IN-ECO CIWLI2001A User manual

说明书材质要求:105g铜版纸

折叠方式:骑马钉

说明书成品尺寸: 137x195mm

备注:

第二:特别注意:

1.印刷时看样请参考我司提供的实物样品颜色。不得偏色

2.137C的专色不得参考C=0,M=35,Y=90,K=0对应的四色

色谱颜色来看样印刷

第一:

专色用6级防晒油墨

+CMYK油墨要求:

1.PANTONE137C专色油墨(

专色用6级防晒油墨):

2.C色油墨:泗联天蓝墨

3.M色油墨:泗联金红墨

4.Y色油墨:pantone123C专色油墨

5.K色油墨:泗联黑墨

如果自己配色,油墨配比为:泗联中黄

(

防晒)

2000g

泗联金红

(

防晒)

225g

特别注意:此页内容不印刷

日期 设计师

更改记录

版本号

1.新设计

2021.10.30 蔡鑫宇1121.V01

Lithium-Ion Impact Wrench

Llave De Impacto De Iones De Litio

Visseuse À Choc Li-ion

Lithium-Ion Impact Wrench

Llave De Impacto De Iones De Litio

Visseuse À Choc Li-ion

EN

ES

FR

CIWLI2001A CIWLI2001AX CIWLI2001A-X

(X stands for 1 to 9)

INGCO Global

S

a

m

e

Ba

t

t

e

r

y

1

2

0

+

T

o

o

ls

The symbols in instruction manual and the label on the tool

Double insulated for additional protection.

Read the instruction manual before using.

CE conformity.

Wear safety glasses, hearing protection and dust mask.

Charging the battery only below 40ºc

Always recycle batteries

Do not destroy battery by fire

Do not expose battery to water

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or

retailer for recycling advice.

Safety alert.

Please only use the accessories supported by the manufacturer.

|English

3|English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING Read all safety warnings and all instructions.Failure to

follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered and dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tools in a damp location is unavoidable, use

a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

4|English

3) Personal safety.Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool safety principles. A

careless action can cause severe injury within a fraction of a second.

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-

position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

4) Power tool use and care Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and grasping surfaces do

not allow for safe handling and control of the tool in unexpected situations.

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

5|English

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool. Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance

with these instructions, taking into account the working

conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous

situation.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A

charger that is suitable for one type of BATTERY pack may create a risk

of fire when used with another BATTERY pack.

b) Use power tools only with specifically designated BATTERY packs.

Use of any other BATTERY packs may create a risk of injury and fire.

c) When BATTERY pack is not in use, keep it away from other metal

objects, like paper clips, coins, keys, nails, screws or other small

metal objects, that can make a connection from one terminal to

another. Shorting the BATTERY terminals together may cause burns

or a fire.

d) Under abusive conditions, liquid may be ejected from the BATTERY;

avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help. Liquid ejected from the

BATTERY may cause irritation or burns.

e) Do not use a BATTERY pack or tool that is damaged or modified.

Damaged or modified batteries may exhibit unpredictable behaviour

resulting in fire, EXPLOSION or risk of injury.

f) Do not expose a BATTERY pack or tool to fire or excessive

temperature. Exposure to fire or temperature above 130 °C may cause

explosion.

g) Follow all charging instructions and do not charge the BATTERY

pack or tool outside the temperature range specified in the

instructions. Charging improperly or at temperaturesoutside the specified

range may damage the BATTERY and increase the risk of fire.

Cordless impact driver safety

warnings

1. Hold power tool b y insulated gripping sur-

faces, when performing an operation where

the fastener may contact hid d en wiring.

Fasteners contacting a " live" wire may mak e

exposed metal parts of the power tool " live" and

could give the operator an electric shock .

2. Be sure no one is b elow when using the tool in

high locations.

3.

4. W ear ear protectors.

5. D o not touch the b it or the workpiece immed i-

ately after operation. They may b e extremely

hot and could b urn your sk in.

