Impco L Setup guide

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 1 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

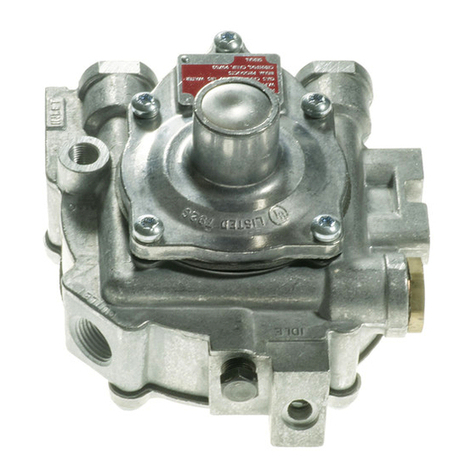

MODEL L

TWO-STAGE REGULATOR REPAIR KIT INSTRUCTIONS

Important: Any maintenance, service or repair

should be performed by trained and experi-

enced service technicians. Proper tools and

equipment should be used to prevent injury to

the servicing technician, property or system

components. Service repairs should always be

performed in a safe environment and the tech-

nician should always wear protective clothing

to prevent injury.

The IMPCO PPI-16 repair kit instructions will

provide the technician information to success-

fully repair the Model L regulator. Always in-

spect the major casting pieces for damage,

corrosion or cracks before attempting a service

repair. Be sure the repair kit part number you

are using is correct for the regulator being ser-

viced. Diaphragms are color coded and have

different performance characteristics:

BLACK: Hydrin diaphragm material is the

standard material and is well suited for the

most common applications.

YELLOW: Silicone diaphragm material is the

optional upgrade material that provides excel-

lent flexibility in cold weather climates and is

more resistant to chemical contamination.

Model L Two Stage Converter

Do not use Teflon tape to seal any fuel fittings.

Failure to follow this warning may cause the

regulator to leak internally, possibly resulting in

serious injury and/or property damage and may

void any warranty coverage.

Part # Description

RK-L Repair Kit Model L, Hydrin Diaphragm

RK-L-2 Repair Kit Model L, w/Silicone Diaphragm

REPAIR KIT PART NUMBERS

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 2 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

MODEL L SERIES CONVERTERS

ITEM# PART# DESCRIPTION

1 S7-1 NSS Screen, atmospheric vent

2 S1-59* NSS Screw, 8-32 x 5/8" SEMS (8)

3 AC1-63 NSS Cover ass'y, secondary

4 W1-27* NSS Washer, hand primer

AD1-30* NSS Diaphragm ass'y, secondary, Hydrin

AD1-31* NSS Diaphragm ass'y, secondary, Silicone

6 L1-87* NSS Lever, secondary

7 S4-37* NSS Seat, secondary

P1-7 NSS Pin, sec. lever fulcrum (early models)

P1-8 NSS Pin, sec. lever fulcrum (later models)

9 S2-97 NSS Spring, secondary regulator (blue)

10 S1-59* NSS Screw, 8-32 x 5/8" SEMS (6)

C1-62 NSS Cover, primary diaphragm (early models)

C1-50816-001 NSS Cover, primary diaphragm (later models)

12 S2-92 NSS Spring, primary regulator (2)

13 AD1-32* NSS Diaphragm ass'y, primary

14 AB1-57 NSS Body ass'y

15 P3-13 NSS Plug, hex head, 1/8 NPT (2)

16 S1-59* NSS Screw, 8-32 x 5/8" SEMS (5)

17 C1-61 NSS Cover, water passage

18 G1-118* NSS Gasket, water passage

19 S1-5 NSS Screw, 1/4-20 x 5/8" SEMS (2)

20 P1-34 NSS Pin, primary valve

21 G1-119* NSS Gasket, vaporizing chamber

22 AC1-64 NSS Cover, vaporizing chamber

23 S1-3* NSS Screw, 10-24 x 5/8" SEMS (9)

24 S4-18* NSS Seat, primary

25 S4-23* NSS Seat support, primary

26 S2-93 NSS Spring primary valve

27 B3-25551 NSS Bushing, fuel inlet

28 S1-1560-004 NSS Pan HD, Torx (2)--later models

NSS=Not Sold/Serviced Separately

* Item included in repair kit

5

8

11

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 3 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

REBUILD INSTRUCTIONS

1. Model L Repair Kit (RK-L) contains all nec-

essary parts to replace components subject

to deterioration (see page 2 for repair kit

components). Installation of repair kit should

be necessary only at the time of a major

overhaul or when converter has been out of

service for a significant length of time.

