Impco Genius Max User manual

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 1 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

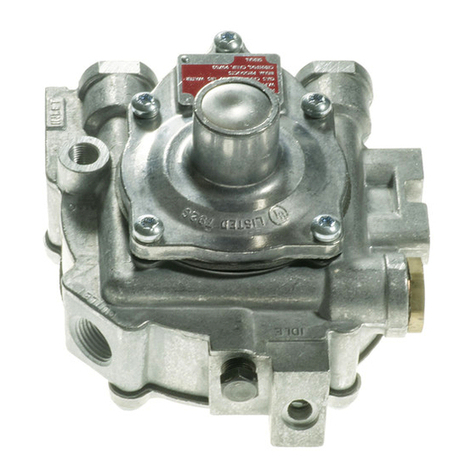

Genius Max

REGULATOR REPAIR KIT INSTRUCTIONS

NOTE: Only die cast Genius Max

regulators manufactured late 2014 and

after can be repaired using the repair kits

listed below. Repairable units are

identified by the IMPCO logo and the

words Genius Max cast into the top

cover. All Genius Max regulators black

in color are not serviceable using these

repair kits.

Important: Any maintenance, service or

repair should be performed by trained and

experienced service technicians. Proper

tools and equipment should be used to

prevent injury to the servicing technician,

property or system components. Service

repairs should always be performed in a

safe environment and the technician should

always wear protective clothing to prevent

injury.

The IMPCO PPI-131 repair kit instructions

will provide the technician information to

successfully repair the Genius Max

regulator. Always inspect the major casting

pieces for damage, corrosion or cracks

before attempting a service repair. Be sure

the repair kit part number you are using is

correct for the regulator being serviced.

Prior to disassembly, inspect the body for

any signs of impact, cracks or other damage

to the body that might render the regulator

non-repairable.

Do not use Teflon tape to seal any fuel fittings.

Failure to follow this warning may cause the

regulator to leak internally, that may cause serious

injury and/or property damage.

Genius Max Regulator Repair Kit Part Numbers

Part Number

Description

RK-GMAX-001

Repair Kit, Genius Max

RK-GMAX-002

Repair Kit, Genius Max (Includes the Pressure Relief Device or valve)

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 2 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

Genius Max Regulator (Internal Fittings)

See following page for External Fittings

ITEM # RK-GMAX

DESCRIPTION

1 -

Body, Lower, Genius Max Dc

2 -001, -002

Gasket, Bottom, Genius Max

3 -

Body, Center, Genius Max

4 -

Screw, Set M4x0.7x54mm

5 -001, -002

Gasket, Top, Genius Max

6

Body, Upper, Genius Max

7 -001, -002

Seat, Viton (80 Shore)

8 -

Holder, Seat, Genius Max

9 -

Lever, Genius Max

10 -

Pin, Steel, Ø3 X 30mm

11 -

Screw, Cross Head Pan M4 X 8mm (2)

12 -

Shaft, Link, Genius Max

13 -001, -002

O-Ring, Viton, Metric 1mm CS X 4mm ID

14 -

Plate, Diaphragm Bottom

15 -001, -002

Diaphragm, Genius Max

16 -

Plate, Top, Genius Max

17 -

Washer, Conical Spring, 5mm

18 -

Nut, Locking, M5

19 -

Spring, L48.5mm, O.D. 33.3mm, K11.8N/mm

20 -

Plate, Spring Load Adjustment

21 -

Screw, Adjustment

22 -001, -002

O-Ring, Fluorocarbon 0.070 Cs X 0.301 I.D. (2)1

23 -

Tube, Outlet, Genius Max

24 -

Screw, Shcs Pthd m6 x 40 Class 8.8 Zinc (6)

25 -002

Valve Subasm, Genius Max (includes 22 & 27)

26 -001, -002

Ring, Retaining, Internal

27 -

O-Ring, Fluorocarbon 0.070 Cs X 0.426 I.D.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 3 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

Genius Max Regulator (External Fittings)

Genius Max Regulator (GMX-53400-001 shown)

ITEM # RK-GMAX

DESCRIPTION

Genius Max Sub Assy w/M12 x 1 fitting

Genius Max Sub Assy w/1/4" x 18 NPT

Fitting, LPG Inlet, Genius Max (M12 X 1)

Fitting, LPG Inlet, Genius Max (1/4"-18 Npt)

33 -

Filter, Inlet, Genius Max

34 -001, -002

O-Ring, Fluorocarbon (Fluorel/Viton) 0.07 Cs X .551 I.D.

35 -

Fitting, M8 X 1, Genius Max

36 -001, -002

O-Ring, Fluorocarbon (Fluorel/Viton) 0.070 Cs X .208 I.D.

