In-Ex mikroRover User manual

1. Part list

KidMotor V4i main controller board with plastic base plate,

nylon standoffs, nylon screws and USB-C data cable

Rover-X chassis

DC motor gearbox BO-1

ratio 48:1 x 2

Plastic wheel ATX with tire and

Tapping-screw 2mm. x 2

Ball caster 25mm.

Metal right angle bracket

2 x 3 holes x 2

Motor mounting

plate x 4

M3 x 35mm. screw

M3 x 30mm. screw x 4

M3 x 10mm. screw x 10

M3 x 6mm. screw x 6

M3 locknut

Nut 3mm. x 8

Metal standoffs 3 x 25 mm. x 2

Metal standoffs 3 x 10mm. x 8

Nylon standoffs 3 x 10mm. x 2

ZX-03 Infrared Reector mini-board

with JST3AA-8 cable x 2

Strip bracket

5 holes x 2

Plastic nut driver 3mm.

Assembly Guide

1

mikroRover

2mikroRover

2. Assembly Step

Step 2.1

(2.1.1) Fix the DC motor gearbox with the chassis. Begin by putting the rst gearbox on the chassis as shown

in the Figure 1.

(2.1.2) Insert the motor mounting plate into the slot on the chassis. Next insert the screw M3 x 30mm.

through the mounting plate, holes of gearbox and tighten by the M3 nut following the Figure 1. Next, do same for

the other DC motor gearbox.

Figure 1 Fix the DC motor gearboxes with the chassis.

3

mikroRover

Step 2.2

Take the 2 x 3 holes metal bracket to fix at the front of chassis with M3 x 10mm. screws in

the position as shown in Figure 2. Do it 2 sets.

Figure 2 Fixing the metal bracket for mounting the ball caster as freewheel.

4mikroRover

Step 2.3

Place the ball caster between the 2 x 3 holes metal bracket from step 2.2 above. Insert the M3 x 35mm.

screw through the bracket and ball’s center hole to x with the lock nut M3. Tighten by the nut driver following the

gure 3

Figure 3 Assembly the ball caster of mikroRover.

Step 2.4

Fix 4 pieces of the 3 x 10mm. metal standoffs with the chassis following the Figure 4 by using M3 x 6mm.

screws.

Figure 4 Assembly the standoffs for fixing the controller board with the M3 x 6mm. screws.

5

mikroRover

Step 2.5

(2.5.1) Puts the tire on the ATX wheel. Do both sets.

(2.5.2) Put the wheels with tires onto the DC motor gearbox’s shaft of both motors and then tighten the

2mm. self-tapping screws to x them as shown in Figure 5.

Figure 5 Put on the wheels and screw them onto the shaft of the two DC motor gearboxes.

6mikroRover

Step 2.6

Mount the KidMotor V4i control board onto the metal standoffs and tighten with four of M3 x 6mm.

screws to x the controller board mount to the metal standoffs from step 2.5 according to Figure 6.

Figure 6 KidMotor V4i control board mounting.

7

mikroRover

Step 2.7

(2.7.1) Connect the left motor cable to the motor output - 1 connector of KidMotor V4i board and connect

the right motor cable to the motor output - 2 connector as shown in the Figure 7.

(2.7.2) Check the motor connection by turning the wheel as shown in Figure 8. Observe the operation of

the motor driver’s LED on the KidMotor V4i board. The result is as follows :

• Turn the wheel forward, the LED glows green as the wheel spins.

• Turn the wheel back, the LED glows blue as the wheel spins.

If the test result is the opposite color, reverse the polarity of the motor connecting and test again.

Figure 7 Motor connections on KidMotor V4i board.

8mikroRover

Figure 8 shows a guideline for checking the motor connection.

Step 2.8

Take the ZX-03 infrared reector mini board

and attach it to the metal 3 x 25 mm. standoffs with

M3 x 10mm. screws. Make 2 sets as shown in the

Figure 9.

Figure 9 Attach the metal 3 x 25mm. standoffs to

the ZX-03 sensor mini-board.

9

mikroRover

Figure 10 Fix the strip bracket with the robot chassis for fixing the ZX-03 sensor mini-board.

Step 2.9

Take the 5-hole strip bracket and x it to the robot chassis at the position following in Figure 10 with

M3 x 10mm. screws and M3 nuts.

