IN-ECO LR 060-H06 User manual

www.in-eco.eu

Air and Vacuum

Components

Operating Instructions

Liquid ring vacuum pumps

LR 060-H06, LR 061-H16

03

Contents

IN-ECO spol. s r.o.

Contents

1 Safety 06

1.1 Denitions 06

1.2 Safety alert symbol 06

2 Intended Use 08

3 Intended Use 08

4 Technical Data 09

4.1 Mechanical data 09

4.2 Operating conditions 10

5 Description of Vacuum Pump/Compressor 12

5.1 Design and principle 12

5.2 Operating method 12

5.3 Operating modes 13

5.3.1 Self-priming operation 13

5.3.2 Operation with operating-liquid feed 13

6 Transport and Handling 14

7 Installation 15

7.1 Installation 15

7.2 Electrical connection (motor) 16

7.3 Connecting pipes/hoses (vacuum pump/compressor) 17

7.3.1 Inlet connection 18

7.3.2 Discharge connection 18

7.3.3 Operating-liquid port 18

8 Commissioning 19

8.1 Preparation and start-up 19

8.2 Self-priming operation 20

8.3 Operation with operating-liquid feed 21

9 Operation 23

9.1 Self-priming operation 23

10 Shut-Down and Longer Standstills 24

10.1 Draining 24

10.2 Preparing for longer standstill 24

10.3 Storage conditions 25

04

Contents

IN-ECO spol. s r.o.

11 Servicing 25

11.1 Maintenance 26

11.2 Repairs/troubleshooting 28

11.3 Spare parts 30

11.3.1 Ordering IN-ECO spare parts 30

11.3.2 Ordering standardized parts 30

11.4 Service/Aer-sales service 30

11.5 Decontamination and Declaration of Clearance 30

12 Disposal 30

13 Accessories 31

13.1 Flanges 31

13.2 Non-return valve 31

13.3 Gas ejector 32

13.4 Liquid separator 33

13.5 Cavitation protection 34

14 Exploded View with Parts List 36

14.1 Parts list 36

14.2 Exploded view 37

15 Limited standard warranty 39

16 Waste disposal 39

05

06

1 Safety

1.1 Denitions

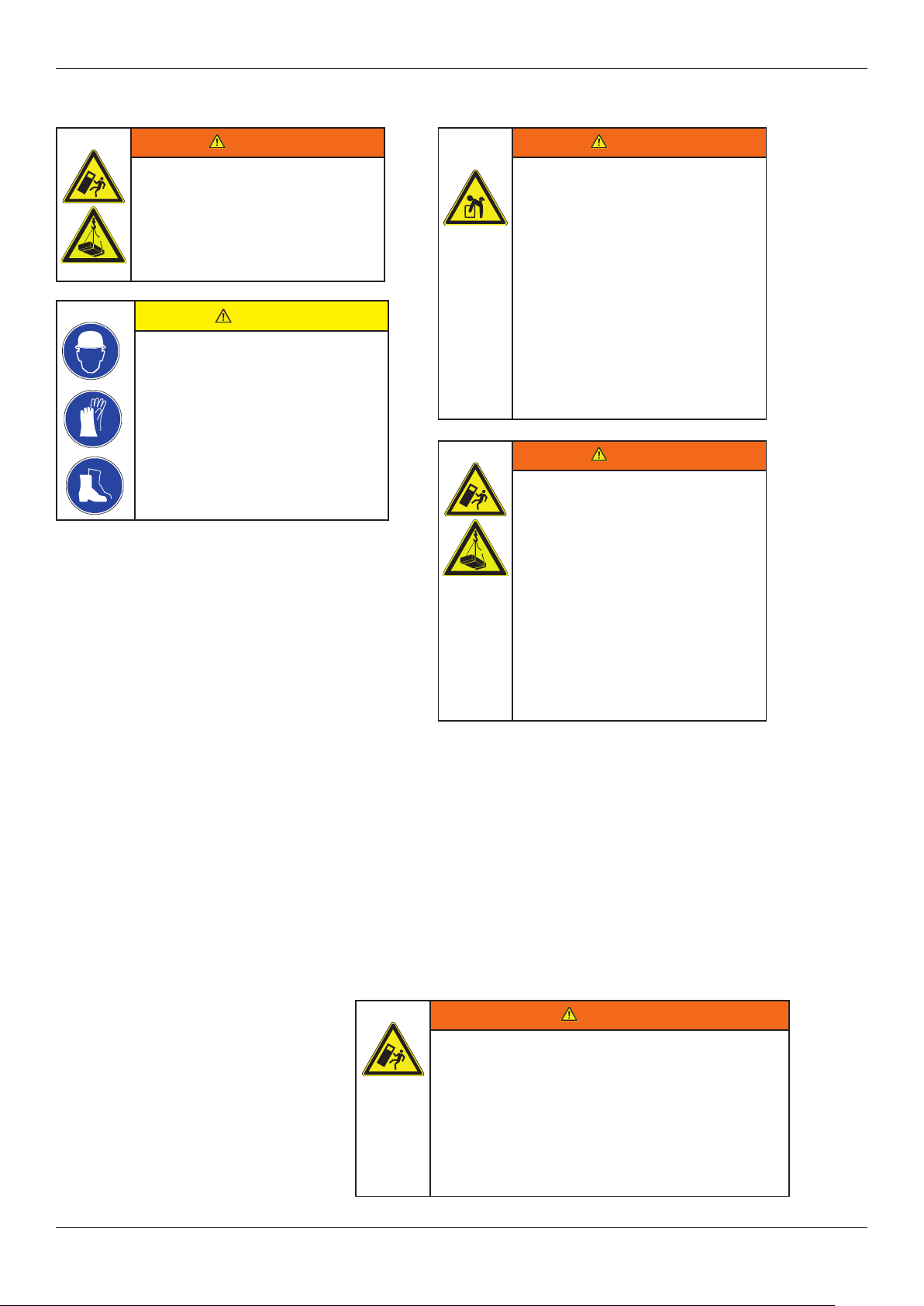

To point out dangers and important information, the following signal words and symbols

are used in these operating instructions:

1.2 Safety alert symbol

The safety alert symbol is located in the safety precautions in the highlighted heading eld on the left next to the signal

word (DANGER, WARNING, CAUTION). Safety precautions with a safety alert symbol indicate a danger of injuries.

Be sure to follow these safety precautions to protect against injuries or death! Safety precautions without a

safety alert symbol indicate a danger of damage.