37 -

Fitting, 12mm Hose BRC Standard

38 -

Fitting, Straight

39 -001, -002

O-Ring, Fluorocarbon (Fluorel/Viton) 0.070 Cs X .614 I.D.

40 -001, -002

Pin, Retainer (2)

32

31

-

-

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 4 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

Genius Max Repair Kit Components.

Item#

Description

RK-GMAX-001

RK-GMAX-002

2

Gasket, Bottom, Genius Max

1

1

5

Gasket, Top, Genius Max

1

1

7

Seat, Viton (80 Shore)

1

1

13

O-Ring, Viton, Metric 1mm Cs X 4mm ID

1

1

15

Diaphragm, Genius Max

1

1

22

O-Ring, Fluorocarbon 0.070 Cs X 0.301 I.D.

2

1

25

Valve Subasm, Genius Max

-

1

26

Ring, Retaining, Internal

1

1

27

O-Ring, Fluorocarbon 0.070 Cs X 0.426 I.D.

1

-

34

O-Ring, Fluorocarbon (Fluorel/Viton) 0.07 Cs X .551 I.D.

1

1

36

O-Ring, Fluorocarbon (Fluorel/Viton) 0.070 Cs X .208 I.D.

1

1

39

O-Ring, Fluorocarbon (Fluorel/Viton) 0.070 Cs X .614 I.D.

6

6

40

Pin, Retainer (Part Number P1-30559)

2

2

Not Shown

Repair Kit Instructions, PPI-131

1

1

Note that Valve Subassembly (25) is only included in RK-GMAX-002 which includes O-rings 22 and 27.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 5 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

DISASSEMBLY INSTRUCTIONS

1. Remove the MAP hose Fitting (35).

2. Remove the Pins (40) retaining the port Fittings (38)

and remove from the Body (1). Remove O-rings (39)

from Fittings.

3. Using a 5mm Allen wrench, remove the six Screws (24)

from the top of the regulator and remove the upper

Body (6).

4. If the Body components stick together, the Center

Body (3) includes two tabs (as shown in the photo)

where a slotted screw driver can be inserted to pry to

the Body components apart.

NOTE: Do not use a screwdriver or other sharp

instrument at any location other than the tabs on the

center body. Sharp objects may scratch or damage the

sealing surfaces, causing the regulator to leak.

.

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 6 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

5. Remove the Nut (18) using an 8mm socket. Remove

the Washer (17) and Plate (16).

6. Lift the Body Center (3) from the Lower Body (1).

7. Remove the two screws (11) securing the fulcrum Pin

(10) and remove the Pin and Lever (9) complete with

Seat Holder (7 and 8).

8. Remove the Link Shaft (12) and its O-ring (13).

NOTE: Do not use any sharp objects that might

scratch the brass Link Shaft.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 7 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

9. Remove the Gaskets (2 and 5) from the Center

Body (3).

NOTE: Do not use any sharp objects that might

scratch any of the sealing surfaces.

10. Press on the Allen Key hole in the center of the

label to push the Adjustment Screw (21) and

Spring Load Plate (20) through the Link Shaft hole.

11. Using retaining ring pliers, remove the Retaining

Ring (26) securing the Pressure Relief Device or

Valve (25).

12. Note the bottom of the brass Valve (25) inside the

channel of the Upper Body (6) and using a small

regular flat-blade screwdriver, gently press the top

of the blade until the Valve pops out the top of the

Upper Body.

NOTE: Use care and avoid scratching any surfaces.

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 8 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

13. RK-GMAX-001 Kit Only (this step is not required when

using RK-GMAX-002): Remove the O-rings (22 and

27) on the Valve (21).

NOTE: The Valve is a pre-set pressure relief device

and is not serviceable. Do not remove the label,

immerse in any fluid or cleaning solvent or attempt to

service the Valve.

14. Remove the LPG Inlet Fitting (32).

15. Remove the Seat (7) from the Lever (8 & 9) by

inserting a small blunt object through the hole from

behind. A ballpoint pen is shown in the picture.

16. Once all of the gaskets and O-rings have been

removed, thoroughly clean the body and metal

components using a solvent to remove any

deposits, varnish or contaminants.

NOTE: Do not use any solvent on the Valve (25) as it

may be rendered unusable.

NOTE: Do not use any type of mechanical tool to

scrape the sealing surfaces as they may cause the

regulator to leak.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 9 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

REASSEMBLY OF REGULATOR

Carefully clean and inspect all metal parts, springs, levers, pivot pins and screws. Replace all parts

that are included in the repair kits.

