Sullair SUPERVISOR CONTROLLER User manual

Failure to follow the instructions

and procedures in this manual or,

misuse of this equipment will

VOID its warranty!

WARRANTY NOTICE

PART NUMBER:

KEEP FOR

FUTURE

REFERENCE

USER MANUAL

©SULLAIR CORPORATION

The information in this manual is current

as of its publication date, and applies to

compressor serial number:

and all subsequent serial numbers.

02250146-049 R02

200906010000

SUPERVISOR CONTROLLER™

AIR CARE SEMINAR TRAINING

Sullair Air Care Seminars are courses that provide hands-on instruction for the proper operation, maintenance,

and servicing of Sullair products. Individual seminars on Stationary compressors and compressor electrical

systems are offered at regular intervals throughout the year at Sullair’s corporate headquarters training facility

located at Michigan City, Indiana.

Instruction includes training on the function and installation of Sullair service parts, troubleshooting common

faults and malfunctions, and actual equipment operation. These seminars are recommended for maintenance,

contractor maintenance, and service personnel.

For detailed course outlines, schedule, and cost information contact:

SULLAIR TRAINING DEPARTMENT

1-888-SULLAIR or

219-879-5451 (ext. 5623)

www.sullair.com

- Or Write -

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department.

TABLE OF CONTENTS

SECTION 1—SAFETY

3 1.1 GENERAL

3 1.2 PERSONAL PROTECTIVE EQUIPMENT

3 1.3 ELECTRICAL SHOCK

4 1.4 DECALS

SECTION 2—DESCRIPTION

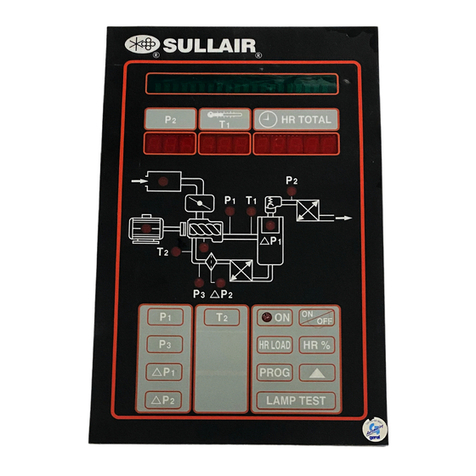

7 2.1 SUPERVISOR KEYBOARD LAYOUT

8 2.2 MAIN DISPLAY

8 2.3 FUNCTION MENU

9 2.4 STATUS—CURRENT PRESSURES, TEMPERATURES, INPUTS AND

OUTPUTS

9 2.5 CONTROL PARAMETERS—PRESSURE, TEMPERATURE AND TIMER

SETTINGS

10 2.6 MAINTENANCE—PREVENTIVE MAINTENANCE INFORMATION AND

TIMERS

10 2.7 FAULT LOG—LOG OF PREVIOUS FAULTS

10 2.8 SENSOR LOG

10 2.9 SEQUENCING—SEQUENCING & COMMUNICATION PARAMETERS

11 2.10 SYSTEM DISPLAY—DISPLAY OF MODES OF MACHINES IN A SE-

QUENCING SYSTEM

11 2.11 CALIBRATION—CORRECTION FACTORS FOR PRESSURES

12 2.12 TEST

12 2.13 FACTORY SETUP- MODEL SETTINGS.

SECTION 3—START-UP PROCEDURES

15 3.1 MOTOR ROTATION DIRECTION CHECK

15 3.2 INITIAL START-UP PROCEDURE

15 3.3 SUBSEQUENT START-UP PROCEDURE

15 3.4 SHUTDOWN PROCEDURE

SECTION 4—TROUBLESHOOTING

17 4.1 TROUBLESHOOTING INTRODUCTION

TABLE OF CONTENTS

26 4.2 MACHINE BEHAVIOR AFTER A POWER OUTAGE

26 4.3 REMOTE STOP/START INPUT

26 4.4 BROWN OUT INPUT

SECTION 5—WIRING DIAGRAMS

SECTION 6—VARIABLE SPEED DRIVE

33 6.1 SAFETY

34 6.2 OVERVIEW

36 6.3 INSTALLATION

36 6.4 SUPERVISOR DISPLAY AND MENUS

37 6.5 STARTUP OF NEW COMPRESSOR PACKAGE

38 6.6 FAULT AND WARNING CODES

41 6.7 COMMISSIONING YOUR VSD:

