April, 2013 IMPCO Technologies Inc. PPI-118

REV. C 3030 South Susan St. Page 1 of 2

Santa Ana, CA 92704

www.impcotechnologies.com

ET98 SHUTOFF/LOCKOFF WITH FILTER

REPAIR KIT INSTRUCTIONS RK-ET98

Important: Any maintenance, service or repair should

be performed by trained and experienced service

technicians. Proper tools and equipment should be

used to prevent injury to the servicing technician,

property or system components. Service repairs

should always be performed in a safe environment

and the technician should always wear protective

clothing to prevent injury.

The IMPCO PPI-118 repair kit instructions will provide

the technician information to successfully repair the

ET98 Lockoff with Filter.

NOTE: This repair kit cannot be used to repair an

ET98 not originally equipped with an integrated

fuel filter.

Always inspect the major casting pieces for damage,

corrosion, cracks, or pits before attempting a service

repair.

PRIOR TO ANY REPAIR OR MAINTENANCE:

1. Close the valve on the LPG or Natural Gas source.

2. Run engine until it stalls from lack of fuel.

Do not allow LPG to contact the skin. LPG is

stored in the fuel tank as a liquid. When LPG

contacts the atmosphere, it immediately ex-

pands into a gas, resulting in a refrigeration ef-

fect that can cause severe burns to the skin

and/or eyes.

REBUILD INSTRUCTIONS

1. Remove the Bolt (10) at the bottom of the Filter

Bowl (8) and remove the Filter Bowl assembly.

Some residual pressure may be present

2. Remove the Bracket (3) and O-ring (2).

3. Remove the Filter (5) from the Filter Bowl (8) and

O-rings (6, 9) from the Bolt (10) and rim of Filter

Bowl. Discard Filter and O-rings.

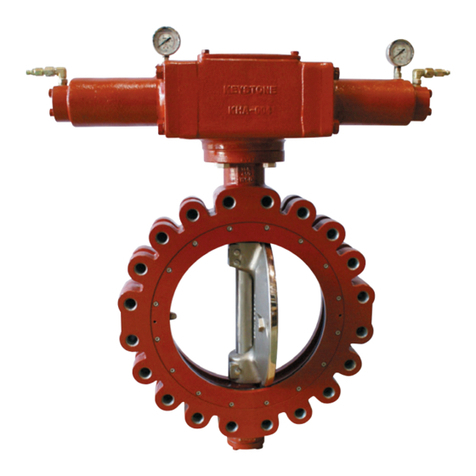

Old (with wire leads) and new (integrated elec-

trical connector) ET98-51315-001

Shutoff/Lockoff Valves

4. Thoroughly clean the Filter Bowl (8), Bolt (10),

Bracket (3) and the Valve Body (1) with a safety

solvent. DO NOT submerge the induction coil

in cleaning solvent, water or any type of liquid.

5. Lubricate O-rings with Vaseline or petroleum jelly.

6. Place the O-ring (7) in the rim of the Filter Bowl

(8).

7. Place O-ring (9) on the Bolt (10). Insert Bolt all

of the way into the Filter Bowl (8).

8. Place O-ring (6) on the Bolt (10) and slide

down to the bottom of the Filter Bowl (8). NOTE

O-ring (6) may already be installed in the filter

(5). Place Filter (5) over Bolt.

9. Place O-ring (4) on the top of the Filter (5).

10. Insert O-ring (2) into the ET98 Valve Body (1).

If necessary, apply extra Vaseline or petroleum

jelly to the O-ring to hold in place during as-

sembly.

11. Place the Bracket (3) on top of the Filter Bowl (8)

and mount the entire assembly on the Lockoff

Body (1). Thread Bolt (10) into the Lockoff Body

(1), ensuring that the O-ring (3) is properly seat-

ed. Torque bolt to 11.1 +/- 1.1 ft/lbs. (15 +/- 1.5

Nm).

12. Open fuel valve and inspect for leaks using an

approved leak detector solution. If no leaks are

found, re-connect the negative battery cable. If

a leak is detected, correct the problem before

proceeding with these instructions.

13. Turn Key to ON and inspect for leaks again

using an approved leak detector solution. Per-

form a final leak test with the engine running.