Carefully clean the body casting and inspect all sealing surfaces. Wipe with a clean rag. Clear out the

inlet and outlet passages with compressed air. Be sure no foreign material remains in these passages.

17. Lightly lubricate with petroleum jelly or Vaseline

and place the O-ring (34) on the Fuel Inlet Fitting

(32).

18. Install the LPG fuel fitting (32). Torque to 18-22

Nm (13.3-16.2 ft-lbs.).

19. Press the Seat (7) into the Holder (8), installed on

the Lever (9).

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 10 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

20. Slide the O-ring (13) on the Link Shaft (13).

21. Place the Link Shaft (12) through the hole in the

Lever (9) and slide to the end of the slot in the

Lever. Slide the Pin (10) into the Lever, then

place the assembly into the Lower Body (1).

22. Secure the Pin (10) with two Screws (11) and

torque to 1.7-2.3 Nm (15-20 in-lbs.).

23. Lightly lubricate with petroleum jelly or Vaseline,

then place the Bottom Gasket (2) on the Center

Body (3). Press firmly into the grove, ensuring

the Gasket isn’t twisted and properly seated.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 11 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

24. Lightly lubricate with petroleum jelly or Vaseline,

then place the Top Gasket (5) on the top of the

Center Body (3).

25. Place the Center Body (3) on the Lower Body (1)

inserting the Link Shaft (12) through the Center

Body.

26. Place the Bottom Diaphragm Plate (14)

downward (flat side up) over the threaded Link

Shaft (12)

27. Lightly lubricate the perimeter of the Diaphragm

(15) with petroleum jelly or Vaseline, then place

on top of the Center Body (3). Using your finger,

press on the perimeter of the Diaphragm to

ensure it properly seats into the Center body.

NOTE: The Diaphragm is positioned so the raised

outer ring or bag is up (as pictured).

Place the Plate (16) flat side down on top of the

Diaphragm. Place the Washer (17) concave side

downso its perimeter is in contact with the Plate.

Hand thread Nut (18) on Link Shaft (12).

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 12 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

28. Torque the Nut (18) to 1.35-1.65 Nm (12-14.5 in-

lbs.).

29. Place the Spring (19) on top of the Diaphragm

Plate (16).

30. Lubricate O-ring (22) with petroleum jelly or

Vaseline, and place on the Adjustment Screw

(21).

NOTE: There is no need to separate the Adjustment

Screw from the Plate (20).

31. Press the Plate (20) and Adjustment Screw (21)

assembly into the bottom of the Top Body (6) so

the Adjustment Screw fits flush with the top of the

Body.

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 13 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

32. Place the Top Body (6) on top of the Center (3)

and Lower Body (1) assembly. Press down to

compress the spring while lightly tightening the

Screws (24).

33. Torque each Screw (24) in a criss-cross pattern

in the order pictured to 7.4-8.6 Nm (5.5-6.3 ft-

lbs.).

34. Lubricate O-ring (36) with petroleum jelly or

Vaseline, and place on MAP Fitting (35). Thread

into the Top Body (6) and using a 10mm socket

wrench, torque to 2.55-3.45 Nm. (22.5-30.5 in-

lbs.).

35. Lubricate O-rings (22 and 27) with petroleum jelly

or Vaseline, and place on the Valve (25).

NOTE: When using repair kit RK-GMAX-002,

discard the old Valve and use the new one included

in the kit, complete with new O-rings.

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 14 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

35. Press in the Valve (25) until it seats below the rim

of the Top Body (6).

36. Secure the Valve (25) with the new Ring Clip (26)

using Ring clip pliers.

37. Lubricate O-rings (39) with petroleum jelly or

Vaseline, and place two on each of the Port

Fittings (38).

38. Insert the Coolant Fittings (38) into the ports on

the Lower Body (1) and secure with Retaining

Pins (40).

December, 2014 IMPCO Technologies Inc. PPI-131 REV. A

3030 South Susan St. Page 15 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

39. Insert the Fuel Outlet Fitting (37) into the port of

the Upper Body (6) and secure with Retaining

Clips (40) as pictured.

40. Install the Genius Max regulator in the vehicle and

turn on the fuel supply to pressurize the regulator.

Using soap and/or a commercial leak detector

solution, check for leaks, especially around the

Center Body (3). If no leaks are found, start the

engine, allow to idle and check for leaks again. If

leaks are found, the rebuild has failed and the

regulator must be replaced.

47. If no leaks are found, check the outlet pressure

using computer based diagnostic software to

read the fuel rail pressure sensor. Start the

engine and note the pressure. The pressure

should read 1.45-1.55 Bar (21.0-22.5.psi). If

not, the pressure can be adjusted using a 4mm

Allen key. Turn the Adjustment Screw (21)

clockwise to reduce pressure and counter-

clockwise to increase. Once the outlet pressure

has been set to 1.45-1.55 Bar (21.0-22.5 psi),

the regulator can be returned to service.