1.3 Signal words

1.4 Všeobecné bezpečnostné pokyny

DANGER

WARNING

CAUTION

NOTICE

NOTE

The signal words are located in the safety precautions in the highlighted heading

eld. They follow a certain hierarchy and indicate (in conjunction with the safe-

ty alert symbol, see Chapter 1.2) the seriousness of the danger and the type of

warning.

See the following explanations:

Safety

IN-ECO spol. s r.o.

DANGER

Danger of injuries.

Indicates an imminently hazardous situati-

on, that will result in death or

serious injury if the corresponding

measures are not taken.

WARNING

Danger of injuries.

Indicates a potentially hazardous

situation, that could result in death or

serious injury if the corresponding

measuresare not taken.

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

These operating instructions:

> must have been read completely and

understood before beginning any work

with or at the pump-motor unit,

> must be strictly observed,

> must be available at the operating locati-

on of the pump-motor unit.

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Only operate the pump-motor unit

> for the purposes indicated under „Inten-

ded Use“! page 6!

> with the uids indicated under‚Intended

Use‘! page 6!

> with the values indicated under

‚Technical Data‘!, page 8!

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Transport and handling as well as assem-

bly and disassembly of the unit may be

carried out by trained and responsible

personnel only!

CAUTION

Danger of injuries.

Indicates a potentially hazardous situation,

that may result in minor or moderate injury

if the corresponding measures are not taken.

CAUTION

Danger of damage.

Indicates a potentially hazardous situation

that may result in property damage

if the corresponding measures are not

taken.

CAUTION

Danger of damage.

Indicates a potentially hazardous

situation that may result in property

damage if the corresponding measures

are not taken.

NOTICE

Indicates a possible disadvantage, i.e.

undesirable conditions or consequences can

occur if the corresponding measures are not

taken.

NOTE

Indicates a possible advantage if the corre-

sponding measures are taken; tip.

07

Safety

IN-ECO spol. s r.o.

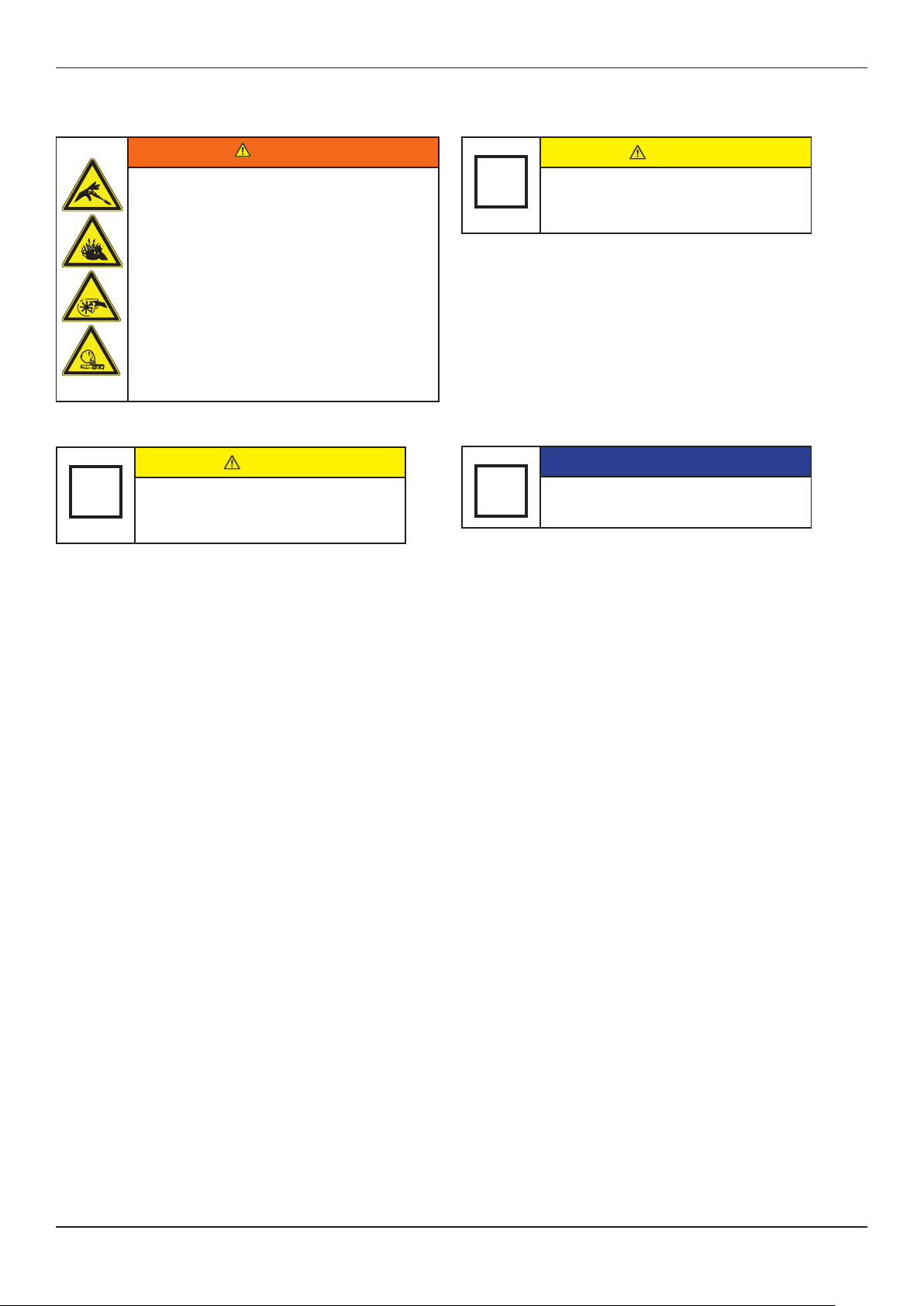

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

> Deenergize.

> Secure against being switched on again.

> Determine whether deenergized.

> Ground and short-circuit.

> Cover or block off adjacent energized

parts.

DANGER

Electrical danger!

Work on electrical installations

may be carried out by trained

and authorized electricians only!

WARNING

When working on the unit, there is a

danger of injury,e.g. in the form of cuts/

cutting off, crushing and burns!

During transport/handling as well as assem-

bly and disassembly always wear personal

protective equipment (safety helmet, pro-

tective gloves, safety boots)!

WARNING

Hair and clothing can be pulled into the

unit or caught and wound up moving

parts!

Do not wear long, loose hair or

wide, loose clothes!

Use a hair net!

WARNING

Danger from rotating external fan of unit!

Only operate the unit with the fan

guard mounted!

WARNING

Danger from rotating external fan of unit!