10 mikroRover

Step 2.10

Take the ZX-03 mini-board with the metal standoffs from step 2.8 and attach them to the strip bracket

that mounted to the robot chassis from step 2.9 at the locations in Figure 11 with the M3 x 10mm. screws.

Figure 11 Installing the ZX-03 mini-board to the robot chassis.

11

mikroRover

Step 2.11

Connect the left ZX-03 board to the D2 port of KidMotor V4i and the right ZX-03 board to the D1 port as

shown in Figure 12.

Now the mikroRover robot - Lite version is ready for coding as shown in the Figure 13.

Figure 12 Connect the sensor cables to the digital port of the KidMotor V4i controller board.

12 mikroRover

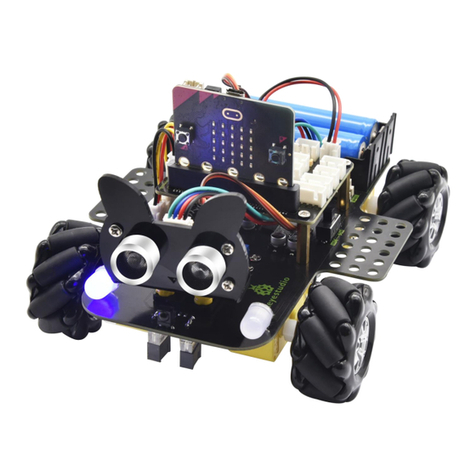

Figure 13 The mikroRover-Lite robot is assembled and ready for coding.

13

mikroRover

Figure 14 shows all parts are used for assembly the ultrasonic distance sensor.

Figure 15 Mounting the metal bracket to the ZX-SONSR1M ultrasonic distance sensor

3. Installation the distance sensor ZX-SONAR1M

(3.1) Prepare all parts following the Figure 14. consist of ZX-SONAR1M module with JST3AA-4 cable,

Metal right angle 2 x 3 holes bracket 2 pieces, Nylon standoffs 3 x 10mm. 2 pieces and M3 x 6mm. screws 4 pieces.

(3.2) Attach the 2 x 3 hole metal right angle brackets to the mounting holes of the ZX-SONAR1M sensor

module by using M3 x 10mm. screws tighten to the threaded hole of the brackets. No need for using 3mm. nut to

x it. Fix 2 of brackets to ZX-SONAR1M module’s hole as shown in Figure 15.

14 mikroRover

(3.3) Attach the ZX-SONAR1M module that xed the metal bracket from step 3.2 to the front of the robot

chassis with M3 x 10mm. screws and 3 x 10mm. nylon standoffs as shown in Figure 16.

Figure 16 Attaching the ZX-SONSR1M ultrasonic distance sensor to the robot chassis.

15

mikroRover

(3.4) Connect the ZX-SONAR1M’s signal cable to the

D5/A1 port connector of the KidMotor V4i main controller

board. Now the mikroRover robot is ready with line and object

sensor as shown in Figure 17.

Figure 17 A mikroRover robot is equipped with the

line sensors (by ZX-03) and the contactless object

sensor (by ZX-SONAR1M)

Figure 18 Attach the metal standoffs to the base of the Gripper-X mechanism.

Connect the ZX-SONAR1M’s

signal cable to the D5/A1 port

4. Installation the Gripper-X

(4.1) Take two of metal 3 x 10mm. standoffs and

attach them to the base of the Gripper-X mechanism at the

recommended positions in Figure 18. Tighten them with

M3 x 6mm. screws.

position for fixing

the 3 x 10mm.

metal standoffs

(4.2) Attach the Gripper-X mechanism with the

metal standoffs from step 4.1 to the front of the robot chassis

above the distance sensor module and x it by using

M3 x 10mm. screws tighten through the holes of the Gripper-X

mechanism into the metal standoffs as shown in Figure 19.

16 mikroRover

(4.3) Connect the Grip-Servo motor cable to SV1 output port (GPIO18) and connect the Lift-Servo motor

of the Gripper-X to SV2 port (GPIO19) following the Figure 20.

Figure 19 Attaching the Gripper-X mechanism to the

mikroRover robot chassis.

Figure 20 Connect the servo motor cable to the

controller board.

Figure 21 The mikroRover robot is ready for learning and competition activities.

Grip-Servo moter

to SV1 (GPIO18)

Lift-Servo moter

to SV2 (GPIO19)

A mikroRover robot as shown in Figure 21 will be ready for learning computing practical through programming

the robot.

Table of contents

Other In-Ex Robotics manuals