PPI-131 REV. A IMPCO Technologies Inc December, 2014

3030 South Susan St. Page 16 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

WARNING:

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY CAUSE

SERIOUS INJURY, DEATH AND/OR PROPERTY DAMAGE

SERVICE TECHNICIANS AND USERS SHOULD CAREFULLY READ AND ABIDE BY THE PROVISIONS SET FORTH IN

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37 FOR STATIONARY ENGINES, #52 FOR CNG VEHICULAR

FUEL SYSTEMS OR #58 FOR LPG SYSTEMS.

INSTALLERS LPG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE

AND LOCAL LAWS AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #58, STANDARD FOR STORAGE

AND HANDLING OF LIQUEFIED PETROLEUM GASES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

OF FEDERAL, STATE OR LOCAL LAW.

COUNTRIES OUTSIDE OF USA REFER TO THE GOVERNING AGENCIES OVERSEEING CNG AND PROPANE

APPLICATIONS.

CNG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE AND LOCAL

LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #52, COMPRESSED NATURAL GAS (CNG)

VEHICULAR FUEL SYSTEMS, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION OF FEDERAL, STATE OR

LOCAL LAW.

LPG AND/OR NATURAL GAS INSTALLATIONS ON STATIONARY ENGINES MUST BE DONE IN ACCORDANCE WITH

FEDERAL, STATE AND LOCAL LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37, STATIONARY

COMBUSTION ENGINES AND GAS TURBINE ENGINES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

WITH FEDERAL, STATE OR LOCAL LAW. FAILURE TO ABIDE BY THE ABOVE WILL VOID ANY IMPCO WARRANTY ON

THE PRODUCTS AND MAY CAUSE SERIOUS INJURY OR PROPERTY DAMAGE.

SERVICE TECHNICIANS DUE TO THE INHERENT DANGER OF GASEOUS FUELS, IMPCO PRODUCTS SHOULD NOT BE

INSTALLED OR USED BY PERSONS NOT KNOWLEDGEABLE OF THE HAZARDS ASSOCIATED WITH THE USE OF

GASEOUS FUELS. ANY MAINTENANCE, SERVICE OR REPAIR SHOULD BE PERFORMED BY TRAINED AND

EXPERIENCED SERVICE TECHNICIANS.

PROPER TOOLS AND EQUIPMENT PROPER TOOLS AND EQUIPMENT SHOULD BE USED TO PREVENT INJURY TO

THE SERVICING TECHNICIAN, PROPERTY OR SYSTEM COMPONENTS. SERVICE REPAIRS SHOULD ALWAYS BE

PERFORMED IN A SAFE ENVIRONMENT AND THE TECHNICIAN SHOULD ALWAYS WEAR PROTECTIVE CLOTHING TO

PREVENT INJURY.

INSPECT BEFORE USE ALWAYS INSPECT THE MAJOR CASTING PIECES FOR DAMAGE, CORROSION OR CRACKS

BEFORE ATTEMPTING A SERVICE REPAIR. BE SURE THE REPAIR KIT PART NUMBER YOU ARE USING IS CORRECT

FOR THE COMPONENT(S) BEING SERVICED.

NO TEFLON TAPE DO NOT USE TEFLON TAPE TO SEAL ANY FUEL FITTINGS. FAILURE TO FOLLOW THIS WARNING

MAY CAUSE THE REGULATOR TO LEAK INTERNALLY, POSSIBLY RESULTING IN SERIOUS INJURY, DEATH AND/OR

PROPERTY DAMAGE AND MAY VOID ANY WARRANTY COVERAGE.

Other Impco Controllers manuals

Popular Controllers manuals by other brands

norbar

norbar T-BOX 2 Operator's manual

AFRISO

AFRISO AVD 10 operating instructions

Mitsubishi Electric

Mitsubishi Electric SV13/22 Programming manual

Johnson Controls

Johnson Controls York 366-70488 Installation and Maintenance

Sullair

Sullair SUPERVISOR CONTROLLER user manual

Graham

Graham Vari Speed S1000 instruction manual

Tekmar

Tekmar Mixing Control 356 manual

Akerstroms

Akerstroms SESAM 800 RXM operating manual

Vexve

Vexve AM40 Instructions & user's manual

J.P. Instruments

J.P. Instruments EDM-730 pilot's guide

MidNite Solar

MidNite Solar The Kid quick start guide

Ewellix

Ewellix CAHB-2 Series Installation, operation and maintenance manual