Only operate the unit with the fan guard mounted!

It is prohibited to remove the fan guard!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping uid!

Danger from rotating external fan of unit!

Only operate the unit with the pipes/hoses connected to the

intake and discharge connection, as well as to the operating-

-liquid port!

WARNING

Danger in the form of cuts or cutting off extremities on

the impeller of the pump-motor unit!

> Do not reach into the unit through open connections!

> Do not insert objects into the unit through the openings!

WARNING

Danger due to gauge pressure and vacuum!

> Check the connections of the pipe/hose connections for

leaks!

WARNING

Danger due to gauge pressure and vacuum! Danger due

to escaping uid! Check the connections of the pipe/hose

connections for leaks!

WARNING

Danger of burns and scalding from hot surfaces of the

pumpmotor unit and from hot uids!

> Do not touch during operation!

> Allow to cool after shut-down!

WARNING

Danger in the form of cuts or cutting off extremities on

the impeller of the pump-motor unit!

> Do not reach into the unit through open connections!

> Do not insert objects into the unit

through the openings!

WARNING

Hazard: Long, loose hair can be drawn

into external fan through fan guard grate,

even with fan guard mounted!

Protective measures:

Wear hair net!

WARNING

Danger zone: Hot surface.

Hazard:

Burns/scalding possible.

Protective measures:

Do not touch! Wear protective gloves!

CAUTION

Danger of unit tipping over!

> Secure the pump-motor unit on the instal-

lation surface before putting into operation!

WARNING

Danger due to gauge pressure

and vacuum! Danger due to escaping

uid!

> Before beginning work on the unit or

system:

Interrupt supply of operating liquid.

> Bleed lines and vacuum pump/compressor

(depressurize).

08

2 Intended Use

These operating instructions

> apply to liquid-ring vacuum pumps/compressors of the LR series, types LR 060, LR 061

> contains instructions bearing on transport and handling, installation, commissioning, operation, shut-down, storage,

servicing and disposal of the LR

> must be completely read and understood by all operating and servicing personnel before beginning to work with or

on the LR,

> must be strictly observed,

> must be available at the site of operation of the LR.

About the operating and servicing personnel of the LR:

> These persons must be trained and authorized for the work to be carried out.

> Work on electrical installations may be carried out by trained and authorized electricians only.

3 Intended Use

The LR

> are pump-motor units for generating vacuum or gauge pressure

> are used to extract, transport and compress the following

> all dry and humid gases, which are not explosive or ammable

> preferably air or air/vapor mixtures

In case of corrosive or toxic gases/vapors contact service.

> are designed for operation with the following operating liquids:

– Water with a pH of 6 to 9, free of solid materials (such as sand)., If the pH values or operating liquids

differ, it is necessary to contact service.

> are intended for industrial applications, are designed for continuous operation.

When operating the LR the limits listed in Chapter 4, „Technical Data“, Pg. 9 ff. must

always be complied with.

Foreseeable Misuse

It is prohibited

> to use the LR in applications other than industrial applications unless the necessary protection is provided

on the system, e.g. guards suitable for children‘s ngers,

> to use the device in rooms in which explosive gases can occur if the LR is not expressly intended for this purpose;

> to extract, to deliver and to compress explosive, ammable, corrosive or toxic uids unless the L-BV7 is specically

designed for this purpose,

> to operate the LR with values other than those specied in Chapter 4, „Technical Data“, Pg. 9 ff.

Any unauthorized modications of the LR06 are prohibited for safety reasons. Any maintenance and repair work, such

as replacing worn or defective components, may only be carried out by companies authorized by the manufacturer

(please contact service).

Intended Use

IN-ECO spol. s r.o.