6. K eep hand s away from rotating parts.

SAVE THESE INSTRUCTIONS.

WAR NING :

D O N O T let comfort or familiarity

with prod uct ( gained from repeated use) replace strict

ad herence to safety rules for the sub j ect prod uct.

MI SUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal inj ury.

Symbols

The followings show the symb ols used for tool.

volts

d irect current

no load speed

revolutions or reciprocation per minute

numb er of b low

Important safety instructions for

battery cartridge

1.

Before using b attery cartrid ge, read all instruc-

tions and cautionary mark ings on ( 1) b attery

charger, ( 2) b attery, and ( 3) prod uct using b attery.

2. D o not d isassemb le b attery cartrid ge.

3. I f operating time has b ecome excessively

shorter, stop operating immed iately. I t may

result in a risk of overheating, possib le b urns

and even an explosion.

|English

ENGLISH (Original instructions)

•without notice.

•

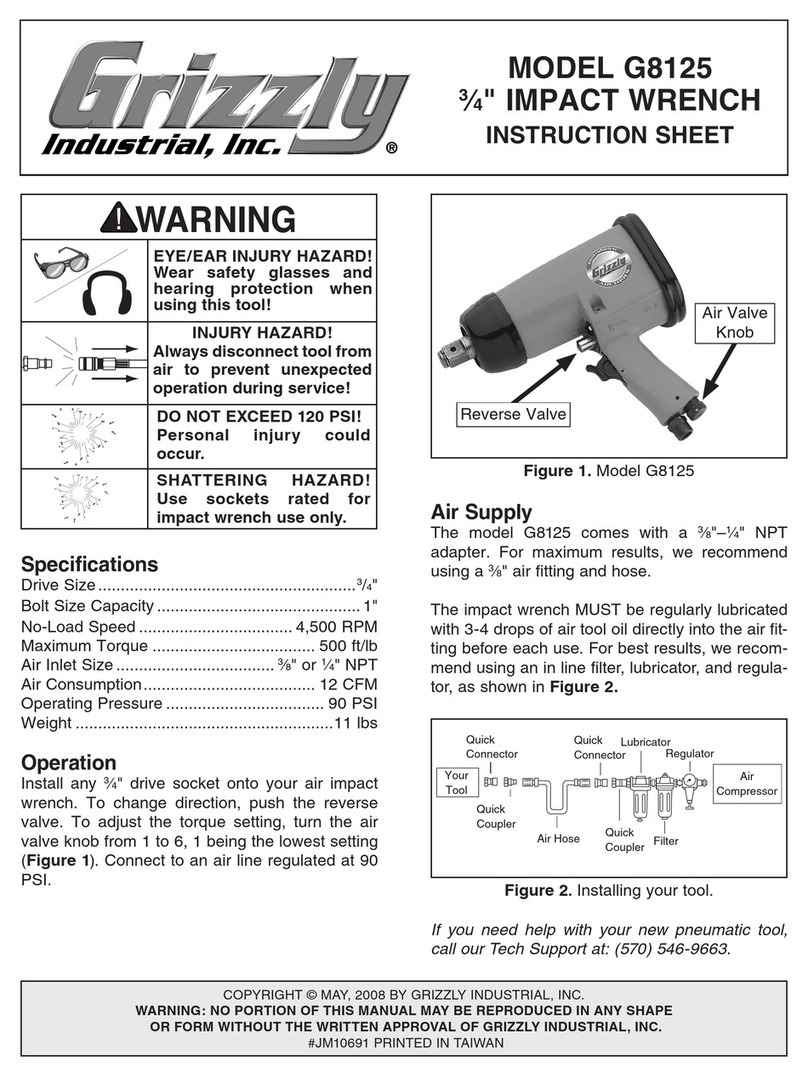

SPECIFICATIONS

Machine screw

Stand ard b olt

High tensile b olt

Hard impact mod e

Soft impact mod e

Hard impact mod e

Soft impact mod e

Rated voltage

Charging time

Fastening capacities

I mpacts per minute

N o load speed ( RPM)