41 6.8 AFTER THE FIRST 48 HRS OF OPERATION:

41 6.9 EVERY SIX MONTHS

41 6.10 EVERY TWELVE MONTHS:

42 6.11 CLEANING VSD HEAT SINKS

46 6.12 CLEANING VSD HEAT SINK FILTERS

Section 1

3

SAFETY

1.1 GENERAL

Sullair Corporation and its subsidiaries design and

manufacture all of their products so they can be

operated safely. However, the responsibility for safe

operation rests with those who use and maintain

these products. The following safety precautions are

offered as a guide which, if conscientiously followed,

will minimize the possibility of accidents throughout

the useful life of this equipment.

The compressor should be operated only by those

who have been trained and delegated to do so, and

who have read and understood this Operator's

Manual. Failure to follow the instructions, procedures

and safety precautions in this manual may result in

accidents and injuries. NEVER start the compressor

unless it is safe to do so. DO NOT attempt to operate

the compressor with a known unsafe condition. Tag

the compressor and render it inoperative by

disconnecting and locking out all power at source or

otherwise disabling its prime mover so others who

may not know of the unsafe condition cannot attempt

to operate it until the condition is corrected.

Install, use and operate the compressor only in full

compliance with all pertinent OSHA regulations and/

or any applicable Federal, State, and Local codes,

standards and regulations. DO NOT modify the

compressor and/or controls in any way except with

written factory approval.

While not specifically applicable to all types of

compressors with all types of prime movers, most of

the precautionary statements contained herein are

applicable to most compressors and the concepts

behind these statements are generally applicable to

all compressors.

1.2 PERSONAL PROTECTIVE

EQUIPMENT

A. Prior to installing or operating the compressor,

owners, employers and users should become

familiar with, and comply with, all applicable

OSHA regulations and/or any applicable Federal,

State and Local codes, standards, and regula-

tions relative to personal protective equipment,

such as eye and face protective equipment,

respiratory protective equipment, equipment

intended to protect the extremities, protective

clothing, protective shields and barriers and elec-

trical protective equipment, as well as noise

exposure administrative and/or engineering con-

trols and/or personal hearing protective equip-

ment.

1.3 ELECTRICAL SHOCK

A. This compressor should be installed and main-

tained in full compliance with all applicable Fed-

eral, State and Local codes, standards and

regulations, including those of the National Elec-

trical Code, and also including those relative to

equipment grounding conductors, and only by

personnel that are trained, qualified and dele-

gated to do so.

B. Keep all parts of the body and any hand-held

tools or other conductive objects away from

exposed live parts of electrical system. Maintain

dry footing, stand on insulating surfaces and DO

NOT contact any other portion of the compressor

when making adjustments or repairs to exposed

live parts of the electrical system. Make all such

adjustments or repairs with one hand only, so as

to minimize the possibility of creating a current

path through the heart.

NOTE

OPERATOR IS REQUIRED TO READ

ENTIRE INSTRUCTION MANUAL.

SECTION 1

4

C. Attempt repairs in clean, dry and well lighted and

ventilated areas only.

D. DO NOT leave the compressor unattended with

open electrical enclosures. If necessary to do so,

then disconnect, lock out and tag all power at

source so others will not inadvertently restore

power.

E. Disconnect, lock out, and tag all power at source

prior to attempting repairs or adjustments to

rotating machinery and prior to handling any

ungrounded conductors.

1.4 DECALS

See Figure 1-1. The Supervisor control panel

contains several decals which contain necessary

information for safe performance. These decals

should never be removed. If a decal becomes

damaged, contact your nearest Sullair Department

for replacement parts (Note: When ordering new

decals, use part number printed on decal face).

DANGER

All field equipment must be tested for elec-

trostatic fields prior to servicing or making

contact with the machine using the follow-

ing or equivalent test equipment:

• 90-600 VAC: Volt detector such as

Fluke Model 1AC-A

• 600-7000 VAC: Voltage detector

such as Fluke Networks Model

C9970

It is the responsibility of each organization

to provide/arrange training for all their

associates expected to test for electrostatic

fields.

