2

General

Information

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often

for continued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MANUAL. Keep

it in a safe place so that you

may refer to it often. Reasonable

care and safe methods should be

practiced. Check local codes and

requirements before installation.

Unpacking Pump:

Remove pump from carton.

When unpacking unit, check for

concealed damage. Claims for

damage must be made at the

receiving end through the delivery

carrier. Damage cannot be

processed from the factory.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

CALIFORNIA PROPOSITION

65 WARNING:

This product

and related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive harm.

Pumps Not Operating or in

Storage:

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-operational for

3 months or longer and prior to

electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually

rotated (6 revolutions) after

setting non-operational for 3

weeks or longer and prior to

electrical start-up.

Seal Failure:

An electrode is installed in the

seal chamber so if any water

enters the chamber through

the first seal the electrode will

be energized and a signal will

be transmitted to the sensing

unit at ground surface causing

a red light to turn on. The

electrode probe is installed in

all units, but the sensing unit

is supplied at extra cost and

must be ordered.

In operation the seal failure

unit indicates only that there is

some water in the seal chamber.

The pump will continue to

operate, but the seal should be

checked immediately after failure

is indicated.

The sensing unit is recommended

on all installations as good

insurance against motor failure.

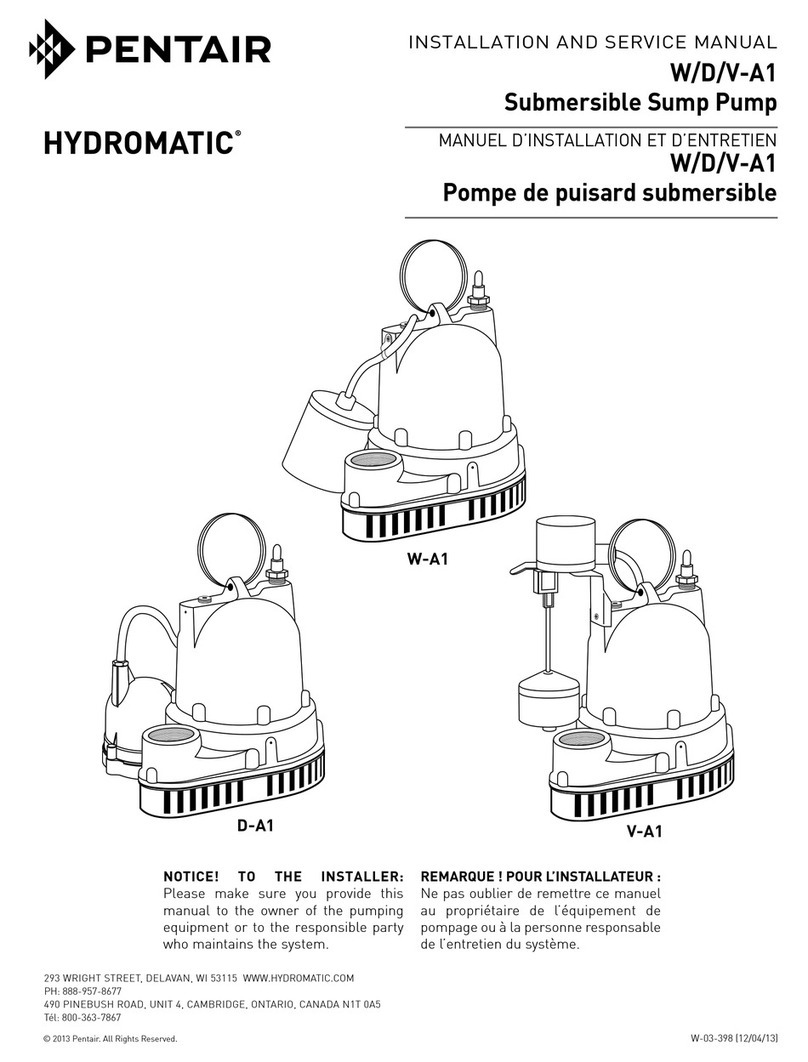

Pump:

The submersible pumps in this

manual are supplied for 1 and 3

phase and for 200, 230, 460 or

575 volts. Power cable is supplied

with the green wire for ground. Be

sure green wire is connected to a

good ground such as water pipe or

ground stake.

