iv

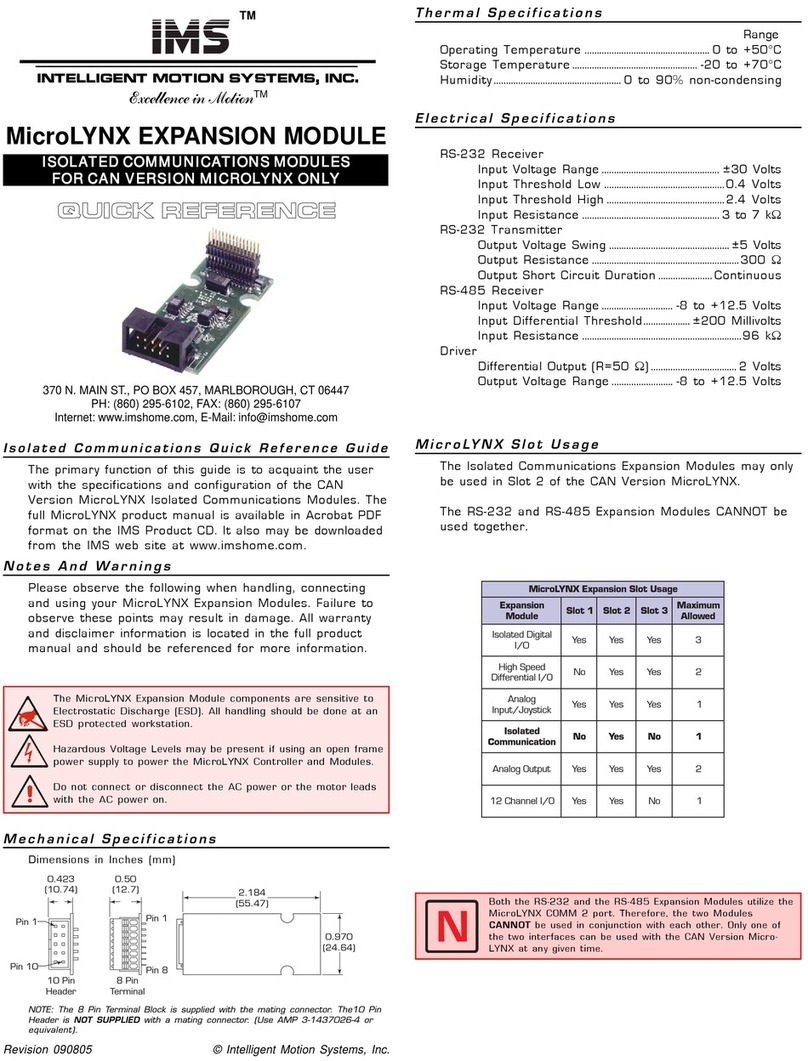

Figure 1.3.1: Mechanical Specifications................................................................................... 1-19

Figure 1.3.2: 16-Pin Wire Crimp Connector P1 Pin Numbers................................................ 1-21

Figure 1.3.3: P2 Pin Assignment ............................................................................................. 1-22

Figure 1.3.4: P3: 4-Pin Locking Wire Crimp Motor Connector.............................................. 1-22

Part 2: Connections and Interface

Figure 2.1.1: MForce MicroDrive Mounting Recommendations............................................... 2-3

Figure 2.1.2: Grounding and Shielding for Logic Connections.................................................. 2-4

Figure 2.1.3: MForce MicroDrive Power Connections .............................................................. 2-5

Figure 2.1.4: Aux-Logic Connection ......................................................................................... 2-6

Figure 2.2.1 A & B: Per Phase Winding Inductance.................................................................. 2-8

Figure 2.2.2: 8 Lead Motor Series Connections....................................................................... 2-10

Figure 2.2.3: 8 Lead Motor Parallel Connections.................................................................... 2-11

Figure 2.2.4: 6 Lead Half Coil (Higher Speed) Motor Connections ....................................... 2-11

Figure 2.2.5: 6 Lead Full Coil (Higher Torque) Motor Connections ...................................... 2-12

Figure 2.2.6: 4 Lead Motor Connections................................................................................. 2-12