SECTION 1

5

Figure 1-1: Decals

KEY

NO. PART NO.

Q

T

Y

DESCRIPTION NOTE

1 250017-903 1 decal, warning auto start

2 250027-935 1 decal, danger breath air (I)

3 250003-144 1 sign, warning “food grade” lube

4 041065 1 decal, auto start

(I) OSHA and FDA guidelines are superseded by any Federal, State or

Local regulations whenever applicable.

NOTES

6

Section 2

7

SUPERVISOR CONTROLLER™ USER MANUAL

DESCRIPTION

2.1 SUPERVISOR KEYBOARD

LAYOUT

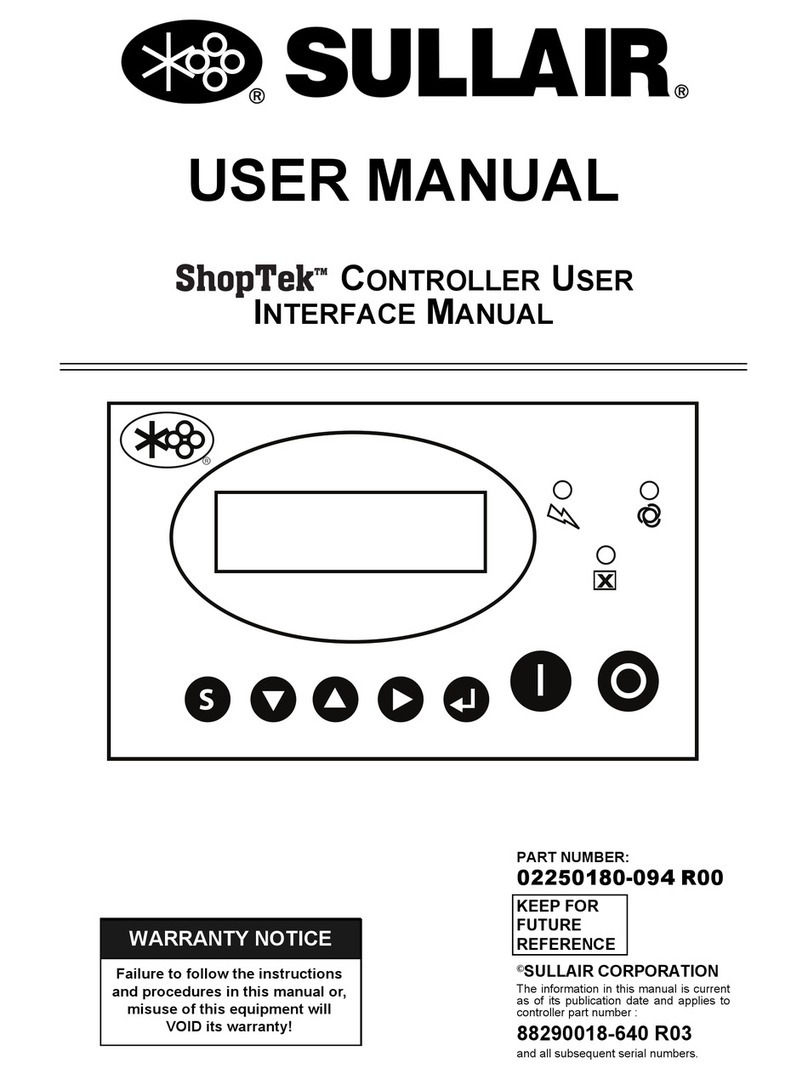

Refer to Figure 2-1. The Display module has eleven

keys grouped in two rows.

The top row has the following seven keys :

—Help key, used to display possible causes of

and correction for an alarm or fault.

—Returns to main display.

—Used to edit text or numbers (move cursor

left).

—Used to edit text or numbers (move cursor

right).

—Used to change numbers or text, or scroll.

—Used to change numbers or text, or scroll.

—Used to select an item from a menu, or start

Figure 2-1: Supervisor Controller Panel

SUPERVISOR CONTROLLER™ USER MANUAL SECTION 2

8

and end an edit on a parameter.

The bottom row has four keys :

—Stop, stops machine. Clears faults and

warnings if machine is stopped.

—Run, starts machine. Clears warnings if

machine is running.

—Toggles auto mode.