Note: Gaskets and diaphragms deteriorate if

converter is stored after use.

2. Inspect repair kit component parts to ensure

the kit is complete. Start disassembly by

removing the eight screws (2) securing sec-

ondary cover assembly (3).

3. Tap cover (3) loose with plastic screwdriver

handle and remove secondary diaphragm

assembly (5). The diaphragm assembly

must be moved away from water inlet-outlet

to disengage diaphragm link from the lever

assembly. Discard diaphragm assembly.

4. Early Models Only For later models, skip to

step 7. Loosen screw (10) which retains ful-

crum pin (8).

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 4 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

5. Remove screw (10).

6. Slide fulcrum pin (8) to side as shown to

release lever assembly (6 & 7). In some

cases, the pin may come out entirely.

Retain it for reassembly steps. Skip to

Step 8.

7. Later Models Only For early models,

skip to Step 8. Remove two screws (28)

with T-20 Torx tool to release the fulcrum

pin (8).

8. Remove secondary lever and seat as-

sembly (6 & 7) and secondary regulator

spring (9). Retain pin and spring; discard

lever and seat.

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 5 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

9. Remove remaining screws (10) securing

primary diaphragm cover (11) and re-

move the cover.

10. Removal of primary diaphragm cover

(11) frees two primary springs (12) and

primary diaphragm assembly (13). Re-

move springs and retain for reuse.

11. Remove primary diaphragm assembly

(13). Slide the diaphragm assembly to

disengage slot from primary valve pin

(20). Discard primary diaphragm as-

sembly. Pencil tip points out pin.

Note: Primary valve is actuated by this

pin through the body. This isolates the

diaphragm from any contact with liquid

propane.

12. Turn over and loosen fuel inlet bushing

(27) using a tube wrench or six sided

socket.

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 6 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

13. Removal of fuel inlet bushing (27) re-

leases primary valve spring (26).

14. Remove primary valve spring (26) and

retain for reuse.

15. Remove primary valve seat (24) and

support (25) and discard.

16. Loosen and remove nine screws (23) in

vaporizing chamber cover (22).

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 7 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

17. Break cover (22) loose by tapping with a

screw driver handle. Remove cover and

vaporizing chamber gasket (21). Discard

gasket.

18. Remove primary valve pin (20) from con-

verter body and retain for reuse.

19. Remove five screws (16) from water

passage cover (17).

20. Tap cover to loosen and remove cover

(17) and water passage gasket (18). Dis-

card gasket.

Clean covers, body and metal parts as

necessary with a safety solvent and al-

low to dry prior to reassembly. Do not

use harsh solvents such as brake or car-

buretor cleaner on any of the non-

metallic components as they will damage

the material.

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 8 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

21. Replace water passage cover gasket

(18) and cover (17). Tighten screws

(16), alternating from side to side.

Torque to 25-35 in-lbs. (1.8-4.0 Nm).

22. Install primary valve pin (20) as shown,

in converter body (14). Check that pin

moves up and down freely.

23. Put new vaporizing chamber gasket (21)

in place on vaporizing chamber cover

(22). Press gasket firmly.

24. Reassemble cover (22) and gasket (21)

to heat exchanger body (14). Check to

assure gasket is not folded under cover

at any point.

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 9 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

25. Hand tighten nine screws (23) in place.

Then tighten from side to side until all are

firmly seated and torque to 25-35 in-lbs.