Figure 2.3.1: Full Duplex Communications (RS-422)............................................................. 2-13

Figure 2.3.2: Half Duplex 2 Wire Communications (RS-485) ................................................ 2-14

Figure 2.3.3: RS-485 Interface, Multiple MForce System........................................................ 2-15

Figure 2.4.1: Uses for the Digital I/O...................................................................................... 2-20

Figure 2.4.2: Flying Lead I/O Connections ............................................................................. 2-24

Figure 2.4.3: 7-Pin Pluggable Terminal I/O Connections........................................................ 2-24

Figure 2.4.4: Plus 2 I/O Connections - Expanded I/O Configuration..................................... 2-25

Figure 2.4.5: Plus 2 I/O Connections - Closed Loop Configuration........................................ 2-25

Figure 2.4.6: Sinking Input Example using a Push Button Switch ........................................... 2-26

Figure 2.4.7: Sourcing Input Example using a Push Button Switch ......................................... 2-27

Figure 2.4.8: Sinking Output Example.................................................................................... 2-28

Figure 2.4.9: Switch Interface to Input, Sinking ...................................................................... 2-29

Figure 2.4.10 Sourcing Input Example using a Push Button Switch ........................................ 2-30

Figure 2.4.11: Sinking Output Example.................................................................................. 2-31

Figure 2.4.12: Sourcing Output Example................................................................................ 2-32

Figure 2.4.13: MFI Clock Functions....................................................................................... 2-33

Figure 2.4.14: Step Direction I/O Equivalent Circuit.............................................................. 2-33

Figure 2.4.15: Capture/Trip I/O Equivalent Circuit................................................................ 2-34

Figure 2.4.16: Analog Input - Voltage Mode ........................................................................... 2-35

Figure 2.4.17: Analog Input - Current Mode .......................................................................... 2-36

Appendices

Figure A.1: DC Cabling - Under 50 Feet...................................................................................A-3

Figure A.2: DC Cabling - 50 Feet or Greater - AC To Full Wave Bridge Rectifier......................A-3

Figure A.3: AC Cabling - 50 Feet or Greater - AC To Power Supply..........................................A-3

Figure B.1: NPN Interface to an MDI Sinking Input................................................................A-5

Figure B.2: PNP Interface to a Sourcing Input ..........................................................................A-6

Figure B.3: Sinking Output to Relay .........................................................................................A-7

Figure B.4: Mixed Output Example- Standard I/O Set..............................................................A-7

Figure B.5: NPN Sinking Input on an MForce Plus2Motion Control .....................................A-8

Figure B.6: PNP Sourcing Input on an MForce Plus2Motion Control.....................................A-8

Figure B.7: Sourcing Output to Sourcing Input ........................................................................A-9

Figure B.8: Mixed Input/Output Example - Enhanced I/O.....................................................A-10

Figure B.9: TTL Interface to an Input Group..........................................................................A-10

Figure B.10: Outputs Interfaced to LED’s as a Group .............................................................A-11

Figure C.1: Connecting a Remote Encoder .............................................................................A-12

Figure C.2: Differential Encoder Signals..................................................................................A-13

Figure D.1: MD-CC400-000..................................................................................................A-15

Figure D.2: MD-CC400-000 Mechanical Specifications.........................................................A-15

Figure D.3: Hardware Update Wizard.....................................................................................A-16

Figure D.4: Hardware Update Wizard Screen 2.......................................................................A-16

Figure D.5: Hardware Update Wizard Screen 3.......................................................................A-17

Figure D.6: Windows Logo Compatibility Testing ..................................................................A-17

Figure D.7: Hardware Update Wizard Finish Installation........................................................A-17

Figure D.8: Hardware Properties .............................................................................................A-18

Figure D.9: Windows Device Manager....................................................................................A-18

Figure D.10: PD16-1417-FL3 Prototype Development Cable ................................................A-19

Figure D.11: PD10-1434-FL3 ................................................................................................A-21

Figure E.1: Size 14 Wiring and Connection ............................................................................A-22

Figure E.2: Size 14 Mechanical Specifications..........................................................................A-22