—Toggles Local/Remote mode. This can be

used to disable sequencing.

2.2 MAIN DISPLAY

Line 1—Machine state :

E-Stop—E-Stop button pressed, or auxiliary E-Stop

present.

Stopped—Machine not running.

Unloaded—Machine running unloaded.

Loaded—Machine running, loaded and modulating.

Full Load—Machine forced to full load. (Used only in

sequencing modes).

Remote Stop—Compressor is off but armed to start.

The machine will start when the remote start contact

is closed. NOTE : the machine may start at any time.

Seq Stop—Compressor is off but armed to start. The

machine will start when the sequencing conditions

meet the criteria to start. NOTE: the machine may

start at any time.

Trim—Machine running, loaded and modulating in a

sequenced system.

Line 2—Fault or Warning, blank means no fault or

warning is present. If there are multiple alarms, they

will be shown for 2 seconds each. If an alarm is

active, pressing the ‘?’ key will give troubleshooting

information on that alarm.

Line 3—P2—Line pressure

Line 4—T1—Discharge Temperature

2.3 FUNCTION MENU

While in the main display, if any of the arrow keys are

pressed, the function menu is displayed. This menu

is used to view status or edit parameters.

The function menu has the following entries :

Status—Current pressures, temperatures, inputs

and outputs.

VSD Satus—(VSD packages only) See Section 6.

Control Parameters—Pressure and temperature

and timer settings.

Maintenance—Preventive maintenance information

and timers.

Fault Log—Log of previous faults.

Sensor Log—Log of sensor readings leading up to a

fault.

Sequencing—Sequencing parameters.

System Display—Display of modes of machines in

a sequencing system.

Calibration—Correction factors for pressures.

Test—Used by Sullair personnel for troubleshooting

serial communications.

Factory Setup—Model settings.

VSD Setup—(VSD Packages only) See Section 6.

To select a function, use the up and down arrow keys

to scroll to the desired function as indicated on last

line of display, then press the enter key.

After entering a function, the information can be

viewed by using the up and down arrow keys. If the

function shows status then values cannot be

changed. If the function displays parameters, then

the values can be changed.

To change a value, scroll to the line to be changed

using the up arrow and down arrow keys, and push

the enter button. The value can be changed by using

the up arrow or down arrow keys. When editing is

finished, pushing the enter key will fix the value. If

during a change the ESC key is pushed, editing is

terminated and the original value is reset.

The left and right arrow keys can be used to move to

other digits or letters in a value. For example to

change a value from 100 to 500, the left arrow key

can be used to position the cursor to the 1 digit in the

100, and the up arrow key used to increment the digit

to 5.

Text fields can also be edited in the same manner.

Push the enter key to start the edit, use the left and

SECTION 2 SUPERVISOR CONTROLLER™ USER MANUAL

9

right arrow keys to move to the letter to be changed,

then use the up and down arrow to change the letter.

Push the enter key to complete the edit. The

following are detailed descriptions of the various

displays.

2.4 STATUS—CURRENT

PRESSURES,

TEMPERATURES, INPUTS

AND OUTPUTS

All inputs and outputs are displayed showing both the

designator and the description (eg. T1- Discharge)

along with the selected temperature (C or F) or

pressure (psi, bar, kPa) units. Digital inputs and

outputs are shown either as a ‘0’ (zero) or ‘1’ (one).

Zero is off and one is on. This is a view only display.

The order of display is :

Temperatures—T1 through T4 depending on model.

Pressures—P1 through P4 depending on model.

Delta pressures—dp1 through dp3 depending on

model.

Load Hours—Hours machine has run loaded.

Run Hours—Hours machine has run loaded or

unloaded.

Load Cycles—Number of load/unload cycles.

Starts—Number of times machine has started.

E-Stop String—E-Stop push button.

Aux E-Stop—Auxiliary E-Stop, wired by customer.

Digital Inputs—D1 through D10, depending on

model.

Relay Outputs—K1 through K8, depending on

model.

2.5 CONTROL PARAMETERS—

PRESSURE, TEMPERATURE

AND TIMER SETTINGS

Parameters that control the operation of the machine

are viewed and set using this display. These

parameters may vary by machine model.

The Control Parameters are :

Unload pressure—The pressure where the machine

is unloaded. For example if this parameter is set to

110 psi (7.6 bar) the machine will unload when the

line pressure is above 110 psi (7.6 bar).