Machine screw

Stand ard b olt

High tensile b olt

Hard impact mod e

Soft impact mod e

Hard impact mod e

Soft impact mod e

Rated voltage

Charging time

Fastening capacities

I mpacts per minute

N o load speed ( RPM)

1Hr approx

M10 - M20

M10 - M16

5 mm - 14 mm

0 - 2100 /min

0 - 1300 /min

0 - 2000 /min

Max.20V

0 - 3300 /min

6) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of the

power tool is maintained.

b ) Never service damaged BATTERY packs. Service of BATTERY

packs should only be performed by the manufacturer or authorized s

ervice providers.

4 . If electrolyte gets into your eyes, rinse them

out with clear water and seek medical atten-

tion right away. It may result in loss of your

eyesight.

5 . Do not short the battery cartridge:

( 1)Do not touch the terminals with any con-

ductive material.

( 2)Avoid storing battery cartridge in a con-

tainer with other metal obj ects such as

nails, coins, etc.

( 3)Do not ex pose battery cartridge to water

or rain.

A battery short can cause a large current

breakdown.

6 . Do not store the tool and battery cartridge in

locations where the temperature may reach or

ex ceed 5 0 ° C ( 122 ° F) .

7 . Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

8 . Be careful not to drop or strike battery.

9 . Do not use a damaged battery.

10 . The contained lithium-ion batteries are subj ect

to the Dangerous G oods Legislation req uire-

ments.

F or commercial transports e.g. by third parties,

forwarding agents, special requirement on pack-

aging and labeling must be observed.

F or preparation of the item being shipped, consult-

ing an ex pert for hazardous material is required.

P lease also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

SA V E TH ESE INSTRUCTIONS.

CAUTION:Only use genuineING C Obattteries.

U se of non-genuine batteries, or batteries that

have been altered, may result in the battery bursting

IN GC O

Tips for maintaining max imum

battery life

1. C harge the battery cartridge before completely

discharged. A lways stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery car-

tridge. Overcharging shortens the battery

service life.

3.

1. B utton 2. B attery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click.

and result in damage to the tool and battery cartridge

and a personal injury.

cartridge. F ailure to hold the tool and the battery

C harge the battery cartridge with room tem-

perature at 10 ° C - 4 0 ° C ( 5 0 ° F - 10 4 ° F) . Let

a hot battery cartridge cool down before

charging it.

4 . C harge the battery cartridge if you do not use

it for a long period ( more than six months) .

also void the I N GCO warranty for the I N GCO tool and

charger. CAUTION: $OZD\VLQVWDOOWKHEDWWHU\FDUWULGJH

IXOO\XQWLOWKHUHGLQGLFDWRUFDQQRWEHVHHQI f not,

it may accid entally fall out of the tool, causing inj ury to

you or someone around you.

CAUTION: 'RQRWLQVWDOOWKHEDWWHU\FDUWULGJH

IRUFLEO\ I f the cartrid ge d oes not slid e in easily, it is

not b eing inserted correctly.

CAUTION: $OZD\VVZLWFKRIIWKHWRROEHIRUH

LQVWDOOLQJRUUHPRYLQJRIWKHEDWWHU\FDUWULGJH

CAUTION: +ROGWKHWRRODQGWKHEDWWHU\FDU

)81&7,21$/

'(6&5,37,21

CAUTION: $OZD\VEHVXUHWKDWWKHWRROLV

VZLWFKHGRIIDQGWKHEDWWHU\FDUWULGJHLVUHPRYHG

EHIRUHDGMXVWLQJRUFKHFNLQJIXQFWLRQRQWKHWRRO

,QVWDOOLQJRUUHPRYLQJEDWWHU\

FDUWULGJH

_(QJOLVK

2

1

Indicating the remaining battery

capacity

►1. Indicator lamps 2. C heck button

P ress the check button on the battery cartridge to indi-

cate the remaining battery capacity. The indicator lamps

light up for few seconds.

