1

Table Of Contents

Section 1: Introduction To The MicroLYNX ..................... 3

Electrical Specifications ...................................................................................... 4

Communications Specifications ....................................................................... 5

Mechanical Specifications................................................................................... 5

Environmental Specifications ........................................................................... 5

Mounting Information........................................................................................ 6

Connector Information ...................................................................................... 6

MicroLYNX Terminology Explained............................................................ 7

Shopping List ......................................................................................................... 8

Section 2: Connecting Power............................................... 9

Tools and Equipment Required ....................................................................... 9

How to Connect Power ..................................................................................... 9

Section 3: Connecting A Motor......................................... 1 1

Tools and Equipment Required ..................................................................... 11

Recommended Stepping Motors .................................................................... 11

How to Connect the Motor ............................................................................ 12

Section 4: Connecting Communications .......................... 15

Tools and Equipment Required ..................................................................... 15

Connecting Communications......................................................................... 15

Section 5: Establishing Communications ......................... 1 8

Tools and Equipment Required ..................................................................... 18

Installing the LYNX Terminal Software ..................................................... 18

Using the LYNX Terminal Software ........................................................... 20

Section 6: Controlling Motor Current ............................. 22

Current Control Variables .............................................................................. 22

Section 7: Setting The Motor Resolution ......................... 23

Setting the Motor Resolution Exercise......................................................... 23

Section 8: Using The Isolated Digital I/O........................ 24

The Isolated Digital I/O Defined .................................................................. 24

Setting the Pull-up Voltage .............................................................................. 25

The Input Output Setup Variable ................................................................. 26

The IO Variable .................................................................................................. 30

Setting the Digital Filtering for the I/O ...................................................... 32

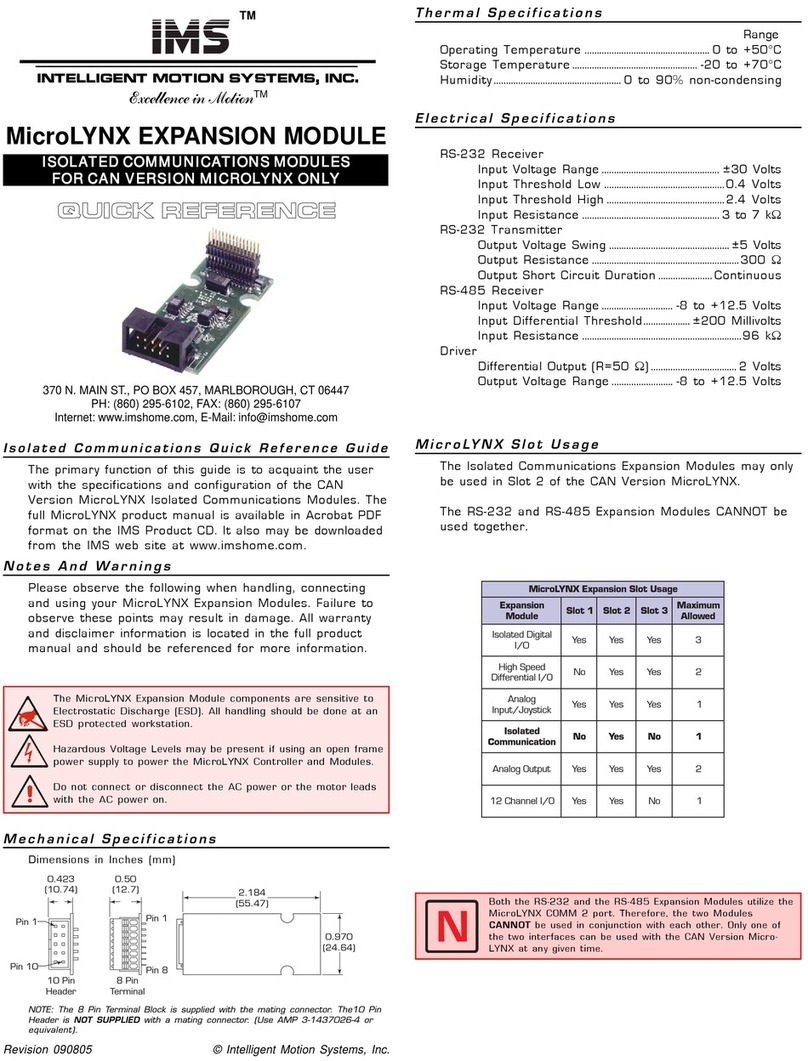

Section 9: Expanding The MicroLYNX ............................ 33

MicroLYNX Expansion Modules ................................................................. 33

Choosing the Expansion Modules for Your Application ....................... 33

Expanding the Isolated Digital I/O ............................................................... 35

The High-Speed Differential I/O Module .................................................. 37

The Analog Input/Joystick Interface Module ........................................... 45

Section 10: LYNX Software Components ........................ 50

LYNX Software Components ........................................................................ 50

Variables................................................................................................................ 50

Commonly Used Variables ............................................................................. 50

Instructions .......................................................................................................... 53

Flags ....................................................................................................................... 59

Keywords.............................................................................................................. 59

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.