Load delta—The pressure differential below the

unload pressure where the machine is loaded. For

example if the unload pressure is set to 110 psi (7.6

bar) and the load differential is set to 10 psid (0.7

bar), the machine will load when the line pressure

goes below 100 psi (6.9 bar).

Setpoint—(VSD packages only) The targeted

pressure for the variable speed controls. This is

normally adjusted near the bottom of the load/unload

band above. The speed will be adjusted to maintain

this pressure. Refer to Section 6 for additional

details.

Unload Time—If the machine is running in AUTO

mode, this parameter specifies the amount of time

that the machine will run unloaded before shutting

off. If the time is set less than 15 minutes (for

example 5), there may be times when the machine

will run unloaded for more than 15 minutes. This is

because there is another timer that keeps the

machine from being started more than four times an

hour. This secondary timer is disabled when a

machine is configured for VSD motor control.

Drain Interval—If the machine has an electric

solenoid drain, this parameter and the following

parameter (Drain Time) are used to turn on the drain.

The interval is the time between activations of the

drain and the Drain Time is the length of the time

energized. This does not apply to the Sullair SCD

zero loss drain, which is not controlled or monitored

by the Supervisor.

Drain Time—Length of time that drain is energized.

Restart time—

Time to wait after power up before starting machine.

This parameter is used to keep several machines

from starting at the same time after power up, or to

delay start until other equipment is started. If

disabled parameter is zero, the machine will not

automatically start after power up. If this parameter is

a number larger than zero, the machine restarts after

a delay defined by this time. For example, if the

WARNING

Enabling this function also enables auto-

matic restart after power recovery. Be sure

to depress the Emergency Stop button to

defeat this function when automatic start is

to be prevented.

SUPERVISOR CONTROLLER™ USER MANUAL SECTION 2

10

Restart Time is set to 10 seconds, then the machine

will be enabled to start after 10 seconds.

Wye to delta transition timer—Also used to control

the closed inlet start valve. Disable by setting to zero

(0), standard for full voltage start. Requires

approximately 4-6 seconds for wye-delta or solid

state starting.

Modulate—Default state is Yes for normal machine

control. Select No for Load/No Load operation.

Language select—English, German, Spanish,

Italian and French may be selected for display

language.

Temp Units—Temperature units may be set to

degrees F or degrees C.

Press Units—Pressure units may be set to psi, bar,

or kPa.

(VSD packages only)—Additional adjustments for

VSD operation are shown in Section 2.

2.6 MAINTENANCE—

PREVENTIVE

MAINTENANCE

INFORMATION AND TIMERS

The following lines are on the Maintenance display.

Information—The top two lines may be changed to

advise what to do when there is a maintenance

warning. For example a distributor can put in his

name and telephone number.

Ser. No—Serial number of machine.

Warn at—When the following drop below this

number, a warning is issued.

Oil Filter hours—Hours before oil filter change.

PN—Oil Filter part number.

Separator hours—Hours before separator change.

Prim.—Primary separator part number.

Sec.—Secondary separator part number.

Air Filter hours—Hours before air filter change.

Prim.—Primary air filter part number.

Sec.—Secondary air filter part number.

Oil hours—Hours before oil change.

PN—Oil part number.

Oil Anal.—Hours before oil analysis.

These hours and part numbers can be changed

using the enter and arrow keys.

2.7 FAULT LOG—LOG OF

PREVIOUS FAULTS

The fault log shows the last 16 faults that occurred.

The top line of the display shows the run hours where

the fault occurred, and the second line shows the

fault. The faults can be scrolled through using the up

and down arrow keys. They are ordered by most

recent first. (ie. when the function is entered the most

recent fault is displayed. Pressing the down arrow

displays the previous fault etc).

2.8 SENSOR LOG

Log of sensor readings leading up to a fault.

The sensor log shows the sensor readings leading

up to a fault. The top line shows the last fault. The

following lines show T1, T2, P1 & P2. Each line

represents readings that are 5 seconds apart for one

minute, then one minute apart for 10 minutes. There

is a second set of readings for T3, T4, P3 & P4.

2.9 SEQUENCING—

SEQUENCING &

COMMUNICATION

PARAMETERS

The following parameters can be viewed and edited.