NOTE: D epending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

> 8 0 %

30 % to 8 0 %

< 30 %

Indicator lamps Remaining

capacity

Lighted Off

Tool / battery protection system

The tool is equipped with a tool/battery protection sys-

tem. This system automatically cuts off power to the

motor to ext end tool and battery life. The tool will auto-

matically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

W hen the battery is operated in a manner that causes

it to draw an abnormally high current, the tool automat-

ically stops without any indication. In this situation, turn

the tool off and stop the application that caused the tool

to become overloaded. Then turn the tool on to restart.

Overheat protection

W hen the tool/battery is overheated, the tool stops

automatically. In this situation, let the tool/battery cool

before turning the tool on again.

Switch action

CAUTION: Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

To start the tool, simply pull the switch trigger. Tool

speed is increased by increasing pressure on the switch

trigger. R elease the switch trigger to stop.

NOTE: The tool automatically stops if you keep pull-

ing the switch trigger for about 6 minutes.

Electric brake

This tool is equipped with an electric brake. If the tool

consistently fails to quickly stop after the switch trigger

is released, have the tool serviced at a IN GC O service

center.

Lighting up the front lamp

CAUTION:Do not look in the light or see the

source of light directly.

1

►1. L amp

_(QJOLVK

1

►1. Switch trigger

1

1

2

2

1. R eversing switch lever

CAUTION: A lways check the direction of

rotation before operation.

CAUTION: U se the reversing switch only after

the tool comes to a complete stop.C hanging the

direction of rotation before the tool stops may dam-

age the tool.

CAUTION: W hen not operating the tool,

always set the reversing switch lever to the neu-

tral position.

This tool has a reversing switch to change the direction

of rotation. D epress the reversing switch lever from the

A side for clockwise rotation or from the B side for coun-

terclockwise rotation.

W hen the reversing switch lever is in the neutral posi-

tion, the switch trigger cannot be pulled.

1. Hard 2. Soft 3 . B utton

Y ou can change the impact force in three steps: hard,

soft.

This allows a tightening suitable to the work.

E very time the button is pressed, the number of blows

changes in two steps.

C hanging the impact force

1

23

H igh

Low

Change

only when

running !

Only Clockwise !

H igh

Low

Change

only when

running !

Only Clockwise !

Reversing switch action

►1. B utton

H igh

Low

Change

only when

running !

Only Clockwise !

1

,PSDFWIRUFHJUDGHGLVSOD\HG

RQSDQHO

0D[LPXPEORZV 3XUSRVH ([DPSOHRIDSSOLFDWLRQ

High 3, 300 min- 1 ( /min) Tightening when force and

speed are d esired . Tightening wood screws,

tightening b olts.

Low 2, 000 min- 1 ( /min) Tightening with less force to

avoid screw thread b reak age. Tightening sash screws, tight-

ening small screws such as M6.

127( Amod e is availab le only when the tool rotates clock wise. W hen rotating counterclock wise in A mod e, the

impact force and speed are the same as hard mod e.

127( W hen all lamps on the switch panel go out, the tool is turned off to save the b attery power. The impact force

grad e can b e check ed b y pulling the switch trigger to the extent that the tool d oes not operate.

127( W hile pulling the switch trigger, the impact force grad e cannot b e changed .

+LJK

/RZ

Change

only when

running !

Only Clockwise !

+LJK

/RZ

Change

only when

running !

Only Clockwise !

High

Low

+LJK

/RZ

Change

only when

running !

Only Clockwise !

+LJK

/RZ

Change

only when

running !

Only Clockwise !

,PSDFWIRUFHJUDGHGLVSOD\HG

RQSDQHO

0D[LPXPEORZV $SSOLFDWLRQ :RUN

3, 300 min

2, 000 min

- 1 ( /min) Tightening when force and

speed are d esired . Assemb ling the steel frame.

ad j ustment with small d iameter

b olt.

Assemb ling furnitures.

