10

1-7

INSTALLERUSER

MAINTENANCE TECHNICIAN

1.7 COMMISSIONING THE DEVICE.

System lling. Once the device is connected, ll

the system via the boiler lling valve.

Filling is performed at low speed to ensure the

release of air bubbles in the water via the boiler

and central heating system vents and the distri-

bution manifold (if any).

Close radiator vent valves when only water

escapes from them.

Close the lling cock when the boiler pressure

gauge indicates approx. 1.2 bar.

IMPORTANT: during these operations, start

the circulation pumps by acting on the main

switch positioned on the boiler control panel

aer having activated the T.A. devices relating

to the various zones.

(Only for DIM H-LT and H-2LT).

Act manually on the 3-way mixing vale using the

relevant lever on the electric actuator, keeping the

same opening in order to de-aerate the system

and, if necessary, control the correct operating

pressure.

Once these operations are complete, make sure

that the lever on the electric actuator is free from

the manual lock position.

1.8 CIRCULATION PUMP.

e pump is ideal for the requirements of each

central heating system in a domestic and residen-

tial environment. In fact, the pump is equipped

with electronic control that allows you to set

advanced functions.

Adjustments. Turn the selector and position it on

the desired curve to adjust the circulator pump.

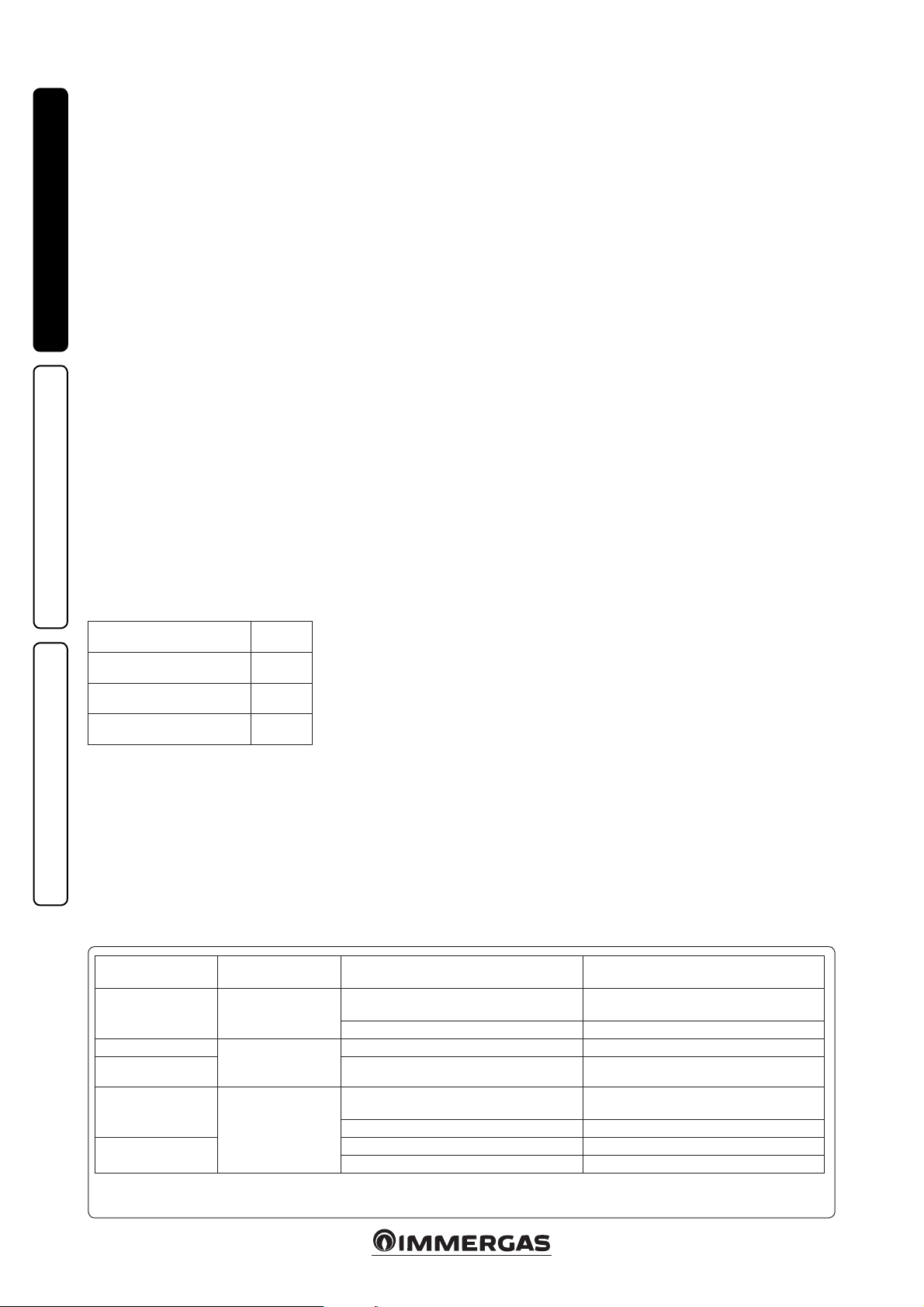

Program LED

P 1 lower (ΔP-V)

