting of the method of averaging

Average Parameter

Setting of the parameters of the set averaging method

Basic balancing

„Zero Value“ calibration of the probe in ambient air

To reach the probe settings, select the individual probe display mode for the probe intended for

configuration in the measuring display using the / buttons (also see Item 4.2). By actuating the

button , the probe setting of the currently used probe is called up.

NOTE:

It is only possible to configure one probe at a time. Should several probes require to be

adjusted, the procedure must be respectively repeated for these other probes.

Attention:

Ensure that the correct probe is set before commencing with adjusting the parameters.

The SONO-VIEW offers the option to access the measuring parameters of the probe. Before adjusting

any parameters, please inform yourself precisely in regard to the function of the same in the respective

probe manual. Any performed changes may affect the measurement value, the accuracy, and the

measuring rate.

13

4.4.1 Sensor Info

If this menu item is selected, various information of the probe is called up and displayed.

4.4.2 Material Calibration

The menu item „Material Calibration“enables to adjust a material-specific calibration stored in the probe.

This enables to significantly increase the accuracy of the measurement.

There are up to 15 material-specific calibrations deposited in the firmware of a SONO probe. These are

presented here and can be selected with the buttons / . The character „1“ set in front of a calibration

hereby points out the current standard calibration.

Store the selected calibration as standard in the probe using the button . The set calibration will

subsequently be stored in the non-volatile memory of the probe. The menu item “Material calibration” is

exited by actuating the button .

4.4.2.1 Choose

The sub-item "Select" allows you to select between up to 15 material-specific calibrations.

You can exit the menu item „Sensor Info” with the

button .

After selecting the menu item "Material cal.", use the

/ buttons to "CHOOSE" one of the 15 stored

material-specific calibrations or "CHANGE" to

perform a new calibration on one of the 15

calibration memories. The corresponding sub-point

is selected with the key and the key leaves

this menu point.

Use the / buttons to select between the

material-specific calibrations. The "!" shows the

current standard calibration before calibration. Save

the selected calibration with the button as a

standard in the probe. The setted calibration curve is

not stored in the probe. By pressing the key , you

can leave this sub-item "Select" again.

14

4.4.2.2 Change

The "CHANGE" sub-point allows you to perform a 1-point calibration or 2-point calibration.

4.4.2.2.1 1-Point

With this material calibration option, a linear equation (f (x) = mx + b) is calculated with the dry density.

So it is necessary to have the dry density of the measured material before activating this option. A

reference moisture content and the tp value (propagation time of the radar signal) which can be

measured or set at the point of the reference moisture.

Even if a polynomial of higher degree is useful for obtaining greater accuracy, the linear equation is

often sufficient to achieve very good results.

NOTE:

To perform a 1-point calibration, you need a material sample as well as the dry density of the

material to be measured. The moisture value has to be determined with another method like kiln

drying or similar, before activating this calibration procedure.

Procedure:

Use the / buttons to toggle between 1-point

calibration and 2-point calibration. The corresponding

procedure is executed with the key and the key is

for finishing this procedure.

At the beginning of the calibration, the selected

calibration memory (01 - 15) has to be overwritten with

the / buttons. Press the button to accept the

setting and press the button to move to the previous

item.

The percentage reference moisture of the material to

be measured, must then be set with the /

buttons. Press the button to accept the setting and

press the button to move to the previous item.

In the following step, the dry density of the material to

be measured must be set with the / buttons.

Press the button to accept the setting and press the

button to move to the previous item.

15

In the next step, the tp value (radar signal time) has to be determined by a measurement with the

connected probe or by manual setting with pre-determined tp values.

Measure tp:

Set tp:

Use the / buttons to select between "Measure"

and "Set". The corresponding sub-point is selected

with the key and the key can be used to switch

to the previous point.

Press the key to start the tp measurement and

press the key to move to the previous point.

After starting the measurement with the key , the

mean value of 10 measured tp values is formed.

During this phase, the SONO-View does not respond

to any input.

After completion of the measurement, the tp mean

value is displayed. Press the key to accept the

measured value and press the key to move to the

previous point.

The tp value can be adjusted manually using the /

buttons. Press the button to accept the setting and press

the button to move to the previous item.

16

In the last step, the calibration settings can be saved with "Save" to the previously selected calibration

memory location, or can be canceled with "Discard".

NOTE:

After performing "Save", the original material calibration is preceded by an "OWN:", indicating

that this is a specially prepared material calibration.

4.4.2.2.2 2-Point

For the 2-point, a linear equation (f (x) = mx + b) can be calculated with two moisture values of a material

and the corresponding tp values (running times of the radar signal) which are measured or set at the

respective material moisture. Even if a polynomial of a higher degree is useful for obtaining greater

accuracy, the straight line equation is often sufficient to obtain very good results.

NOTE:

In order to perform a 2-point material calibration, you need two material samples with different

moisture values. Moisture values should be determined by another method like kiln drying or

similar, before activating this calibration procedure. The sequence - "lower moisture value"

(more dry material) and then - "upper moisture value" (moist material) must be observed.

Procedure:

In the next step, the tp value (radar signal time) has to be determined by a measurement with the

connected probe at the lower moisture point or by manual setting with pre-determined tp values.

Use the / buttons to toggle between "Save" and

"Discard". The corresponding sub-point is selected

with the key and the key can be used to switch

to the previous point

Subsequently, the percentage moisture value at the

lower point of the material to be measured, must be set

with the / buttons. Press the button to accept

the setting and press the button to move to the

previous item.