+LJK

/RZ

Change

only when

running !

Only Clockwise !

_(QJOLVK

Change

only when

running !

Change

only when

running !

B

A

1

A SSEM BLY

CAUTION: A lways be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Selecting correct impact socket

Always use the correct size impact socket for bolts and

nuts. An incorrect size impact socket will result in inac-

curate and inconsistent fastening torque and/or damage

to the bolt or nut.

Installing or removing impact socket

CAUTION: M ake sure that the impact socket

and the mounting portion are not damaged before

installing the impact socket.

CAUTION: A fter inserting the impact socket,

do not use it.

►1. Impact socket 2. Square drive

Align the hole in the side of the impact socket with the

detent pin on the square drive and push the impact

socket onto the square drive until it locks into place. Tap

it lightly if required.

To remove the impact socket, simply pull it off.

Installing hook

►1. Groove 2. Hook 3 . Screw

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool. To install

the hook, insert it into a groove in the tool housing on

either side and then secure it with a screw. To remove,

loosen the screw and then take it out.

OP ERA TION

CAUTION:

A lways insert the battery cartridge

all the way until it locks in place. If you can see the

red indicator on the upper side of the button, it is not

locked completely. Insert it fully until the red indicator

cannot be seen. If not, it may accidentally fall out of the

tool, causing injury to you or someone around you.

the bolt or nut. Turn the tool on and fasten for the proper

fastening time.

1

2

_(QJOLVK

3

2

1

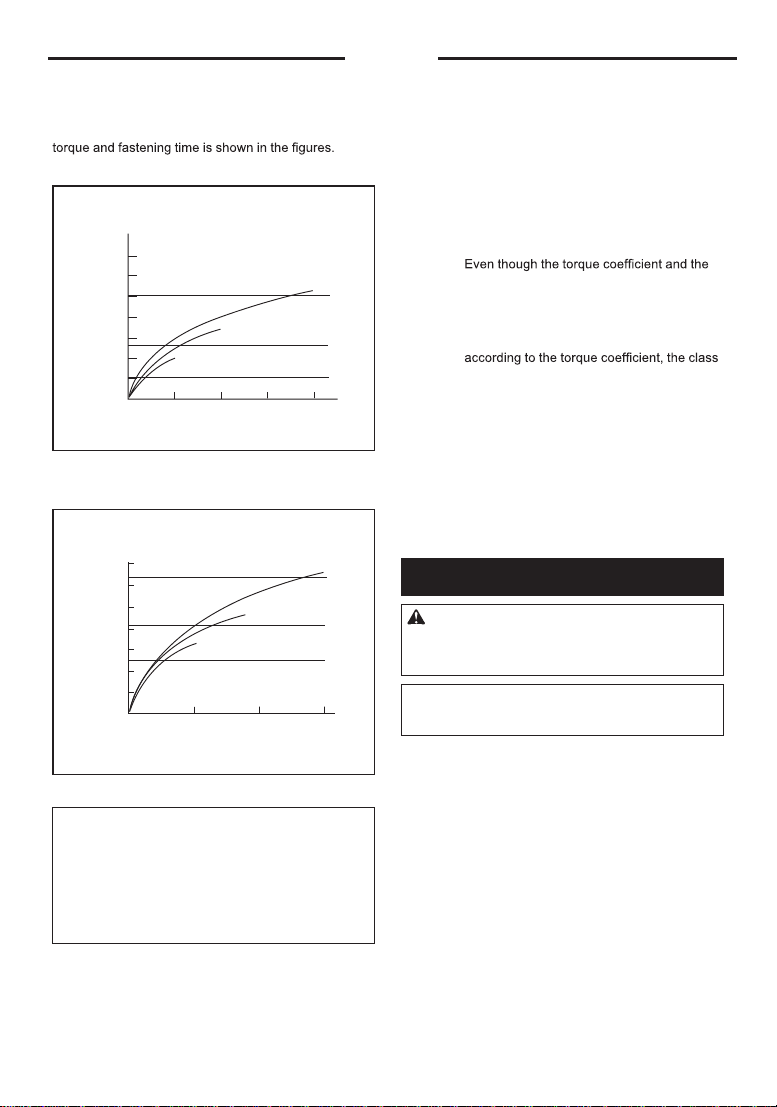

The proper fastening torq ue may d iffer d epend ing upon

the k ind or siz e of the b olt, the material of the work piece

to b e fastened , etc. The relation b etween fastening

3URSHUIDVWHQLQJWRUTXHIRUVWDQGDUGEROW

0

280

( 207)