P 2 upper (ΔP-V) green

C 3 lower (ΔP-C) - H=3 m

C 4 upper (ΔP-C) - H=4 m orange

Min. - Max. blue

- Program P (1 lower 2 upper ) (P-V) - Pro-

portional curve (green LED). This allows

the pressure level (head) to be proportionally

reduced as the system heat demand decreases

(ow rate reduction). anks to this function,

the electric power consumption of the cir-

culator pump is reduced further: the energy

(power) used by the pump decreases accord-

ing to the pressure level and ow rate. With

this setting, the pump guarantees optimal

performance in most heating systems, thereby

being particularly suitable in single-pipe and

two-pipe installations. Any noise originating

from the water ow in the pipes, valves and

radiators is eliminated by reducing the head.

Optimal conditions for thermal comfort and

acoustic well-being.

- Programs C (3 lower 4 upper ) (P-C) -

Constant curve (orange LED). e circulator

pump maintains the pressure level (head)

constant as the system heat demand decreases

(ow rate reduction). With these settings, the

circulator pump is suitable for all oor systems

where all the circuits must be balanced for the

same drop in head.

- MIN. - MAX. program (blue LED). e pump

is distinguished by adjustable operating curves

by positioning the selector in any point between

the Min. and Max. positions, thereby satisfying

any installation requirement (from a simple

single-pipe to more modern and sophisticated

systems) and always guaranteeing optimum

performance. e precise working point can be

selected in the entire eld of use by gradually

adjusting the speed.

Real-time diagnostics: a lit LED (in various

colours) provides information regarding the

pump operating status, see g. 1-7

Possible pump release. The pump block is

indicated by a xed red LED switching on. Turn

the selector up to the MAX. position, disconnect

and reconnect the power to restart the automatic

release process. e pump will then activate the

procedure, which will last for a maximum of

15 minutes and the LED will ash upon each

restart. It then turns blue for a few seconds and

goes back to red if the attempt to restart is not

successful. Once the process is complete, position

the selector back on the desired curve and if the

problem has not been resolved, perform the

manual release procedure as described below.

- Disconnect the power to the boiler (the LED

switches o).

- Close the system ow and return and allow the

pump to cool down.

- Empty the system circuit via the relative cock.

- Remove the motor and clean the impeller.

- Once unblocked, remount the motor.

- Fill the primary circuit; restore boiler power

and set the desired curve.

Attention: a scalding hazard is present due to

high uid temperatures and pressures. Scalding

hazard as a result of contact.

1.9 SIZING THE SYSTEMS.

e ow temperatures to the various system

zones may be reduced with respect to the boiler

outlet temperatures, according to the mixture

of the ow and return uids inside the DIM. In

the event that the DIM is used to feed Low-Tem-

perature zones, check that the design parameters

allow you to achieve a maximum surface tem-

perature of the radiant oor in compliance with

standard UNI EN 1264.

1.10 KITS AVAILABLE ON REQUEST.

• System cut-o cock kit (on request). e man-

ifold is designed for the installation of system

interception cocks, to be placed on the ow

and return pipes of the connection assembly.

is kit is particularly useful for maintenance

as it allows the DIM to be drained separately

without having to empty the entire system.

• External probe kit.

• Safety thermostat kit.

• By pass kit for H-LT and H-2LT. versions.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Circulating pump

LED Description Diagnostics Remedy

LED steady on Pump

noisy

Insucient system pressure, circulating pump

in cavitation Restore correct thermal circuit pressure

Presence of foreign matter in the impeller Remove the motor and clean the impeller

Flashing white LED Noises during cir-

culation of the heat

transfer uid

Presence of air in the system Vent the system

LED steady on Flow rate too high Reduce rotation speed

LED o e circulator does

not work

Power outage Ensure the boiler is correctly powered, ensure

the circulator is correctly powered

Faulty circulating pump Replace the circulating pump

Red LED Rotor seized Remove the motor and clean the impeller

Insucient power supply voltage Check boiler power supply voltage