For more details on sequencing see the Supervisor

Sequencing and Protocol Manual.

Sequence By—Sequencing mode can be set to:

Disabled—Control does not do any sequencing.

Remote—Enables Remote Start/Stop, Remote

Load/Unload and Local/Master inputs

Hours—Uses the Seq Hrs parameter to deter

mine order of sequencing

Number—Uses the Com Number to determine

order of sequencing

Seq Hrs—This is an hour counter used when the

‘Sequence By’ parameter is set to ‘Hours’. Each hour

NOTE

Unload pressure MUST be lowered to

rated pressure when using Load/No Load

mode.

SECTION 2 SUPERVISOR CONTROLLER™ USER MANUAL

11

that the machine is running increments this counter.

When then ‘Sequence By’ parameter is set to

‘Hours’, the machine with the least amount of Seq

Hrs is started first, and the machine with the most

Seq Hrs is shut off first.

Com Number—Communications number. When two

or more machines are connected together using the

network (RS-485 channel), each machine must have

a unique number or address. These must be

assigned in numerical order. For example in a three

machine system the machine communications

numbers should be 1, 2 & 3.

Machines—This is the total number of machines

connected to the network (RS-485 channel). For

example in a three machine system, this parameter

should be set to 3. Up to sixteen machines may be

networked if all have Supervisor Controllers and

limited to eight if some have Supervisor II’s.

Low Press—This is the lowest pressure allowed

before immediately starting a machine. Recovery

Time—This parameter keeps multiple machines from

loading, unloading and starting at the same time. For

example if a low pressure condition causes a

machine to start, the next machine will not start

unless the Recovery Time has elapsed, and the

pressure has not recovered (i.e., has risen over ‘Low

Press’).

Rotate—This parameter is used only in very special

cases.

The only time this parameter should be used is in a

situation where, once a machine is started, it never

stops (ie. the unload timer never expires). This can

happen when the load matches the output of the

machine, all the time. In this case the machine will

never unload and shut off. The rotate forces the

machine to stop after it’s Seq Hrs. are greater that

the other machines. For example in a two machine

system, with Rotate set at 100 hrs. The machine that

is running will shut off when the Seq Hrs. are 100

more that the machine that is stopped.

Minute, Hour, Day, Month, Year—For Controllers

manufactured after April 2009 or if the

Communications Module is present in the system,

the time and date can be set using these parameters.

2.10 SYSTEM DISPLAY—DISPLAY

OF MODES OF MACHINES IN

A SEQUENCING SYSTEM

Note that this display is only applicable when there

are two or more machines connected to the

communications network (RS-485) and the

Sequence By parameters on each machine are set to

‘Hours’ or ‘Number’.

The columns are described below

Communication Number Status—

E—Emergency Stop

M—Manual stop

R—Remote stop

B—Standby

S—Starting

U—Unloaded

L—Loaded

T—Trim machine

F—Full load

Sequencing Hours

Capacity—Not used at this time.

Local System Pressure—Pressure read by

machines pressure transducer.

The top line is a legend that describes each column.

The right hand number on the top line is the system

pressure. The system pressure is the highest

pressure reading of all the machines. Note that the

local pressure readings can be used to determine

what machines may need to be calibrated. The

system pressure transducers on all machines should

read within 1(one) psi of one another. The calibration

function can be used to set the readings to be the

same.

2.11 CALIBRATION—

CORRECTION FACTORS

FOR PRESSURES

The first line of this display is the password. If the

password is 0 then the following parameters are not

protected and can be changed. If the password is

non-zero, then enter the displayed number plus 4 to

enable changing the parameters. For example if the

number displayed is 10 then changing the password

to 14 will enable editing.

NOTE

Leave this parameter disabled unless

instructed by Sullair Service Personnel.

SUPERVISOR CONTROLLER™ USER MANUAL SECTION 2

12

The four pressures P1, P2, P3 & P4 as well as the

differential pressure dP1 can be calibrated. The

number on the right hand side of the line is added to

the transducer reading to give the calibrated reading.

The calibrated reading is shown in the middle of the

line.

Cap and KW calibration (VSD packages only) may

be used to adjust values shown on VSD Status

displays. These are factory set to nominal values

(100%), but may be adjusted as desired.