09

4 Technical Data

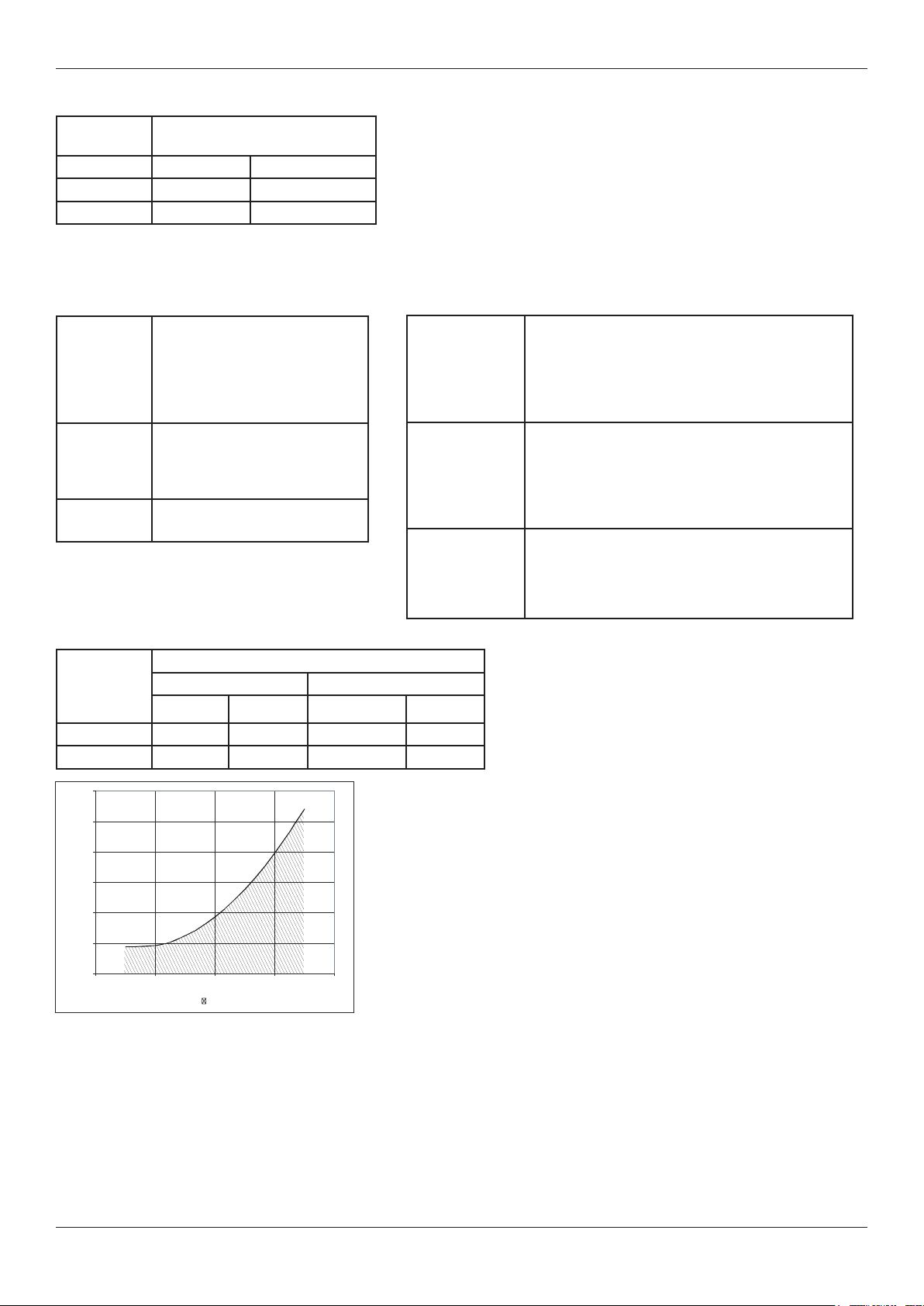

4.1 Mechanical data

Technical Data

IN-ECO spol. s r.o.

Dimensions

LR 060-H06 / LR 061-H16

Spare part list LR 060 - H06 / LR 0161 - H16

9.7

A2

A1

10.54

90

218

62.7 100

125

144.5

G1

171

139.5

165

13.5

G1/4

G1/4

G1/2

73.5

G1/4

G1/4

Typ A1 A2

LR 060-H16 368,4 287,9

LR 061-H06 386,7 287,9

1) Casing

2) Port plate

3) Impeller

4) Lantern

5) Motor

6) Mechanical seal

The recommended replacement

interval of the mechanical seal is

every 30 months.

Stainless steel

Stainless steel

Bronze

Cast iron with teon coating

IE1 motor

Pot lead

Material:

10

Minimum distances for heat dissipation

Max. discharge pressure p2 max during

compressor operation (at inlet pressure p1 =

1 bar abs. [14.5 psia]):

Temperatures Pressures

Technical Data

IN-ECO spol. s r.o.

4.2 Operating conditions

Type Minimum distance from

fan guard to adjacent surface

(mm) (inches])

LR 060-H16 34 1,34

LR 061-H06 34 1,34

Type

p2 max

[bar abs.] [psia]

at 50 Hz: at 60 Hz: at 50 Hz: at 60 Hz:

LR 060-H16 2 2 29,0 29,0

LR 061-H06 2 2 29,0 29,0

Temperature

of pumped

gases/va-

pors:

max. +80 °C [max. +176 °F]

At higher uid temperatures,

measures must be taken on

the system to prevent burns,

e.g. mount separating safety

device (cover).

Operating

liquid tem-

perature:

max. +80 °C [max. +176 °F] min.

+5 °C [min. +41 °F]

Nominal value:

+15 °C +59 °F]

Ambient

temperature:

max. +40 °C [+104 °F]

min. +5 °C [+41 °F]

Min. inlet

pressure:

Dependent on the operating liquid temperature

(see Fig. 2, Pg. 10)

When this temperature is dropped below, the hose

ofthe liquid separator (accessory) must be connec-

ted to the connection for cavitation protection (Pg.

17).

Max.

discharge

pressure

during

vacuum-pump

operation:

1,1 bar abs. [16,0 psia]

Max.

permissible

pressure in

pump-motor

unit:

8 bar abs. [116 psia]

If higher pressures can occur in the system, then

corresponding protective devices must be provi-

ded.

Obr. 2: Minimum inlet pressure/cavitation limit

.[ °C, °F] = Temperature of operating liquid

p1 [mbar abs., psia] = Inlet pressure abs.

The minimum permissible inlet pressure of the pump-motor unit is dependent on the temperature of the operating

liquid. During operation without cavitation protection, the minimum inlet pressure must be set above the shaded area.

0

50

100

150

200

250

300

02 04 06 08 0

fl

[°C]

p

1

[mbara bs .]

11

Nominal operating-liquid ow rate

(with dry air extraction and with water at 15°C [59 °F] as operating liquid)

Operating-liquid lling amount for priming

Water requirement (L/min) / Inlet pressure P

Technical Data

IN-ECO spol. s r.o.

Type

Flow rate

[m³/h] [ft³/h]

at 50 Hz: at 60 Hz: at 50 Hz: at 60 Hz:

LR 060-H16 0,20 0,20 7,06 7,06

LR 061-H06 0,23 0,23 8,12 8,12

Type

Filling amount

[l] [gal (US)] [gal (UK)]

LR 060-H16 0,40 0,106 0,088

LR 061-H06 0,55 0,145 0,121

water Requirement

(L/min)

water Requirement

(L/min)

Inlet pressure P1(mbar abs.) Inlet pressure P1(mbar abs.)

0 100 200 300 400 500 600 700 800 900 1000

0

2.0

4.0

6.0

8.0

0 100 200 300 400 500 600 700 800 900 1000

0

0.4

0.6

0.8

1.0

LR 060-H06

LR 060-H06

LR 061-H16

LR 061-H16

8.0

6.0

4.0

2.0

50 Hz / RPM 2850/min 60 Hz / RPM 3450/min

12

5 Description of Vacuum Pump/Compressor

Description of Vacuum Pump/Compressor

IN-ECO spol. s r.o.