12

M20

M16

M16

M20

M12 M12

N • m

( ft• lb s)

240

( 177)

200

( 148)

160

( 118)

120

( 89)

80

( 59)

40

( 30)

Fastening time ( second ) Fastening torq ue

3URSHUIDVWHQLQJWRUTXHIRUKLJKWHQVLOHEROW

0123

M12H

M14H

M16H

M12H

M14H

M16H

280

( 207)

240

( 177)

200

( 148)

160

( 118)

120

( 30)

80

( 59)

40

( 89)

N • m

( ft• lb s)

Fastening time ( second ) Fastening torq ue

127( Hold the tool pointed straight at the b olt or nut.

127( E xcessive fastening torq ue may d amage the

b olt/nut or impact sock et. Before starting your j ob ,

always perform a test operation to d etermine the

proper fastening time for your b olt or nut.

127(

I f the tool is operated continuously until the b attery

cartrid ge has d ischarged , allow the tool to rest for 15 min-

utes b efore proceed ing with a fresh b attery cartrid ge.

The fastening torq ue is affected b y a wid e variety of

factors includ ing the following. After fastening, always

check the torq ue with a torq ue wrench.

end ) will cause a red uction in the fastening torq ue.

3. Bolt

•class of b olt are the same, the proper fasten-

ing torq ue will d iffer accord ing to the d iame-

ter of b olt.

• E ven though the d iameters of b olts are the

same, the proper fastening torq ue will d iffer

of b olt and the b olt length.

4. The use of the universal joint or the extension

b ar somewhat red uces the fastening force of the

impact wrench. Compensate b y fastening for a

longer period of time.

5. The manner of hold ing the tool or the material

of d riving position to b e fastened will affect the

torq ue.

6. O perating the tool at low speed will cause a red uc-

tion in the fastening torq ue.

0$,17(1$1&(

CAUTION: $OZD\VEHVXUHWKDWWKHWRROLV

VZLWFKHGRIIDQGWKHEDWWHU\FDUWULGJHLVUHPRYHG

EHIRUHDWWHPSWLQJWRSHUIRUPLQVSHFWLRQRU

PDLQWHQDQFH

NOTICE: 1HYHUXVHJDVROLQHEHQ]LQHWKLQQHU

DOFRKRORUWKHOLNH'LVFRORUDWLRQGHIRUPDWLRQRU

FUDFNVPD\UHVXOW

To maintain prod uct SAFE TY and RE LI ABI LI TY ,

repairs, any other maintenance or ad j ustment should

b e performed b y I N GCO Authoriz ed or Factory Service

Centers, always using I N GCO replacement parts.

1. W hen the b attery cartrid ge is d ischarged almost

completely, voltage will d rop and the fastening

torq ue will b e red uced .

2. I mpact sock et

• Failure to use the correct siz e impact sock et

will cause a red uction in the fastening torq ue.