There are also three other parameters in the

calibration function:

Protect—When set to yes, protects the control

parameters from change.

Fault on Warn—Force fault on warning.

Force Unload—When set to yes, forces the machine

to unload.

2.12 TEST

Used by Sullair personnel for troubleshooting of

serial communications.

2.13 FACTORY SETUP- MODEL

SETTINGS.

The factory setup display is used by Sullair personnel

to initially set up the machine. The following values

reflect the machine configuration.

Model—Model number of machine.

Cooling—Air or Water.

Press Trans—Pressure transducer range 200, 250,

500.

P1 Max—Maximum discharge pressure.

KT Fluid—Yes or No, indicating fluid.

Water Switch—Water pressure switch, Yes or No.

Oil Switch—Oil pressure differential switch, Yes or

No.

Min Load Psi—Minimum acceptable load P1

pressure setting. Separator Maintenance warning is

disabled for loaded P1 pressures below this value

(i.e., during start-up).

Lube Cycle—Pre-lube/ Post-lube function timer - 0

seconds (disabled) to 30 seconds.

K8 Option—K8 output relay function selector—

Disabled, Oil pump prelube and postlube control,

Master Control for special external sequence control.

Stop Timer—Time to run machine before stopping.

Protect—Protect control parameters.

Load Hours—Hours machine was running and

loaded.

Run Hours—Hours machine was running loaded

and unloaded.

Load Cycles—Number of load/unload cycles.

Starts—Number of machine starts.

Capacity—Maximum capacity of machine.

Spiral Valve—(VSD packages only) Yes or No,

indicating spiral valve control.

VSD- Describes signal from Supervisor controls to

the VSD controls:

None—No VSD

Pressure—The Supervisor pressure signal is

connected to a drive analog input

Serial—The drive is connected on the

Supervisor serial data bus

Speed—The Supervisor provides a speed

signal to a drive analog input.

Com Module—Yes/No Enables or disables the

communication module if installed.

13

NOTES

SUPERVISOR CONTROLLER™ USER MANUAL SECTION 2

14

Table 2-1: Supervisor Controller Menu Tree

Section 3

15

SUPERVISOR CONTROLLER™ USER MANUAL

START-UP PROCEDURES

3.1 MOTOR ROTATION

DIRECTION CHECK

After the electrical wiring has been done, it is

necessary to check the direction of the motor

rotation. With the control system in MANUAL mode,

press the and pads in succession to

bump start the compressor. When looking at the

motor from the end opposite the compressor unit, the

shaft should be turning clockwise on all gear driven

models, and counterclockwise on direct drive

models. If the motor shaft is not turning in the proper

direction, disconnect the power to the starter and

exchange any two of the three power input leads,

then recheck rotation. A “Direction of Rotation” decal

is located on the coupling guard between the motor

and compressor to show proper motor/compressor

rotation.

Variable speed drive packages will have main motor

direction set at the time of construction, but the fan

direction is affected by installation. If fan-cooled,

ensure that fan rotation is correct. To change

direction, disconnect the power and exchange any

two of the three fan motor leads at the fan motor

starter.

3.2 INITIAL START-UP

PROCEDURE

The following procedure should be used to make the

initial start-up of the compressor.

1. Be sure that all preparations and checks

described in the Installation Section have

been made.

2. Read the preceding pages of this manual

thoroughly.

3. Jog motor to check for correct rotation of fan

(refer to Section 3.1).

4. Start the compressor in the desired operating

mode or .

5. Slowly open the shut-off valve to the service

line.

6. Check for possible leaks in piping.

7. Slowly close the shut-off valve to assure

proper nameplate pressure unload setting is

correct. The compressor will unload at

nameplate pressure. If adjustments are nec-

essary, see Control System Adjustment sec-

tion in the compressor operator’s manual.

8. Observe the operating temperature. Refer to

compressor operator’s manual for accept-

able operating range. If temperature

exceeds this range, the cooling system and

installation environment should be checked.

9. Open shut-off valve to the service line.

10. Reinspect the compressor for temperature

and leaks the following day.

3.3 SUBSEQUENT START-UP

PROCEDURE

On subsequent start-ups, check that the proper level

is visible in the fluid sight glass and simply press the

START or AUTO MODE button. When

the compressor is running, observe the instrument

panel and maintenance indicators.