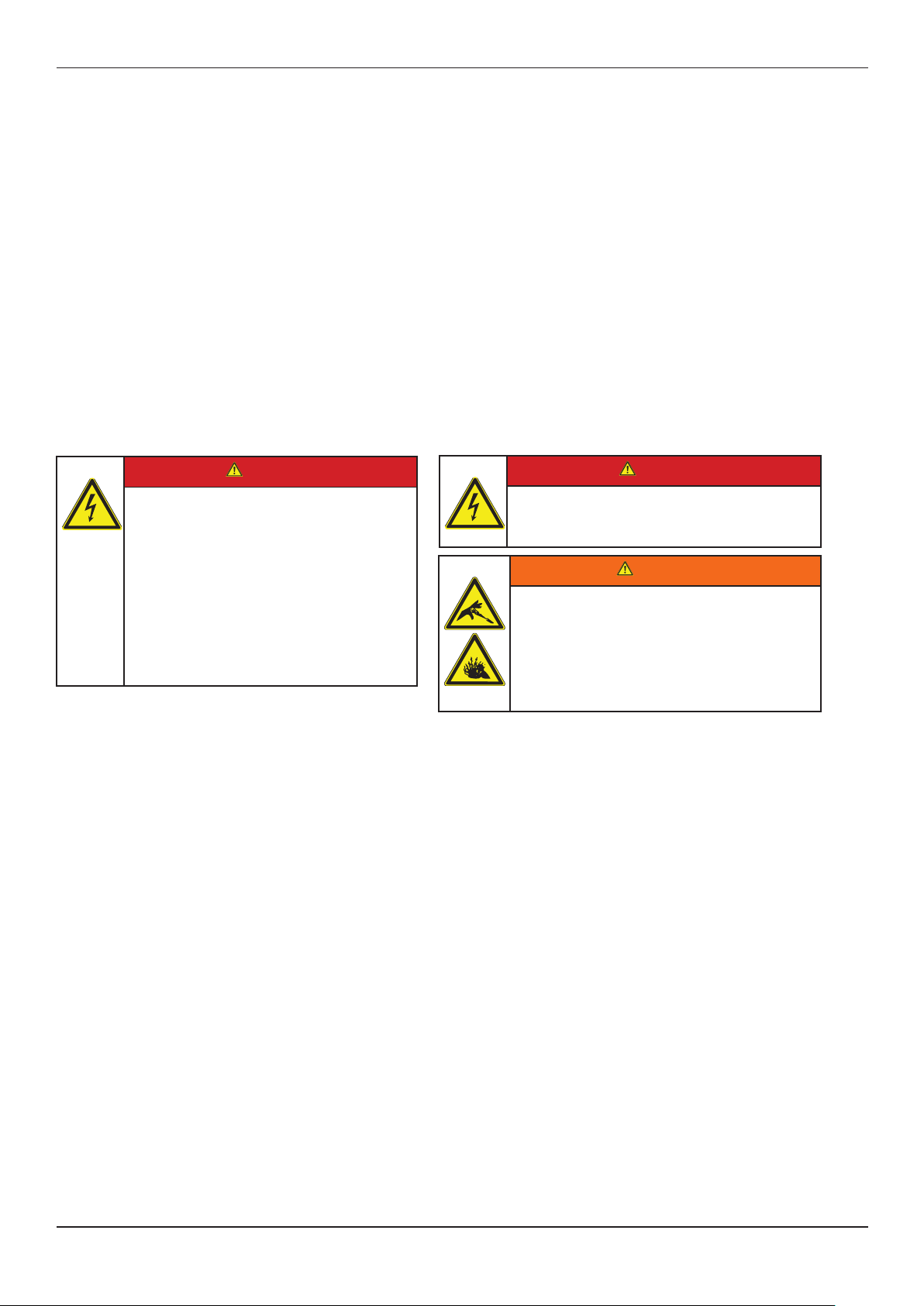

5.1 Design and principle

5.2 Operating method

When the impeller turns, the operating liquid is put into motion and accelerated. This forms a liquid ring that also rota-

tes. Due to centrifugal force, this ring is arranged concentrically to the housing and eccentrically to the impeller.

During a complete rotation of the impeller, the following occurs:

> The impeller cells are completely lled with operating liquid at the upper vertex.

> During the rst half rotation, the liquid ring lifts off the impeller hub. The space in the cells increases so that the pum-

ped gases/vapors are sucked in through the inlet port.

> The space in the cells is largest at the lower vertex, as these are virtually free of operating liquid.

> During the second half rotation, the liquid ring approaches the hub again. The space

in the cells decreases so that the pumped gases/vapors are compressed and pushed out through the discharge port

Fig. 3:

1

3

2

4

Rotor with xed blades (1) is rotating in the stator (2), in which is situated eccentrically. Water ring is created from

the service liquid (3) by the centrifugal force. The vacuum is formed and the pressure is changed in the compression

chambers (4) between the blades and water ring. During the operation, the pump has to be supplied by adequate

quantity of service liquid to achieve desired performance. Service liquid is also very useful for cooling of the liquid ring

vacuum pump and for receiving possible contamination of sucked gas.

13

Description of Vacuum Pump/Compressor

IN-ECO spol. s r.o.

5.3 Operating modes

The pump-motor unit can function in several different operating modes. These differ in how the pump-motor unit is

supplied with operating liquid:

> Self-priming operation

> Operation with operating-liquid feed:

- Non-automatic operation

- Automatic operation

5.3.1 Self-priming operation

In this operating mode the pump-motor unit automatically sucks in the operating liquid. The operating-liquid ow rate is

automatically adjusted.

See Fig. 8, Pg. 20.

5.3.2 Operation with operating-liquid feed

In this operating mode the pump-motor unit DOES NOT automatically suck in the operating liquid.

A certain volume ow („nominal operatingliquid ow rate“) or pre-pressure must be set for the operating liquid.

Here the following additional distinctions are made:

Non-automatic operation

In this case the operating liquid feed is switched on and off manually with a stop valve.

See Fig. 11, Pg. 22.

Automatic operation

In this case the operating liquid feed is switched on and off by a solenoid valve. The solenoid valve is dependent on

the motor operating mode:

. Motor/pump-motor unit switched on: Valve open.

. Motor/pump-motor unit switched off: Valve closed.

See Fig. 12, Pg. 22.

i

NOTICE

The following is dependent on the operating

mode:

> when and how the pumpmotor

unit must be lled with

operating liquid the rst time,

> how the pump-motor unit is put into operati-

on.

The specications for this are contained in

Chapter 7, „Installation“, Pg. 15ff., and

Chapter 8, „Commissioning“, Pg. 19ff.

14

6 Transport and Handling

Transport and Handling

IN-ECO spol. s r.o.

Packing:

On delivery the pump-motor unit is bolted to a pallet and covered with a cardboard box.To unpack, remove the cardbo-

ard box and unscrew the securing bolts on the feet of the pump-motor unit.

WARNING

Danger from tipping or falling

loads!

Prior to transport and handling make sure

that all components are securely assem-

bled and secure or remove all components

the fasteners of which have been loosened!

WARNING

Danger from lifting heavy loads!

Manual handling of the unit is

only permitted within the

following limits:

. max. 30 kg [max. 66 lbs] for men

. max. 10 kg [max. 22 lbs] for women

. max. 5 kg [max. 11 lbs] for pregnant

women

For weights above the given values use

suitable lifting appliances and handling

equipment!

WARNING

Danger from tipping or falling

loads!

When transporting with lifting equipment,

observe the following basic rules:

. The lifting capacity of lifting equipment

and lifting gear must be at least equal to

the unit‘s weight.

. The pump-motor unit must be

secured so that it cannot tip or fall.

. Do not stand or walk under

suspended loads!

WARNING

Danger from tipping loads!