•

Aworn impact sock et ( wear on the hex end or sq uare

_(QJOLVK

|English

CIWLI2001A CIWLI2001AX CIWLI2001A-X (X stands for 1 to 9)

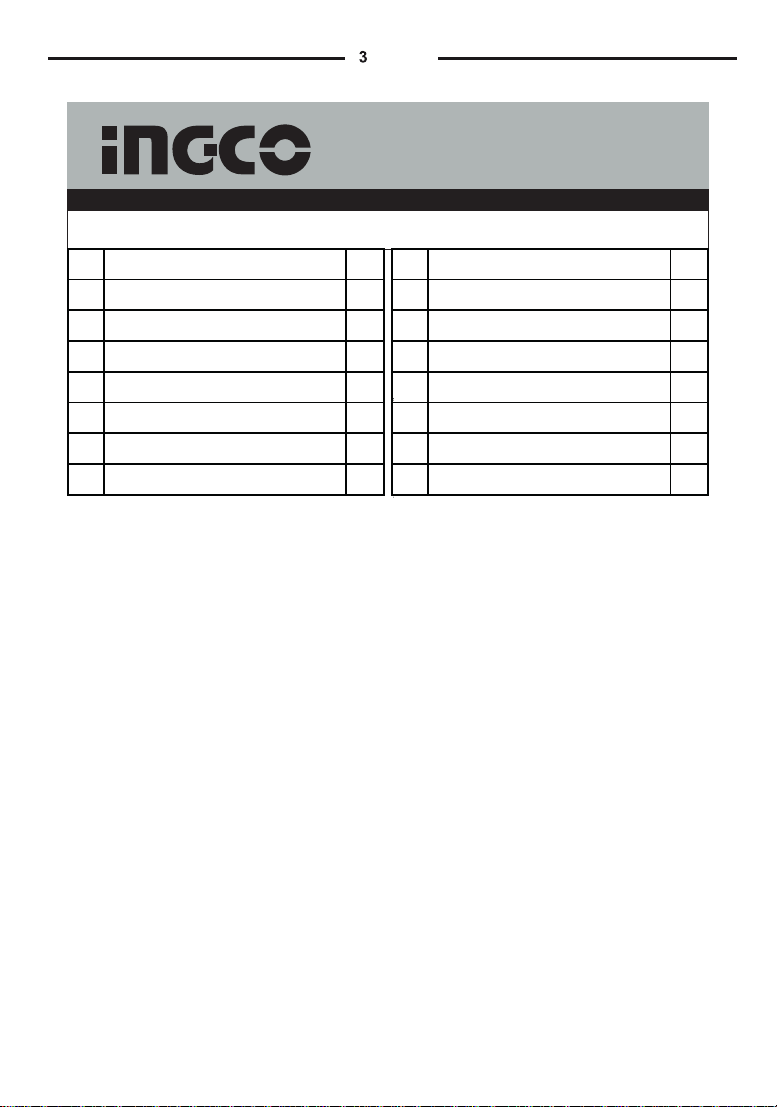

EXPLODED VIEW

1 |English

CIWLI2001A CIWLI2001AX CIWLI2001A-X (X stands for 1 to 9)

SPARE PART LIST

No. Part Description Qty

1

2

3

4

5

6

7

No. Part Description Qty

9

8

12

13

14

10

11

1

1

1

1

9

1

1

Tapping Screw ST3.9*22

Gear Box Assy & Hammer Assy

Stator

Motor Gear

Rotor

F/R Change Lever

Left&Right Shell

Function Panel

Terminal

Controller

Trigger

Tapping Screw ST3.5*16

Battery

Charger

4

1

1

1

1

1

1

CIWLI2001A CIWLI2001AX CIWLI2001A-X(X stands for 1 to 9)

www.ingco.com

MADE IN CHINA

1121.V01 No. 45 Songbei Road, Suzhou

Industrial Park, China.

INGCO TOOLS CO., LIMITED

This manual suits for next models

1

Table of contents

Popular Impact Driver manuals by other brands

Milwaukee

Milwaukee 9070-20 Operator's manual

Panasonic

Panasonic EY7202 - 12V IMPACT DRIVER operating instructions

Red Stone

Red Stone RS 10.8Li CC Original instructions

Pattfield Ergo Tools

Pattfield Ergo Tools PE-20 IDB Original instructions

RIDGID

RIDGID OCTANE R86039VN Operator's manual

Alemlube

Alemlube 6III4 owner's manual