3.4 SHUTDOWN PROCEDURE

To shut the compressor down, simply press the

STOP button.

16

NOTES

Section 4

17

SUPERVISOR CONTROLLER™ USER MANUAL

TROUBLESHOOTING

4.1 TROUBLESHOOTING

INTRODUCTION

The information contained in the Troubleshooting

chart has been compiled from factory experience. It

contains symptoms and usual causes for the

described problems. However, DO NOT assume that

these are the only problems that may occur. All

available data concerning the trouble should be

systematically analyzed before undertaking any

repairs or component replacement procedures.

A detailed visual inspection is worth performing for

almost all problems and may avoid unnecessary

additional damage to the compressor. Always

remember to:

a. Check for loose wiring.

b. Check for damaged piping.

c. Check for parts damaged by heat or an

electrical short circuit, usually apparent

by discoloration or a burnt odor.

Should your problem persist after making the

recommended check, consult your nearest Sullair

Distributor or the Sullair Corporation factory Service

Department.

NOTE

Whereas Section 4.1 and Section 4.2 por-

tray common systematic setbacks that

can occur during controller operation, for

a more thoroughly in-depth coverage of

machine operation setbacks, consult the

Troubleshooting Section in the machine’s

operator’s manual.

Table 4-1: Troubleshooting Guide—Supervisor Controller

Message Model Enable Probable Cause Remedy

Air Filter Maint ALL ALWAYS Differential Pressure

Across Inlet Filter High

Replace filter

Check inlet filter pressure

switch.

Aux Motor Overload ALL ALWAYS Auxiliary Motor Tripped on

Cooling Fan, Oil Pump or

Other Motor

Reset auxiliary overload after

heater element cools. Verify

correct motor amps.

Check for loose connections

Check motor starter contact

for proper operation.

Check line voltage, if low

consult power company.

E-Stop ALL ALWAYS E-Stop Button Active Release button.

E-Stop Push Button Check wiring

SUPERVISOR CONTROLLER™ USER MANUAL SECTION 4

18

E-Stop ALL ALWAYS Auxiliary E-Stop String

Open

Check auxiliary E-Stop

devices.

E-Stop String Check wiring.

Low Water Pressure ALL Water-

cooled

Cooling Water Pressure

Below 10 psi (0.7bar)

Check for closed valves or

broken pipes.

Oil Change Due, Oil Filter

Change, Separator Change

Due, Air Filter Change, Oil

Analysis Due, Maintenance

Due

ALL ALWAYS Maintenance Due Select Maintenance from

menu to see service due and

part numbers.

Main Motor Overload ALL ALWAYS Main Motor Overload Reset overload after heater

element cools down.

Make sure compressor is

properly configurated.

Make sure load pressure is

set below limit of compres-

sor.

Check motor starter contacts

for proper operation.

Check line voltage, if low

consult power company.

I/O Mod Com Error, Com Mod

Com Error, Motor Mod Com

Error, VSD Com Error

ALL ALWAYS Module Network Error; The

Network that Connects the

Display Module, I/O Mod-

ule and Other Optional

Modules is Not Working

Correctly

Check wiring.

Replace module referred to

in error message, if problem

persists replace display mod-

ule.

Oil Filter Maint., dP2 Oil Filter

High

ALL ALWAYS Pressure Across Oil Filter

Above 20 psi (1.4 bar)

While Running

Oil filter clogged, replace oil

filter.

FLOODED ALWAYS Low ambient temperature,

sump heater may be

required in ambients below

40°F (4°C).

ALL ALWAYS Sensor failure, check sen-

sor, wiring and tubing.

Table 4-1: Troubleshooting Guide—Supervisor Controller

Message Model Enable Probable Cause Remedy

Other manuals for SUPERVISOR CONTROLLER

2

Table of contents

Other Sullair Controllers manuals

Sullair

Sullair ShopTek User manual

Sullair

Sullair SUPERVISOR CONTROLLER Series User manual

Sullair

Sullair Supervisor II User manual

Sullair

Sullair 02250165-411 R01 User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair 02250160-842 User manual

Sullair

Sullair SUPERVISOR II Series User manual

Sullair

Sullair 900 User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair Supervisor IE User manual