Heat Sensors:

All motors have heat sensor units

embedded in the motor winding

to detect excessive heat. The

heat sensors are set to trip at

130°C on the H3H. The sensors

automatcally reset when motor

cools to safe temperature.

The sensors are connected in

series with the motor starter coil

so that the starter is tripped if heat

sensor opens. The motor starter is

equipped with overload heaters so

all normal overloads are protected

by the starter.

IMPORTANT: If Hydromatic®

electrical starting equipment is

not supplied, the heat sensor

circuit must be connected in

series with the starter coil or

warranty is void.

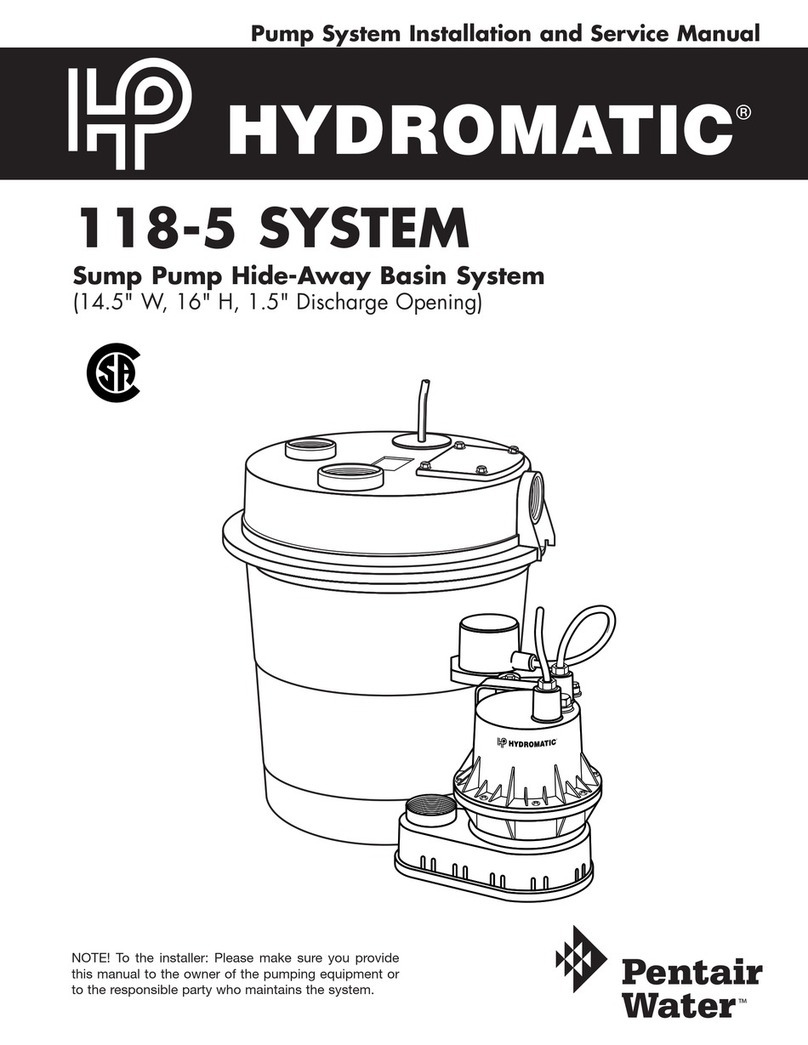

Sump Level Control:

Sump level is controlled by

Hydromatic switch controls.

The float is held in position in

the sump by a weight attached

to the power cord above

the float. The cord supports the

float and is adjusted for height

from the surface.

Duplex systems use three

controls: one set at turn-off, one

set at turn-on for one pump, and

one set for turn-on for two pumps.

Pumps alternate operation on each

successive cycle.

Two pumps operate together only

if sump level rises to the third

or override control. The override

control also brings on the second

pump in case of failure of the

first pump. Extra floats with

appropriate controls can be

supplied for alarm functions.

Triplex systems use four controls:

one set at turn-off, one set at

turn-on for one pump, one set

at turn-on for two pumps, and

one set at turn-on for three

pumps. Pumps alternate each

successive cycle.

Three pumps operate together

only if sump level rises to the

fourth control (second override).

This control also brings on the

third pump in case of failure

of either or both of the first

two pumps.