Be sure to observe the routing of the strap belts as shown in

Fig. 4, S. 14, even if the motor is provided with attachment

points such as transport eyes or eye bolts.

These are solely designed for the separate transport of the

motor, however not for the different weight distribution that re-

sults for the mounted vacuum pump/mounted compressor, so

that the unit could tip!

CAUTION

Tipping or falling can lead to

crushing, broken bones etc.!

Sharp edges can cause cuts!

Wear personal safety equipment

(protective helmet, protective

gloves, safety shoes) during

transport!

Transport and handling by means of a

crane and strap belts is advisable.

Attach the strap belts as shown in Fig. 4, Pg. 14:

- Use two strap belts, of which one is routed under the vacuum pump/

compressor housing, and one under the fan guard.

- The strap belts should be seated securely in the undercuts so that

the unit cannot slip out.

- The belts must be sufciently long (spread angle smaller than 90°).

- Make sure that no damage is caused to any attached ttings.

Fig. 4

15

7 Installation

Installation

IN-ECO spol. s r.o.

7.1 Installation

CAUTION

Danger of crushing from unit tipping

over!

In the unmounted state, the unit can easily

tip due to its weight distribution!

Wear gloves and safety shoes!

Handle the unit with the appropriate care!

WARNING

Electrical danger!

The pump-motor unit must be installed

so that the electrical device cannot be

damaged by external inuences!

In particular, the feed pipes must be se-

curely routed, e.g. in cable ducts or in the

oor.

CAUTION

Danger of tripping and falling!

Make sure the unit does not

present a danger of tripping!

CAUTION

Danger of injuries from ying parts!

Select installation so that parts that are

thrown out through the grate if the external

fan breaks cannot hit persons!

i

CAUTION

Danger of damage to the pump-motor unit

due to overheating!

When installing the unit, make sure that

heat dissipation and cooling are not ob-

structed. The minimum distances specied

in Chapter 4.1, „Mechanical data“,

Section „Minimum distances for heat

dissipation“, Pg. 10 must be complied with.

Discharge air of other units may

not be directly sucked in again!

For the space requirement and arrangement of the holes for installing and securing the pumpmotor

unit, please see Fig. 1, Pg. 10.

For minimum clearances for heat dissipation and cooling, see Chapter 4.1, „Mechanical

data“, Section „Minimum distances for heat dissipation“, Pg. 10.

The pump-motor unit must be installed as follows:

. on level surfaces,

. with shaft in horizontal position

. on stationary (xed) surfaces or structures,

. at a maximum height of 1000 m [3280 ft] above sea level.

Observe the following when installing the pump-motor unit:

. The load bearing capacity of the base plate or the foundation must be designed

for at least the weight of the unit.

. The vibration behavior at the operating location must be taken into account.

The total vibrations of the unit are dependent on the following factors:

– the characteristic vibrations of the unit,

– the alignment and installation,

– the condition (vibration behavior) of the load-bearing surface,

– the inuences by vibrations of other parts and system components (external vibrations).

The maximum permissible value for vibrations is veff = 4.5 mm/s. To ensure proper operation and a long service life of the unit,

this value may not be exceeded. Generally, this value can be adhered to without a special foundation or a special base plate. The

points on the unit for measuring the vibration speed are shown in Fig. 5, Pg. 15.

Fig. 5: Points for measuring the vibration speed Fig. 6: Securing elements for bolting feet to supporting surface

Bolt the feet of the unit to the

suporting surface with suitable

securing elements, as

shown in Fig. 6, Pg. 15.

LR 060-H16

LR 061-H06: M = 4 x M8-6.8

16

Installation

IN-ECO spol. s r.o.

iCAUTION

Incorrect connection of the motor can lead to

serious damage to the unit!

Observe the motor rating plate. It is imperative that the operating conditions correspond to the data given on the rating

plate!

Deviations permissible without reduction in performance:

>±5 % voltage deviation

>±2 % frequency deviation

Make the connection in accordance with the circuit diagram in the terminal box. Connect the protective conductor.

>Use suitable cable lugs when doing so

>The electrical connection must be permanently safe

For motor overload protection:

> Use motor circuit breakers.

>Set the motor circuit breakers to the nominal current spe-

cied on the rating plate.

For supply by converter:

>High-frequency current and voltage harmonics in the mo-

tor supply cables can lead to emitted electromagnetic

interference.

>Use shielded supply cables, whereby the shield must be

installed on both sides

7.2 Electrical connection (motor)

The electrical connection must be carried out as follows:

- according to the applicable national and local laws and regulations,

- according to the applicable systemdependent prescriptions and requirements,

- according to the applicable regulations of the utility company.

DANGER

Electrical danger!

Malpractice can result in severe

injuries and material damage!

DANGER

Electrical danger!

Before beginning work on the unit or system, the

following measures must be carried out:

. Deenergize

. Secure against being switched on again.

. Determine whether deenergized.

. Ground and short-circuit.

. Cover or block off adjacent energized parts.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping uid!

Before beginning work on the unit or system:

. Interrupt supply of operating liquid.

. Bleed lines and vacuum pump/compressor

(depressurize).

WARNING

Electrical danger!

Clearance between bare live parts and between bare

live parts and ground: at least 5.5 mm [0.217“] (at a

nominal voltage of Vn ≤ 690V)

Make sure there are no protruding pieces of wire!

WARNING

Electrical danger!

The terminal box must be free from

- foreign bodies

- dirt

- a humidity

Terminal box cover and cable entries must be tightly

closed so as to make them dustproof and waterproof.

Check for tightness at regular intervals.

DANGER

Electrical danger!

The electrical connection may be carried out by

trained and authorized electricians only!

17

Installation

IN-ECO spol. s r.o.

To prevent foreign bodies from entering the unit, all connections are sealed off when delivered.

Do not remove the sealing plugs until immediately before connecting the pipes/hoses.

For the arrangement of the pipe/hose connection, see Fig. 7, Pg. 17. The pumped gases/vapors are sucked in via

the inlet connection (see Chapter 7.3.1,Pg. 18) and discharged via the discharge connection ((see Chapter 7.3.2, Pg.

18). For operation the unit must be continuously supplied with operating liquid. This is fed in via the operating-liquid

port (Chapter 7.3.3, Pg. 26) and discharged together with the pumped gases/vapors through the discharge connecti-

on.

Fill with operating liquid:

When and how the pump-motor unit must be lled with operating liquid the rst time is dependent on the operating

mode:

. For self-priming operation: During installation.