After selecting the menu item "Material cal.", use the

/ buttons to "CHOOSE" one of the 15 stored

material-specific calibrations or "CHANGE" to perform

a new calibration on one of the 15 calibration

memories. The corresponding sub-point is selected

with the key and the key leaves this menu point.

17

Measure tp:

See point „4.4.2.2.1“ Measure tp

Set:

The next step is to determine the tp value (radar signal time), of the upper moisture value, a

measurement (with the connected probe) or manual setting.

Subsequently, the percentage moisture value at the

lower point of the material to be measured, must be set

with the / buttons. Press the button to accept

the setting and press the button to move to the

previous item.

The tp value of the lower moisture point can be setted

manually using the / buttons. Press the button

to accept the setting and press the button to move to

the previous item.

The percentage reference moisture of the upper point

of the material to be measured, must then be set with

the / buttons. Press the button to accept the

setting and press the button to move to the previous

item.

Use the / buttons to select between "Measure"

and "Set". The corresponding sub-point is selected

with the key and the key can be used to switch

to the previous point.

18

Measure tp:

See point „4.4.2.2.1“ Measure tp

Set:

In the last step, the calibration settings can be saved with "Save" to the previously selected calibration

memory location, or can be canceled with "Discard".

NOTE:

After performing "Save", the original material calibration is preceded by an "OWN:", indicating

that this is a specially prepared material calibration.

4.4.3 Offset Balancing

In order to compensate measurement errors e.g. due to density deviations in the material or due to the

installation conditions, there is an option to perform a linear displacement of the measurement value.

This is the purpose of this menu item. It is possible to displace the measurement value between -10 and

+10 percent points. The set displacement is stored in the probe and will subsequently also affect the

analogue output. The setting is maintained in a traceable manner.

Adjust the offset to the desired value using the

buttons / . Subsequently store the set value in

the probe with the button . You can exit this menu

item with the button .

The tp value for the upper moisture value can be

adjusted manually using the / buttons. Press the

button to accept the setting and press the button

to move to the previous item.

Use the / buttons to toggle between "Save" and

"Discard". The corresponding sub-point is selected

with the key and the key can be used to switch

to the previous point.

19

4.4.4 Averaging Mode

This menu item allows you to switch on or switch over a measurement averaging in the moisture probe.

The configuration of SONO- probe is present in the factory before delivery. SONO moisture probes offer

the following options:

Mode CC: (Cyclic Cumulated)

With automatic summation of a moisture quantity during one batch process.

Mode CH: (Cyclic Hold)

Similar to Mode CC but without summation.

Mode CH is recommended for applications in the construction industry.

If the SONO-probe is installed under a silo flap, Mode CH can measure moisture when batch cycles are

very short, down to 2 seconds. Mode CH executes an automatic filtering, e.g. if dripping water occurs.

Mode CA: (Cyclic -Average-Filter)

For relative short measuring processes with continual average value, filtering and an accuracy of up to

0.1%

Mode CK: (Cyclic -Kalman-Filter with Boost)

Standard setting for SONO-MIX for use in fresh concrete mixer with continual average value with special

dynamic Kalman filtering and an accuracy of up to 0.1%.

Mode CS: (Cyclic -Successive)

For very short measuring processes (e.g. 2…10 seconds) without floating average and without filter

functions, with internal up to 100 measurements per second and a cycle time of 250 milliseconds at the

analogue output. Measurement mode CS can also be used for getting raw data from the SONO-probe

without averaging and filtering.

Mode CF: (Cyclic -Float-Average)

For continual average value with filtering and an accuracy of up to 0.1% for very slowly measuring

processes, e.g. in fluidized bed dryers, conveyor belts, etc.

NOTE:

Please also refer to the information in your Probe User's Manual

Use the / buttons to set the desired "Average

Mode" and then set the mode as the default with the

button . The setting is then stored in the probe.

Press the button to exit the "Average Mode" menu

item.

20

4.4.5 Averaging Parameters

Depending on the set „Averaging Mode“, there are various „Average Parameters“ available for control

purposes.

Averaging Mode

Available Parameters

CC –Cyclic Cumulate

Average Time

Filter Upper Limit Offset

Filter Lower Limit Offset

Upper Limit Keep Time

Lower Limit Keep Time

Moisture Threshold

No Material Delay

Boost

Offset

Invalid Measure Count

CH –Cyclic Hold

Average Time

Filter Upper Limit Offset

Filter Lower Limit Offset

Upper Limit Keep Time

Lower Limit Keep Time

Moisture Threshold

No Material Delay

Boost

Offset

Weight

Invalid Measure Count

CA –Cyclic Average

Average Time

Filter Upper Limit Offset

Filter Lower Limit Offset

Upper Limit Keep Time

Lower Limit Keep Time

Invalide Measure Count

CK –Cyclic Kalman

Average Time

Filter Upper Limit Offset

Filter Lower Limit Offset

Upper Limit Keep Time

Lower Limit Keep Time

Q-Parameter

R-Parameter

Kalman with Boost

Boost

Offset

Offset with Moist Average

Other manuals for SONO-VIEW

2

Table of contents

Other IMKO Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Proline Promass I 300 PROFIBUS PA operating instructions

ADTEK

ADTEK CS2-SG manual

VIDA TECH

VIDA TECH F7012 installation manual

ROOTECH

ROOTECH Accura 3300 user guide

ICP DAS USA

ICP DAS USA PM-3133i user manual

MAGEE Scientific

MAGEE Scientific Aethalometer AE33 quick start guide