(1.8-4.0 Nm). Replace any screws dam-

aged during use or disassembly.

26. Insert new primary valve seat support

(25) into primary valve spring (26). Ta-

pered neck of valve seat will slide inside

spring (26) opening at either end.

27. Place the primary valve seat (24), seat

support (25) and spring (26) in vaporizing

chamber cover. Clean seat area with

compressed air or a rag.

Note: The seat (24) must be in-

stalled with the rubber side against

the pin, not against the primary seat

support (25).

28. Fuel inlet bushing (27) ready to insert

over primary spring (26).

Note: Apply Loctite®567 or equivalent to

ensure a gas tight seal. DO NOT USE

TEFLON TAPE.

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 10 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

29. Tighten fuel inlet bushing (27) 2 to 3

turns past finger tight using a tube

wrench or 6 sided socket.

30. New primary diaphragm assembly (13)

ready to be put in place. Extrusions on

plate on underside of diaphragm slide in-

to groove on primary pin (20) to connect

two components. Be sure the extruded

slot is engage in the pin groove.

31. After diaphragm (13) is in place, pull up

gently on diaphragm to verify that it is

firmly connected to primary pin (20).

32. Place two primary regulator springs (12)

upon locating perches extruded from

back-up plate on primary diaphragm as-

sembly (13).

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 11 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

33. Early Models Only For later models,

skip to Step 34. Press the nub of the

seat (7) through the lever (6), ensuring a

proper fit. Place secondary lever and

seat assembly (6 & 7) on primary dia-

phragm cover (11). Push fulcrum pin (8)

into place to retain lever.

34. Later Models Only For early models,

skip to 35. Press the nub of the seat (7)

through the lever (6), ensuring a proper

fit. Place the fulcrum pin (8) through the

lever and seat assembly (6 & 7), center,

then place the lever on the cover (11)

with the fulcrum pin seated inside the

slot. Secure the fulcrum pin with two

screws with a T-20 Torx tool and torque

to 17-23 in-lbs. (1.9-2.6 Nm).

35. Press primary cover (11) in place over

the primary springs (12) and diaphragm

(13). Be sure to place over locator pins

closest to water passage cover first, then

over pins at opposite end. Check that di-

aphragm is equally visible all around the

cover and that no portion is folded under.

36. Replace all screws (10) and tighten until

they just contact body. (Use new screws

from repair kit if old ones are damaged).

Then tighten again solidly, first on one

side then diagonally across body on the

opposite side until all screws are firmly

tightened and torque to 25-35 in-lbs.

(1.8-4.0 Nm).

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 12 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

37. Insert secondary regulator spring (9) in

place between secondary lever and seat

assembly (6 & 7) spring perch on primary

cover. Make sure springs snaps into

place ahead of detent in lever.

38. Use IMPCO G2-2 gauge or a straight

edge to check lever height. When using

a straight edge, the lever should be 5/32”

above the body (lightly pull the lever up

against the secondary seat to measure).

If adjustment is needed, bend lever as

close to the fulcrum as possible.

39. Install new secondary diaphragm (5).

Note slot in position to slide into place

and engage secondary lever (6).

40. Replace hand primer seal washer (4)

indicated by pencil.

July, 2015 IMPCO Technologies Inc. PPI-16 REV. D

3030 South Susan St. Page 13 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

41. Secondary cover (3) with screws (2) in

place, positioned over diaphragm (5).

42. Replace cover (3). Finger tighten eight

screws (2) until all contact the cover.

Tighten screws, alternating sides, until all

screws are firmly seated and torque to

25-35 in-lbs. (1.8-4.0 Nm).

43. Apply 100 psi of air pressure to the inlet

side of the regulator and test for leaks.

Draw a soap bubble across the regulator

outlet to verify that no air is flowing

through the outlet. If air escapes, the re-

build has failed and the regulator must

be replaced. Actuate the primer button

and the soap bubble should burst and air

flow should be noted at the converter

outlet. Use soap and/or a commercial

leak detector solution to inspect the gas-

ket seals around the perimeter of the

converter for leaks. If leaks are found,

the regulator must be replaced. If no

leaks are found, the regulator can be re-

installed and returned to service.