. For operation with operating-liquid feed: After completing installation

For self-priming operation you now pour operating liquid into the working space of the pump-motor unit before you

connect the pipes/hoses to the unit. To do this, pour operating liquid into the open inlet connection, discharge connec-

tion or operating-liquid port. For proper lling quantities, see Chapter 4.3, „Operating conditions“, Section „Operatingli-

quid lling amount for priming“, Pg. 11. Then attach the pipes/hoses to the unit as described in the following.

7.3 Connecting pipes/hoses (vacuum pump/compressor)

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping uid!

. During operation, connected pipes and vessels are

pressurized or vacuumized!

. Make sure that all connections are sufciently tight!

Use only pipes and vessels of sufcient strength!

Obr. 7: Pipe/hose connection of vacuum pump/compressor

NOTICE

Attach pipes/hoses free of mechanical tensions.

Support the weight of the pipes/hoses.

iCAUTION

If the unit is run dry, the mechanical seal will

be destroyed in a matter of seconds!

DO NOT switch on as long as the unit is not

lled with operating liquid!

1 3

31

4

57

26

1) OUTPUT of air and suction liquid

2) Connection of operating liquid (water temperature

max. 35 °C, optimal temperature is 15°C)

3) INPUT of suction vacuum

4) Connection of vacuum safety valve

5) Discharge (threaded connector)

6) Connection of manometer

7) Cavitation protection (noise reduction)

18

Installation

IN-ECO spol. s r.o.

iCAUTION

The tightening torque for pipe

connections on intake and

discharge connections may not

exceed 100 Nm [73.8 ft lbs]!

iCAUTION

The tightening torque for pipe

connections on intake and

discharge connections may not

exceed 100 Nm [73.8 ft lbs]!

7.3.1 Inlet connection

The inlet connection (Fig. 7, Pg. 17) is marked with an

arrow pointing downward (↓).Connect the inlet pipe

here. The pumped gases/vapors are sucked in via this.

7.3.2 Discharge connection

The discharge connection (Fig. 7, Pg. 17) is marked

with an arrow pointing upward (↑). Connect the dis-

charge pipe here. Both the pumped gases/vapors and

the operating liquid are discharged via this pipe.

7.3.3 Operating-liquid port

The operating-liquid port (Fig. 7, Pg. 17) is located between the discharge and

inlet connection. Connect the feed pipe for the operating liquid here.

iNOTICE

For operating liquid with impurities:

> Install a lter, screen or separator in the

supply line if necessary. i

NOTICE

In case of operating liquid with a high lime

content:

. Soften operating liquid OR

. Decalcify pump-motor unit regularly (see

Chapter 11.1, „Maintenance“, Pg. 26).

i

NOTICE

To prevent installation residues (e.g. welding

spatter) from entering the unit, a start-up

screen should be installed in the inlet pipe for

the rst 100 operating hours.

19

Commissioning

IN-ECO spol. s r.o.

8 Commissioning

8.1 Preparation and start-up

If a shut-off device is installed in the discharge pipe: Make sure that the unit CANNOT be operated

with the shut-off device closed.

Fill with operating liquid:

When and how the pump-motor unit must be

lled with operating liquid the rst time is

dependent on the operating mode:

> For self-priming operation:

During installation.

> For operation with operating-liquid feed:

After completing installation.

For operation with operating-liquid feed, you now ll the working area of the unit with

operating liquid. To do this, open the respective stop valve for approx. 20 sec.:

> For non-automatic operation:

Stop valve (Fig. 11, Pg. 22, item 4).

> For automatic operation: Stop valve in the bypass pipe(Fig. 12, Pg. 22, item 4a).

Then proceed with commissioning as described in the following.

iNOTICE

Maximum permissible quantity of water entrai-

ned via the inlet connection:

See Fig. 13, Pg. 22

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping uid!

Danger due to rotating parts!

The pump-motor unit may only be put into operation

when the following conditions are met:.

- Fan guard and vacuum pump/compressor housing

are mounted.

- The lines to the discharge connection, inlet con-

nection and operating-liquid port are

attached.

- The lines and connections have been tested for

strength and leaks.

iCAUTION

If the unit is run dry, the mechanical seal will

be destroyed in a matter of seconds!

DO NOT switch on as long as the unit is not

lled with operating liquid!

iCAUTION

If the pumped gases/vapors discharged on the

pressure side are passed on, then it must be

ensured that the maximum discharge pressure

of 1.1 bar abs. [16.0 psia] is not exceeded!

20

Commissioning

IN-ECO spol. s r.o.

Check connections of the pipes/hoses for leaks.

Check direction of rotation:

> The direction of ow of the pumped gases/vapors is marked with arrows on the intake and discharge connection.

> The intended direction of shaft rotation is marked with an arrow on the motor mounting adapter between the intake

and discharge connection, as well as with an arrow on the fan guard.

> The pump-motor unit may not be allowed to run dry! Have you lled it with operating liquid

beforehand (during or after installation)?

provozního režimu agregátu:

See sections „Fill with operating liquid“ ,Pg. 17 a Pg. 18.

> Briey switch on pump-motor unit.

> Compare the actual direction of rotation of the external fan with the intended direction of shaft rotation as indicated

with the arrows.

> Switch off pump-motor unit again.

> If necessary, reverse the direction of rotation of the motor.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping uid!

Before beginning work on the unit or system:

. Interrupt supply of operating liquid.

. Bleed lines and vacuum pump/compressor (depres-

surize).

DANGER

Electrical danger!

The electrical connection may be carried out by trai-

ned and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system, the

following measures must be carried out:

- Deenergize.

- Secure against being switched on again.

- Determine whether deenergized.

- Ground and short-circuit.

- Cover or block off adjacent energized parts.

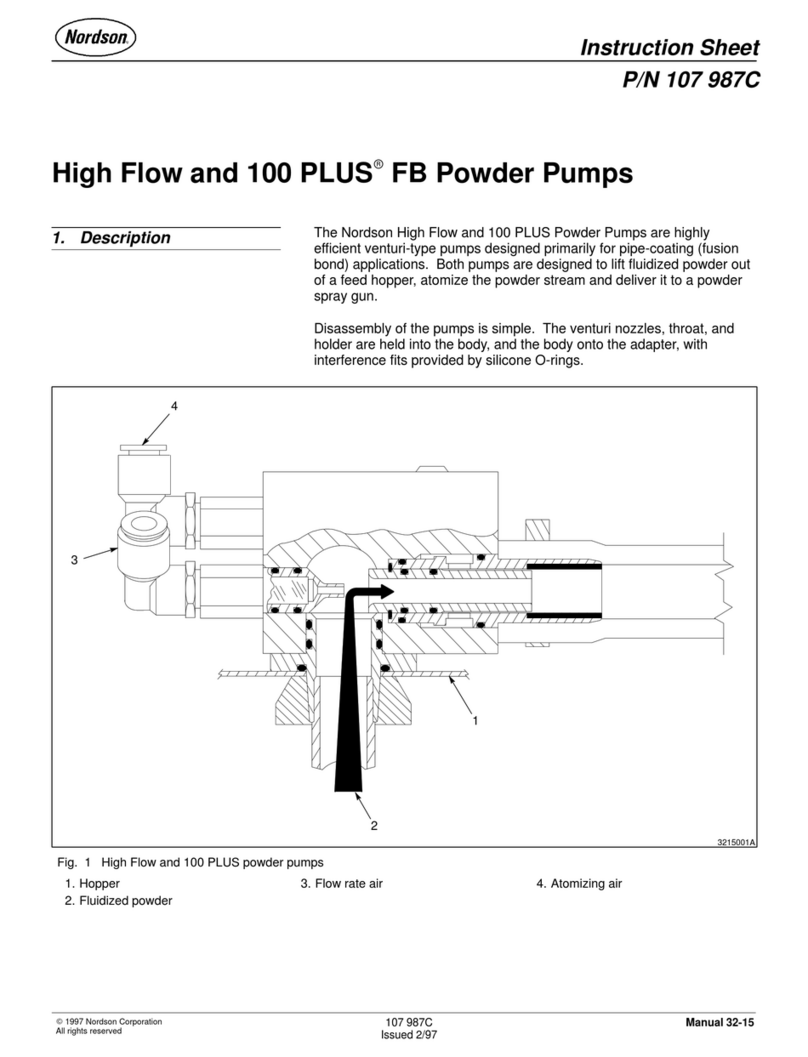

See Fig. 8, Pg. 20.

Here the following must be watched:

> The pump-motor unit must be pre-throttled on the inlet side. This means a vacuum of at least 900 mbar abs. [13.1

psia] must be present in the inlet pipe (Item B) at switchon.

> During switch-on, the liquid level in the feed pipe (Item A) and in the reservoir (Item C) respectively must be at the

same level as the center of the unit shaft (Item 1).

> During operation the liquid level in the reservoir (Item C) may not drop below approx. 1 m [3.28 ft] below the center

of the unit shaft (Item 1).

Starting the pump-motor unit:

> Switch on the unit.

> The operating liquid is sucked in.

A Feed pipe for operating liquid

B Inlet pipe

C Reservoir for operating liquid

1 Required liquid level when switching on

2 Min. liquid level during operation

900 mbar abs

13,1 psa

A B

1

2

≤1m

≤ 3,28 ft

8.2 Self-priming operation

Fig. 8: Self-priming operation

This manual suits for next models

1

Table of contents

Other IN-ECO Water Pump manuals

Popular Water Pump manuals by other brands

Nordson

Nordson High Flow FB instruction sheet

Concentric

Concentric 4F649 Operating instructions & parts manual

Grundfos

Grundfos BMQE 15 Product guide

SIP

SIP 04919 user manual

Ribimex

Ribimex Ribiland PRPVC751V User and maintenance manual

Grundfos

Grundfos Unilift KP 150 Installation and operating instructions

Craftsman

Craftsman 390.2514 owner's manual

BIANCO PUMPZ

BIANCO PUMPZ BIA - AUTOSUB user manual

Sears

Sears CRAFTSMAN 390.2521 owner's manual

Wilo

Wilo Stratos PARA-C Installation and operating instructions

PCB Piezotronics

PCB Piezotronics 108A04 Installation and operating manual

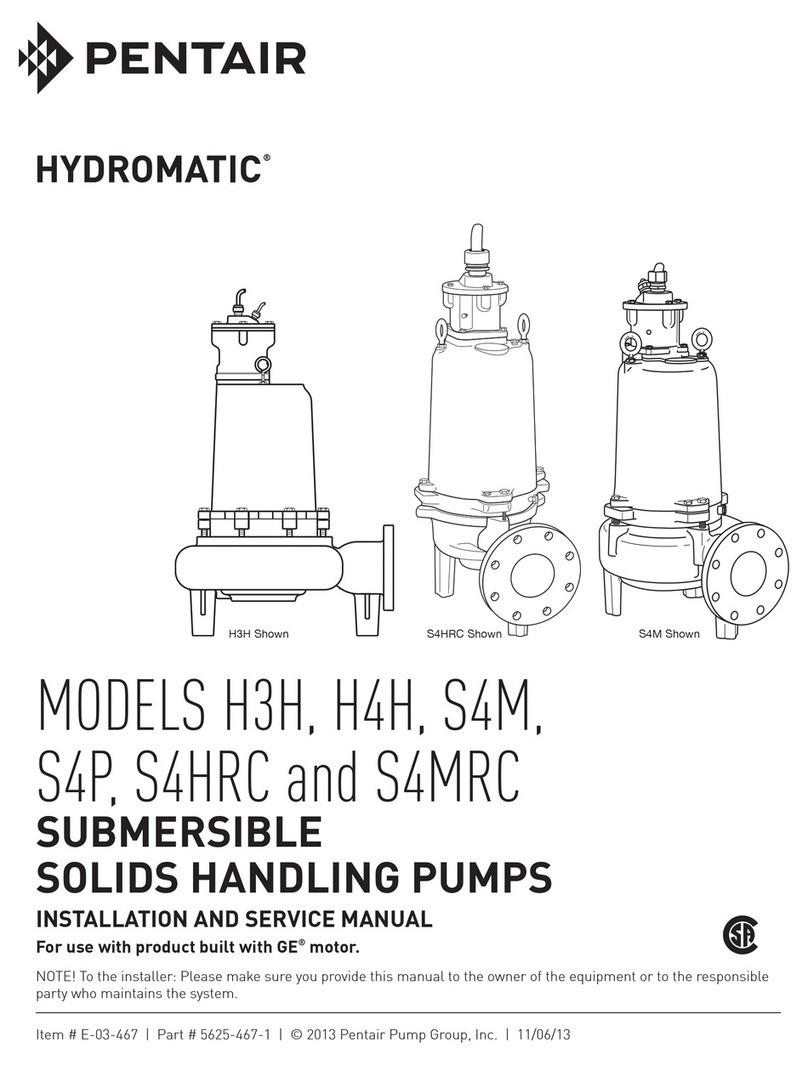

Pentair

Pentair HYDROMATIC H3H Installation and service manual