Note: Use only brass or plastic fittings in

the water inlet and outlet passages. A

steel fitting will cause the casting to dete-

riorate due to electrolysis.

PPI-16 REV. D IMPCO Technologies Inc. July, 2015

3030 South Susan St. Page 14 of 14

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

WARNING:

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY CAUSE

SERIOUS INJURY, DEATH AND/OR PROPERTY DAMAGE

SERVICE TECHNICIANS AND USERS SHOULD CAREFULLY READ AND ABIDE BY THE PROVISIONS SET FORTH IN

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37 FOR STATIONARY ENGINES, #52 FOR CNG VEHICULAR

FUEL SYSTEMS OR #58 FOR LPG SYSTEMS.

INSTALLERS LPG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE

AND LOCAL LAWS AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #58, STANDARD FOR STORAGE

AND HANDLING OF LIQUEFIED PETROLEUM GASES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

OF FEDERAL, STATE OR LOCAL LAW.

COUNTRIES OUTSIDE OF USA REFER TO THE GOVERNING AGENCIES OVERSEEING CNG AND PROPANE APPLICA-

TIONS.

CNG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE AND LOCAL

LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #52, COMPRESSED NATURAL GAS (CNG) VEHIC-

ULAR FUEL SYSTEMS, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION OF FEDERAL, STATE OR LOCAL

LAW.

LPG AND/OR NATURAL GAS INSTALLATIONS ON STATIONARY ENGINES MUST BE DONE IN ACCORDANCE WITH

FEDERAL, STATE AND LOCAL LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37, STATIONARY

COMBUSTION ENGINES AND GAS TURBINE ENGINES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

WITH FEDERAL, STATE OR LOCAL LAW. FAILURE TO ABIDE BY THE ABOVE WILL VOID ANY IMPCO WARRANTY ON

THE PRODUCTS AND MAY CAUSE SERIOUS INJURY OR PROPERTY DAMAGE.

SERVICE TECHNICIANS DUE TO THE INHERENT DANGER OF GASEOUS FUELS, IMPCO PRODUCTS SHOULD NOT BE

INSTALLED OR USED BY PERSONS NOT KNOWLEDGEABLE OF THE HAZARDS ASSOCIATED WITH THE USE OF

GASEOUS FUELS. ANY MAINTENANCE, SERVICE OR REPAIR SHOULD BE PERFORMED BY TRAINED AND EXPERI-

ENCED SERVICE TECHNICIANS.

PROPER TOOLS AND EQUIPMENT PROPER TOOLS AND EQUIPMENT SHOULD BE USED TO PREVENT INJURY TO

THE SERVICING TECHNICIAN, PROPERTY OR SYSTEM COMPONENTS. SERVICE REPAIRS SHOULD ALWAYS BE

PERFORMED IN A SAFE ENVIRONMENT AND THE TECHNICIAN SHOULD ALWAYS WEAR PROTECTIVE CLOTHING TO

PREVENT INJURY.

INSPECT BEFORE USE ALWAYS INSPECT THE MAJOR CASTING PIECES FOR DAMAGE, CORROSION OR CRACKS

BEFORE ATTEMPTING A SERVICE REPAIR. BE SURE THE REPAIR KIT PART NUMBER YOU ARE USING IS CORRECT

FOR THE COMPONENT(S) BEING SERVICED.

NO TEFLON TAPE DO NOT USE TEFLON TAPE TO SEAL ANY FUEL FITTINGS. FAILURE TO FOLLOW THIS WARNING

MAY CAUSE THE REGULATOR TO LEAK INTERNALLY, POSSIBLY RESULTING IN SERIOUS INJURY, DEATH AND/OR

PROPERTY DAMAGE AND MAY VOID ANY WARRANTY COVERAGE.

This manual suits for next models

2

Table of contents

Other Impco Controllers manuals